Table of Contents

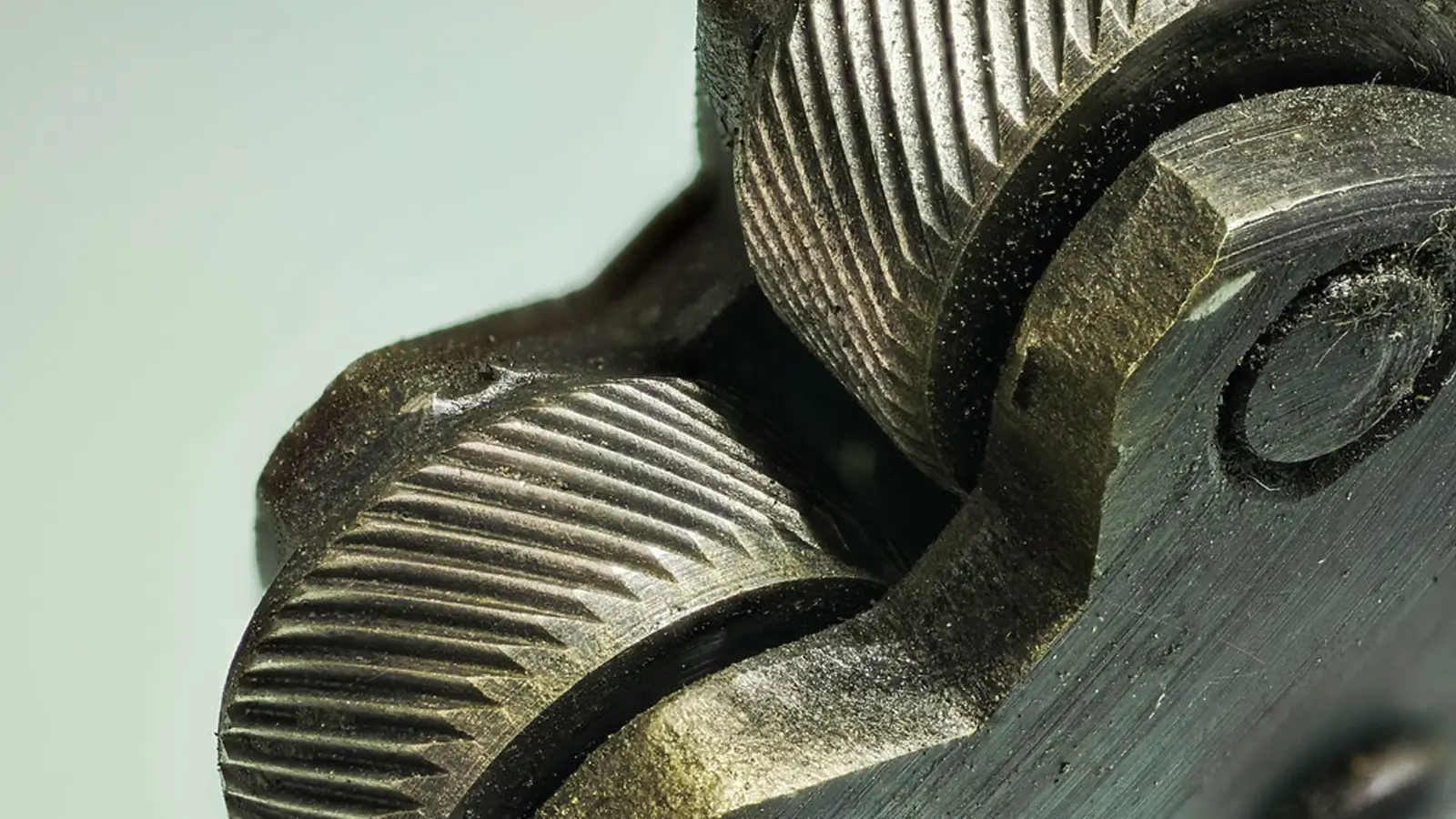

Knurling is a surface machining process that uses specialized tools to press regular patterns onto a part’s surface. It is commonly used for anti-slip, decorative, or assembly assistance purposes in metal components.

Knurling is a surface machining process that uses specialized tools to press regular patterns onto a part’s surface. It is commonly used for anti-slip, decorative, or assembly assistance purposes in metal components.

In this blog, we will give an introduction to Knurling Patterns.

Key Takeaways:

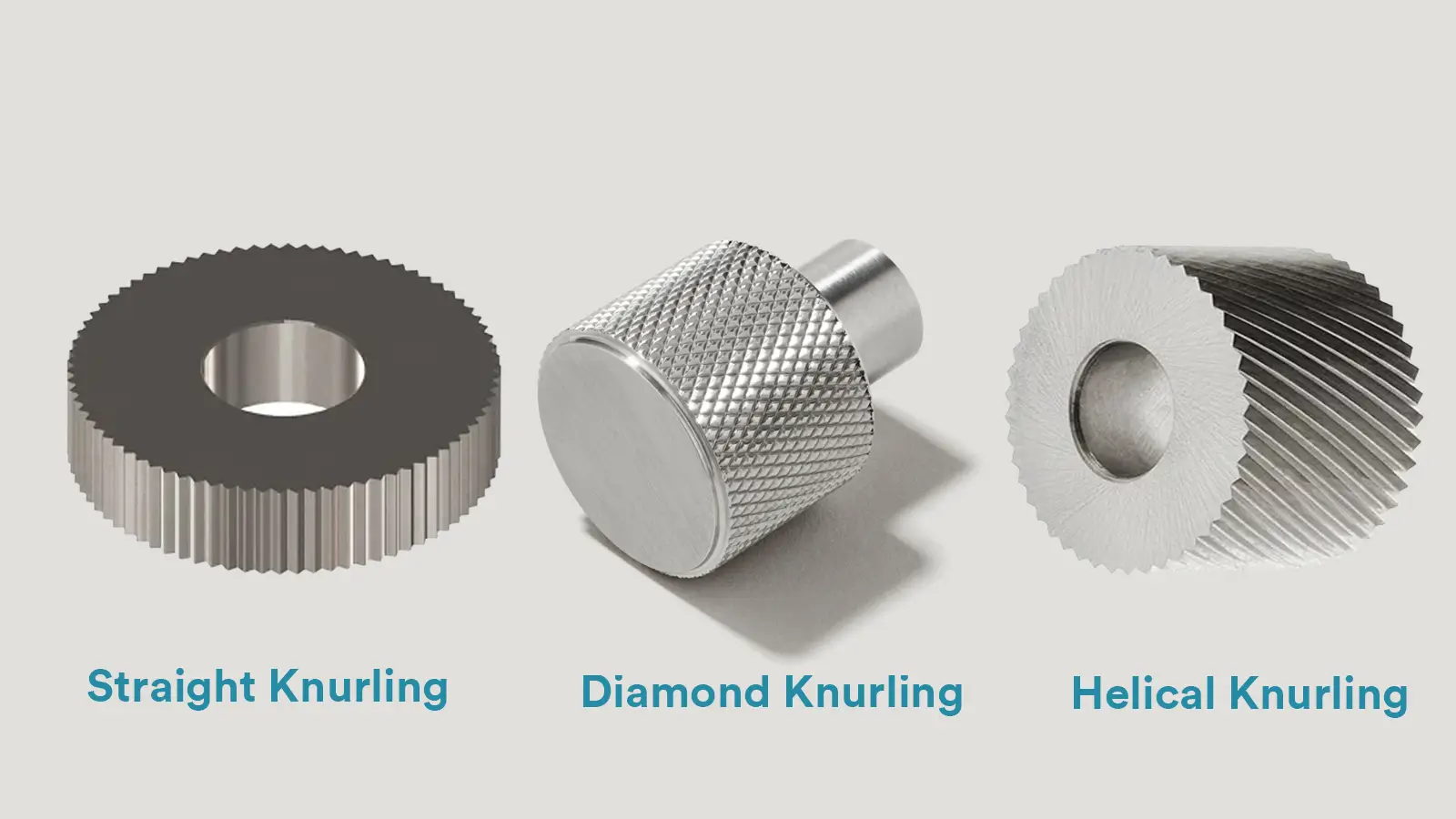

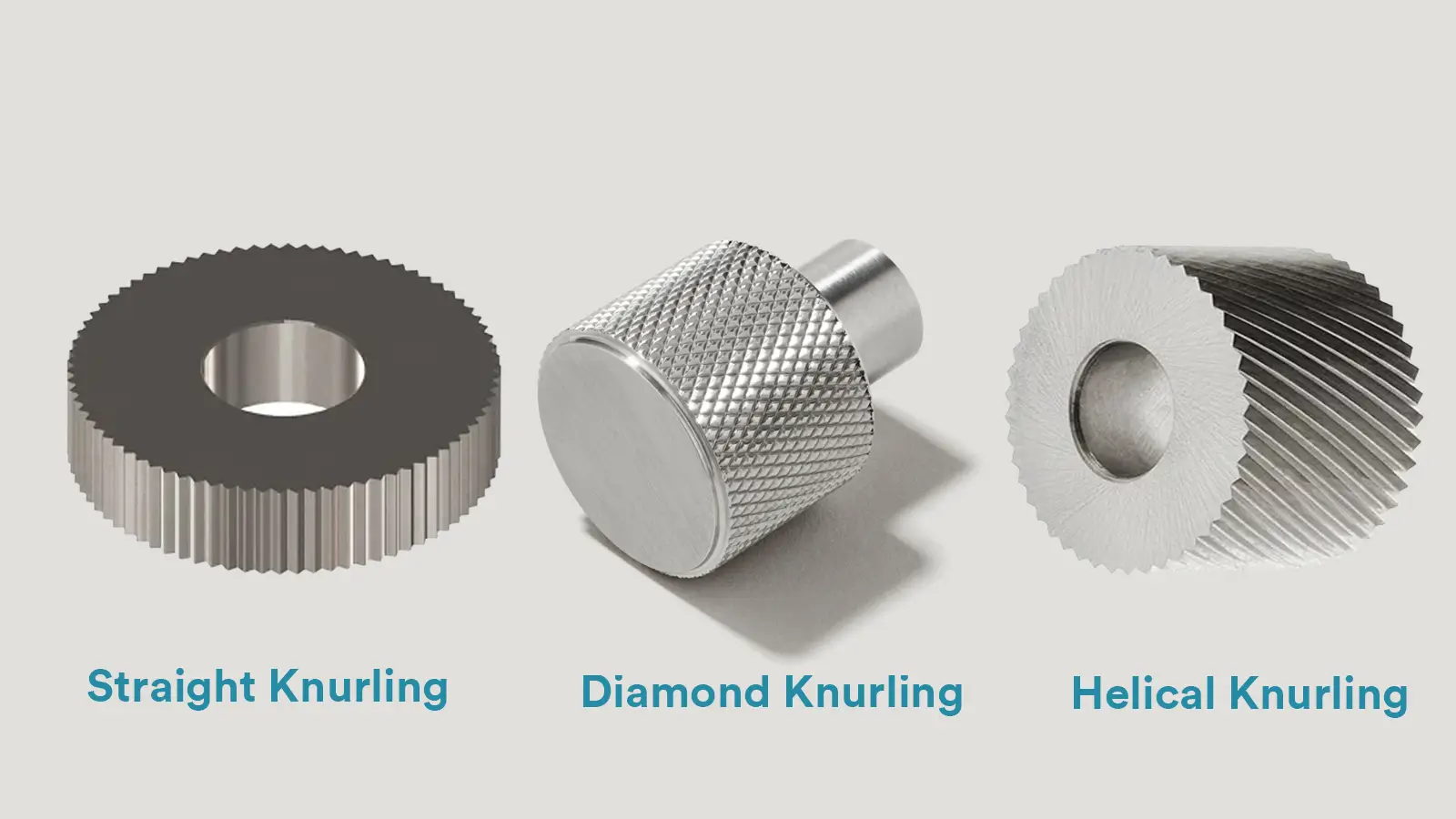

- The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

- Use diamond knurling for maximum all-around grip, straight knurling for one-directional force, and diagonal knurling when aesthetics are a priority.

- A coarse pitch (low TPI) provides a strong, aggressive grip for tools, while a fine pitch (high TPI) offers a smoother, more comfortable feel for precision instruments.

1. What is Knurling Pattern?

Knurling patterns refer to the geometric textures created on a workpiece surface by pressing or cutting knurling tools.

Different knurling patterns not only affect appearance but also influence grip, anti-slip performance, assembly fit, and decorative effect.

2. Types of Knurling Patterns

Knurling patterns primarily include straight knurling, diagonal (or helical) knurling, and diamond knurling. Each type has distinct characteristics in terms of anti-slip performance, aesthetics, and wear resistance.

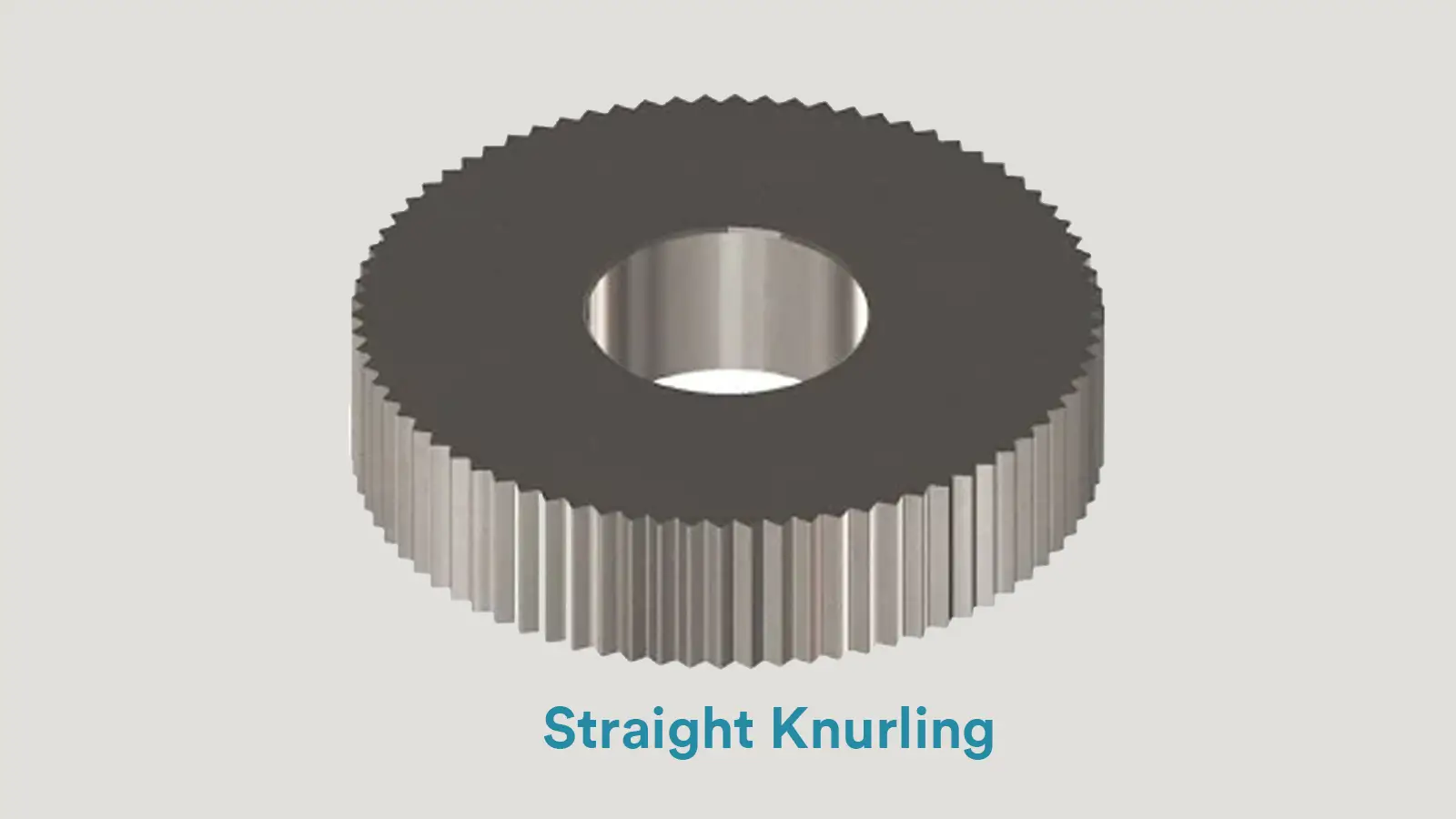

2.1. Straight Knurling

Straight knurling features a pattern of parallel straight lines that provide reliable anti-slip properties and increased torque transmission specifically in one direction.

This makes it particularly well-suited for applications requiring stable axial grip or controlled linear movement, such as assembly positioning components.

You’ll commonly find straight pattern serving functional purposes on knobs, shaft components, nut outer rings, micrometer sleeves, instrument adjustment knobs, and various sliding mechanisms.

The manufacturing advantages include relatively simple processing that yields a uniform texture, making it suitable for high-speed production environments.

However, its directional nature means grip effectiveness is limited primarily to one orientation with relatively low lateral friction.

Successful implementation also requires high alignment accuracy during manufacturing to prevent visual defects, such as “double-tracking” or distorted patterns.

2.2. Diagonal Knurling

Characterized by unidirectional inclined lines typically at 30° or 45° angles, diagonal knurling offers both practical and aesthetic benefits.

Available in left-hand (LH) or right-hand (RH) orientations, this pattern provides self-cleaning properties as the angled grooves tend to shed debris more effectively than straight patterns.

Beyond its functional advantages, it delivers enhanced decorative effects that elevate product appearance.

These qualities make it particularly valuable for electronic device knobs, instrument components, and other aesthetically sensitive parts, such as premium flashlight bodies, camera lens focus rings, and custom tools.

The visual appeal and suitability for rotating components are significant advantages, although designers must remain mindful that the pattern’s directional nature requires careful attention to orientation during assembly, ensuring that LH/RH configurations properly match the intended design.

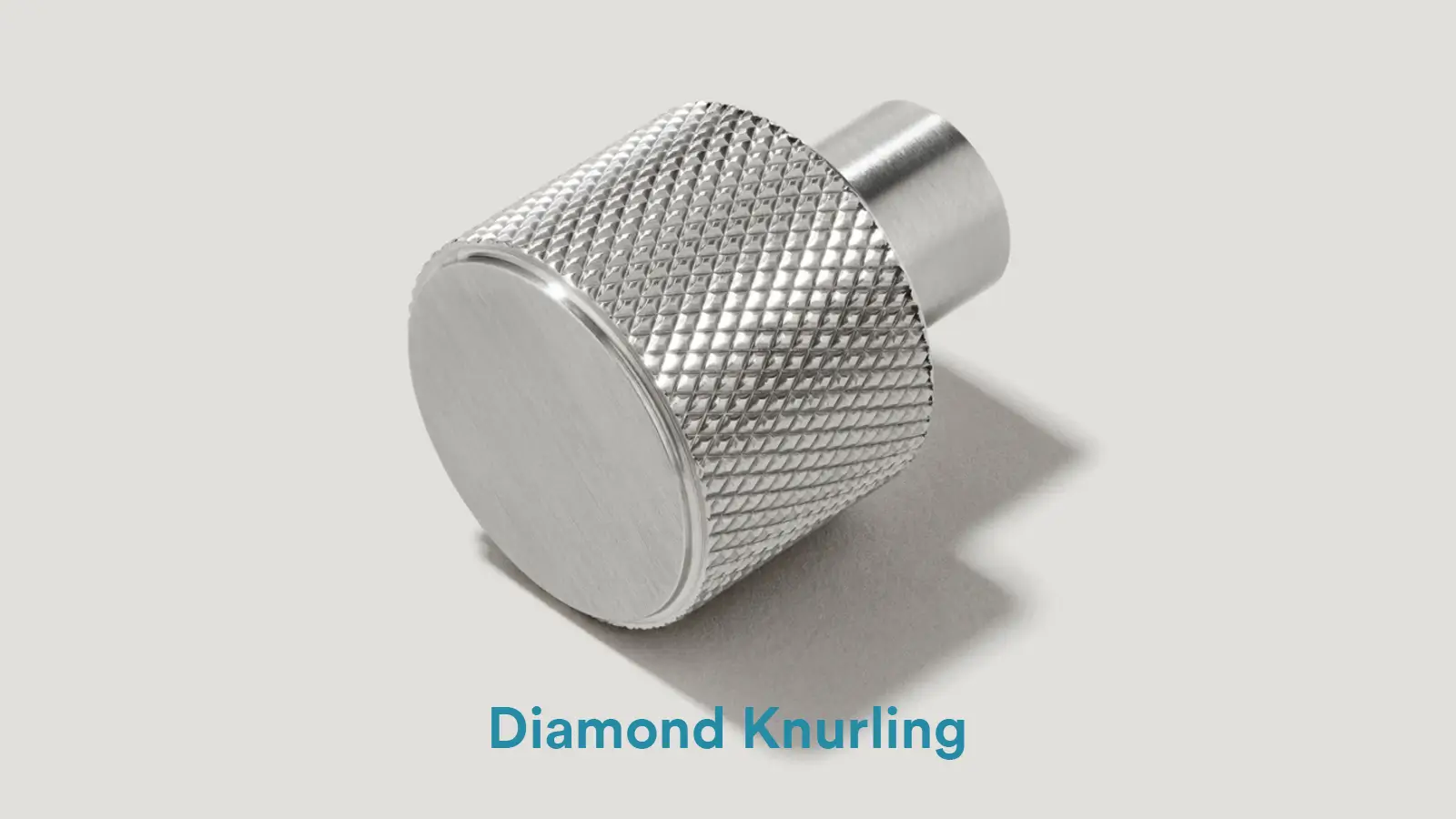

2.3. Diamond Knurling

As the most prevalent knurling type, diamond knurling creates a distinctive grid pattern through crossed diagonal lines typically intersecting at 90°.

This configuration delivers the strongest anti-slip performance available, providing excellent multi-directional friction that ensures secure grip from all angles.

These superior gripping characteristics make it the go-to choice for tool handles, mechanical knobs, fitness equipment, bottle caps, and various everyday hardware items.

The exceptional grip strength and optimal anti-slip effect represent significant advantages that account for its widespread popularity.

However, producing this pattern requires substantially higher processing pressure than other knurling types, placing greater demands on both tools and materials.

The manufacturing process also necessitates precise synchronized operation of dual forming wheels to achieve the characteristic crisp diamond pattern.

Knurling Types Comparison Chart

| Characteristic | Straight Knurling | Diagonal/Helical Knurling | Diamond Knurling |

|---|---|---|---|

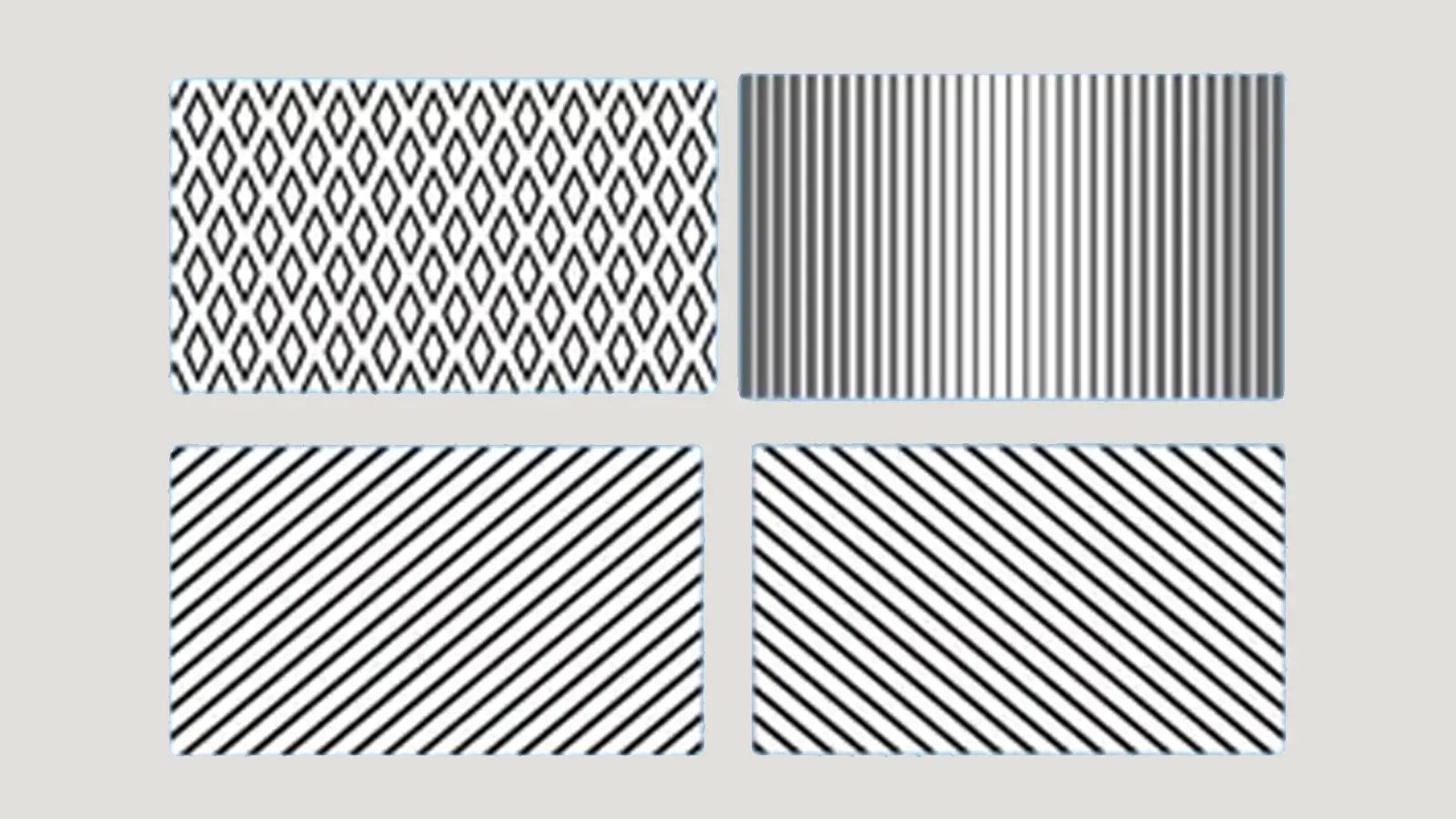

| Visual Pattern | Parallel Straight Lines | Unidirectional Inclined Lines (LH/RH) | Criss-Cross Diamond Pattern |

| English Name | Straight Knurling | Diagonal / Helical Knurling | Diamond Knurling |

| Core Function | Unidirectional anti-slip & torque increase | Bidirectional anti-slip, self-cleaning & decoration | Omnidirectional best anti-slip & grip |

| Anti-Slip Properties | Excellent axial grip, poor lateral grip | Good multi-directional grip, balanced performance | Strongest, most uniform multi-directional friction |

| Aesthetics | Low, industrial look | High, dynamic and refined appearance | Medium, classic, functional look |

| Wear Resistance | Good | Good | Excellent (larger contact area, more load points) |

| Common Applications | Micrometer thimbles, linear actuators, uni-directional knobs | Premium flashlights, camera focus rings, dashboard knobs, custom knives | Tool handles, bottle caps, heavy-duty valve wheels, gym equipment |

| Processing Features | Very high alignment requirement, prone to “double-tracking” | High alignment requirement, must match handedness to design | Requires synchronized wheels, high machining pressure |

| Advantages | Simple, efficient process, uniform pattern | Visually appealing, suitable for rotation, self-cleaning | Strongest grip, best anti-slip, most versatile application |

| Disadvantages | Single-direction grip | Sensitive to installation orientation | High demands on tooling and machine rigidity |

3. Knurling Patterns Parameters

Knurling textures are defined by several parameters that collectively determine the “tooth profile” and appearance.

3.1. Pitch / Modulus

Definition: The distance between two adjacent tooth centerlines, measured in millimeters (P) or teeth per inch (TPI).

TPI: Teeth per inch (e.g., 16 TPI means 16 teeth per inch).

P: Pitch in millimeters (e.g., P = 1.6 mm).

Selection Guidelines:

Coarse Pitch (Low TPI, e.g., 8–16 TPI): Large, deep teeth for strong grip but rough texture. Suitable for heavy-duty tools like wrenches and valve wheels.

Fine Pitch (High TPI, e.g., 20–40 TPI): Small, dense teeth for smooth comfort and fine aesthetics. Ideal for precision instruments, medical devices, and high-end consumer products.

Workpiece Diameter Matching: The product of the workpiece diameter (in inches) and TPI should be an integer to avoid incomplete “residual teeth.”

Smaller pitch → Denser pattern → Smoother surface, suitable for small parts or decorative components.

Larger pitch → Coarser pattern → Stronger grip, ideal for handles or knobs.

Common Ranges: 0.4–1.2 mm (fine), 1.2–2.0 mm (medium), >2.0 mm (coarse).

3.2. Tooth Angle

Definition: The angle between the two sides of a knurling tooth.

Common Angles:

90°: Standard for diamond and straight knurling, offering high strength and versatility.More durable, suitable for high-pressure or long-term use.

30°/45°: Primarily for diagonal knurling, providing unique visual and tactile effects. Smaller angles (e.g., 30°) create sharper teeth for enhanced grip.

60°: Offers stronger grip but is prone to tip wear

3.3. Knurl Depth

Definition: The vertical distance between the peak and valley of the knurling texture.

Selection Guidelines:

Too shallow → Pattern is unclear, anti-slip performance is insufficient.

Too deep → Risk of material deformation or surface damage.

Recommended Value: 30%–40% of the pitch.

4. How to Choose the Right Knurling Pattern

Selecting the appropriate knurling type requires considering the part’s function, material, size, and processing method.

4.1. Determine Functional Requirements

Maximum Grip (Handheld): Choose diamond knurling for optimal radial and axial friction.

Prevent Axial Rotation (Tools): Straight knurling is sufficient.

Press Fit: Typically uses straight knurling, where the teeth act as anchor points.

Aesthetics or Minor Grip: Consider diagonal knurling with a smaller pitch (fine texture).

4.2. Consider Workpiece Size and Material

Small-Diameter Workpieces (e.g., D < 5 mm): Use fine pitch/small modulus knurling to prevent deformation of slender parts. Cut knurling is recommended for precision.

Large-Diameter/Heavy-Duty Workpieces: Use coarse pitch/large modulus knurling for stronger grip and durability.

Soft Materials (e.g., aluminum, brass): Prefer form knurling but avoid excessive deformation or burrs.

Hard Materials (e.g., stainless steel, hardened steel): Prefer cut knurling to ensure clear and complete pattern formation.

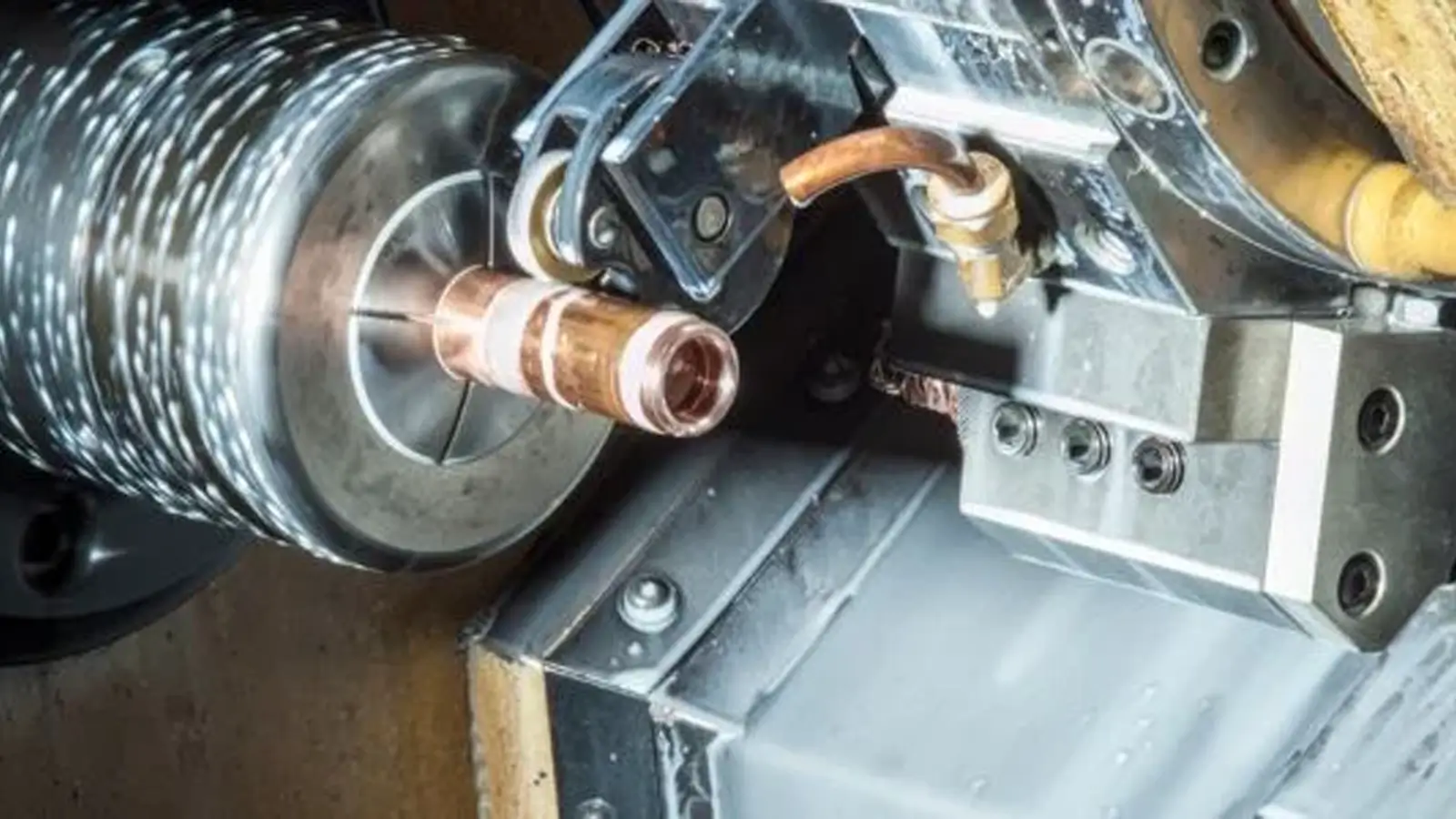

4.3. Determine Processing Method

High Precision and Strict Outer Diameter Tolerances: Choose cut knurling.

High Production Efficiency, Cost Sensitivity, and Soft Materials: Choose form knurling (requires precise calculation of post-rolling diameter).

Note: Clearly specify the knurling type (Straight/Diamond/LH/RH), pitch, and angle in technical drawings to avoid machining errors.

Related blog:

- The Complete Guide to Knurling: Types, Uses, and Design Tips

- Types of Knurling Tools and How to Choose the Right One

- CNC Knurling vs Conventional Knurling: Key Differences, Features, and How to Choose

- How Material Properties Affect Knurling: Choosing Between Form and Cut Knurling

- Types of Knurling Patterns and How to Choose the Right Knurling Type

- Knurling Process: Form Knurling vs. Cut Knurling

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Form Knurling vs. Cut Knurling

Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter.

Types of Knurling Patterns

The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

CNC Knurling vs Conventional Knurling

For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched.

Types of Knurling Tools

Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances.