If you work in the aerospace, medical, or electronics industry or are just curious about how complex metal parts are manufactured, you have probably heard about CNC milling.

Tools for shaping metal vary in their types and purposes, making it complicated to obtain an appropriate insight into CNC milling. It results in difficulty choosing a CNC milling machine or understanding the principles of its operation.

Here is the complete guide for CNC milling machines, this post will get answers to all common topic-related questions.

What Is a CNC Milling Machine?

Such machines are used for both commercial and industrial production of components from prepared material. Parts can be made from metals, plastics, ceramics, and composites.

CNC milling machines can be used to produce machine parts that are not symmetrical from an axial perspective. Depending on a particular component’s unique curvatures or surface contours, a combination of drilling, tapping, slots, recesses, and other elements may be required.

How does a CNC Milling Machine work?

The operation process of the CNC milling machine consists of two parts, which are pre-programming and preparation of components, i.e., material cutting itself.

Pre-Programming

In CNC milling, pre-programmed Computer-Aided Design (CAD) software installed on a computer connected to the mill dictates the movement of the machine’s axis. To be executed, instructions to the mill must be coded using means of G-code and M-code programming.

G-code. This software programming language is used to control a CNC machine directly. It is written in a logical way and is responsible for dictating commands to change geometry. In other words, G-code makes the machine change the geometric coordination of its axes.

M-code. In its turn, M-code is responsible for non-geometry machine functions. Some of them may include spindle rotation start and stop, pallet change, flood coolant on and off, and others. M-code is more customizable than G-code.

Preparation of Components

The general principle of milling can be described as rotating a cylindrical cutter along multiple axes. It enables the creation of slots, holes, and details in the workpiece, turning it into a specialized part.

The moving section of a CNC mill, which is called the spindle, includes the cutter and can be positioned either vertically or horizontally. Such configuration enables the cutting tool to reach any X-Y-Z position on the workpiece, performing cutting and shaping.

The workpiece can be fixed or mounted on a table or positioned in a linear direction to the spindle with the cutting tool. Arranging the described process enables removing material from the workpiece to obtain the desired shape.

Pre-programming enables the subsequent operation of CNC machines, the result of which is the fully completed component.

Related Post: Up Milling vs Down Milling

Is CNC Milling and Manual Milling the Same?

CNC Milling

High accuracy. CNC milling enables the production of components with the highest precision possible.

Consistency. CNC machines can reproduce parts with the same measurements multiple times.

Safety. The use of computer-based machinery implies that no human intervention during the process is needed, which results in the complete protectionof employees.

Cost-effectiveness. Despite the high amount of initial capital needed to purchase and install CNC mills, they do not require as many operators as machines for manual milling. Moreover, computer-based pieces of machinery produce less waste. Thus, they are more cost-effective in the long run.

High production. CNC mills are optimal for producing large-sized orders consisting of thousands of pieces. The process is automated and less time-consuming.

Manual Milling

Manual milling is known as the labor-based one, and it implies the use of tools intended for manual metal-shaping by workers themselves. It has the following distinctive features:

Fast production. Manual milling does not require as much preparation, such as programming, before manufacturing. Thus, small-sized orders can be finished quickly.

It is possible to state that being the more advanced material cutting method, CNC milling enables high-volume production of first-rate parts with a minimum human intervention needed. At the same time, manual milling-based manufactures produce less precise components but in a shorter time. Despite both methods adopting technically the same process of shaping, they significantly differ from each other.

CNC Milling vs CNC Lathe Machine

Both CNC milling machines and CNC lathe turning machines are computer-based tools for shaping workpieces. Their distinctive functions are often mixed up because they are utilized in the same processes with a similar purpose. Read below to know the differences in CNC technologies between these two types of milling centers.

CNC Milling Machine

For a CNC milling machine, the workpiece should be fixed in a position while the cutting tool is maneuvered on the top of the prepared material. Gradually removing particles of material using cutting tools rotating at high-speed CNC mills shapes the workpiece.

The techniques CNC milling can apply with the use of their tools include outside cuts, drilling, chamfering, interior cuts, hollowed-out spaces, and spherical and round shaping.

CNC milling machines are flexible and can work with asymmetrical designs.

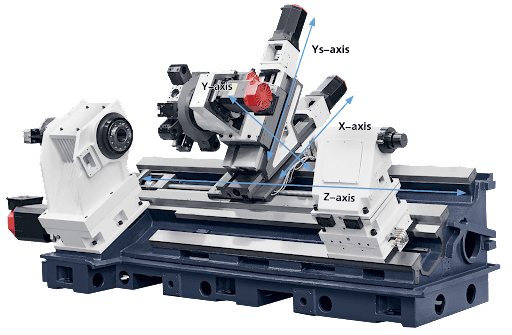

CNC Lathe

CNC Lathe is a machine that shapes workpieces by spinning them on an axis while shaping with a cutting tool. It is intended to shape longer, horizontal pieces from different materials. Such machines are perfect for parts that are symmetrical around an axis. An example of CNC Lathe is shown in the image below.

The techniques CNC lathe can apply with the use of their tools include sanding, frilling, cutting, knurling, reaming.

The techniques CNC lathe can apply with the use of their tools include sanding, frilling, cutting, knurling, reaming.

Lathe machines that include additional options such as Y-axis and sub-spindles are called CNC turning centers.

In one sentence, a CNC milling machine uses a spinning tool with a fixed workpiece, while a CNC lathe’s operation involves spinning the material.

Compared to a CNC mill, a CNC lathe is less versatile.

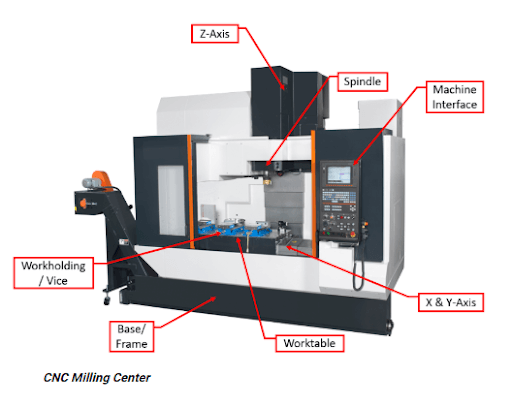

What are the main components of a CNC Milling Machine?

CNC Milling machine is a complex center consisting of numerous parts. The simplified overview of CNC milling center components is shown in the image below.

Base/frame. The structure supports the milling center and makes it stable and rigid. It usually is accompanied by detachable columns.

Spindle. It is the part of the CNC center that rotates a workpiece on an axis. It is comprised of a motor, a taper for tools holding, and a shaft. The spindle receives input on movement from the CNC controller.

X, Y, and Z axes. They are primary rotation axes programmed using G-code and moved by the CNC controller.

Worktable. It is a solid base to fix the workpiece on. Worktables usually have T-slots for vice, fixture, or a part clamping.

Tool holders. It is the component that precisely and firmly holds the end mill in place. Examples of tool holders are quick change tap holders, custom tool holders, and Jacobs taper tooling.

Workholding / vice. It is a slinging, locking mechanism that enables securing a part and its holding during machining operations.

Machine interface/control panel. A computer-based milling center is controlled by this panel containing the main electronics and implementing cutting functions by a program set. The CNC control panel has a monitor and programming buttons.

What are the cutting tools used by a CNC Milling Machine

The cutting or milling tools used by CNC milling centers are the devices that help to remove material from a workpiece. This process is called “shear deformation.” A sharp tool rotates at high speed and cuts tiny particles, which are then ejected away. A variety of cutting tools, listed below, enables the versatility of CNC milling machines.

End mill. It is the most widely used, collaboratively with vertical CNC mills, tool. It has cutting teeth at one end and on its sides.

Roughing end mill. It is similar to the end mill nut that has serrated teeth intended to remove large sections of material with less precision.

Face mill. Such a device is a solid body with interchangeable cutter inserts. The purpose of the face mill is to make flat sections on the workpiece.

Fly cutter. It is a solid body within which there are one or two tool bits that make broad and cuts intended smooth surface finish.

Thread mill. Such mills are widely used to cut internal or external threads in hard materials or asymmetrical parts.

Drill bit. There are twist drills, center drills, and ejector drills used for cutting operations such as making holes. They can have one or more flutes and a conical cutting point.

Reamer. This device is needed to widen existing holes and finish their inner surfaces. The respective process of enlarging the hole is called reaming.

Hollow mill. It looks like an inverted end mill and is used to create full points and form radii.

Side-and-face cutter. Such mills have teeth on their sides and around their circumference and are intended to make unbalanced cuts such as slots and grooves.

Slab mill. The slab cutter does not have side teeth and is used to mill flat surfaces.

The range of cutting tools ensures the conducting of operations needed to shape a workpiece of any design regardless of its complexity.

What are the different types of CNC Milling Machines?

The contemporary market is presented with numerous types of CNC milling machines adapted for one or another purpose. Here is the list of the existing ones.

Horizontal milling machines. These centers’ tolling spins horizontally while removing material from a component.

Vertical milling machines. A simple three axis vertical center’s tolling moves vertically (in the direction of gravity). They are also known as C-frame machines and are considered traditional ones.

Multi-axis milling machines. Some machines are equipped with additional axes that expand the capability of a CNC machine. 4, 5, 6 and 7 axis machines are not rare and known to be effective for shaping the most complex parts.

Turret milling machines. Unlike the vertical mill’s spindles, which can be mobile or not, turret ones have stationary spindles. Turret milling centers’ worktables move perpendicular and parallel to the spindle axis to enable the cutting.

Bed milling machines. Such centers are considered to be more rigid than turret milling machines, and their worktables move only perpendicular to the spindle, opposed to perpendicular, and parallel.

Traveling column milling machines. In this type of CNC mill, both the worktable and workpiece are stationary, while the traveling column makes three linear axes movements. The traveling column is composed of the spindle and the cutting tool.

Double / multi-spindle milling machines. These either horizontal or vertical milling centers equipped with several spindles is considered one of the advanced type of milling machines. They often have pallet changers intended to transport raw parts to the center and unload finished workpieces out of the center.

It is vital to carefully choose the type of CNC milling machine based on the type of components intended to produce.

How do you build a CNC milling program?

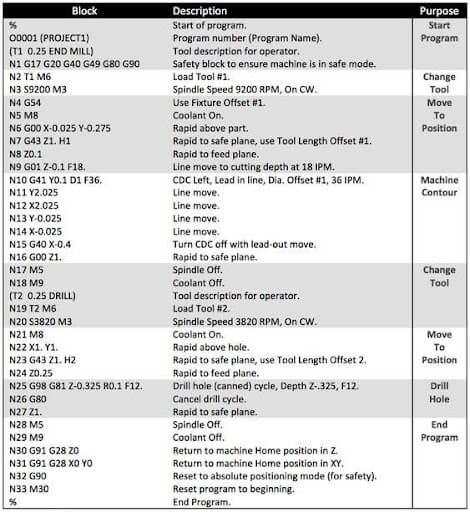

A CNC milling program or programmed Computer-Aided Design (CAD) software is something a CNC machine cannot work without. The purpose, functions, and two constituents of such a program are described above. Read below the more advanced information on how a CNC milling program is practically built.

Writing G-code

It is possible to utilize such programs as Autodesk Fusion 360 or SolidWorks Cam to help in both code creation, but you should know the basics first.

CNC machines have their coordinate system with three axes which are X, Y, and Z. Plane designations for CNC mills are described in the image below.

The planes for the 3 axes (Source: Siemens)

To create G-code, a “G” is followed by a number, which is a command for the machine to change geometry. For instance, the piece of the code looks like this “G00G58X-120.Y-5.” In this example, “G00” means a rapid, non-cutting move. “G58” is the work coordinates. “X-120” is the command to go -120 mm. on the X-axis. “Y-5” is to go -5 mm. on the Y-axis.

G-code is a part of the command structure and is not separated from M-code.

Writing M-code

There is a set of complementary functions that are not directly related to material cutting but are fulfilled by a CNC machine. The M-code used for commanding to execute those functions is built similarly to the M-code.

M-code consists of an “M” and a number. The examples of commands can be “M00” – program stop, “M06” – tool change, “M30” – end of the program (Reset), and others.

You can see an example of command structure, which incorporates both G-coding and M-coding on the image below.

How much does a CNC Milling Machine cost?

The mentioned above points show how versatile CNC milling machines can be. Considering the number of milling centers’ types and the diverse modification opportunities, costs start from $5k for a professional CNC router.

There is no upper limit that can be spent on such centers as multi-axis, multi-spindle mills with automated pallet changers. A median would be approximately $200k.

You can see some examples of costs by type of CNC machines in the image below.

Here is the list of the key factors that affect the cost of the CNC milling machine.

1. The scope of application of the milling machine.

2. The number of axes.

3. The physical dimensions of the machine (size) determine the maximal size of a component shaped.

4. The presence of an automatic pallet changer.

5. Number of revolutions per minute (RPM) supported and the spindle power.

6. The degree of closeness between measurements and the actual values (accuracy).

7. Types and diversity of materials supported by the CNC milling machine. [

8. Type of coolant through spindle (CTS) system and the control system supported.

It is recommended to focus on a particular manufacturer’s necessities while choosing the optimal CNC milling machine.

Final word

CNC milling centers are widespread pieces of machinery useful for creating precise parts of components. They are versatile due to modifications and the sets of cutting tools they are compatible with.

CNC milling is a more advanced, precise, and safe process compared to manual milling. In contrast to CNC lathe, CNC milling centers can work on asymmetrical designs.

The costs of CNC milling centers can vary from $5k to $500k+ depending on the scope of functions they can fulfill. If you need outsourcing CNC machining parts, feel free to contact us.