Table of Contents

Many people view prototyping as a waste of time and money, thinking direct mass production is more convenient.

This is like cooking a full table of dishes from a recipe without tasting first—you end up with inconsistent saltiness no one will eat, and far greater losses in the end.

Having worked in product consulting for years, I’ve seen countless clients skip prototyping, only to end up with unsellable, unused defective products.

Today, let’s break down why prototyping is critical and how to pick the right prototyping methods.

Why Prototyping Is Indispensable in Product Development?

We can’t skip prototyping—and a real story proves it.

When I was at a foreign trade company, a client wanted to develop a new thermos cup.

They deemed prototyping unnecessary and went straight to mold opening and production.

But when the first batch arrived, the heat retention was poor, and the lids leaked nonstop.

Customer returns poured in, and the client lost not just mold fees, but several distributors too.

Prototyping is like tasting a bite before cooking the whole pot—you adjust saltiness in time to avoid wasting the entire batch.

Its core role is to reduce risks and speed up time-to-market. If problems surface after mass production, fixing them is costly and time-consuming; but if you catch issues during prototyping, modifying designs or materials costs far less.

Practically, prototypes let you validate ideas early. It’s like prepping for a party: mental rehearsals don’t work as well as simulating with a few friends to spot potential flaws.

A good prototype also helps secure investments and team communication—saying “I want to make this” is less convincing than letting people touch and use a physical sample.

Today’s market has many prototyping services; don’t assume outsourcing is expensive.

One client spent two months failing to make a prototype themselves, but a professional service finished it in a week—and even cut material costs.

Prioritizing prototyping and choosing the right service isn’t asking for trouble; it’s buying insurance for your product.

3D Printing: Fast, Flexible Prototyping—Which Scenarios Fit?

1. What Is 3D Printing Prototyping, and How Is It Different?

3D printing isn’t as high-end or mysterious as many think.

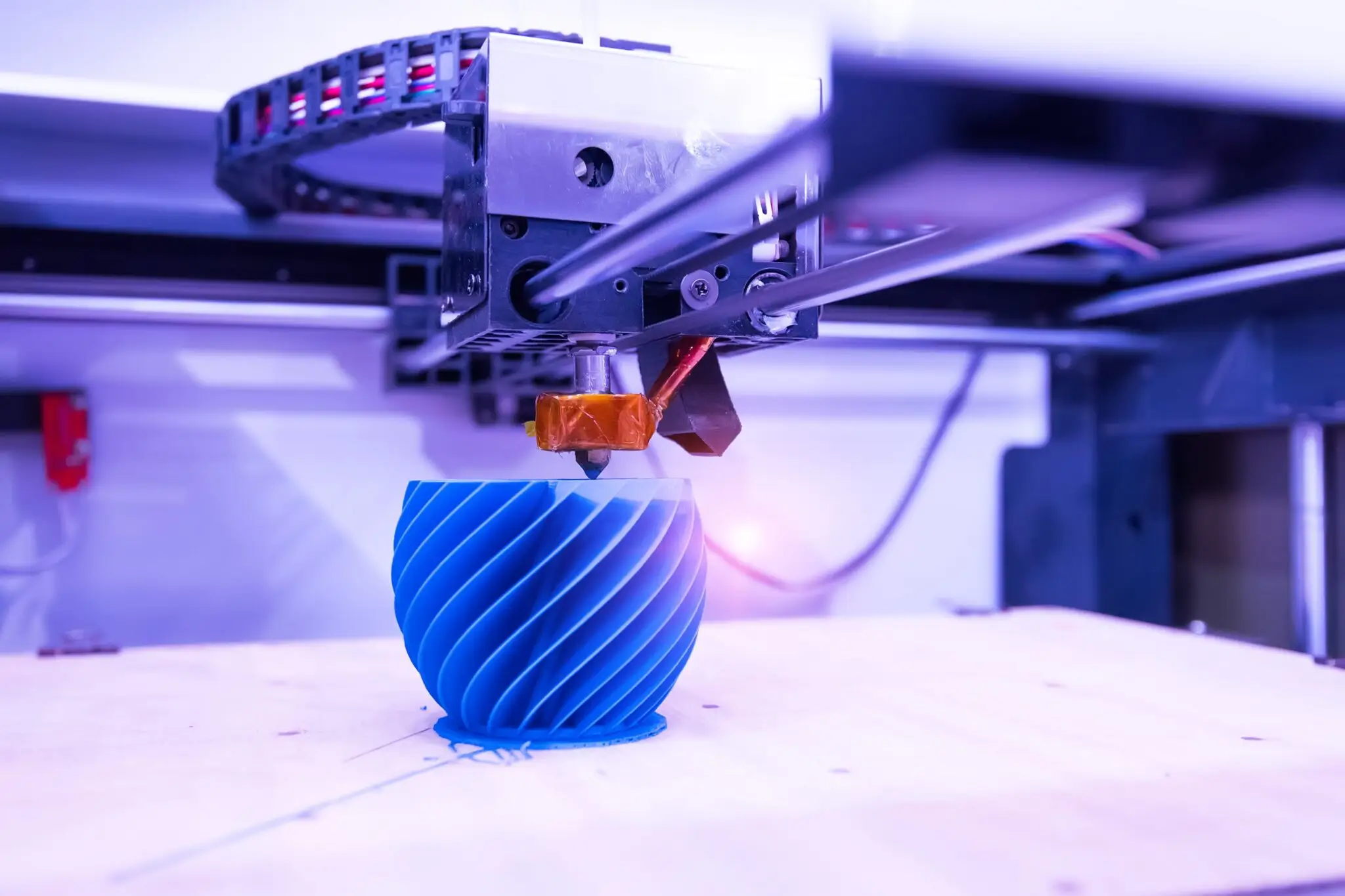

It’s “additive manufacturing”—stacking materials layer by layer like building blocks, unlike traditional methods that carve down a single piece of material.

I once helped a friend make a small toy prototype via 3D printing in 3 days; traditional methods would’ve taken at least half a month.

It’s perfect for quick idea validation: if you design a small part and want to check its shape or assembly, 3D printing delivers cheaply and fast.

A smart home client tested 5-6 housing versions with 3D printing before finalizing a design that’s both good-looking and functional—skipping this would’ve meant huge losses from early mold opening.

Market services like Alibaba Cloud’s 3D Printing Platform and Ecoreprap’s Rapid Prototyping Service can speed up sampling, but note: different 3D printing methods fit different needs—don’t choose randomly.

2. Common 3D Printing Methods and How to Choose?

| Method | How It Works | Advantages | Disadvantages | Suitable Scenarios |

|---|---|---|---|---|

| FDM (Fused Deposition Modeling) | Melts plastic filaments (like squeezing toothpaste) and stacks layer by layer | Low cost, simple operation | Average precision, rough surface , weaker in vertical direction | Simple prototypes (product housings, small brackets) ; e.g., a student’s 200 rmb graduation project prototype. |

| SLA (Stereolithography) | Uses laser to cure liquid resin into shape | Detailed, smooth surface, high precision | Brittle (can’t withstand force) , resin has slight odor (needs ventilation) | High-appearance/precision items (jewelry, precision parts) e.g., a jewelry client uses it to get customer orders quickly. |

| SLS (Selective Laser Sintering) | Uses laser to sinter powder (e.g., nylon) | High strength, works as functional prototypes , no support structures needed | Higher cost than FDM , powdery surface | Functional parts (gears, mechanical components) ; e.g., a mechanical parts client tested gear transmission with it. |

| SLM (Selective Laser Melting) | Similar to SLS, but for metal (titanium alloy, stainless steel) | Extremely high strength | Very high cost | High-material-demand fields (aerospace, medical) ; e.g., a medical device client made surgical tool prototypes. |

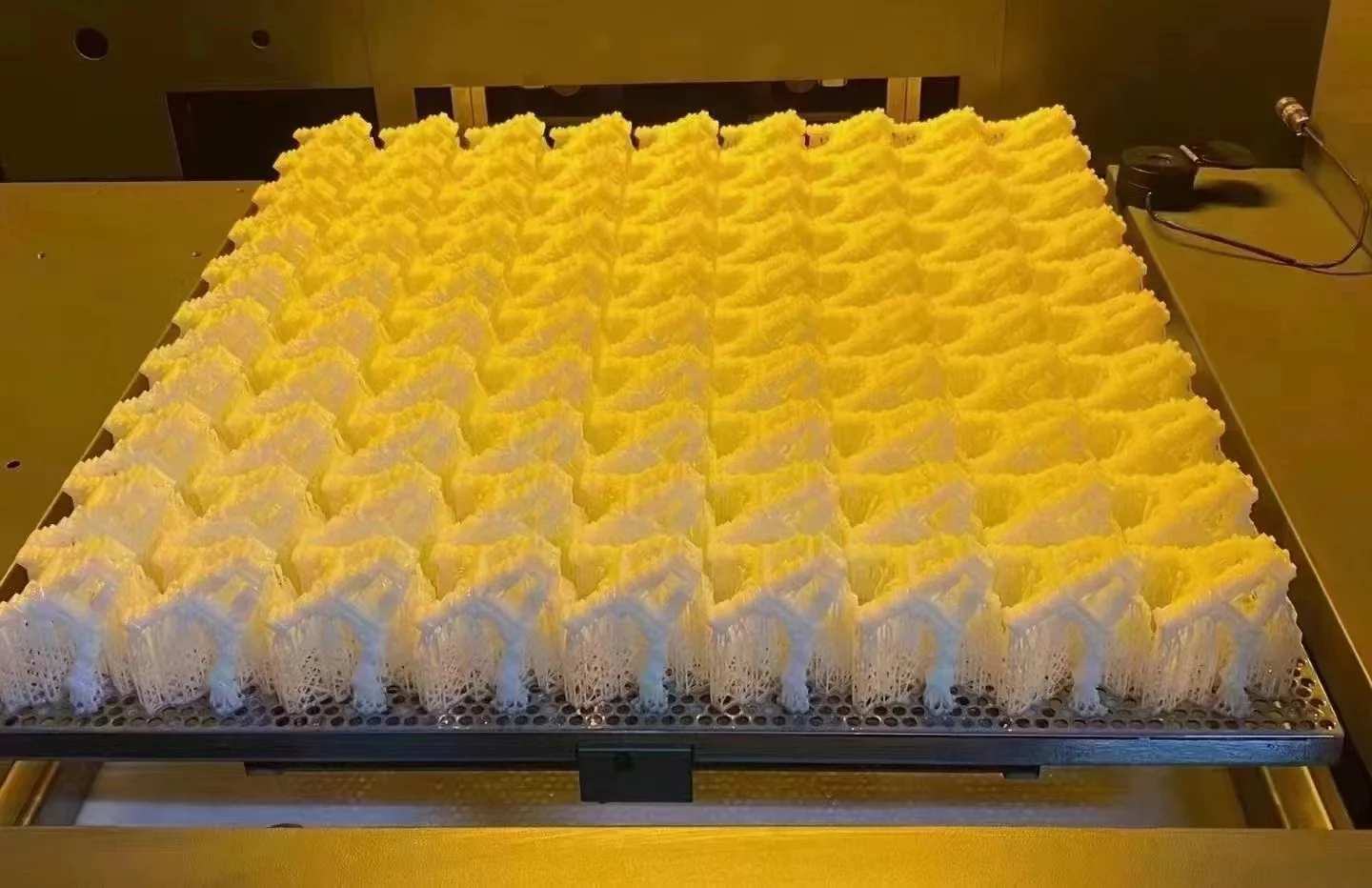

| DLP (Digital Light Processing) | Similar to SLA, uses projector-like light for faster curing | Fast speed, good for small detailed models | Limited printing size (can’t handle large items) | Small, detailed models (mini figurines, small parts) ; e.g., a trendy toy designer makes multiple samples a day. |

| Binder Jetting | Uses binder to bond powder; supports full color | Cost-effective , makes colored prototypes | Average strength (not for functional testing) | Display samples (e.g., product models to check color matching). |

3. Answers to Common 3D Printing Questions

Q1: Which method fits functional prototypes?

SLS is first choice—it makes strong prototypes that simulate real usage (e.g., testing part load-bearing or transmission).

For metal functional prototypes, SLM works, but cost must be considered. A drone client used SLS for propeller prototypes; they withstood multiple tests, enabling smooth mass production.

Q2: How to choose between SLA and SLS?

Simply put: SLA makes “good-looking” prototypes, SLS makes “useful” ones. Prioritize appearance/details (product housings, jewelry)—choose SLA.

Prioritize strength/functionality (mechanical parts, tools)—choose SLS.

A home appliance client used SLA for housing prototypes (to check appearance) and SLS for internal brackets (to test strength), with great results.

Q3: Is 3D printing cheaper than CNC machining?

It depends. For small, simple prototypes, 3D printing is cheaper. For large metal prototypes or those needing ultra-high precision, CNC may be more cost-effective.

One client spent 500 yuan on 3D printing for a small metal bracket, but switching to CNC for a larger version saved 200 rmb.

Also, CNC is cheaper for mass production, while 3D printing suits small batches.

CNC Machining: High Precision and Sufficient Strength, When Should It Be Used?

1.What Is CNC Machining in Prototyping? How Is It Different from 3D Printing?

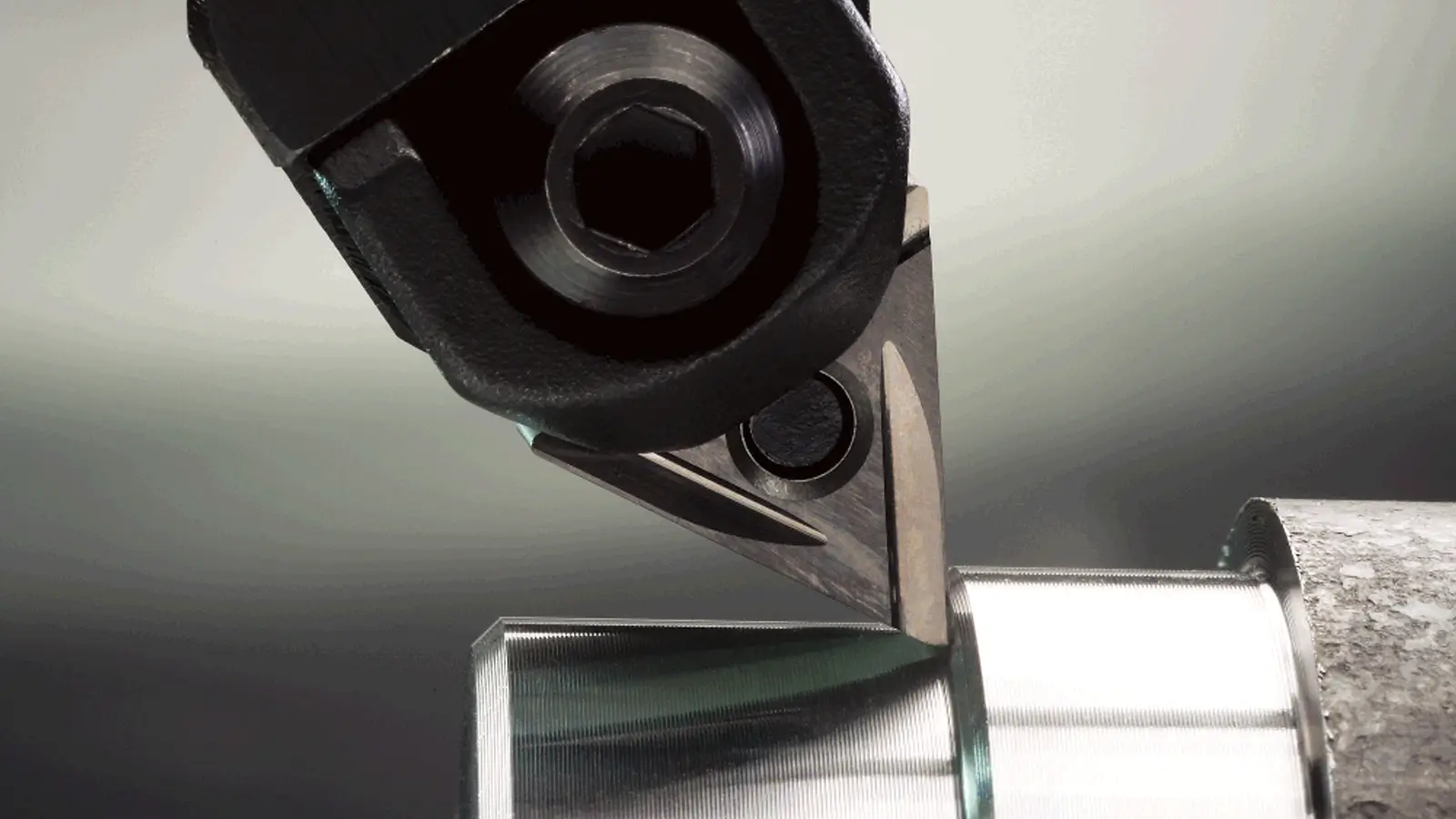

CNC machining is subtractive manufacturing—like carving wood, it shapes materials by removing excess, unlike 3D printing (additive, stacking layers).

It excels at metal/high-strength materials (aluminum alloy, stainless steel, titanium alloy), where 3D printing either costs too much or lacks strength.

A client making industrial equipment once struggled with 3D-printed metal housings (too brittle, low precision) but succeeded with CNC machining, which met precision and weight-bearing needs.

Its downside: complex shapes (e.g., internal hollows) are hard to machine or costly.

Popular CNC services: China Manufacturing, ECOREPRAP. Always confirm machinable materials and precision upfront.

2.Advantages & Suitable Scenarios of CNC Prototyping

2.1Ultra-high precision

Reaches 0.001mm (accurate to a fraction of a hair). Ideal for precision parts (e.g., optical equipment needing ≤0.002mm error).

2.2Tough material compatibility

Handles hard-to-machine metals (aluminum, stainless steel) and high-temperature parts (e.g., automotive components).

2.3Small-batch efficiency

More cost-effective than 3D printing for 50–100 units.

A tool client got 50 prototypes in 3 days (vs. 1+ week for 3D printing).

2.4Disadvantages

Slower than 3D printing (especially for complex parts) and costlier than FDM/SLA.

Not for simple appearance checks.

3.Common CNC Machining Questions

3.1When to choose CNC over 3D printing?

- Metal/high-strength material needs

- Precision ≤0.01mm

- Small batches (≥50 units).

Example: Drone metal brackets (needs strength + precision) use CNC; plastic housings for appearance checks use 3D printing.

3.2How precise is CNC?

Usually 0.001mm (enough for auto parts, medical devices).

Higher precision = higher cost—avoid overkill (e.g., toy parts only need 0.1mm).

3.3What materials work?

- Metals: Aluminum, stainless steel, titanium, copper

- Plastics: ABS, PC, POM, nylon

- Composites: Carbon fiber-reinforced plastic (lightweight, strong for sports gear).

Choose based on use (e.g., PEEK for high heat, titanium for strength).

Vacuum Casting: Cost-Effective for Small-Batch Production?

1.What Is Vacuum Casting? How Is It Different?

Vacuum casting makes a silicone mold first, then pours liquid materials (resin, rubber) into it (vacuum-cured) to get prototypes—like using an ice tray.

It’s ideal for 10–100 small-batch units.

A phone case client needed 50 samples: 3D printing was slow, CNC costly, but vacuum casting delivered in 3 days at half CNC’s cost.

Prerequisite: A master mold (from 3D printing/CNC) for the silicone mold (initial mold time, fast subsequent production).

2.Advantages & Applications

Cheaper than injection molding: Injection steel molds cost tens of thousands; silicone molds cost thousands.

A small appliance client made 100 housings for ~¥10k (vs. ¥50k injection mold fees).

Detail replication: Silicone captures tiny patterns/logos (e.g., cosmetic bottles with fine grooves).

Material flexibility: Simulates soft/hard/transparent/colored textures (e.g., soft toy buttons matching final product feel).

Applications: Electronic housings, medical accessories, toys, cosmetics packaging.

Not for >100 units or metal.

3.Common Vacuum Casting Questions

3.1How many parts per mold?

10–100 units (ordinary silicone = ~50, high-strength = ≥100). For ≥1,000 units, use injection molding.

3.2Vacuum casting vs. injection molding?

Vacuum casting: Small batches (10–100), low mold cost, fast setup.

Injection molding: Large batches (≥1,000), high mold cost (steel molds last long).

Example: A stationery client tested 50 samples via vacuum casting, then switched to injection molding for mass orders.

3.2Suitable for functional testing?

Yes for appearance/assembly/simple strength (e.g., drop tests); no for long-term durability (e.g., repeated bending) or high heat/pressure (material properties differ from mass-produced parts).

How to Choose the Right Prototyping Service?

Step 1: Clarify Your Needs

Answer these first to avoid mistakes:

Purpose: Appearance (SLA/vacuum casting) → Functional test (SLS/CNC) → Display (FDM/Binder Jetting)

Material: Plastic (FDM/SLA) → Metal (CNC/SLM) → Soft rubber (vacuum casting)

Quantity: 1–10 (3D printing) → 10–100 (vacuum casting) → ≥100 (CNC/injection)

Time/budget: Urgent (3 days: FDM/SLA) → Low budget (FDM cheapest).

Mistake example: A client chose FDM for assembly testing (insufficient precision) and had to rework with CNC.

Step 2: Screen Service Providers (3 Key Checks)

Cases & reputation: Look for similar projects; avoid providers with “low precision” or “delays” in reviews.

Delivery & after-sales: Confirm timelines (put in contract); prefer free modification policies (e.g., 2 free fixes).

Compare 3+ quotes: Avoid rock-bottom prices (poor quality).

A client chose the cheapest provider but got bubbly prototypes—reworking with a mid-priced provider saved money.

Step 3: Confirm Samples First

Never skip samples—test:

Size: Use calipers to check deviations.

Appearance: No scratches/bubbles; correct color.

Function: Test moving parts (e.g., gears) or strength.

Mistake example: A client made 50 phone stands without sampling—all failed (angle error, phones slid).

Frequently Asked Questions

1.What’s the cheapest method?

- 1–5 simple plastics: FDM (~¥150 for student projects).

- 10–100 plastics: Vacuum casting (50 housings = ~¥1k vs. ¥2k FDM).

- Metals: Small/simple (FDM metal); large/high-precision (CNC).

Note: Cheap prototypes that fail needs cost more in rework.

2.What’s the fastest method?

- Urgent (3 days): FDM (1–3 days) or SLA (3 days max).

- Metal/small batches: CNC (3–7 days), vacuum casting (5–10 days, mold time).

Tip: Expedited service (50–100% extra cost) cuts time by 1–2 days.

3.Can 3D printing replace CNC?

No—they complement:

3D printing: Fast, flexible for complex/small batches (low precision/strength).

CNC: High precision/strength for metals/small batches (slow for complex shapes).

Example: Drone housings (SLA 3D printing) + internal metal brackets (CNC).

4.4-Step Service Selection Summary

Clarify needs (purpose, material, quantity, precision, time).

Pick method (e.g., 1–10 plastic appearance = FDM/SLA).

Compare 3+ providers (cases, after-sales, quotes).

Confirm sample before mass production.

Use ZeroGPT for needs analysis, but verify samples yourself.

Final Words

Prototyping isn’t a formality—it’s a critical step to reduce risks and validate ideas.

What matters most is focusing on what problem does the prototype solve? and what do customers truly need, then selecting the right tools and methods accordingly.

Product development is a long-term process that rewards careful planning and iteration.

Taking the time to get the prototyping phase right might feel slow at first, but it ultimately leads to better products and faster success in the market.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.