This article will help you learn the other manufacturing methods vs CNC machining and the future of CNC machining.

The age of precision CNC machining is here and it’s not going away soon.

Machining has been around for over a century, and it is here to stay. It will evolve as society evolves, but the basics of it should always be around.

CNC Machining (Computer Numerical Control) is a process where physical parts are created using a machine tool guided by computer programming. CNC Machining is unique because the machine tool has the intelligence to make decisions for itself without human oversight.

A recent article cites research conducted by Deloitte which found that nearly 90% of manufacturers are experiencing either moderate or severe shortage in staffing for skilled tradesperson such as CNC Machinists. The study concluded that these shortages were caused by the lack of qualified candidates entering these trades.

What is CNC machining?

CNC machining(numerical control machining) is a method of machining parts on NC machine tools, which uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of various parts, small batch, complex shape, high precision and to realize high efficiency and automatic processing.

The controlled action of the machine roughly includes the starting and stopping of the machine, the starting and stopping of the spindle, the change of rotation direction and speed, the direction, speed and mode of the feed motion; Tool selection, length and radius compensation, tool replacement, coolant opening and closing, etc. .

Other machining types

Die casting and 3d printing are the other machining methods verus CNC machining, the process are total different and the available material.

Die casting

Die casting is a metal casting process, which is characterized by the use of mold cavity on the molten metal to apply high pressure. Molds are usually made of stronger alloys, a process somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, cold chamber die casting machine or hot chamber die casting machine is required.

Because of the high cost of casting equipment and molds, die casting is generally used only for mass production. It is relatively easy to make die-cast parts, which generally require only four major steps and have a low incremental cost per item. Die casting is particularly suitable for the production of a large number of small and medium-sized castings, so die casting is the most widely used in a variety of casting processes. Compared with other casting technologies, die casting has a smoother surface and a higher dimensional consistency.

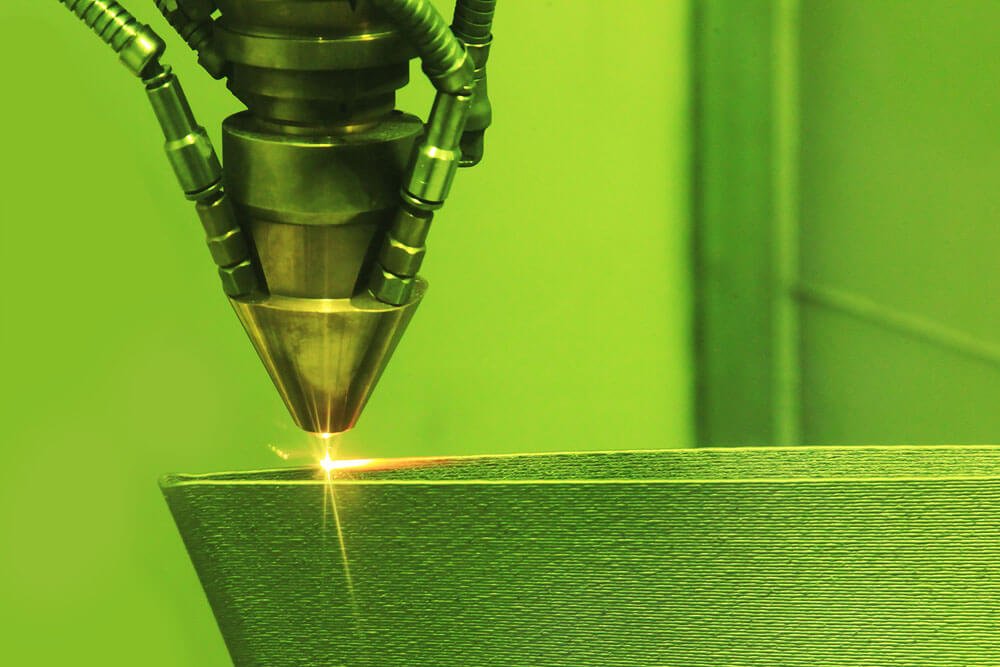

3D printing

3D printing metal is Selective laser sintering technology, which begins with pre design graphics on a computer, before using a 3D printer to melt tiny particles of plastic, metal, or glass with a high powered laser, to make slices in the desired three-dimensional shape. The sintering machine accumulates these slices layer by layer to obtain the required parts. That’s how metal 3d printing works.

Can CNC machining be replaced by another process?

Not. Die casting and 3d printing has some advantage, but they cannot replace cnc machining in some area.

About the dimension tolerance, the CNC machining part is much better than the die casting object. Meanwhile, there has extra process for die casting process, such as removing the burr. So does metal 3d printing.

Why are CNC machinists so difficult to find?

A recent article cites research conducted by Deloitte which found that nearly 90% of manufacturers are experiencing either moderate or severe shortage in staffing for skilled tradesperson such as CNC Machinists. The study concluded that these shortages were caused by the lack of qualified candidates entering these trades.