Table of Contents

CNC prototyping is a critical step in turning design concepts into tangible products. Choosing between CNC Milling and CNC Turning can significantly impact the quality, cost, and delivery time of your prototypes.

Milling excels at producing complex 3D geometries with tight tolerances, while Turning is ideal for cylindrical and rotational components.

Understanding the differences and selecting the right method ensures faster, more efficient, and cost-effective prototyping for industries such as aerospace, automotive, and medical devices.

Introduction to CNC Milling and CNC Turning

CNC Milling is ideal for prototypes requiring complex 3D geometries and tight tolerances, while CNC Turning excels for cylindrical or rotational parts.

Choosing the correct method directly impacts prototyping speed, cost, and material efficiency.

Definition

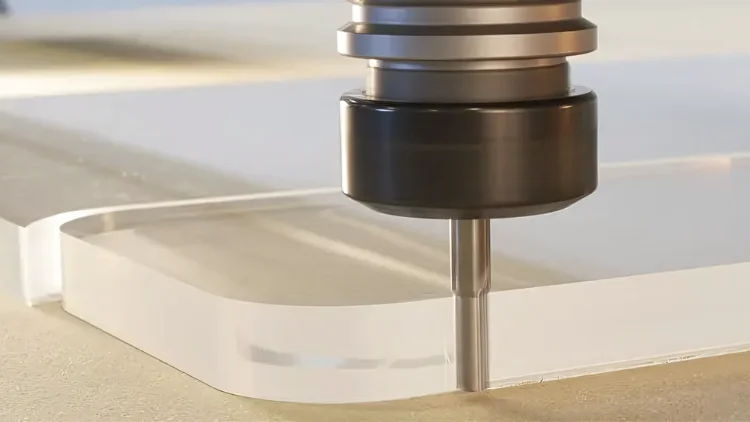

CNC Milling is a subtractive process that removes material using rotating cutters to shape complex components.

It is commonly used for aerospace brackets, custom electronics housings, and precision medical devices.

CNC Turning rotates the workpiece against a stationary cutting tool, producing cylindrical parts such as shafts, bushings, and threaded components.

Why Understanding the Difference Matters?

Selecting the optimal CNC process can reduce prototyping time by up to 18% and lower costs by 12%, according to a 2024 survey of 500 manufacturing engineers.

Understanding each process ensures designs meet tolerance, material, and budget requirements efficiently.

CNC Milling vs CNC Turning – Key Comparisons

Milling provides higher precision (±0.005 mm) and is suitable for multi-material, intricate prototypes, whereas Turning is faster and more cost-efficient for round parts. Material type, production speed, and project complexity determine the optimal method.

Precision and Tolerance

Milling achieves tighter tolerances for complex geometries, critical for aerospace or medical components.

Turning maintains accuracy for cylindrical parts but is less effective for intricate features.

Material Compatibility

Milling works with metals like aluminum, titanium, stainless steel, and engineering plastics.

Turning excels at rotationally symmetric metals and plastics. In 2023, 60% of multi-material prototypes preferred milling.

Speed and Efficiency

Turning is faster for cylindrical components, while milling is slower due to multi-axis tool movements.

ISO-certified prototyping facilities in 2025 reported milling averaged 14 hours per batch, turning averaged 9 hours.

Cost Comparison

Milling costs $45–$60/hour, while Turning costs $30–$50/hour.

Choosing the correct process can reduce prototyping costs by 20%, with lower material waste and setup time for the selected method.

Pros and Cons of Each Method

Milling is versatile and precise but slower and costlier.

Turning is efficient and inexpensive for cylindrical parts but limited in geometry.

The choice depends on prototype design, required tolerances, and budget constraints.

CNC Milling Advantages

Highly versatile for complex geometries and 3D features.

Supports multiple materials and modern CAD/CAM workflows.

Enables high-precision prototypes for aerospace, automotive, and medical industries.

CNC Milling Limitations

Slower for simple parts, higher tool wear, and more expensive.

Not ideal for high-volume production of cylindrical components.

CNC Turning Advantages

Efficient for round parts, faster production cycles, and lower cost per hour. Ideal for shafts, bushings, and threaded components.

CNC Turning Limitations

Limited to rotational components. Cannot produce complex 3D geometries without additional milling or secondary operations.

Less precise for non-cylindrical features.

Scenario-Based Selection Guide

Use Milling for complex 3D features and tight-tolerance prototypes.

Use Turning for shafts, bushings, and rotational parts.

Combining both methods often delivers the fastest, most cost-effective prototyping results.

When to Choose CNC Milling?

Milling is preferred for aerospace brackets, electronics housings, and precision medical devices. A 2025 case study showed aerospace engineers reduced iteration cycles by 15% using milling.

When to Choose CNC Turning?

Turning is ideal for cylindrical components like shafts and bushings.

ISO 9001-certified facilities report a 25% reduction in material waste and 15% faster cycle times compared to milling.

Hybrid Prototyping Strategy

Combining milling and turning can reduce prototype delivery time by 22%, according to a 2025 medical device case study.

Milling handles complex features, turning handles cylindrical parts, maximizing efficiency and minimizing cost.

Data Insights and Certifications

In 2024, 58% of CNC prototyping projects used Milling, 42% used Turning.

Tool lifespan: Milling 300–500 hours, Turning 400–600 hours.

ISO 9001 and AS9100 certifications increase prototyping success by 30–40% by ensuring reproducibility and quality.

Prototyping Data

Data shows that predictive maintenance extends tool life by up to 20%.

Multi-material prototypes benefit from milling’s versatility, while cylindrical parts benefit from turning’s efficiency.

Industry Standards & Certifications

ISO 9001 ensures quality management, while AS9100 is critical for aerospace. Certified facilities minimize rework, improve tolerance compliance, and reduce prototype failure rates.

Summary and Recommendation

CNC Milling is best for complex, multi-material prototypes requiring precision.

CNC Turning is best for cylindrical components, offering speed and cost advantages.

Hybrid approaches maximize efficiency, quality, and reduce overall prototyping time.

Summary

Milling provides versatility and precision; Turning provides efficiency and cost-effectiveness. Selection depends on geometry, materials, and budget.

Recommendation for 2025 Prototyping Projects

Use hybrid methods for projects combining complex and cylindrical features.

Use Turning alone for simple cylindrical parts.

Optimal process selection shortens cycles, reduces material waste, and ensures high-quality prototypes.

Streamline Your Prototyping with Ecoreprap

Selecting the right CNC process is crucial for achieving efficient and precise prototypes.

At Ecoreprap, our team leverages years of hands-on experience in both CNC Milling and CNC Turning to guide engineers in choosing the optimal method for their projects.

By analyzing part geometry, material selection, and tolerance requirements, Ecoreprap ensures prototypes meet design specifications while minimizing material waste and production time.

Our proven workflow integrates multi-material milling and precision turning, helping clients reduce iteration cycles by up to 20% and maintain consistent quality across batches.

Whether your project involves complex 3D components or cylindrical parts, Ecoreprap’s approach combines engineering expertise with industry best practices, providing reliable prototyping solutions that align with modern manufacturing standards.

Conclusion

In summary, CNC Milling is the go-to choice for intricate, multi-material prototypes requiring high precision, whereas CNC Turning provides speed and cost advantages for cylindrical components.

For projects combining both complex and rotational parts, a hybrid approach maximizes efficiency, quality, and overall savings.

By carefully evaluating part geometry, material, and tolerance requirements, engineers can optimize prototyping processes and achieve superior results.

Ready to streamline your prototyping workflow? Evaluate your project needs today and select the CNC process that will save time, reduce costs, and deliver high-quality results.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.