Table of Contents

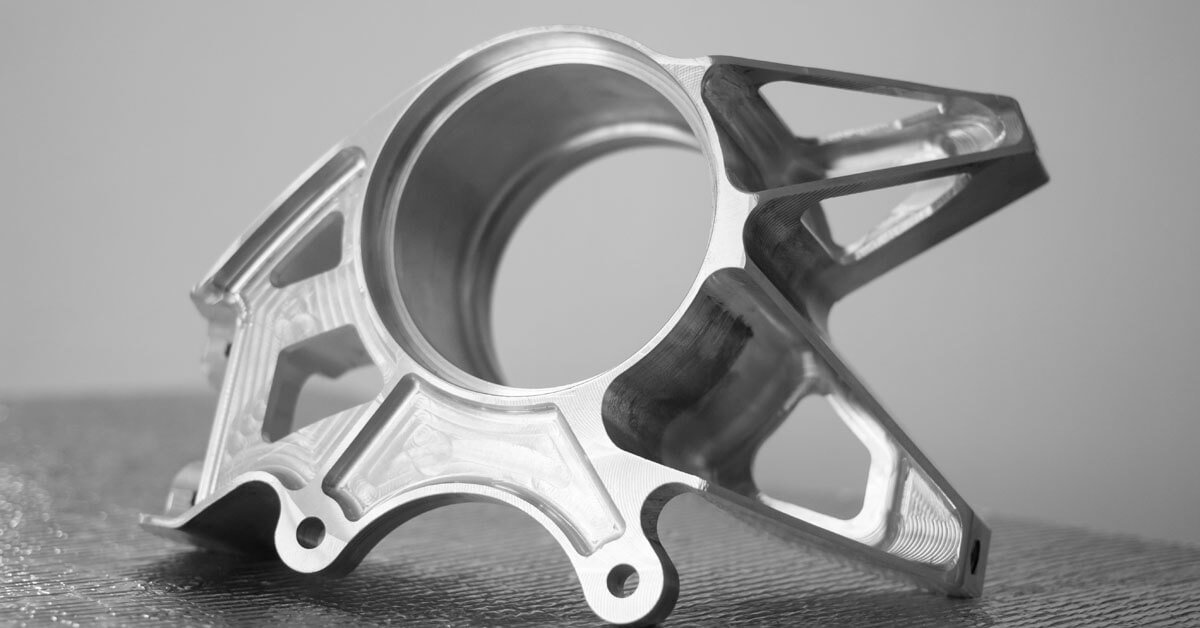

Aluminum UAV parts combine the advantages of light weight and high strength, but these benefits also make them particularly sensitive to deformation during manufacturing.

Aluminum UAV parts combine the advantages of light weight and high strength, but these benefits also make them particularly sensitive to deformation during manufacturing.

To understand how to prevent such issues, it is first necessary to examine the types of deformation that commonly occur, their impact on UAV performance, and the tolerance requirements for critical components.

This foundation establishes a clear context for analyzing the root causes and devising effective machining strategies.

Common Deformation Problems in Aluminum UAV Parts

Aluminum is widely used in UAV structures because of its excellent strength-to-weight ratio.

However, during machining and operation, aluminum parts often experience unexpected deformation.

These distortions are usually caused by residual stress, external forces, or thermal effects.

As a result, they can seriously affect the final quality and reliability of the drone.

Typical Deformation Patterns in UAV Frames and Housings

Before solving deformation problems, it is necessary to understand how they appear.

Aluminum UAV frames and housings often show several common deformation patterns during manufacturing and later use.

1. Arm Bending and Torsion

Slender drone arms may bend longitudinally after machining.Asymmetric processing can cause torsional deformation,and residual stress from heat treatment may lead to slow warping over time.

2. Uneven Base Plates and Center Plates

Thin aluminum plates tend to bulge in the center or warp at edges,reducing flatness and affecting installation accuracy.Stress release during use may further distort the plates.

3. Local Deformation in Housings

Aluminum housings are prone to local dents and bulges.

Thin-wall areas deform easily around fastening points,and curved shells may show inconsistent curvature.

Welded or connected sections are also vulnerable to irregular deformation.

4. Hole Misalignment and Position Errors

Hole displacement directly affects assembly precision.

Shifted mounting holes, poor coaxiality,and tilted threaded holes are common issues.

These defects make precise assembly more challenging.

Flatness and Alignment Issues

The deformation patterns above lead to geometric accuracy problems.Flatness and alignment are crucial for flight stability and assembly quality.

1. Flatness Problems

Flatness defects appear on surfaces used to mount motors,flight controllers, or sensors.

Multiple mounting surfaces may lose parallelism,and excessive flatness error can cause sealing failure,reducing waterproof and dustproof performance.

2. Centering and Alignment Errors

Alignment accuracy is critical.If the motor mounting surface is not perpendicular to the propeller axis,power efficiency decreases.

Inconsistent symmetry between arms disrupts flight balance,and misaligned module interfaces make assembly difficult.

For sliding or guiding components, poor straightness reduces motion smoothness.

3. Accumulated Assembly Errors

Small errors can accumulate during assembly.

Multiple slightly deformed parts can amplify deviation,and forced assembly introduces internal preload stress, affecting long-term reliability.

Differences in thermal expansion between materials may also change alignment under temperature shifts.

Impact of Deformation on UAV Performance and Assembly

Understanding the forms of deformation and geometric deviations helps evaluate real-world impact.

Deformation influences almost every aspect of UAV performance,from flight stability to maintenance efficiency.

1. Effects on Flight Performance

Structural deformation affects aerodynamics.

Uneven surfaces increase air resistance and reduce efficiency.

Unbalanced mass distribution causes vibration.

Distorted structures may reduce control accuracy,and severe asymmetry can compromise flight stability.

2. Effects on Structural Reliability

Unintended deformation leads to local stress concentration.

Under cyclic loads, these areas are more prone to fatigue failure.

Bending reduces overall stiffness,and changes in natural frequency may cause resonance, posing safety risks.

3. Effects on Assembly and Maintenance

Deformation creates many manufacturing challenges.

Parts may fit too tightly or misalign.

Uneven bolt preload reduces joint reliability.

Deformation can cause sealing failure.

Misalignment accelerates wear in moving parts,and deformed components are harder to replace,reducing overall maintainability.

Tolerance Expectations for Aluminum UAV Parts

Clear and reasonable tolerance standards are essential.

Tolerance design balances ideal performance, manufacturing capability, and cost efficiency.

1. Typical Geometric Tolerances

- Flatness of key mounting surfaces: within 0.1 mm per meter

- Straightness of arms: within 0.15 mm per meter

- Parallelism between motor mounts: less than 0.2 mm

- Perpendicularity to axis: within 0.1° (~0.17 mm per 100 mm)

- Symmetry deviation: within 0.3 mm

2. Dimensional Tolerance Guidelines

- Critical mounting holes: ±0.05 mm

- General structural dimensions: ±0.1 mm to ±0.2 mm

- Overall contour dimensions: ±0.3 mm to ±0.5 mm

- Thin-wall thickness variation: within ±10%

3. Special Application Considerations

Large parts may require proportionally relaxed tolerances.

Thin-wall structures need careful balance between rigidity and weight.

High-temperature environments require allowance for thermal expansion.

High-performance drones for racing or surveying usually need stricter control.

4. Inspection and Quality Control

Combine first-article full inspection with batch sampling.

Critical parts should be measured using CMM equipment.

Assembly should include real-time fit checks,and dedicated fixtures improve accuracy.

Main Causes of Deformation in Machined Aluminum Parts

Deformation of aluminum parts after machining is a common and challenging issue in precision manufacturing.

The causes are complex, often resulting from a combination of material properties, machining processes,applied forces, and structural design.

Understanding these factors is the first step toward effective prevention and correction measures.

Residual Stress in Aluminum Sheets

The most fundamental internal cause of deformation is the residual stress locked inside the aluminum sheets.

This stress is not generated during machining but occurs during prior rolling and heat treatment processes.

1. Rolling-Induced Stress

During rolling, the surface and core of aluminum move and cool at different rates,

creating uneven stress distribution.

Typically, the surface is under compression, while the core experiences tension.

When the material is cut or milled, this delicate balance is disrupted,causing the part to warp or twist.

Especially during rough machining, rapid material removal severely disturbs the original stress balance.

To improve dimensional stability, aerospace and high-end UAV industries often use T651 aluminum,pre-treated to relieve internal stress, which significantly reduces post-machining deformation.

Uneven Material Removal and Tool Path Design

Beyond internal stress, machining strategy is a key external factor.

Improper material removal or tool path design can disturb the part’s stress and rigidity balance.

1. Asymmetric Milling

Milling only one side of a workpiece releases stress in that region while leaving the opposite side unchanged.

This asymmetry inevitably causes bending toward the machined side.

2. Cavity and Wall Thickness Imbalance

When one side of a cavity is milled heavily while the other remains thick,uneven stiffness can cause deformation.

Aggressive roughing strategies, such as deep cuts without layering or alternating passes,also increase thermal and mechanical stress release.

Tool paths should be designed to be uniform, symmetric, and progressive,maintaining overall rigidity during machining.

Heat Accumulation and Thermal Deformation

Heat generated during high-speed cutting is another major contributor.

Although aluminum conducts heat well, local hotspots can cause significant thermal expansion.

1. High Spindle Speeds with Improper Feed

Excessive spindle speed without adequate feed prevents chips from carrying away heat,leading to localized temperature rise.

2. Inadequate Cooling

Insufficient or improperly directed coolant flow cannot control temperature effectively.

Local overheating causes expansion, and as the material cools,uneven contraction leads to deformation.

This effect is especially pronounced in thin-walled or detailed features.

Fixture and Clamping Deformation

The way a workpiece is fixed applies external forces.

Incorrect clamping can unintentionally induce deformation.

1. Over-Tight Clamping

Excessive clamping force may cause elastic or plastic deformation.

When the fixture is removed, the part springs back, altering its shape.

2. Fixture Flatness and Accuracy

Imperfect fixture surfaces can hold the workpiece in a twisted state,leading to a part that appears flat during machining but deforms upon release.

Vacuum fixtures on large thin sheets, though generally uniform,can create uneven forces if seals are misaligned or leaks exist.

Inherent Challenges of Thin-Walled UAV Design

UAVs prioritize extreme lightness, which requires large thin-walled structures.By nature, these structures are prone to deformation.

1. Trade-Off Between Weight and Rigidity

Reducing wall thickness decreases bending stiffness exponentially.

Even minor reductions dramatically lower rigidity,making parts highly sensitive to cutting forces, clamping, and gravity.

2. Design-Driven Deformation Risks

Large open areas without reinforcement or abrupt wall thickness changes magnify deformation risks.

Optimal designs balance weight reduction with manufacturability,using proper rib layout and smooth thickness transitions.

Summary and Prevention Strategies

Machining deformation in aluminum parts is a systemic issue that spans material selection, structural design, and machining processes.

Effective control involves:

1. Material Selection

Use high-quality aluminum with low residual stress, such as T651-grade, stress-relieved alloys.

2. Balanced Machining Strategy

Ensure symmetric, progressive material removal and avoid aggressive cutting sequences.

3. Thermal Management

Control cutting temperature via optimized spindle speed, feed, and cooling.

4. Scientific Clamping

Use proper fixture design and clamping force to avoid induced deformation.

5. Design for Manufacturability

Consider manufacturability in the design stage, using reinforcement ribs and uniform wall thickness to reduce deformation risks.

By systematically addressing these factors,high-performance, lightweight UAV structures can maintain precision and reliability.

How to Diagnose the Root Causes of Aluminum Part Deformation?

When aluminum parts exhibit unexpected warping or deformation after machining,

quickly and accurately identifying the root cause is critical.

A systematic diagnostic process should start with observation and measurement,progress through process and design analysis, and use logical elimination and comparative testing to pinpoint the core factors causing deformation.

Flatness Measurement and Data Collection Methods

Accurate measurement is the first step in diagnosis,as reliable data forms the foundation for subsequent analysis.

For flatness issues, high-precision tools are preferred.

Laser trackers or coordinate measuring machines (CMMs) with high-accuracy probes

can capture a 3D point cloud of the entire surface, generating detailed flatness maps

that precisely show bulges or depressions.

When these devices are unavailable, high-precision electronic levels on a granite surface plate or measurements using straightedges and feeler gauges along multiple diagonal directions can also provide effective quantitative data.

Measurements should simulate the part’s free state—remove it from fixtures and place it on three adjustable supports to eliminate external stress.

Only then does the measurement reflect true deformation.

It is also essential to record the deformation type:overall bending, torsion, or local indentation.

Stress-Relief Testing and Analysis

If measurements show regular or overall bending/twisting,internal residual stress is likely the main cause.

Stress-relief testing is a key method to verify this hypothesis.

1. Conducting Stress-Relief Tests

Remove a small sample from a non-critical area or perform a shallow milling pass

outside the deformed region.

Observe whether the sample or part changes shape noticeably.

Significant shape changes indicate high internal residual stress,and machining disrupted the original stress balance.

2. Comparative Material Analysis

Compare deformation across different batches or suppliers.

If one batch shows significantly higher deformation,it confirms poor internal stress control and highlights the importance of using stress-relieved materials like T651 aluminum.

Distinguishing Fixture-Induced vs. Material Deformation

Elastic deformation from clamping often overlaps with permanent material deformation.

Clear differentiation is crucial for accurate diagnosis.

1. Compare Machining-State and Free-State Measurements

Measure key surfaces while the part is clamped using a dial indicator or probe.

Then carefully release the part and let it rest to fully rebound,and re-measure the same surfaces.

2. Interpreting the Results

Large differences indicate significant elastic deformation due to clamping.

Check clamp layout and force for over-constraining or local pressure issues.

If the part remains deformed after release, internal stress or thermal effects

from machining are the likely causes.

For vacuum fixtures, check gaps between the part and table at multiple points before and after machining to detect uneven suction.

Common Failure Patterns and Root Cause Correlation

Reverse-engineering deformation patterns helps quickly identify likely causes.

Specific failure modes often point to particular process or design defects.

1. Regular Overall Bending

Smooth, consistent bending often indicates residual stress release or single-sided heavy milling causing stress imbalance.

Uneven wall thickness can exacerbate this effect.

2. Irregular Twisting or Multi-Directional Warping

Complex distortions are usually associated with local high heat input during machining, such as high-speed milling of thin-walled areas with insufficient cooling.

3. Local Indentation or Edge Lifting

Sudden local bulges or depressions suggest improper clamping,localized high pressure, or intensive machining on the backside of that region.

4. Large Thin-Wall Deformations

Unpredictable bulging or collapse in thin-walled frames or housings points to insufficient structural rigidity.

Check wall thickness, reinforcement ribs, and overall stiffness design.

If the same pattern occurs across multiple parts, the root cause is likely specific to a process, tool path, or fixture design,rather than random variation.

Summary of Diagnostic Approach

Diagnosing aluminum part deformation requires a logical process of elimination and verification:

1. Precise Measurement and Documentation

Start with high-accuracy flatness measurement and detailed recording of deformation patterns.

2. Stress Testing

Use stress-relief tests to distinguish residual stress-related deformation from other causes.

3. Clamping Analysis

Compare machining-state and free-state measurements to identify elastic deformation caused by fixtures.

4. Correlate Failure Patterns

Match observed deformation types to known process, material, or design issues to locate root causes.

This systematic approach reduces troubleshooting time and provides a solid foundation for implementing precise corrective measures.

How to Prevent Aluminum Deformation in UAV Machining?

Preventing deformation of aluminum UAV parts is a systematic process that spans design, material selection, process planning, and execution.

Compared to correcting deformation after it occurs, proactive control measures are key to producing high-precision, lightweight parts consistently.

The core principle is to balance internal material stress, machining forces, and thermal input to eliminate or offset the root causes of deformation.

Machining Process and Tool Path Optimization

Optimizing machining processes and tool paths is the primary method for controlling forces and heat impact during machining. The goal is to maintain stability and balance throughout the process.

1. Multi-Stage Machining Strategy

Divide machining into roughing, semi-finishing, and finishing stages.

Roughing quickly removes most material, allowing some cutting heat and stress while maintaining uniform allowance for subsequent operations. Semi-finishing smooths the remaining material and corrects possible roughing-induced deformation.

Final finishing uses low-stress parameters to achieve the target dimensions and surface quality.

This staged approach allows internal stresses to gradually release and rebalance between steps.

2. Balanced Material Removal

Tool paths should be symmetrical whenever possible to avoid heavy cuts on a single side. For frame parts, alternate machining opposite sides.

For cavities, use spiral or inside-outward paths to maintain rigidity symmetry.

Finishing should employ low-stress methods: sharp tools, small radial cuts, high cutting speeds, and sufficient coolant, minimizing plastic deformation and heat generation.

Scientific Control of Machining Parameters

Cutting parameters directly affect cutting forces, heat generation, and thermal conduction. Optimizing them systematically is essential to prevent deformation.

1. Cutting Speed

Select a speed that balances tool life and heat generation. Excessive speed raises temperature, increasing thermal deformation risk; too low speed may cause material work hardening, increasing cutting forces.

For aluminum alloys, medium-high speeds within manufacturer recommendations are preferred, combined with effective cooling.

2. Feed Rate

Ensure each tooth of the cutter engages material adequately.

Too low feed causes friction and heat accumulation; too high feed increases forces, risking vibration or tool deflection in thin walls.

3. Depth of Cut

Radial depth significantly impacts rigidity and forces.

For thin-walled or delicate features, use shallow radial cuts with fast feed to reduce radial force.

Axial cuts can be deeper to maintain effective tool engagement. Always ensure continuous chip formation for efficient heat removal.

Material and Heat Treatment Selection

Controlling internal stress at the source is one of the most effective ways to prevent deformation. Material grade, supplier, and condition are critical.

1. Choosing Aluminum Alloys

6061-T651 and 7075-T651 are common choices. 6061-T651 offers good machinability and moderate strength with stable stress, suitable for most UAV structures.

7075-T651 provides higher strength but is more sensitive to cutting parameters.

The T651 condition is essential, indicating solution heat treatment, stress-relieving stretching, and artificial aging, ensuring minimal internal residual stress and superior machining stability compared to standard T6.

2. Post-Roughing Stress Relief

For complex or high-risk parts, apply stress-relief aging after roughing.

Heat the part at a controlled temperature to relax residual stresses induced by rough machining before finishing.

Using certified, high-quality suppliers ensures batch consistency and stress stability.

Fixture and Environmental Control

Stable and well-designed fixturing and controlled environments are external guarantees for reproducible machining, directly affecting deformation control.

1. Flexible and Dedicated Fixtures

Follow the “N-2-1” principle (restrict N degrees of freedom) and apply clamping forces to rigid areas rather than thin walls.

Evenly distribute clamping force to avoid local elastic deformation.

Vacuum fixtures with proper seal placement provide uniform suction but must ensure surface flatness and cleanliness.

2. Temperature Management

Maintain a stable ambient temperature (e.g., 20℃ ±2℃).

Avoid direct sunlight or air conditioning drafts on machines.

For precision parts, allow blanks to thermally equilibrate. Cutting fluid temperature should also be controlled, ideally using a temperature-controlled coolant circulation system.

3. In-Process Inspection

Set up inspection stations after semi-finishing or finishing to measure critical dimensions and tolerances using dial indicators or height gauges.

This identifies deviations early and provides real-time feedback to adjust subsequent machining parameters, forming a closed-loop manufacturing control.

In summary, preventing aluminum UAV part deformation requires a holistic approach: controlling material stress, designing for manufacturability, using balanced low-stress machining strategies, and maintaining stable fixturing and environmental conditions.

Meticulous control at each stage ensures high-precision, high-performance final parts.

How to Prevent Aluminum UAV Part Deformation During Machining

Preventing deformation of aluminum UAV parts is a systematic task that spans design, materials, machining, and execution.

Taking preventive measures is more effective than correcting deformations afterward.

The key is to balance internal material stress, machining forces, and heat input to eliminate or counteract deformation causes from the start.

Optimizing Machining Process and Tool Paths

Tool path and process optimization directly control cutting forces and thermal effects, aiming for stable and balanced machining.

1. Multi-Stage Machining Strategy

Divide machining into roughing, semi-finishing, and finishing stages.

Roughing quickly removes most material, allowing limited stress release.

Semi-finishing evens out residual stress and prepares a stable condition for finishing.

Finishing uses low-stress parameters to achieve final dimensions and surface quality.

2. Balanced Material Removal

Use symmetrical tool paths to avoid removing large amounts from one side continuously.

For frame parts, alternate machining opposite sides. For cavities, use spiral or outward-expanding paths.

In finishing, apply low-stress techniques with sharp tools, small radial depth, high feed rates per tooth, and adequate cooling to minimize heat and plastic deformation.

Controlling Machining Parameters

Cutting parameters directly affect forces, heat, and stability.

1. Cutting Speed

Select speeds that balance tool life and heat generation.

Too high speed raises temperature and causes thermal deformation; too low speed increases cutting force and risk of chatter.

For aluminum, mid-to-high recommended speeds with effective cooling are optimal.

2. Feed Rate

Proper feed ensures cutting rather than rubbing.

Too low feed increases friction and heat; too high feed increases force and vibration risk.

Maintain sufficient per-tooth feed to remove heat efficiently.

Conclusion

By understanding the common deformation patterns, their underlying causes, and critical tolerance requirements, manufacturers can adopt a systematic approach to control stress, optimize machining processes, and manage environmental factors.

These insights provide the basis for applying targeted preventive measures in design, material selection, and process planning, ensuring that aluminum UAV parts maintain dimensional stability, structural integrity, and reliable performance from prototype to production.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.