CNC Machining Shop: the Complete Guide in 2023

Updated: December 04, 2023

Table of Contents

- 1. What Is a CNC Machine Shop?

- 2. What Can You Find In a CNC Machine Shop?

- 3. How to Optimize Your CNC Machine Shop

- 4. Tips to Choose a Quality CNC MachineShop

- 5. What Software is Used in the Machine Shop?

- 6. What is the Target Audience for CNC Machine Shop?

- 7. How Much Does It Cost to Start a CNC Machine Shop?

- 8. What Kind of Design Should I Send a CNC Machine Shop?

- 9. What is the Most Versatile CNC Machine for a Small Shop?

- 10. How to Determine CNC Machine Shop Rates?

- 11. What Types of CNC Machines Needed to Start Machine Shop?

- 12. Conclusion

Introduction

Probably, you are an enthusiast of CNC machining or an entrepreneur intending to launch precision machining service. In both cases, you should be curious about how such businesses are equipped, what services they provide, and what software they use.

Let’s dive into the functioning of a CNC machining shop in greater detail.

1. What Is a CNC Machine Shop?

Ultimately, CNC shop is a place where offer tight tolerances machining part with subtractive manufacturing process. The machining process looks like a single room, a floor with a number of rooms for intended use, and even an entire building with multiple manufacturing lines.

CNC machining factory work with nearly any machinable materials like wood, plastic, metal, and even machinable foam. It’s done using machining center — completely automated, computer-controlled units performing operations as per pre-programmed instructions.

It’s hardly possible for a manufacturing shop to serve all the industries. So, they typically focus on several specific ones like automotive, aerospace, chemical industry, etc. As an option, it’s possible to produce less specialized parts or rough workpieces that are used in various sectors.

Nowadays, Custom machining is of utmost importance for manufacturing overall. The market is highly competitive. So, it’s not good enough to just be better or deliver more affordable services than competitors. CNC machining is about the level and quality of service delivered. An example of a CNC shop flow is shown in the image below.

2. What Can You Find In a CNC Machine Shop?

What types of machining equipment are normally need for machining factory to operate. The list below includes both CNC units and complementary machines:

- Milling CNC machine. It’s simply a unit that rotates cutting tools with sharp edges. These remove chips of material. Milling CNC machines can be either horizontal or vertical. There are mills with different numbers of axes supported and of different sizes. This way, they can withstand huge loads and execute multiple types of cuts.

- Drill press. Probably the most straightforward unit. It’s a mounted drill controlled by a lever. Drill presses can penetrate thick parts of strong material with high precision.

- Lathe/turning center. It’s a kind of machining that rotates a workpiece (usually a symmetrical one) and moves it against a cutting tool rather than vice versa. It performs such operations as knurling and facing.

- Grinding machine. It’s powerful equipment that uses an abrasive wheel to grind the workpiece, i.e., to remove a substantial portion of the material to form a planar surface. It may be used as a form of the finishing process.

- Bandsaw. It’s a multi-use machine serving for the preparation of workpieces before fabrication. This machine makes straight, precise cuts. It removes sections of material (or divides bars/ sheets into several pieces) before further processing.

- Electrical Discharge Machine (EDM) equipment. EDM is the process of using sparks to penetrate a workpiece. It uses a wire for the tool electrode.

- Machining centers. as well as turning centers, these are the most versatile pieces of equipment in a CNC shop. Normally they have 4,6 or even 8 axes, along which cutting tools can move. They carry out the process at high production rates and may even have robotic pallet changers to speed up the manufacturing.

- Surface finishing tools. Well, some complex CNC units with multiple axes can be equipped with tools for finishing. There is still the need for specialized equipment that can perform bead blasting, sandblasting, buffing, polishing, and coloring of parts fabricated.

- Coordinate measuring machine (CMM). It’s a device that measures the geometry of parts perfectly. It ensures that the machined part matches the desired dimensions. Basically, it’s a tool for quality assurance testing. It is placed at the end of a manufacturing line to reject sub quality parts.

- Vernier caliper. It’s a more distinguished tool used for measuring the inner dimension and depth of the workpiece with the help of so-called jaws.

- 3D scanner. It’s another interesting unit that does not participate in cutting operations directly. It scans a part’s external dimension and produces and digital 3D model of it for further review and use.

- Micrometer and pin gauges. For micro parts or ones that were requested to be extremely precise, these tools are used. Micrometer measures length and thickness. Pin gauges measure the diameter of the smallest holes.

There are other types of tools performing production and complementary tasks. It’s always that a particular niche has certain requirements for its parts to be produced. This normally results in the need to purchase some additional sorts of equipment.

3. How to Optimize Your CNC Machine Shop

Under the term “optimize,” the streamlining of the process is normally understood. The desired result here is to make sure employees and production equipment are used in a rational way and without substantial delays. It will lead to lower manufacturing costs per part fabricated. Ways to do so are the following:

3.1 Ensure Seamless End-to-End Fabrication

Some CNC service suppliers, unfortunately, fail to optimize their supply chain. It leads to inconsistencies in supply, over or understocking, production delays, and other forms of unpleasant surprises. Here are the tips for ensuring good, end-to-end production:

3.1.1. Have a solid supply chain management system. It has to ensure two things: that raw materials and tooling are delivered in required quantities plus 5-10% more (rejection rates and unpredictable issues) and that transport keeps up with the pace of manufacturing, so there is no overstocking.

3.1.2. Construct an optimal manufacturing line. Avoid placing production units in the way half-finished components have to be moved between rooms multiple times. This will prolongate the manufacturing process overall.

Aim at building complete lines with units for preparing raw workpieces, for processing these to half-finished parts, for finishing these parts, and for packing into primary and secondary packaging if necessary.

3.1.3. Ensure the rotation of personnel. The worst-case scenario on your manufacturing line is the complete stop of production – breakage. If 3 machinists are needed to fix it, these must be present every hour of a CNC shop operating. This will not cause the situation when you will have to wait for a specialist to arrive at the premises.

3.2 Ensure One-Stop Post Finishing

The idea here is basically the same as for the supply chain. A single part may require some types of finishes to be applied. So, it’s wise to ensure a one-stop finishing service. For this purpose, it’s necessary to pre-plan and construct several lines for applying finishes:

- Hand and form fit function finishing. This aspect implies the manual adding of necessary components. For example, adding inserts or functional assemblies. Screws or bolts also belong to this process.

- Sanding and polishing. Bead blasting, polishing, and sanding are all normally executed via the same CNC or manually operated unit. It takes hours and is the last stage of manufacturing, so it should be placed closer to the warehouse/ to the end of the production line.

- Painting and printing. Clean paint is a great portion of a product’s quality. The process must be performed in a strictly controlled environment that is similar to sanding and polishing in a CNC unit.

- UV coating. It’s simply an application of UV ink that is further cured with ultraviolet to fully solder. It serves the protection of a component.

- Laser etching. It is the process of removing a thin part of a material from a part’s surface using a laser. This way it’s possible to produce a brand name logo or anything else.

- Powder coating. It’s much like a detailed spray painting. Parts are coated with dry powder and then baked at a temperature of 200°C. You can learn what is powder coating here.

Even if it’s impossible to have all of the details, a CNC shop must offer hand form fit function finishing, CNC polishing, bead-blasting, and either powder coating or painting.

3.3 Ensure Robust Quality Assurance

The thing is that none of the industrial machines is 100% accurate. Normally, there is some production error or deviation from the set dimensions. Sometimes it is within limits, but it may also breach them, which must be detected. here are the ways of doing so and protecting your brand’s reputation:

- Optical inspection. It’s performed manually by a machine operator (optionally, with the help of some sort of tooling). It helps to detect and remove sub quality components timely.

- Verification of purchased products. Selection of finished goods (10-100 units) must be obligatory sent for an obligatory, independent quality inspection. This way, you will also receive a quality certificate.

- Inspection by the Quality control department. You must have im-house QA specialists and an equipped room with measuring instruments. There you will be checking the dimensions and properties of the finished goods to see if they match the standards and requirements set.

Don’t neglect any of the described needs for your CNC shop, as they impact the level of your service significantly.

3.4 Ensure Safety in the Workplaces

It’s crucial that your workers are not endangered. CNC shops are quite a place where incidents are absolutely unheard of. So, consider sticking to these recommendations to prevent those:

- Make sure your workers are not roaming around working machines 24/7. They are supposed to rest behind a plastic protective screen and watch the process go smoothly.

- Specific dress code. Actually, your workers are supposed to wear protective gloves and eyewear at least. It’s better to also provide them with some industrial coats and casks, if necessary.

- Pay attention to waste management. Any CNC must strive to be an environment-friendly business. It is also tightly connected with safety concerns, such as hazardous substances, sharp-edged metal chips, etc.

- Hazard control. There are some flaming and toxic materials stored in a CNC shop. Make sure these are approached as per safety standards.

- Routine machine maintenance. Every unit obligatory must pass routine checks daily or even more frequently. But it’s also crucial not to forget to stop production lines for planned maintenance, so no unexpected breakage is possible.

So, there are methods in which you guarantee that your CNC shop is subject to no safety issues.

4. Tips to Choose a Quality CNC Machine Shop

There are some parameters according to which you can determine if a chosen contractor is any good. Or, use them to see if your own CNC business qualifies as a quality manufacturing shop:

- ISO Certified. Remember the entire quality and production things described above? A CNC shop cannot get such certification unless they have got some robust Quality Assurance, manufacturing, and production practices in place. The ISO-9001 certification proves that you can trust your project to the contractor.

- Respect to customer privacy. It starts with not-sharing your email details and phone contacts with unnecessary people and third parties. And it ends with not allowing your patented blueprints to enter a market without your permission.

- Long-term value and competitive price. Partnering with CNC shops is not only about the work done and the price paid. Transportation agreements, supply nuances, manufacturing tempo, and other aspects will greatly affect the efficiency of the business of your own. Choose contractors that aim at long partnership.

- Good communication and customer support. The thing is that good-quality components are of no value if you cannot communicate with a contractor properly. The level of customer support engagement is a clear indicator of how trustworthy a CNC shop is.

Pay attention to these aspects whether you are an owner of a CNC shop yourself or a customer looking for manufacturing services.

5. What Software is Used in the Machine Shop?

Let’s skip programs for sending emails, writing texts, accounting, and other non-related to the manufacturing process itself. So, here is the software that is absolutely crucial for ensuring the seamless CNC fabrication of goods:

- Management software. You see, most manufacturers love to have a management program specifically intended for their niche. Top machine shop software include: E2 Shop System, JobBOSS, MIE Trak PRO, Fulcrum, and ProShop. These digital solutions help to manage workload, supply chain, ISO certification, and many more.

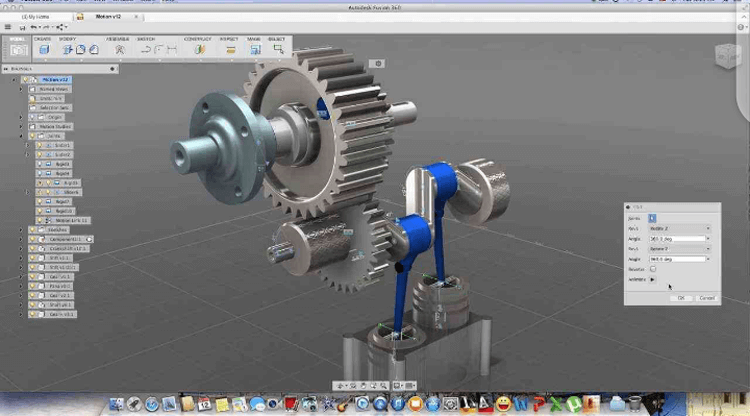

- CAD software. Computer-aided design solutions are programs that use vector-based graphics to construct 2D or 3D models of components. They help to draft construction documentation, visualize engineering concepts, and many more. Some popular options on the market include AutoCAD, Fusion 360, Revit, Civil 3D, and others.

- CAM software. Computer-aided manufacturing solutions help to transform CAD files into G-coded or CAM files that can be used by CNC units to guide machining processes like cutting and non-cutting operations. Available software solutions include FreeCAD, OpenBuilds CAM, Inkscape Laser Plug-In, Estlcam, Carbide Create, and others.

- Internal CNC software. Each CNC unit is computer-controlled by default. It means that there is a specific program allowing for adjusting settings, starting the machine, and stopping it. These internal solutions are installed by suppliers of machinery.

6. What is the Target Audience for CNC Machine Shop?

Reaching the target customers for a CNC shop is not the same as for any other, for example, e-commerce business. Manufacturing services are typically Business to Business (B2B) services. Here are some target customers that are likely to request your assistance:

- Machining and construction enthusiasts. Such customers are typically in need of an extremely small batch or even a single component to be fabricated. It’s up to you to decide whether you are taking such orders and what the pricing will be. Still, there are thousands of people who love DIY everything and need one or another part to be machined occasionally. Do not neglect their impact on your business.

- Industry-specific businesses. Normally, these are your clients in the first place. They run their own businesses that require a supply of CNC machined components. Companies in automotive, aircraft, electronics, and other sectors may require your services.

Be prepared to approach each such customer individualistically, as they tend to carefully select and even audit their partners. They may also organize a tender to get the best conditions, so you must be prepared for some rational competition.

- Other manufacturers/ CNC shops. Surprisingly, your competitors may appear to be your best customers. It happens for various reasons: they may not have enough capacity to handle a contract themselves, or they may experience a production stop for some reason and request you to give them a hand of help. They also may request you to prepare workpieces or some components for their production.

It’s often that a single manufacturer struggles to fulfill a contract independently. Considering the strict contract terms that are extremely unpleasant to violate, you may be frequently asked to outsource some CNC shop’s urgent needs.

Your pricing policy and the types of customers you are willing to partner with are completely up to you. Remember, there is no point in turning down small orders even if they are not that profitable. Just make sure you never work at prime cost.

7. How Much Does It Cost to Start a CNC Machine Shop?

A single CNC unit may cost somewhere between $2000 and $500,000, so it’s kinda difficult to state what capital is needed for a CNC shop startup. But let’s make some estimates anyway for you to have an initial insight.

| Expenditure | Cost | Required? |

|---|---|---|

| Equipment & Supply Expenses | ||

| Equipment & Supply Expenses | ||

| Cleaning supplies | $30-100 | Optional |

| First-aid equipment | $50-300 | Optional |

| Uniforms and protective equipment | $50-500 | Optional |

| Retail Business Expenses | ||

| Shop Decor | $1000-5,000 | Optional |

| Utilities (storefront business) | $200-1,000 | Optional |

| Building improvements and remodeling | $100-1,000 | Optional |

| Storefront Property Rent ➜ | $1250-3,500 | Optional |

| POS System | $0-1200 | Optional |

| Software Expenses (either subscription or license average weighted cost) | ||

| Email marketing tool | $0-100 | Recommended |

| Accounting & Invoicing Software | $0-50 | Recommended |

| Project Management Software | $0-50 | Recommended |

| Social Media Management Tools | $0-50 | Optional |

| Payroll Software | $0-50 | Optional |

| CAD Software | $0-100 | Recommended |

| CAM Software | $0-100 | Recommended |

| Inventory Expenses | ||

| Upfront Costs For Inventory | $300-5,000 | Recommended |

| Package options | $0-3,000 | Recommended |

| Inventory storage | $0-5,000 | Recommended |

| Shrinkage | $0-1,000 | Recommended |

| Distribution costs | $0-750 | Recommended |

| Advertising & Marketing Costs | ||

| Direct Campaigns, Printing and Mailing | $0-800 | Optional |

| Business Cards | $0-50 | Optional |

| Influencer Marketing | $0-750 | Optional |

| Press | $0-500 | Optional |

| Google Ads | $0-400 | Optional |

| Website Costs | ||

| Domain | $12-200 | Optional |

| Development | $0-10,000 | Optional |

| Capital costs (basic ones only. They easily can multiply many times) | ||

| Design computer | $1,000-2,000 | Obligatory |

| CNC mill | $5,000-200,000 | Obligatory |

| CNC lathe | $5,000-200,000 | Obligatory |

| Horizontal bandsaw | $3,000-25,000 | Obligatory |

| Tooling allowance | $1,000-10,000 | Obligatory |

| Shipping and taxes | $3,000-8,000 | Obligatory |

| Transportation vehicle | $10,000-30,000 | Recommended |

| Operating costs (basic ones only. They easily can multiply many times) | ||

| Initial supply of materials | $5,000-15,000 | Obligatory |

| Lease of industrial zone real estate | $10,000-100,000 annually | Obligatory |

| Insurance | $2,000-5,000 annually | Obligatory |

| Total Costs | Most affordable – roughly $50,000 All-inclusive – roughly $600,000 | |

As always, the reality is somewhere between worst-case and best-case scenario. So, approach this project wisely and do not neglect to prepare a proper business plan.

8. What Kind of Design Should I Send a CNC Machine Shop?

CNC machines work with only one type of files – CAM file (G-coded text files with instructions for CNC computer indicated). In case you have such a file intended for a regular, for example, CNC 3-axis mill, and it works properly, be sure that it will be executed correctly.

However, in most cases, businesses have a CAD file with a 3D model of a component to be manufactured. This way, a CNC shop will have to convert the file into a CAM file themselves and probably make some rapid prototyping prior to fully-fledged, large-scale manufacturing.

One more version is a blueprint that will serve as engineering documentation for a CNC shop to rapidly prototype a component, prepare CAD, and then CAM file.

In both cases, you will need to accompany the CAD or CAM files and blueprints with the bill of materials, and some engineering specifications for your desired components, if a CAD file does not include this information.

So, you should send your design as either blueprint, CAD, or CAM file, along with specifications and a bill of materials. It’s better to send them all together for a CNC shop to have all the needed details just in case.

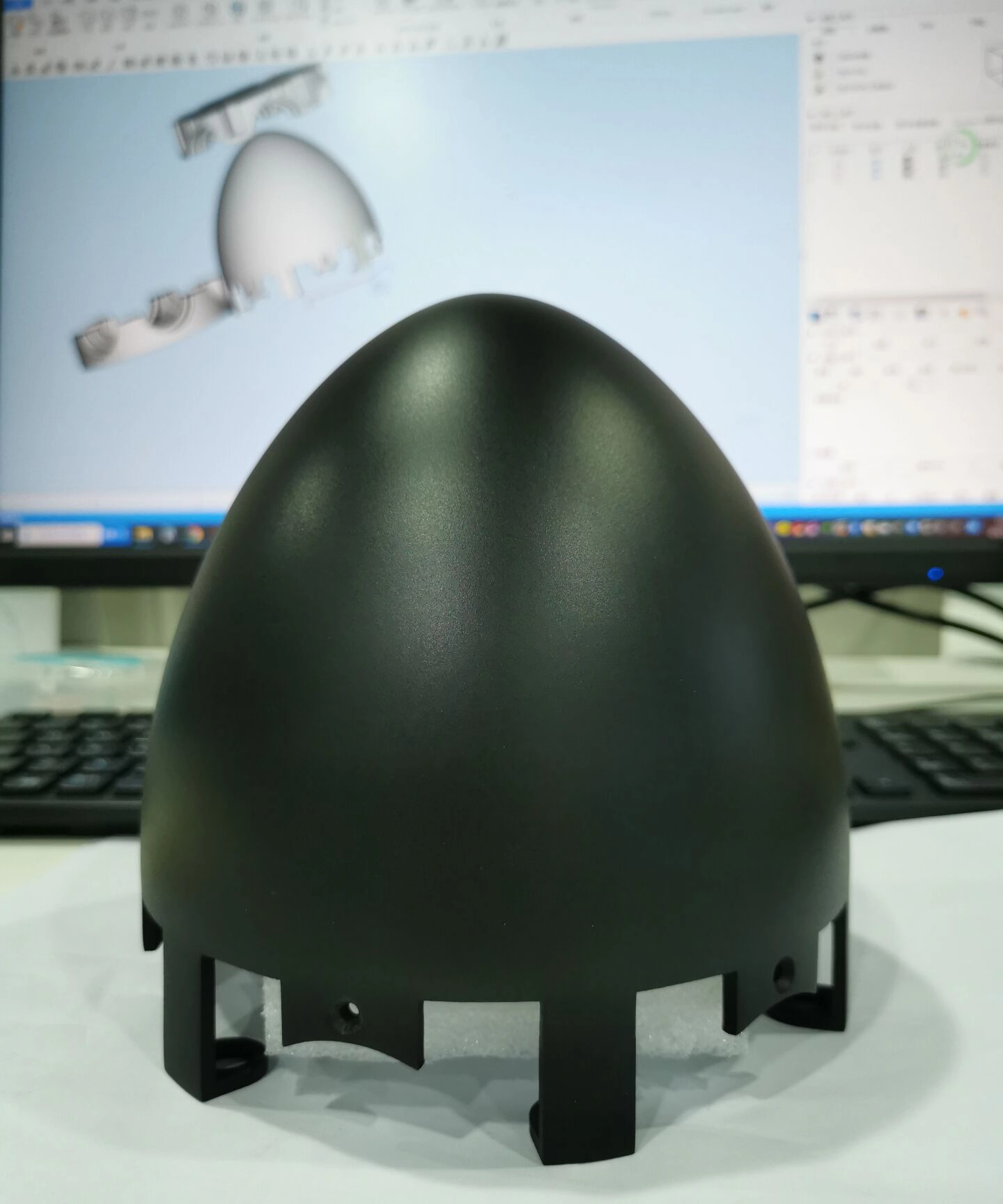

Examples of all of the mentioned are shown in the images below.

9. What is the Most Versatile CNC Machine for a Small Shop?

CNC mill and CNC lathe share the first place. 40% of all the work in CNC shops is done by a mill, the other 40% of work is the lathe. The 20% of work left is split between like a dozen of other CNC unit types. Turning machines and machine centers serve as common replacements for lathes and mills, respectively.

10. How to Determine CNC Machine Shop Rates?

It’s a sensitive question that requires well-thought-out answering. To stay in business, CNC shops have several types of expenditures preplanned and included in the end price. These are both typically and specific, as indicated in the list below:

- A setup charge. It means investing some time in choosing and arranging proper tooling, installing a CAM file, and preparing for working in any other way. Every setup change may cost somewhere between 100$ and 200$, depending on how time-consuming it is. Remember, the time of machine working is limited and, therefore, is a key price-forming factor.

- Raw materials. Unless a customer does not bring their own, a CNC shop typically charges the cost of materials + cost of material transportation + 30-35% more.

- Machining. It may vary in the range of $60-160 per hour. The exact amount is calculated based on the investments in CNC tooling, depreciation cost, plus 10-20% of added value (your profit).

- Post-machining work. It’s normally subcontracted and may include some buffing, polishing, packaging, and anything else of a customer’s choosing. You compute how much it costs for your business and add 20-35% more. It’s so simple.

Always start by estimating expenses. As a rule of any business running, the customer pays off all the expenses for producing its product plus your margin, your profit, which is normally 10-30%.

11. What Types of CNC Machines Needed to Start Machine Shop?

A short answer: $200,000 mill or $200,000 lathe. That’s it. Indeed, some CNC shops operate having a very limited number of units (the extensive list is indicated in the first sections of the post). You will also benefit from having a horizontal bandsaw. It is needed to cut wood or steel, so you have suitable workpieces.

Depending on your niche, you may not need either mill or lathe. Instead, you will have to purchase some other equipment units.

12. Conclusion

In essence, running a CNC shop is not as easy as newbies might think. The main issue is the initial capital costs which are huge. There are also plenty of aspects to give a good thought, starting from a decor for a shop ending with types of customers to work with and pricing policy.

Always start planning your CNC shop with a proper business plan, and carefully choose contractors you trust fabrication of your components to.

Outsource cnc machining is also a good choice to make your custom parts.