Table of Contents

Prototyping is the linchpin of product development.

It’s the crucial phase where ideas are tested and refined before full – scale production.

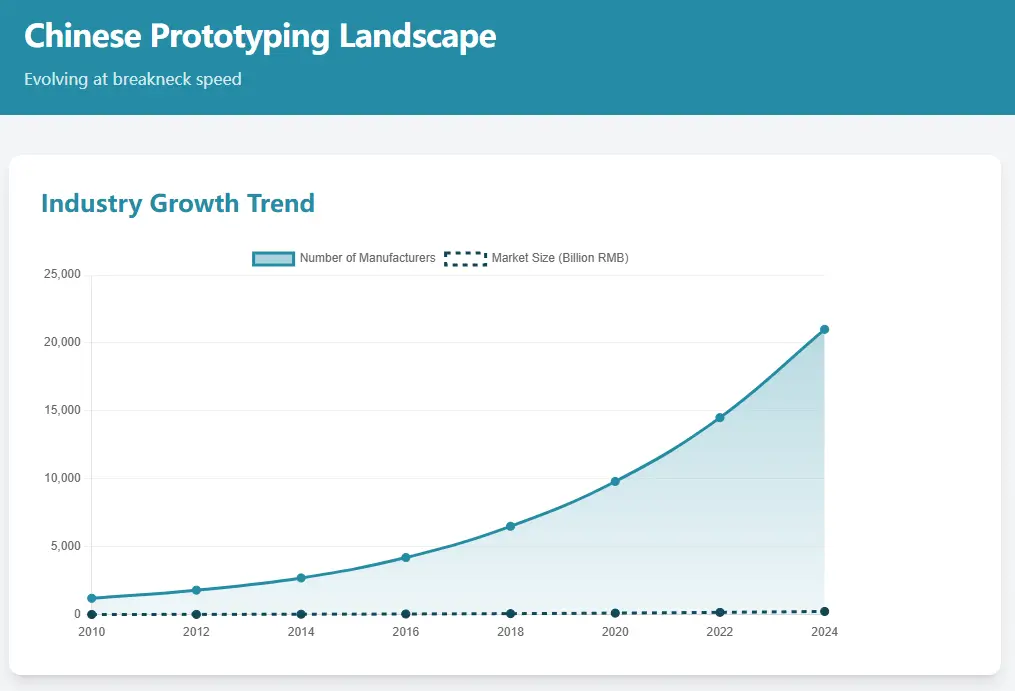

In our globalized era, Chinese prototyping services have surged to prominence.

The Chinese prototyping landscape has evolved at breakneck speed, with countless manufacturers and suppliers offering diverse solutions.

Selecting the right prototyping service can make or break your project.

A misstep may bring delays, skyrocket costs, and result in substandard prototypes.

But Chinese prototyping services offer a world of possibilities. They blend cost – effectiveness with top – notch quality, lightning – fast speed, and innovative thinking.

Thanks to China’s robust manufacturing base, access to cutting – edge technology, and a skilled workforce, these services are a game – changer for businesses globally.

Whether you’re a budding startup or a large multinational, Chinese prototyping services could be the key to meeting your prototype manufacturing needs.

Curious to learn more? Read on to discover the benefits that await.

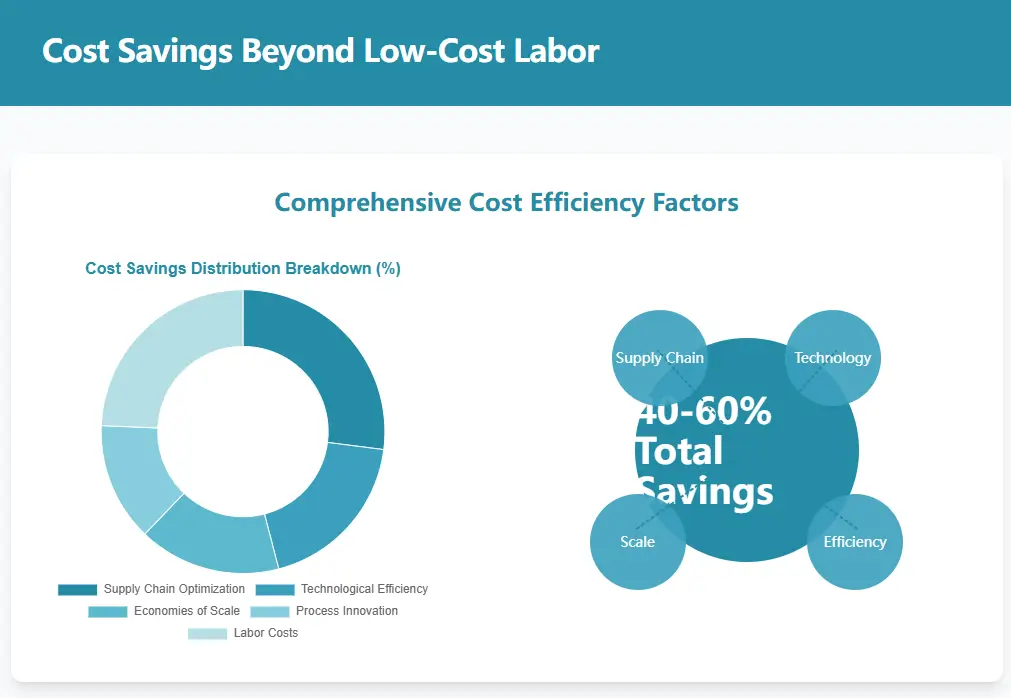

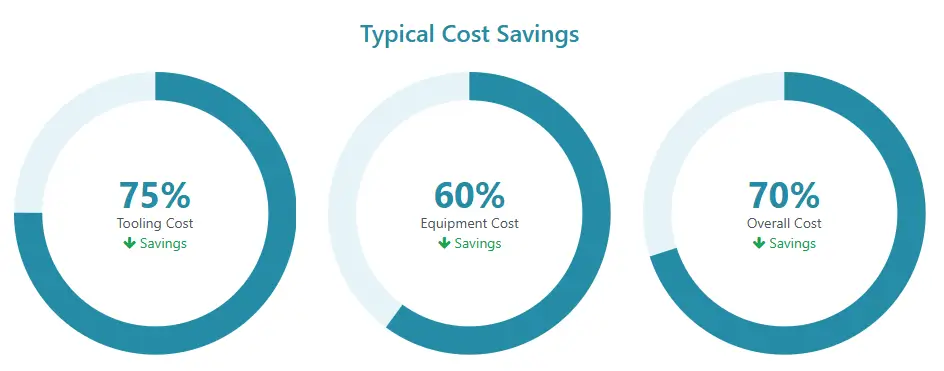

Cost Savings Beyond Low-Cost Labor: The True Value of Chinese Prototyping Services

1.The Dense Supply Chain in China

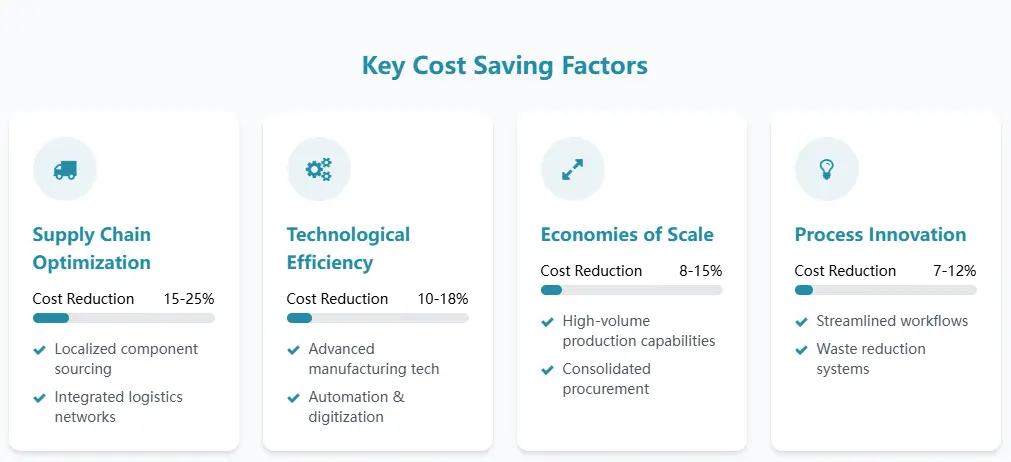

China boasts a highly dense supply chain when it comes to prototyping. This intricate network of suppliers, manufacturers, and service providers ensures that every aspect of the prototyping process is well – supported.

For instance, in the electronics prototyping field, companies can source all the necessary components within a relatively small geographical area.

This proximity reduces transportation costs and lead times.

In Shenzhen, often referred to as the “Silicon Valley of Hardware,” there are thousands of suppliers catering to the prototyping industry.

Whether it’s resistors, capacitors, or specialized microcontrollers, these components are readily available.

This dense supply chain is a cornerstone of China’s prototyping success, enabling companies to streamline their operations and focus on the actual prototyping process.

2. Bulk Purchasing Advantages for Raw Materials

2.1 Examples from the Electronics Prototyping Field

In electronics prototyping, bulk purchasing of raw materials can lead to substantial cost savings.

Chinese manufacturers and suppliers have the ability to buy components in large quantities.

For example, when it comes to printed circuit boards (PCBs), companies in China can purchase the raw materials for PCB manufacturing at a much lower cost per unit compared to international suppliers.

A Chinese prototyping company might be able to source a roll of copper – clad laminate, a key material for PCB production, at a significantly discounted price when buying in bulk.

2.2 Comparison with International Suppliers

International suppliers may not offer the same level of cost – effectiveness due to various factors such as higher labor costs, less efficient supply chains, and smaller production volumes.

A European or American supplier might charge a premium for the same raw materials that a Chinese supplier can provide at a lower price.

This cost differential can have a significant impact on the overall project budget.

For a large – scale electronics prototyping project, the savings from sourcing raw materials in China can be in the tens of thousands of dollars.

2.3 Overall Impact on Project Budgets

The combination of a dense supply chain and bulk purchasing advantages has a profound impact on project budgets.

By reducing costs at every step of the prototyping process, from component sourcing to raw material procurement, companies can allocate their resources more efficiently.

This means that they can either invest more in the design and development of the prototype or use the savings to fund other aspects of the product development cycle.

For example, a company that saves on prototyping costs in China might be able to afford more advanced testing equipment or hire additional design experts.

3.Overall Impact on Project Budgets

The combination of a dense supply chain and bulk purchasing advantages has a profound impact on project budgets.

By reducing costs at every step of the prototyping process, from component sourcing to raw material procurement, companies can allocate their resources more efficiently.

This means that they can either invest more in the design and development of the prototype or use the savings to fund other aspects of the product development cycle.

For example, a company that saves on prototyping costs in China might be able to afford more advanced testing equipment or hire additional design experts.

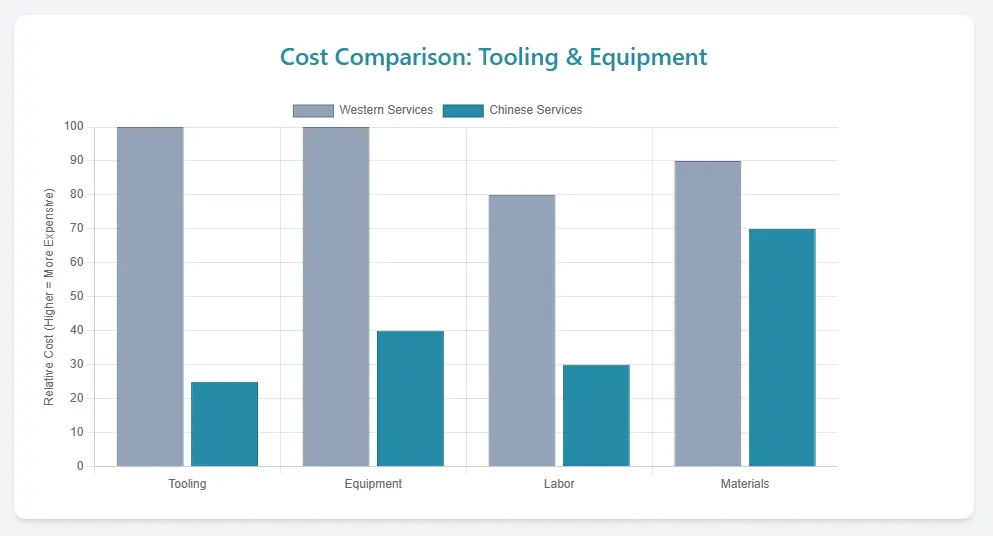

The Advantage of Chinese Prototyping Services: Reduced Tooling and Equipment Costs

1.Overview of China’s Manufacturing Base

China has an extensive manufacturing base that is well – equipped to handle prototyping requirements.

The country has been investing heavily in manufacturing infrastructure for decades, resulting in a wide range of high – quality prototyping tools and equipment.

From large – scale manufacturing plants to small – and medium – sized enterprises, there is a diverse ecosystem of manufacturing capabilities.

In regions like the Pearl River Delta and the Yangtze River Delta, there are countless factories dedicated to prototype manufacturing.

These factories are often equipped with state – of – the – art machinery, including CNC machines.

CNC machines play a crucial role in modern prototyping, allowing for precise and complex manufacturing processes.

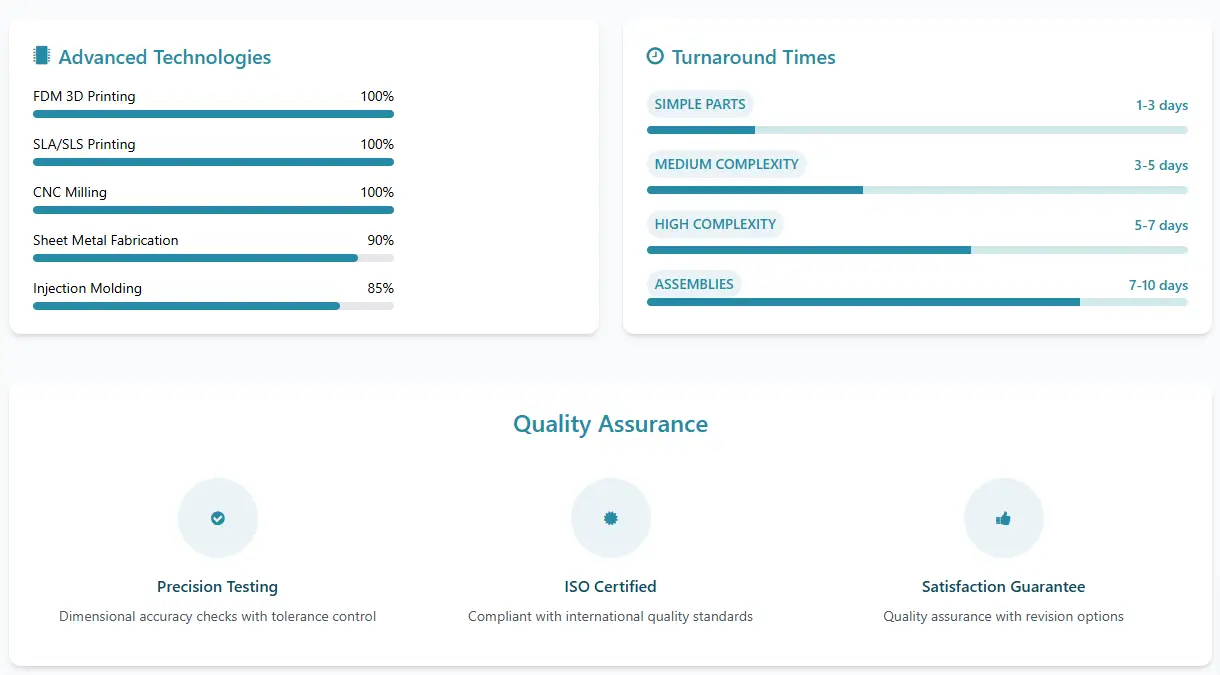

2. Availability of High – Quality Prototyping Tools

Chinese manufacturers and suppliers have access to a vast array of high – quality prototyping tools.

In addition to CNC machines, there are 3D printers, injection molding machines, and various machining tools.

These tools are constantly being updated and improved to meet the evolving needs of the prototyping industry.

For example, the latest generation of CNC machines in China offers higher precision, faster processing speeds, and greater flexibility.

This enables prototyping companies to create more intricate and accurate prototypes.

Moreover, the availability of these tools means that companies can complete their prototyping projects in – house, reducing the need to outsource certain processes and thus saving time and cost.

3. Cost Comparison of Custom Molds in Plastic Injection Molding

3.1 Factors Contributing to Lower Costs

When it comes to plastic injection molding, custom molds in China are often more cost – effective.

One of the main factors is the large number of tool – making companies in the country.

The intense competition among these companies drives down prices. Additionally, China has a relatively lower cost of labor, which is an important factor in mold manufacturing.

The cost of raw materials for mold making, such as steel, is also more competitive in China due to the country’s strong steel industry.

3.2 Impact of Competition Among Tool – Making Companies

The competition among tool – making companies in China has a positive impact on the quality of custom molds as well.

To stay competitive, these companies invest in research and development, improve their manufacturing processes, and offer better customer service.

As a result, companies using Chinese prototyping services can get high – quality custom molds at a fraction of the cost compared to other countries.

For example, a custom mold for a plastic consumer product that might cost $10,000 in the United States could be produced in China for $3,000 – $5,000.

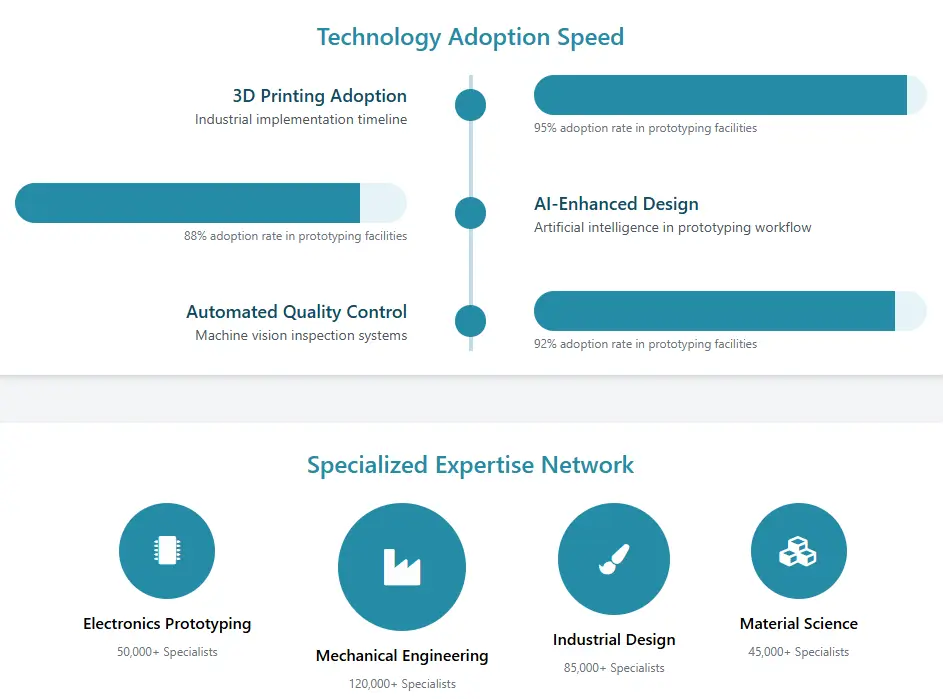

Why Chinese Prototyping Services Offer Unparalleled Access to Advanced Technology and Expertise?

1.Overview of Technological Advancements in Chinese Prototyping

Chinese prototyping has witnessed remarkable technological advancements in recent years.

The country has been at the forefront of adopting and developing new technologies such as additive manufacturing (3D printing) and advanced CNC machining techniques.

These technologies have revolutionized the prototyping process, allowing for faster production times, greater design flexibility, and improved quality.

China is also investing in research and development to further enhance these technologies.

Universities and research institutions are collaborating with prototyping companies to develop new materials and manufacturing processes.

For example, new composite materials are being developed for use in 3D printing, which can improve the strength and durability of prototypes.

2. Skilled Workforce and Specialized Knowledge

China has a large pool of skilled workers with specialized knowledge in prototyping.

These workers have been trained in technical institutions and have years of experience in the manufacturing industry.

In the field of CNC machining, for instance, there are thousands of skilled operators who can program and operate the machines with precision.

Moreover, Chinese prototyping companies often have teams of engineers and designers who are well – versed in the latest design software and prototyping techniques.

This combination of technical skills and design expertise enables them to create innovative and high – quality prototypes.

A Chinese prototyping team might be able to take a complex design concept and turn it into a functional prototype in a shorter time compared to teams in other countries.

3. Examples of Innovative Prototyping Techniques Available in China

One of the innovative prototyping techniques in China is the use of multi – material 3D printing.

This technique allows for the creation of prototypes with different materials in a single print job.

For example, a prototype of a medical device might require a combination of rigid and flexible materials.

Chinese prototyping companies can use multi – material 3D printing to produce such a prototype, which was previously a complex and time – consuming process.

Another example is the development of advanced CNC machining strategies for high – speed prototyping.

These strategies enable faster machining times without sacrificing precision.

This is particularly useful for companies that need to produce prototypes quickly, such as those in the consumer electronics industry.

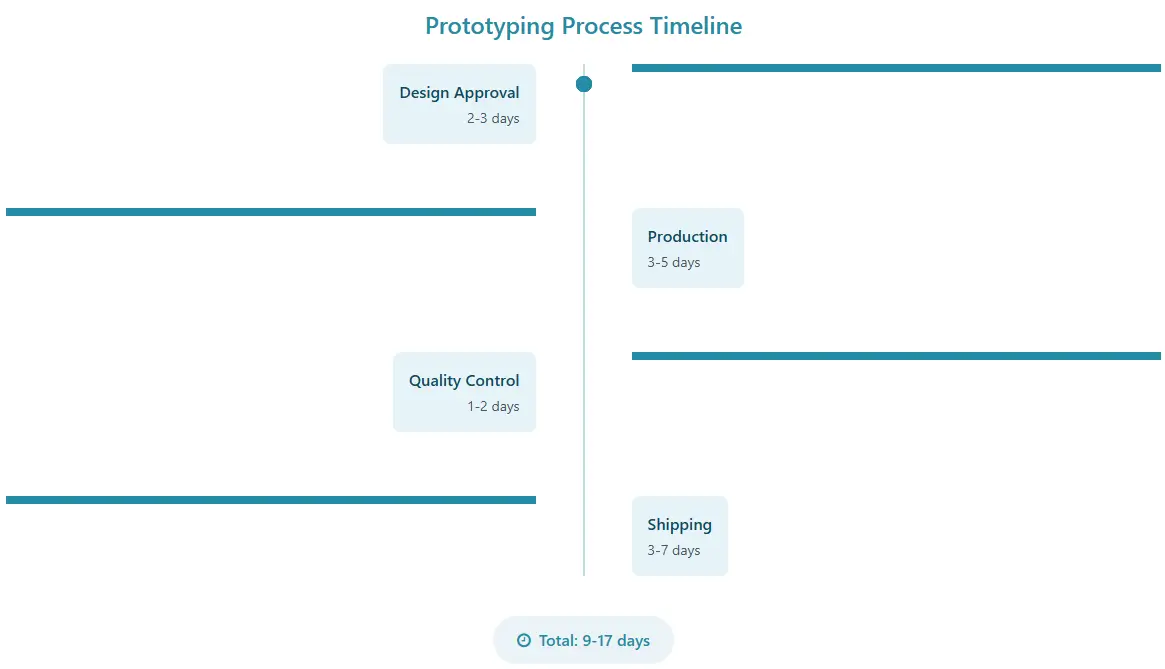

How Chinese Prototyping Services Deliver Faster Turnaround Times?

1. Efficiency of Chinese Prototyping Services

Chinese prototyping services are known for their high efficiency. The combination of a well – organized supply chain, advanced technology, and a skilled workforce allows for rapid prototyping.

Companies in China can often start the prototyping process within a short period after receiving the design specifications.

For example, in the automotive prototyping industry, a Chinese prototyping company can start manufacturing a prototype of a new car part within a week of receiving the design.

This quick start is possible because of the ready availability of raw materials, skilled workers, and the necessary equipment.

2. Streamlined Processes and Logistics

China has streamlined its prototyping processes and logistics to ensure faster turnaround times.

Prototyping companies have optimized their internal processes, from design review to production and quality control.

They use advanced project management software to track the progress of each prototype and ensure that all steps are completed on time.

In terms of logistics, China has an extensive transportation network.

Whether it’s shipping prototypes within the country or exporting them overseas, the logistics infrastructure can handle large volumes efficiently.

This means that companies can receive their prototypes quickly, even if they are located in a different part of the world.

3. Importance of Speed in Product Development Cycles

Speed is of the essence in product development cycles.

A faster prototyping process allows companies to bring their products to market sooner.

This gives them a competitive edge, especially in industries where innovation is rapid, such as the consumer electronics and software – enabled hardware industries.

For example, a startup developing a new mobile app – enabled device can use Chinese prototyping services to quickly turn its concept into a working prototype.

This prototype can then be tested, refined, and brought to market in a shorter time frame compared to using prototyping services in other countries.

This speed can help the startup gain market share and attract investors more quickly.

What can Ecoreprap offer in Prototyping Services?

1.Features

Ecoreprap offers a comprehensive suite of prototyping services. We have an in – depth understanding of China’s dense prototyping supply chain, enabling us to source high – quality raw materials efficiently.

Our access to the latest CNC machines and additive manufacturing technologies is a key feature.

We also have a team of highly skilled engineers and designers with specialized knowledge in various prototyping techniques.

2.Advantages

The advantages are manifold.

By leveraging China’s manufacturing base, we can offer reduced tooling and equipment costs.

Our use of advanced technology ensures high – precision and innovative prototypes.

The speed of our services, made possible by streamlined processes, gives clients a competitive edge in product development cycles.

We can start prototyping projects quickly and deliver within tight deadlines.

3.Benefits

For clients, this means significant cost savings.

They can get high – quality prototypes at a fraction of the cost compared to other regions.

Our fast turnaround times mean they can bring their products to market sooner, maximizing their market share and return on investment.

Ecoreprap’s prototyping services are designed to turn your ideas into reality, offering a seamless and efficient experience from concept to prototype.

If you’re comparing options to find the right partner, explore Top 5 Prototype Manufacturing Suppliers in China for trusted industry leaders.

Conclusion

In summary, using Chinese prototyping services offers several key benefits. For a comprehensive overview of the entire industry, check out The Ultimate Guide to China Prototype Manufacturing.

The cost savings, both from the dense supply chain and bulk purchasing of raw materials, can significantly reduce project budgets.

The reduced tooling and equipment costs, thanks to China’s manufacturing base and competition among tool – making companies, make prototyping more affordable.

Access to advanced technology and a skilled workforce enables the creation of high – quality and innovative prototypes.

And the faster turnaround times ensure that products can be developed and brought to market more quickly.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.