Table of Contents

Engineers, designers, and product developers often face a crucial decision:

whether to produce rapid prototyping parts using 3D printing or CNC machining.

Choosing the right method can dramatically impact cost, lead time, material performance, and part quality.

This guide not only compares these two processes but also provides practical insights for selecting the most efficient solution for your project.

What Are 3D Printing and CNC Machining?

- 3D Printing: An additive manufacturing method, 3D printing builds parts layer by layer directly from a digital model.

Its strength lies in creating highly complex geometries, prototypes, and custom parts with minimal tooling.

However, precision and surface finish can vary depending on printer type and materials.

In practice, engineers often use 3D printing to rapidly test design concepts before moving to full-scale production. - CNC Machining: CNC machining is subtractive—it removes material from a solid block with computer-controlled tools.

This method is preferred when high dimensional accuracy, material strength, and smooth surface finishes are required.

CNC is well-suited for medium-to-high volume production of functional parts, where repeatability and durability are critical. - Practical Insight: In many projects, the optimal workflow combines both: 3D printing for prototyping and iterative design, followed by CNC machining for end-use components.

This hybrid approach balances speed, precision, and cost efficiency.

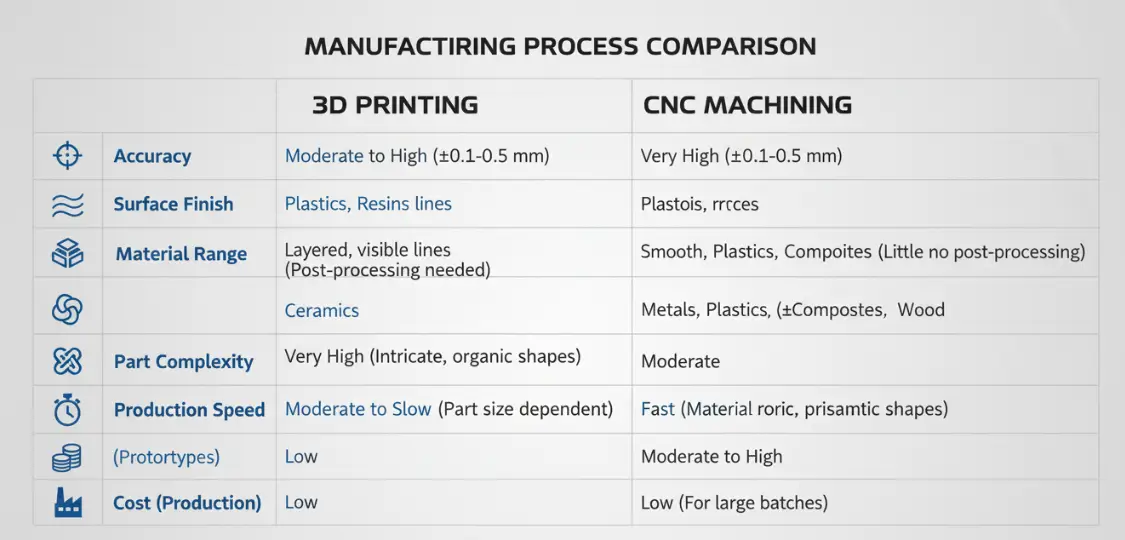

Key Difference Between 3D Printing and CNC Machining

| Process | What it is | Strengths | Limitations | Typical Use Cases |

|---|---|---|---|---|

| 3D Printing | Additive manufacturing, builds layer by layer from digital models using plastics or metals. | Excellent for complex geometries, rapid prototyping, low-volume customization. | Surface finish and tolerances may vary; post-processing often required. | Prototypes, concept models, custom fixtures, medical devices, aerospace tooling. |

| CNC Machining | Subtractive manufacturing, removes material from a solid block using computer-controlled tools. | High accuracy, strong material properties, smooth finishes, scalable to medium/high-volume production. | Limited internal feature access; higher setup costs. | Functional prototypes, end-use parts, molds/dies, production components requiring tight tolerances. |

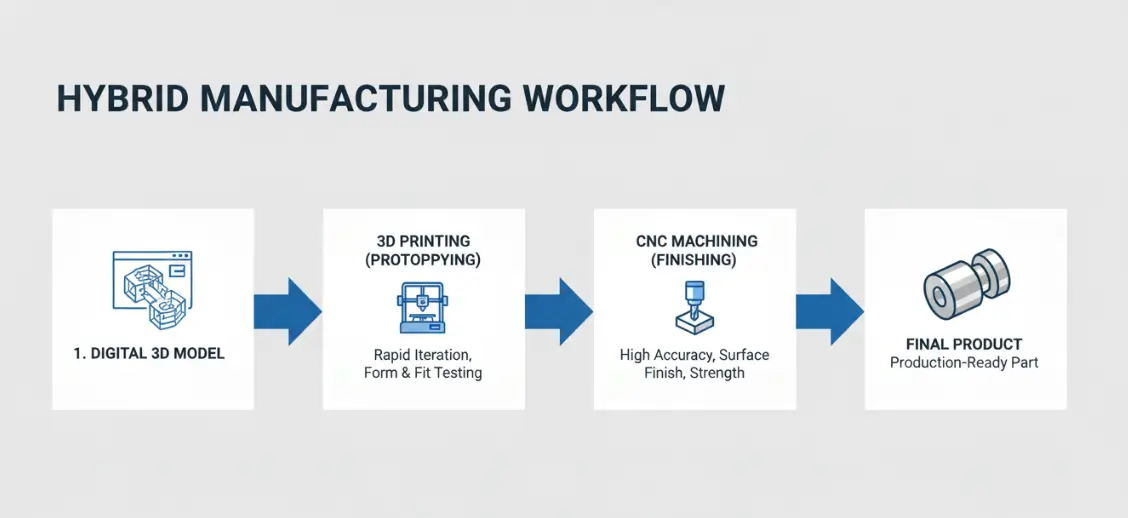

- Hybrid Workflow Strategy:

Step 1: 3D print prototypes, tooling, or complex internal structures. - Step 2: CNC machine key structural features or final components.

- Benefit: Combines speed, accuracy, and material reliability.

- Example: Medical implants: 3D-printed custom shapes + CNC-machined metallic supports.

Choosing the Right Manufacturing Process

- 3D Printing: Best for rapid prototyping, intricate or lightweight designs, and fast design iteration.

- CNC Machining: Ideal for parts that require high strength, tight tolerances, and smooth finishes, especially in medium-to-high volume production.

- Hybrid Approach: Many manufacturers combine both methods—3D print prototypes or custom fixtures, then CNC machine final parts for optimal balance of speed, precision, and cost.

1.Quick guidance

- For rapid prototyping and design exploration: 3D printing wins with speed and flexibility, enabling multiple iterations and complex geometries without tooling costs.

- For functional parts with high strength, tight tolerances, and metal or hard plastics: CNC machining is preferred, delivering better surface finish and mechanical properties, especially at higher volumes.

- For low to moderate volumes where part features are Machinable and tolerances are critical: CNC often remains more cost-effective per part than 3D-printed equivalents.

2.When to use 3D printing?

- Rapid iteration cycles and in-house prototyping to speed up product development.

- Complex, organic, or topology-optimized geometries that are difficult or costly to machine.

- Parts made from materials that are hard to machine or require lightweight design with internal channels, lattice structures, or customized tooling.

3.When to use CNC machining?

- Parts requiring tight tolerances, smooth surface finishes, and high dimensional stability, especially for metal components.

- Medium to high production volumes where unit costs drop with quantity.

- Simple to moderately complex geometries where steel/aluminum or other metals perform best and post-processing is minimal.

4.Hybrid and strategic approaches

Use 3D printing for prototyping and then switch to CNC for tooling-ready versions or final parts, optimizing speed and cost.

A hybrid workflow often provides the best balance of speed, accuracy, and manufacturability.

Cost and Time Considerations

| Factor | 3D Printing | CNC Machining | Practical Insight |

|---|---|---|---|

| Setup Cost | Low, minimal tooling | Higher (fixtures, programming) | 3D printing is cost-efficient for small runs; CNC benefits scale with volume. |

| Unit Cost | Stable for low volumes, rises with quantity | Decreases as volume increases | Use 3D printing for <50 units; CNC for medium/high-volume production. |

| Material Options | Plastics, select metals; anisotropic properties | Broad metals and plastics; consistent properties | CNC offers predictable mechanical performance for critical components. |

| Precision & Tolerance | ±0.1–0.5 mm (consumer); industrial better | ±0.01–0.05 mm; high repeatability | High-precision parts usually require CNC. |

| Surface Finish | Rough, post-processing needed | Smooth, near-net finish | CNC provides superior aesthetics and functional surfaces. |

1.Small-batch or one-off parts

- 3D printing: lowest upfront cost, fastest turnaround, ideal for rapid iterations and complex geometries. Setup is minimal and per-part cost stays relatively stable regardless of batch size. Production lead times are typically shorter for single parts or very small runs.

- CNC: higher setup costs (fixtures, tooling, operator training) and longer lead times for setup, but the per-part cost remains reasonable if the batch is small and material choices are favorable.

2.Medium to mass production

- 3D printing: unit costs rise with higher quantities due to material usage and slower throughput; economies of scale are weaker unless specialized industrial printers and materials are used.

- CNC: lower per-unit cost at higher volumes as setup costs are amortized across many parts; faster cycle times per part with consistent material properties and better surface finishes.

3.Time-to-market considerations

- 3D printing: excels in rapid prototyping and design validation, enabling multiple design iterations in parallel with development timelines.

- CNC: preferred when parts require high strength, precise tolerances, and reliable long-term performance; post-processing and testing can add time but yields predictable results.

4.Cost factors to compare

- Setup costs: 3D printing minimal vs. CNC tooling and fixturing.

- Material costs: 3D printing materials (filaments, resins, powders) vary by type; CNC materials (metals, certain polymers) can be more expensive but may reduce post-processing needs.

- Unit/part costs: 3D printing tends to have stable per-part costs for small runs; CNC per-part costs decrease with volume.

- Labor and overhead: CNC often requires skilled operators; 3D printing can be more automated but may need calibration and post-processing depending on the part.

5.Practical examples

| Industry | 3D Printing Use | CNC Machining Use | Practical Insight |

|---|---|---|---|

| Aerospace | Lightweight lattices, complex internal channels | Structural components requiring certification | Use 3D printing for internal geometries; CNC for load-bearing parts. |

| Medical | Customized implants, surgical guides | Machined housings/components with tight tolerances | Combine 3D printing for patient-specific models and CNC for durable surgical tools. |

| Automotive | Concept models, rapid iterations | Functional prototypes, high-strength end-use parts | Rapid iterations with 3D printing shorten design cycles; CNC ensures performance for production components. |

How to choose between 3D Printing and CNC Machining?

- Is your batch size small (<50)? → Consider 3D printing

- Do you need high precision and material strength? → Consider CNC machining

- Is the geometry complex (internal channels/lattice)? → 3D printing or hybrid

- Do you need speed for prototyping? → 3D printing

- Do you need long-term scalability? → CNC machining

Conclusion: Choosing the Right Manufacturing Process

Selecting between 3D printing and CNC machining depends on your project goals: speed, complexity, material requirements, precision, and production volume.

- 3D Printing: Fast prototyping, high customization, complex geometries.

- CNC Machining: Strong, precise, scalable parts suitable for end-use.

- Hybrid Workflow: Often the optimal strategy—prototype with 3D printing, then finalize with CNC to maximize efficiency, accuracy, and cost-effectiveness.

- Pro Tip: Always evaluate batch size, material constraints, and design complexity before deciding—this avoids unnecessary cost and time in production.

Source: Verified data from the U.S. Department of Energy’s Advanced Manufacturing Office, ASTM International Additive Manufacturing Standards (ASTM F42), and the ISO 9001–certified precision machining and additive manufacturing suppliers directory.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.