Table of Contents

Aluminum is one of the most commonly used materials in CNC machining. However, aluminum is much more easily corroded, even in general environments. To enhance the performance and service life of aluminum and its alloys, proper surface finishing treatments are usually necessary.

A Chromate Conversion Coating (commonly known as Alodine, a brand name, or chem film in the industry) is a coating process applied to improve the performance of aluminum and its alloys, during which a chromate conversion coating forms on the aluminum surface.

The top 4 functions of Chromate Conversion Coating are corrosion resistance, adhesion, conductivity, and dimensional accuracy.

To produce better aluminum parts, it is essential to understand this process thoroughly. This article will provide a detailed guide of Chromate Conversion Coating, including its definition, classification, and best practices.

Key Takeaways:

- Chromate Conversion Coating, Alodine, and Chem Film all refer to the same treatment used to protect aluminum surfaces without affecting dimensions.

- There are two main types of Chromate Conversion Coating : Type I (hexavalent, strongest protection) and Type II (trivalent, environmentally friendly and RoHS-compliant).

- The coating also includes two performance classes: Class 1A for maximum corrosion resistance and Class 3 for better electrical conductivity.

- Different industries choose different combinations of type and class, with Type I/Class 1A used in harsh environments and Type II/Class 3 preferred for electronics and modern, eco-compliant applications.

1. What is Chromate Conversion Coating?

A Chromate Conversion Coating (often referred to by its industry common name *chem film*, or the brand name Alodine®) is a chemical process used for aluminum and its alloys.

It is commonly applied in the aerospace, electronics, automotive, and military industries to enhance the corrosion resistance of aluminum surfaces and improve the adhesion of paint or coatings.

What’s more, the aluminum’s electrical conductivity can be preserved, and the part’s dimension can also be maintained after this process.

As a chem film coating process applied to metal surfaces, particularly aluminum and its alloys, it can form a passive layer at the surface through a chemical reaction.

However, the chromate conversion coating process differs from the plating process, in which a new coating is added to the metal surface.

Instead, the formation of the coating is due to the transformation of an extremely thin existing metal layer through a chemical reaction. That’s why the chem film is called a conversion coating.

The coating would chemically bond with the surface to provide proper corrosion resistance. It is chemically stable and passive, resisting the surface from reacting with corrosive media.

Meanwhile, because the coating is extremely thin and formed in situ, it does not alter the part’s initial dimensions.

And since the chromate conversion coating has a microporous structure, which is beneficial for improvement of adhesion, this finishing process is widely used for aluminum parts that must remain bondable, weldable, or paint-ready.

According to MIL-DTL-5541, chromate conversion coatings are mainly classified into two types. The Type I is a hexavalent chromium system, while the Type II is a trivalent chromium system.

The former one is a traditional formulation that is toxic and not environmentally friendly. The latter one is an eco-friendly substitute formulation that complies with RoHS and REACH regulations.

The working principle of Chromate Conversion Coating is certainly simple. When an aluminum part is immersed in a chromate conversion solution, the aluminum is slightly corroded in the acidic environment, releasing Al³⁺ ions.

As the aluminum is dissolved, the pH value near the surface would increase. This will promote the reduction of chromate (CrO₄²⁻) or dichromate (Cr₂O₇²⁻) ions in the solution to trivalent chromium (Cr³⁺).

Then the trivalent chromium would precipitate together with Al³⁺. Finally, they will combine with water or hydroxide ions to form an amorphous and hydrated composite film.

The film is mainly composed of hydrated aluminum oxide and hydrated trivalent chromium oxide, with a small amount of unreacted hexavalent chromium.

2. Types of Chromate Conversion Coating

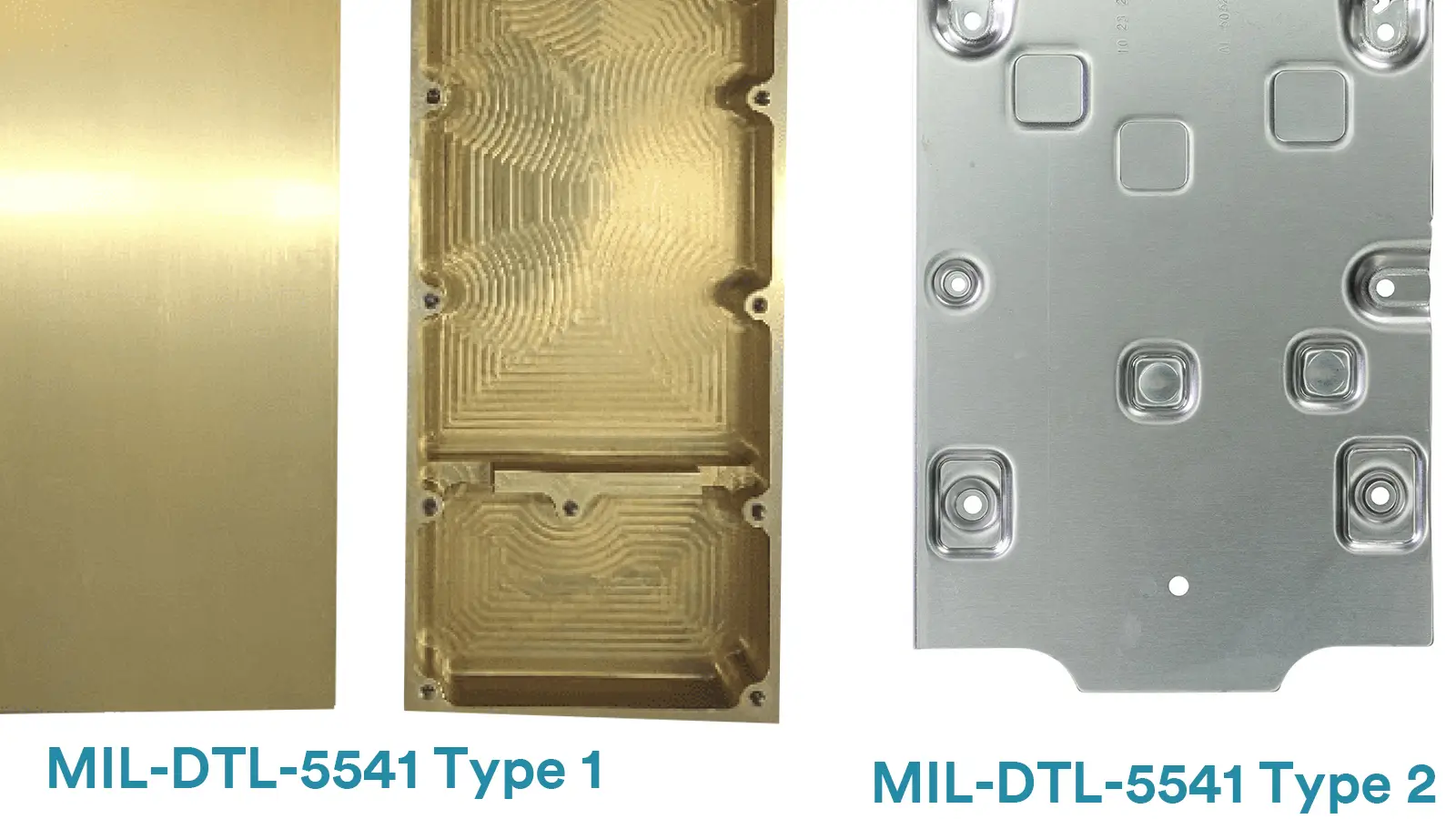

Depending on the main chromium composition of the chromate conversion solution, chromate conversion coating is typically classified into hexavalent chromium chem film and trivalent chromium chem film, which is also respectively known as MIL-DTL-5541 Type 1 and MIL-DTL-5541 Type 2.

The MIL-DTL-5541 specification, fully named as Chemical Conversion Coatings on Aluminum and Aluminum Alloys, is the most popularly used standard for chromate conversion coating technique.

2.1. MIL-DTL-5541 Type 1

- Definition of MIL-DTL-5541 Type 1:

MIL-DTL-5541 Type 1 is produced by solutions containing hexavalent chromium as the key composition.

The chromate conversion bath is commonly composed of chromic acid or sodium dichromate.

The acidic components in the solution would slightly dissolve the aluminum alloy surface, exposing fresh aluminum substrate.

Under acidic conditions, the aluminum substrate is oxidized, while the hexavalent chromium ions in the solution are reduced to trivalent chromium ions.

As the reaction proceeds and the local pH rises, the newly formed trivalent chromium ions combine with water and precipitate onto the aluminum surface, creating a gel-like, water-insoluble compound layer.

Pay attention to the fact that the final chromate conversion coating is mainly composed of trivalent chromium oxides, with a small amount of unreacted hexavalent chromium compounds within the layer.

The MIL-DTL-5541 Type 1 chromate conversion coating typically appears yellow-green to golden.

- Advantages of MIL-DTL-5541 Type 1:

MIL-DTL-5541 Type 1 chromate conversion coating typically exhibits better corrosion resistance than MIL-DTL-5541 Type 2 coating due to its self-healing ability.

The Type 1 coating can perform significantly better in harsh conditions, such as high salt spray, high humidity, or severe mechanical stress. When the coating is slightly damaged, scratched, or corroded, the hexavalent chromium within the coating can migrate to the damaged area and re-passivate the exposed aluminum.

- Disadvantages of MIL-DTL-5541 Type 1:

Severe Toxicity:

MIL-DTL-5541 Type 1 chromate conversion coating is commonly restricted by its damage to health and the environment. Hexavalent chromium is classified as a toxic and hazardous substance, and its use is strictly regulated under directives such as RoHS and REACH.

High Cost:

The process of Type 1 coating is significantly more complex than that of Type 2 coating, resulting in higher equipment costs and longer processing times. Additionally, its cost of waste treatment is significantly higher.

Applications:

Due to environmental concerns and regulatory restrictions, the Type I coating is being increasingly replaced by Type II in many industries and regions.However, Type I is still required in certain military and aerospace applications because of its superior performance and proven reliability.

2.2. MIL-DTL-5541 Type 2

- Definition of MIL-DTL-5541 Type 2:

MIL-DTL-5541 Type 2 is known as a hex-free chromate conversion coating. The main composition of its bath is typically trivalent chromium. And as the technique develops for more environmental friendliness, free-chromium systems such as titanium or zirconium systems have appeared and been applied.

The main compositions of Type 2 coating are similar to those of Type 1 coating, both of which are based on trivalent chromium compounds, such as hydrated chromium oxide and hydrated chromium hydroxide.

However, there is no hexavalent chromium within the Type 2 coating.

The Type 2 bath composition include trivalent chromium salts, fluoride ions, and other additives such as zirconium or titanium salts.

When the aluminum part is immersed in the bath, the fluoride would slightly dissolve the aluminum, thus activating the surface. Then, the locally increased pH on the activated aluminum surface promotes the precipitation and polymerization of trivalent chromium ions and other additives onto the aluminum surface.

Finally, a dense and gel-like chromate conversion coating is formed on the surface, composed of hydrated trivalent chromium oxides and hydroxides.

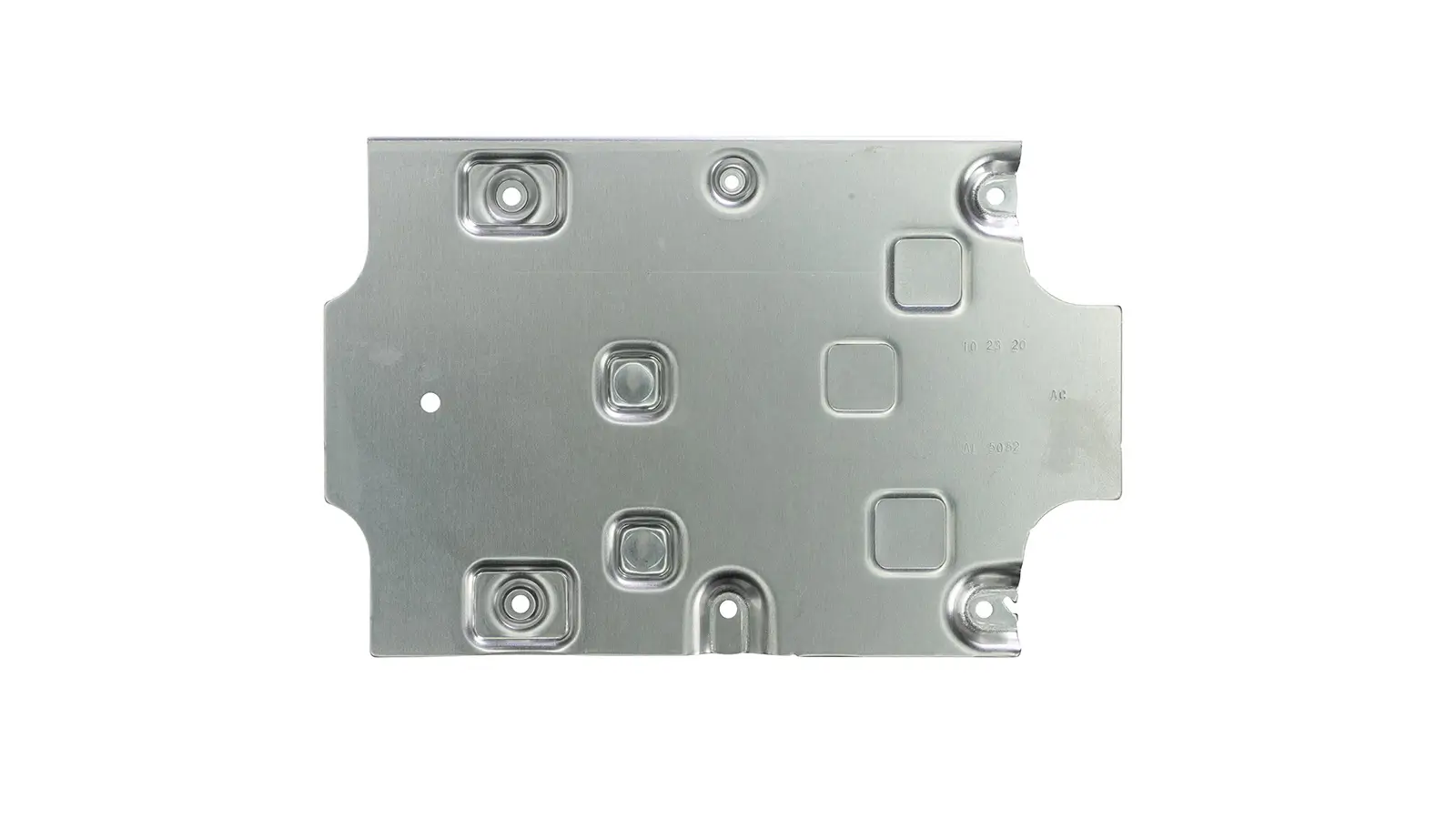

MIL-DTL-5541 Type 2 coating typically appears colorless, light blue, or pale gray.

- Advantages of MIL-DTL-5541 Type 2:

Eco-friendliness:

The entire MIL-DTL-5541 Type 2 coating process contains no hexavalent chromium, ensuring compliance with RoHS, REACH, and similar regulations. Although trivalent chromium is still considered toxic, it is not listed, and its impact on body health and the environment is limited.

Lower Cost:

Most Type 2 coating processes can be performed at room temperature without the need for heating. Compared to the Type 1 process, the Type 2 process is simpler, faster, and more energy-efficient. Additionally, its cost for waste treatment is much lower.

- Disadvantages of MIL-DTL-5541 Type 2:

The primary weakness of Type 2 coating compared with Type 1 lies in its inferior corrosion resistance in harsh conditions. Although its corrosion resistance is also good, it can not endure severe conditions due to a lack of self-healing ability.

Once the coating is damaged, scratched, or corroded, the corrosion would further develop until it is slowed by the barrier effect of the surrounding coating edges.

However, with the development of techniques, Type 2 coating with excellent performance is steadily closing this gap.

- Applications of MIL-DTL-5541 Type 2:

Unlike Type 1 coating, Type 2 coating is more commonly applied to various industries, including civil aviation, consumer electronics, automotive, and export products.

Since it complies with RoHS and REACH restrictions, more fields allow the application of Type 2 coating.

MIL-DTL-5541 Type I vs Type II — Comparison Table

| Category | MIL-DTL-5541 Type I | MIL-DTL-5541 Type II |

|---|---|---|

| Main Chemical Composition | Contains hexavalent chromium (chromic acid, sodium dichromate). | Hex-free; based on trivalent chromium, fluoride ions, zirconium or titanium additives. |

| Chemical Reaction Mechanism | Acid dissolves aluminum surface → aluminum oxidizes → hexavalent chromium is reduced to trivalent chromium → forms gel-like chromate coating with small hex-chrome residues. | Fluoride activates aluminum → pH rise triggers trivalent chromium deposition → forms dense, gel-like hydrated chromium oxide/hydroxide coating. |

| Final Coating Composition | Mainly trivalent chromium oxides + trace unreacted hexavalent chromium. | Hydrated trivalent chromium oxides and hydroxides + zirconium/titanium compounds. |

| Appearance | Yellow-green to golden color. | Colorless, light blue, or pale gray. |

| Corrosion Resistance | Stronger corrosion resistance; features **self-healing** due to hexavalent chromium. | Good but lacks self-healing; less durable in harsh environments. |

| Environmental Impact | Poor; contains toxic hexavalent chromium. Strictly regulated (RoHS, REACH). | Environmentally friendly; hex-free and compliant with RoHS and REACH. |

| Process Difficulty & Cost | More complex; often requires heating; higher equipment and waste treatment cost. | Simpler process; often room temperature; lower energy use and waste treatment cost. |

| Performance in Harsh Environments | Highly suitable for salt spray, humidity, and mechanical stress. | Moderate; improvements are narrowing the gap with Type I. |

| Typical Applications | Military, aerospace, and defense sectors requiring maximum corrosion resistance. | Civil aviation, electronics, automotive, export products, consumer industries. |

| Regulatory Compliance | Heavily restricted; banned in many industries. | Widely accepted due to compliance with environmental regulations. |

3. Classes of Chromate Conversion Coating

Based on the primary application of chromate conversion coating, MIL-DTL-5541 classifies the coatings into Class 1A and Class 3.

The MIL-DTL-5541 Class 1A chromate conversion coating is primarily used to provide maximum corrosion resistance, whereas the MIL-DTL-5541 Class 3 coating is applied to achieve low electrical resistance with general corrosion resistance.

3.1. MIL-DTL-5541 Class 1A

- Features of MIL-DTL-5541 Class 1A

Maximum Corrosion Resistance:

MIL-DTL-5541 Class 1A coating is primarily applied to provide excellent corrosion resistance. Class 1A coating is widely used as the top protective layer in harsh conditions.

Thicker Coating:

To provide sufficient corrosion resistance for the aluminum part, the Class 1A coating is relatively thick, typically ≥ 0.4 g/ft².

Appearance:

The color of MIL-DTL-5541 Type 1 Class 1A coating is typically gold or yellow-brown, while that of Type 2 Class 1A is typically clear to light iridescent.

Poor Conductivity:

The electrical resistance of Class 1A coating is typically high due to its thick coating, resulting in extremely poor or nonexistent electrical conductivity.

Excellent Adhesion:

The adhesion of Class 1A coating is better than that of Class 3 coating. The thick chem film typically has a rougher surface, thus with better adhesion. It usually serves as an ideal primer for paints, powder coatings, or adhesives.

Better Wear Resistance:

Benefiting from its thicker coating, Class 1A is more resistant to abrasion.

- Applications of MIL-DTL-5541 Class 1A:

MIL-DTL-5541 Class 1A chromate conversion coating is particularly used in conditions requiring exceptional corrosion resistance or excellent adhesion for follow-up painting.

It is also widely applied to structural components where electrical contact is not required. The typical applications of Class 1A include aircraft structural components, military equipment, outdoor parts, and large assemblies requiring painting.

3.2. MIL-DTL-5541 Class 3

- Features of MIL-DTL-5541 Class 3

Minimum Electrical Resistance: MIL-DTL-5541Class 3 coating is primarily applied to provide excellent electrical conductivity as much as possible.

Good Corrosion Resistance:

Apart from excellent conductivity, Class 3 coating is used to provide good corrosion resistance. But it is less resistant to corrosion than Class 1A coating.

Thinner Coating:

To preserve electrical conductivity as much as possible, the Class 3 coating is typically thinner, measuring ≤ 0.1 g/ft². Its impact on dimension and tolerance is extremely small.

Appearance:

Whether it is Type I or Type II, their Class 3 coating is colorless, transparent, or a very light shade.

Good Adhesion:

Class 3 coating can also be applied as the bottom coating; however, its adhesion is inferior to that of Class 1A coating. Its primary focus is on maintaining electrical conductivity.

Poor Wear Resistance:

Since the coating is thin enough to maintain conductivity, its wear resistance is inferior to that of Class 1A coating, which is designed to endure severe mechanical abrasion.

- Applications of MIL-DTL-5541 Class 3:

The primary function of Class 3 coating is to provide a certain level of corrosion protection while maintaining electrical continuity on the metal surface.

It is particularly applied in conditions requiring electromagnetic interference shielding or grounding contact.

Its typical applications include electronic enclosures, connectors, and grounding components for military or aerospace.

Note: MIL-DTL-5541 Type 1 and MIL-DTL-5541 Type 2 are classified by the type of chromium, while the main function of coatings classifies MIL-DTL-5541 Class 1A and MIL-DTL-5541 Class 3. They are not overlapping. MIL-DTL-5541 Type 1 Class 1A can provide the maximum corrosion resistance.

MIL-DTL-5541 Class 1A and MIL-DTL-5541 Class 3 Comparision Table

| Characteristics | Class 1A (Corrosion Resistant) | Class 3 (Electrical Conductive) |

|---|---|---|

| Primary Function | Provides maximum corrosion resistance, serves as primer for paint | Provides low contact resistance and electrical continuity with basic protection |

| Coating Weight | ≥ 0.4 g/ft² (approx. 40 mg/dm²) | ≤ 0.1 g/ft² (approx. 10 mg/dm²) |

| Appearance | Type I: Golden/brown Type II: Variable (can be clear, blue, iridescent) | Type I & Type II: Both colorless, transparent, or very light shade |

| Electrical Conductivity | Non-conductive (high resistance) | Conductive (low resistance) |

| Adhesion | Excellent, ideal primer for paint | Adequate, but inferior to Class 1A |

4. What is the Process of Chromate Conversion Coating?

Due to the different bath and coating compositions, the process of MIL-DTL-5541 Type 1 typically differs from that of MIL-DTL-5541 Type 2. The processing steps of Type 1 are more complex than those of Type 2 chromate conversion coating. And the process of Type 2 is more flexible.

4.1. MIL-DTL-5541 Type 1 Process

- Cleaning:

Cleaning is a critical step to ensure coating uniformity. The aluminum part should be generally cleaned in an alkaline cleaning solution to remove dirt, oil, and any residue formed from prior manufacturing processes.

- Rising and Drying:

Rinse the part after the cleaning step to remove all alkaline detergents from the surface. A water-break-free test is usually performed on the surface to ensure complete rise. Then, dry the part completely to prevent water spots.

- Etching:

It is an optional step. If there is any area that should be prevented from the chem film, the etching process can cover the areas to maintain their initial

- Rising and Drying:

Rinse the part totally to clean all etching chemistry off and then dry it completely with hot air.

- Deoxygenating:

Then apply deoxidation to the part to remove any excess materials, oxides, contaminants, and chemicals.

- Rinsing and Drying:

Carefully rinse the part to remove any deoxidation solution and dry it completely.

- Chromate Conversion Coating:

Apply hexavalentchromium solution for chromate conversion coating on the surface by immersing, brushing, or spraying at room temperature. The chemical reaction would work immediately, and chem film would form.

The period of reacting time is based on the application method, as well as the composition and size of the part.

- Final Rising and Drying:

After chromate conversion coating, rinse the part again and dry it thoroughly.

4.2. MIL-DTL-5541 Type 2 Process

Compared to MIL-DTL-5541 Type 1, the process of MIL-DTL-5541 Type 2 is simpler and more flexible, classified into acid-clean and alkaline-clean methods.

- Acid Clean Method

Acid Cleaning:

Immerse the part in an acid cleaning solution to thoroughly clean the surface of any oil, grease, oxidation, and other contaminants.

Rising and Drying:

Totally rinse the residual acid solution off and dry the part with hot air.

Chromate Conversion Coating:

Apply trivalent chromium solution to the aluminum part for trivalent chromate conversion coating.

Rinsing and Drying:

Completely rinse any residue from the part and dry it totally to prevent water spots.

Second Rinsing (Optional):

For TCP-HF Type 2 coating, a second rinsing is needed to be performed on the part by a specific chemical bath or high-quality deionized water, to further enhance and solidify the coating’s performance.

- Alkaline Clean Method

Alkaline Cleaning:

Immerse the component in an alkaline cleaning solution to remove any oil, grease, and other contaminants from the surface.

Rinsing and Drying:

Thoroughly rinse any residual alkaline solution form the part and dry it with hot air.

Deoxygenating:

Deoxygenate the part carefully to remove any remaining oxidation and contaminants.

Rising and Drying:

Rinse all deoxygenating solution off from the part and completely dry it.

Chromate Conversion Coating:

Uniformly apply trivalent chromium solution on the surface to form chromate conversion coating.

Rinsing and Drying:

Rinse and dry the part completely.

Second Rising (Optional):

For TCP-HF Type 2 coating, a second rise is required for stable and improved performance.

Note: Deoxidation is a critical step that must be applied before chromate conversion coating. The acid clean step inherently covers the deoxidizing function. However, it requires the additional application of deoxidation during the alkaline cleaning process before the coating step.

5. What Are the Main Methods for Applying Chromate Conversion Coatings?

The main application methods of Alodine chromate conversion coating include immersion, spraying, and brushing techniques. It is essential to select the correct one based on the size, geometry, and production requirements of the parts.

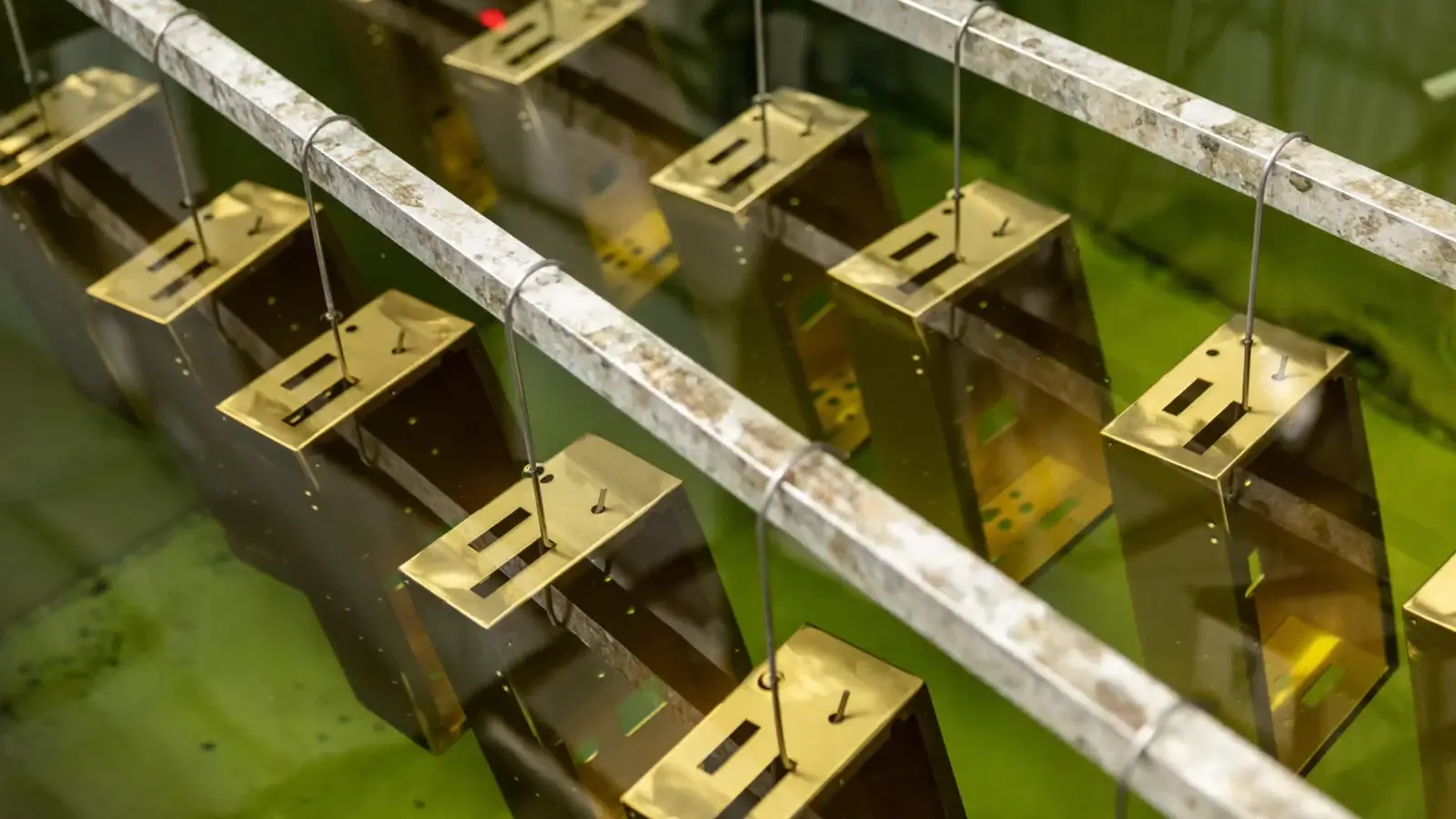

5.1. Immersion Method for Chromate Conversion Coating

Immerse the entire part fully in the bath tank containing chromate salts, where the solution reacts chemically with the metal surface to form a conversion coating.

- Advantages of the Immersion Method

Good Uniformity:

The solution can contact the entire surface of the part mass-producing, including complex internal geometries and holes, resulting in a uniform coating.

High Efficiency:

The immersion method is a simple and efficient process, making it suitable for mass-producing small and complex parts.

Simple Operation:

Once the process parameters such as time, temperature and pH are determined, the operation is relatively easy to control.

- Disadvantages of the Immersion Method

Requiring a large tank and more chemical solution.

Unsuitable for excessively large parts.

Applications: Electronic components, fasteners, small aerospace parts, etc.

5.2. Spraying Method for Chromate Conversion Coating

Use a spray gun or automated spray system to spray the chromate solution onto the part’s surface.

- Advantages of the Spraying Method

It is easy to integrate into continuous production lines, enabling automated operation.

It is suitable for large components, flat parts, or that cannot be immersed in a common tank.

Compared to the immersion method, it would use the solution more economically.

- Disadvantages of the Spraying Method

The uniformity of the coating may be affected by factors such as the nozzle, pressure, and the complexity of thepart.

The solution consumption and recovery system is more complex compared to the immersion method.

- Applications of the Spraying Method

It is widely applied to automotive body panels, large structural components, androlled aluminum. In addition, its applying conditions are commonly on-site repairs or in-situ treatments. And note to remain the part wet for a period of time after spraying to ensure complete film formation.

5.3. Brushing Method for Chromate Conversion Coating

Manually apply the chromate solution to the part’s surface with a brush, cloth, or sponge.

- Advantages of the Brushing Method

It is specifically used for repairing local defects within previously coated surfaces caused by machining or damage.

It does not require complex tanks or spraying equipment.

- Disadvantages of the Brushing Method

The coating thickness and quality are the least stable, relying on the skill of operators.

With low efficiency, it is only suitable for small quantities and small parts, or repair work.

- Applications of the Brushing Method

It is suitable for on-site repairs of aircraft skins, large ship components, and protection of specific areas.

6. What are the Pros and Cons of Chromate Conversion Coating?

6.1. Advantages of Chromate Conversion Coating

- Excellent Corrosion Resistance:

With excellent chemical stability and passivation, the coating forms an ultra-thin layer that maintains the aluminum part’s electrical conductivity and dimensional accuracy, making it suitable for precision applications.

MIL-DTL-5541 Type 1 Class 1A coating has particularly maximum corrosion resistance, even in severely harsh conditions.

- Preserving Conductivity:

The chromate conversion coating is usually so thin that it would not interfere with the coating itself, which is also conductive to the ng itself, which is certainly conductive too.

Compared to anodizing protective coating for aluminum, it is suitable for components that require grounding or EMI shielding. However, if the coating is significantly thicker, the electrical resistance would increase.

- Excellent Adhesion:

Benefiting from the microporous structure of the coated surface, the coating provides excellent adhesion for subsequent coatings, such as paints and adhesives. It is commonly used as a pretreatment before painting or bonding.

- Preserving Dimension:

Since the coating is extremely thin, it has little impact on the part’s dimensions. Therefore, it is suitable for precision parts with strict requirements on dimensional tolerance.

- Simple Process:

The chromate conversion coating process does not need complex equipment and a long time. Furthermore, it can typically be performed at room temperature with low power consumption and high efficiency, making it suitable for mass production processing.

- Flexible Coating Methods:

It can be applied to the surface in various ways, including immersion, brushing, and spraying. It can suit components of various sizes and batches.

6.2. Disadvantages of Chromate Conversion Coating

- Worse Wear Resistance:

Compared with anodizing coating, chromate conversion coating is thinner and softer, making it less resistant to abrasion and other mechanical damage.

- Environmental Concerns:

Since the hexavalent chromium within MIL-DTL-5541 Type 1 coating is toxic and harmful to the human body and the environment, it is strictly regulated in many regions by rigorous safety procedures and waste treatment protocols.

- Limited Corrosion Resistance:

Although MIL-DTL-5541Type 2 is the eco-friendlier substitute coating, its corrosion resistance and long-term stability is still certainly worse than the traditional hexavalent chromium coating.

- Limited Appearance:

The color of the chromate conversion coating is typically gold, brown, or transparent, offering fewer options compared to anodizing, which can be dyed in a wide range of colors.

- Sensitive to Substrate:

Chromate conversion coating is particularly used for aluminum and its alloys, but is unsuitable for many other metal substrates.

Additionally, even for different aluminum alloys, the chemical reaction would also differ much further, might leading to uniform coatings or inconsistent performance on corrosion resistance.

7. What are the Main Applications of Chromate Conversion Coating?

Chromate conversion coating (chem film) is popularly used in industrial fields that require both corrosion resistance and electrical conductivity, such as aerospace, defense, and electronics manufacturing.

What’s more, since the chem film does not obviously change the part’s dimension, it is ideal for precision parts with tight dimensional tolerances.

Therefore, it is an economical and efficient choice for aluminum protection while ensuring compliance with industry standards.

- Aerospace:

The aircraft parts would always be easily corroded due to the high-speed travel at extremely high-altitude atmosphere, even passing through clouds can lead to certain corrosion.

Therefore, maximum protection is necessary for those aircraft parts.

And for those aircraft parts, aluminum is one of the most crucial. Chromate conversion coating is an effective method to protect aluminum aerospace parts from corrosion.

- Maritime/Naval:

Watercraft should be as resistant to corrosion as possible, since water, both fresh and salty, is corrosive to boat interiors and mechanical components.

Boat travel in saltwater would be more severely affected by corrosion.

A conversion coating that passes salt-spray testing can provide those parts with excellent corrosion resistance. In addition, with good adhesion, chromate coating can serve as a paint primer for custom colors on watercraft.

- Military and Defense:

With excellent performance in terms of corrosion resistance, adhesion, and electrical conductivity, Chromate Conversion Coating is widely used in the military and defense fields in various applications.

The U.S. Department of Defense has even established a standard, MIL-DTL-5541, for the finishing method, providing detailed specifications.

- Electrical Industry:

It can provide the desired corrosion protection for wiring housings and many other electrical parts, helping to prolong the service life of these components. Alodine coating

Meanwhile, the coating can effectively preserve the part’s electrical conductivity.

8. What are the Common Tests for Chromate Conversion Coating?

As a critical surface finishing, the coating must pass strict testing for performance including corrosion resistance, adhesion, and electrical conductivity.

- Neutral Salt Spray Test(NSS):

Place the part coated with the conversion film in a specificsalt spray test chamber, continuously exposed to mist of 5% sodium chloride (NaCl) solution, at 35°C temperature.

And then record the period of time for the appearance of white corrosion and red corrosion. According to the standard classifications of MIL-DTL-5541, there are specific time limits for the appearance of white rust and red rust.

- Adhesion Test:

Cross-Hatch Test is typically used to inspect the chem film’s adhesion. It needs to cut a grid or “X”pattern onto the final painted surface, and then apply a standard adhesive tape to the cut area, followed by quick peeling.

The percentage of peeled-off coating reflects the chem film’s adhesion. If the adhesion of the coating is good, the cut edges should remain intact without any damage.

- Conductivity Test:

Use an ohmmeter or specialized instrument to measure the electrical resistance of the coating. The surface resistance must not exceed the specified threshold, as outlined in standard regulations.

9. How to Correctly Specify Chromate Conversion Coating on CNC drawings?

Previously, we introduced the Types of Chromate Conversion Coating and the Classes of Chromate Conversion Coating.

Type defines the “chemical family” of the coating. Class defines the “performance and application objective” of the coating.

A complete product description compliant with the MIL-DTL-5541 standard must include both the Type and Class identifiers.

| Class 1A (Corrosion Resistant/Non-conductive) | Class 3 (Electrically Conductive) | |

|---|---|---|

| Type I (Contains Hexavalent Chromium) | Type I, Class 1A Example: Golden color, maximum corrosion resistance, used for critical structural components | Type I, Class 3 Example: Colorless, conductive, used for electrical connections |

| Type II (Hexavalent Chromium-Free) | Type II, Class 1A Example: Blue/iridescent, environmentally friendly high-corrosion resistance coating | Type II, Class 3 Example: Colorless, environmentally friendly conductive coating |

Type I, Class 1A:

This is the highest-performing combination, providing the maximum corrosion protection and self-healing capability.

It is commonly used in military applications where extreme performance is required and environmental regulations do not restrict its use.

Type I, Class 3:

This combination utilizes mature hexavalent chromium technology, while also offering electrical conductivity, making it suitable for applications such as electromagnetic shielding.

Type II, Class 1A:

This is currently the most common combination for civilian and many export products. It offers excellent corrosion resistance while meeting environmental requirements and can serve as a primer for paint.

Type II, Class 3:

This combination is used in applications where electrical conductivity is required and compliance with environmental regulations (such as RoHS) is mandatory. Examples include enclosures or connectors for consumer electronics.

Correctly indicating Chromate Conversion Coating treatment on CNC drawings is crucial for ensuring the part’s final performance.

Do not simply write “Alodine” (which is a trade name) on the drawing. Instead, use standardized callouts and reference the appropriate military or industry standards.

The most common and clearest method is to provide a general note in the title block or technical requirements section.

For example:

FINISH:

PER MIL-DTL-5541, TYPE II, CLASS 3

Summary:

Chromate conversion coating (also called chem film or Alodine) is a thin chemical passivation applied to aluminum and its alloys to improve corrosion resistance, paint adhesion, and electrical performance without changing part dimensions.

This guide explains Type I (hexavalent) vs. Type II (trivalent), Class 1A vs. Class 3 performance, common application methods (immersion, spray, brush), typical tests (NSS, adhesion, conductivity), and how to correctly specify the finish on CNC drawings per MIL-DTL-5541.

10. FAQs

10.1. What are the Differences between Alodine, Chem Film, and Chromate Conversion Coating?

Chromate conversion coating is a general term referring to all protective coatings formed by the reaction of chromate solutions with metals. It is the correct technical and scientific term for the process and the coating itself.

Chem Film: This is a common industry slang or abbreviation derived from its full name, Chemical Conversion Coating. It specifically refers to the layer formed through a chemical (rather than electrochemical) process.

In daily communication on the factory floor or among engineers, using “Chem Film” is very common and efficient.

However, in formal drawings, technical specifications, or external documents, using “Chromate Conversion Coating” is more rigorous and accurate. When you hear or see “Chem Film,” you can directly equate it to “Chromate Conversion Coating”.

Alodine is a brand name for a popular line of chromate conversion coating products.

10.2. How does Chromate Conversion Coating Differ from Anodizing?

Chromate Conversion Coating is a chemical passivation process commonly used to provide corrosion resistance, adhesion, and electrical conductivity to aluminum parts.

While anodizing is an electrochemical process that primarily provides better wear resistance and various decorative effects on the coating color.

More information: Anodizing vs Alodine: Key Differences and Processes

10.3. How Long Does Chromate Conversion Coating Last?

Under normal conditions, a chromate conversion coating can typically last 5 to 10 years. If the part is exposed to abrasion or harsh outdoor environments, it is better to apply an additional topcoat to the conversion coating.

10.4. How Do I Choose Between Type I and Type II Chromate Conversion Coating?

The choice depends on your performance requirements and environmental compliance needs.

Choose Type I (Hexavalent Chromium/Hex-Chrome):

When: You need maximum corrosion resistance and “self-healing” properties for extreme environments.

Applications: Primarily for military (MIL-SPEC) and aerospace applications where performance is critical and regulations like RoHS may not apply.

Note: Its use is restricted in many commercial industries due to the toxicity of hexavalent chromium.

Choose Type II (Trivalent Chromium/Hex-Free):

When: Your product must comply with environmental regulations like RoHS and REACH.

Applications: The standard choice for consumer electronics, automotive, medical devices, and export products. It offers excellent corrosion resistance and is more cost-effective and environmentally friendly.

For most modern applications, Type II is the recommended and industry-standard choice.

10.5. Does the coating change the dimensions or conductivity of my part?

No, and this is a key advantage.

Dimensional Stability: The coating is extremely thin (typically 0.00001 to 0.00004 inches), forming within the existing surface layer. It will not noticeably alter part dimensions, making it perfect for precision CNC machined parts with tight tolerances.

Electrical Conductivity: The coating itself is conductive. This makes it ideal for applications where electrical continuity is required, unlike anodizing, which is an insulator.

10.6. What are the Common Application Methods?

The method depends on your part’s size, geometry, and production volume:

Immersion Dip: Best for small, complex parts and high volumes. Provides complete, uniform coverage.

Spraying: Ideal for large parts or automated production lines. More solution-efficient.

Brushing: Used for touch-up and repair of localized areas on already-coated or large assembled structures.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.