Table of Contents

Chrome plating and nickel plating are two common types of finishing techniques. They can both provide enhanced corrosion and abrasion resistance and an appealing appearance. The coatings plated on the part surface can make it more decorative and durable.

However, what the differences between them and how to choose the better one? This article will offer a complete guide of comparison between chrome plating and nickel plating.

Both chrome plating and nickel plating are surface finishing techniques used to enhance corrosion resistance, wear resistance, and specific decoration, thus increasing the service life of parts.

Key Takeaways:

- Chrome plating and nickel plating are surface finishing techniques used to enhance corrosion resistance, wear resistance, and decoration.

- The main functional types of chrome coating are decorative chrome coating and hard chrome coating, while nickel plating can be divided into electrolytic and electroless methods.

- For a brilliant, mirror-like finish, decorative chrome plating is recommended, whereas bright nickel plating is a more budget-friendly option with a warmer luster.

- For applications demanding extreme hardness and wear resistance, hard chrome is superior, but electroless nickel plating provides better corrosion resistance and uniform coating on complex parts.

1. What is Chrome Plating?

Chrome Plating is a type of electroplating technique that uses an electric current to deposit a chromium coating onto the surface of a part made of metal or another conductive material.

Chrome plating is widely applied to improve the appearance and enhance corrosion resistance and hardness.

Chrome plating can be classified into decorative chrome coating and hard chrome coating.

Decorative chrome plating is a very thin coating with a bright, silvery and mirror-like finish. The main function of decorative chromium plating is to provide an appealing appearance and meanwhile offer basic corrosion resistance and wear resistance. Therefore, it is usually applied to automotive trim, faucets, appliance housings, and furniture hardware.

Compared with decorative chrome coating, hard chrome coating is much thicker, often up to tens of hundreds of micrometers. Therefore, it is mainly used to provide excellent surface performance including exceptional hardness, wear resistance and protection from heat and corrosive conditions.

Hard chrome plating is popularly used in demanding industrial applications such as hydraulic rods, molds, aircraft landing gear, and printing rollers.

Related blog has more information about Chrome Plating:

What is Chrome Plating: Definition, Types, Process, Cost, Process and Application

2. What is Nickel Plating?

Nickel plating is a surface finishing process that deposits a layer of nickel onto a metal or other conductive material, usually through electrolytic or electroless methods.

Similar to chrome plating, the main purposes of nickel plating are also to enhance corrosion resistance, wear resistance , and appearance. Except that, nickel plating can serve as an undercoat for other coatings, and provide specific electrical, magnetic, or solderable properties.

Nickel plating can be divided into electrolytic nickel plating and electroless nickel plating.

Electrolytic nickel plating, also named as electrochemical nickel plating, is a type of electroplating process that uses direct electric current to reduce nickel ions from a plating solution and deposit them onto the workpiece. It would produce dense and well-adhered nickel coatings with controllable thickness.

In addition, electrochemical nickel plating usually covers bright nickel coating and semi-bright or matte nickel coating. They are primarily used for decoration or as a part of multi-layer nickel systems.

Compared with electrolytic nickel plating, electroless nickel plating required no electrical current. Instead, it relies on a chemical reduction reaction to deposit a nickel-phosphorus coating on the surface. That’s why electroless nickel plating is also named as chemical nickel plating.

During the process, sodium hypophosphite is usually the reducing agent. And decided on the composition of phosphorus, electroless nickel plating can be classified into low-phosphorus nickel plating, medium-phosphorus nickel plating, and high-phosphorus nickel plating.

A key advantage of electroless nickel plating is its exceptional coating uniformity, which ensures consistent thickness even on parts with complex geometries and internal surfaces.

What’s more, it provides excellent corrosion and wear resistance. Meanwhile, its hardness can be further increased up to 1000+ HV through heat treatment.

Due to these strengths, electroless nickel plating is widely used in aerospace, oil & gas, electronics, molds, and automotive components.

Related blog has more information about Nickel Plating:

3. What is the Process of Chrome Plating?

The process of chrome plating includes pre-process, electroplating, and post-process.

Pre-process

- Mechanical Polishing:

For decorative chrome plating, the surface must undergo detailed mechanical polishing or buffing to achieve the desired mirror finish. For hard chrome plating, media blasting or light grinding is enough to remove surface imperfections.

- Chemical Degreasing:

Immersethe part in an alkaline solution or organic solvent to thoroughly remove organic contaminants like oil, grease, and fingerprints.

- Acid Pickling:

Immersethe part in a dilute acid solution such as hydrochloric or sulfuric acid to remove surface oxides like rust or natural oxide films. This process would make the metal surface activated, ensuring a strong bond for the subsequent plating.

Electroplating Process

For Decorative Chrome Plating:

Since the chrome coating is very thin, it is required to plate a copper coating and then a nickel coating under the chrome one for better surface performance.

- Copper Plating:

Immerse the part in a copper plating bath for 10-20 minutes to form a 5–10 μm coppercoating, with the temperature controlled between 40-50℃ and the current density 2-5 A/dm².

The copper undercoating is plated to cover the surface imperfections, thus to improve smoothness and provide an ideal foundation for subsequent layers.

- Chrome Plating:

Immerse the part into a chrome plating bath consisting of 200–300 g/Lchromic anhydride (CrO₃) and 2–3 g/L sulfuric acid (H₂SO₄) to from a very thin chrome coating.

The temperature is usually controlled between 40–50°C and the current density between 15–30 A/dm².

For Hard Chrome Plating:

Different from decorative chrome plating, hard chrome plating is usually directly plated on the part.

The thick chrome coating itself can provide desired corrosion resistance and durability.

During the process, the part would be immersed into a chrome plating bath containing 250~350g/L CrO₃ and 1~2g/L H₂SO₄. And the temperature is often controlled between 50~65℃ with current density controlled between 30~100A/dm².

Post-process

- Rinsing: After removal from the plating tank, the parts must be immediately and thoroughlyrinsed through multiple stages to remove all residual acidic and toxic chromic acid solution. This is a crucial step for environmental compliance and safety.

- Drying: Dry the part to remove moisture, preventing water spots and secondary contamination.

- Hydrogen Embrittlement Relief: For hard chrome coating, it is required to bake the part within 150-250℃ for several hours to drive the hydrogen out of the part.

4. What is the Process of Nickel Plating?

As mentioned above, nickel plating can be classified into electrolytic nickel plating and electroless nickel plating. Their processed are significantly different.

4.1. What is the Process of Electrolytic Nickel Plating?

Pre-process

- Grinding/Polishing: Depending on the final requirement, the workpiece shouldundergo mechanical grinding or polishing to achieve the necessary surface finish.

- Chemical Degreasing: Immerse the part in an alkaline degreasing agent solution to remove organic contaminants like oil, grease, and cutting fluid residue.

- Electrolytic Degreasing: Further clean the part by an alkaline solution with electrical assistance to remove trace particles and oxide films.

- Acid Pickling: Immerse the part in a dilute acid solution such as dilute sulfuric or hydrochloric acid to remove the oxide film and rust from the metal surface. This step can activate the surface and then ensure a strong metallurgical bond between the nickel coating and the pat surface.

- Rinsing: After every chemical treatment step, thorough rinsing withmulti-stage cold water is mandatory to prevent chemical carryover that could contaminate the next bath.

Electroplating

- Racking: Connect the part to the negative terminal as the cathode on a fixture and immerse it in the nickelplating solution. The most commonly used solution for nickel plating is the Watts Nickel Bath, which contains nickel sulfate, nickel chloride, boric acid, and brighteners.

The nickel sulfate is used to provide the primary source of nickel ions and the nickel chloride is to improve anode dissolution and enhance conductivity.

The boric acid acts as a buffer to stabilize the pH of the bath. The brighteners are added to refine the grain structure of the coating, providing it mirror-like shine.

- Electrodeposition: Connect nickel plates or stainless steel to the positiveterminal as the anode. And then apply direct current to them. During the process, nickel ions in the solution are attracted to the cathode surface, and meanwhile gain electrons.

Then they would reduce to nickel atoms, and deposit as a solid nickel coating. In addition, anode dissolution would continuously replenish the nickel ions in the bath.

- Parameter Control: During the electroplating process, the temperature is commonly maintained between 40-60℃ to ensure a brightand low-stress deposit.

And the current density is controlled with a range of 1-5A/dm². A improperly high current density would lead to a burnt and rough deposit.

What’s more, air or mechanical stirring is required to ensure uniform bath temperature and component concentration.

Post-process

- Rinsing: Immediately remove the part from the tank and rinse it thoroughly to remove residual acidic plating solution and chemicals.

- Drying: Completely dry the part by hot air or centrifugal method to eliminate moistureand prevent water spots.

4.2. What is the Process of Electroless Nickel Plating?

Pre-process

- Polishing: Polish the surface to remove imperfections and loose oxide films, making the surface smooth.

- Degreasing: Immerse the part in an alkaline solution to remove oil, grease, and other organic residues.

- Pickling: Immerse the part in a diluteacid such as hydrochloric or sulfuric acid to remove rust and other surface oxides.

- Activation: This is a crucial step uniquely for electroless nickel plating. Since many materials are not inherently catalytic, they must be immersed in the solution containing catalyst like palladium to be activated.

Electroless Plating

- Compounding EN Bath: Compound the electroless nickel solution with soluble nickel salt, reducing agent, complexing agents, stabilizers, and buffers.

Soluble nickel salt like nickel sulfate can provide the nickel ions for the plating, and reducing agent like sodium hypophosphite can provide the electrons for reducing reaction.

Complexing agents are used to control the concentration of nickel ions and phosphorus content in the coating, which would dictate the final properties like hardness and corrosion resistance.

Stabilizers are used to prevent the solution from self-decomposing and buffers can stabilize the pH value of solution.

- Autocatalytic Deposition: Heat the bath and maintain the temperaturebetween 85-95℃ and then immerse the part in it. During the process, nickel ions would be reduced to nickel under the influence of the reducing agent and the catalytic surface. Finally, a nickel-phosphorus alloy coating would deposit on the surface.

- Process Monitoring: Strictly control the temperature, pH value, andcomponent concentrations during the electroless plating process. And it is required to continuously replenish nickel ions and reducing agent as they are consumed, which can maintain the plating rate and quality.

Post-process

Rinsing: Thoroughly rinse the part by fluid pure water for severaltimes to remove the chemical residues off the surface.

Drying: Completely dry the part by hot air.

Heat Treatment (Optional): Trough heat treatment, the hardness and adhesion of the part can be significantly increased.

5. Decorative Chrome Plating vs Bright Nickel Plating

As mentioned above, decorative chrome plating is a type of chrome plating that deposits a thin chrome coating on the part to provide reflective finishing and improve certain corrosion resistance. Much similar to decorative chrome plating, bright nickel plating can also refine the surface and protect the part from corrosion and abrasion.

However, there are specific differences between decorative chromium coating and bright nickel coating. And it is critical to choose the proper one for the parts.

Below is a decorative chrome plating photo.

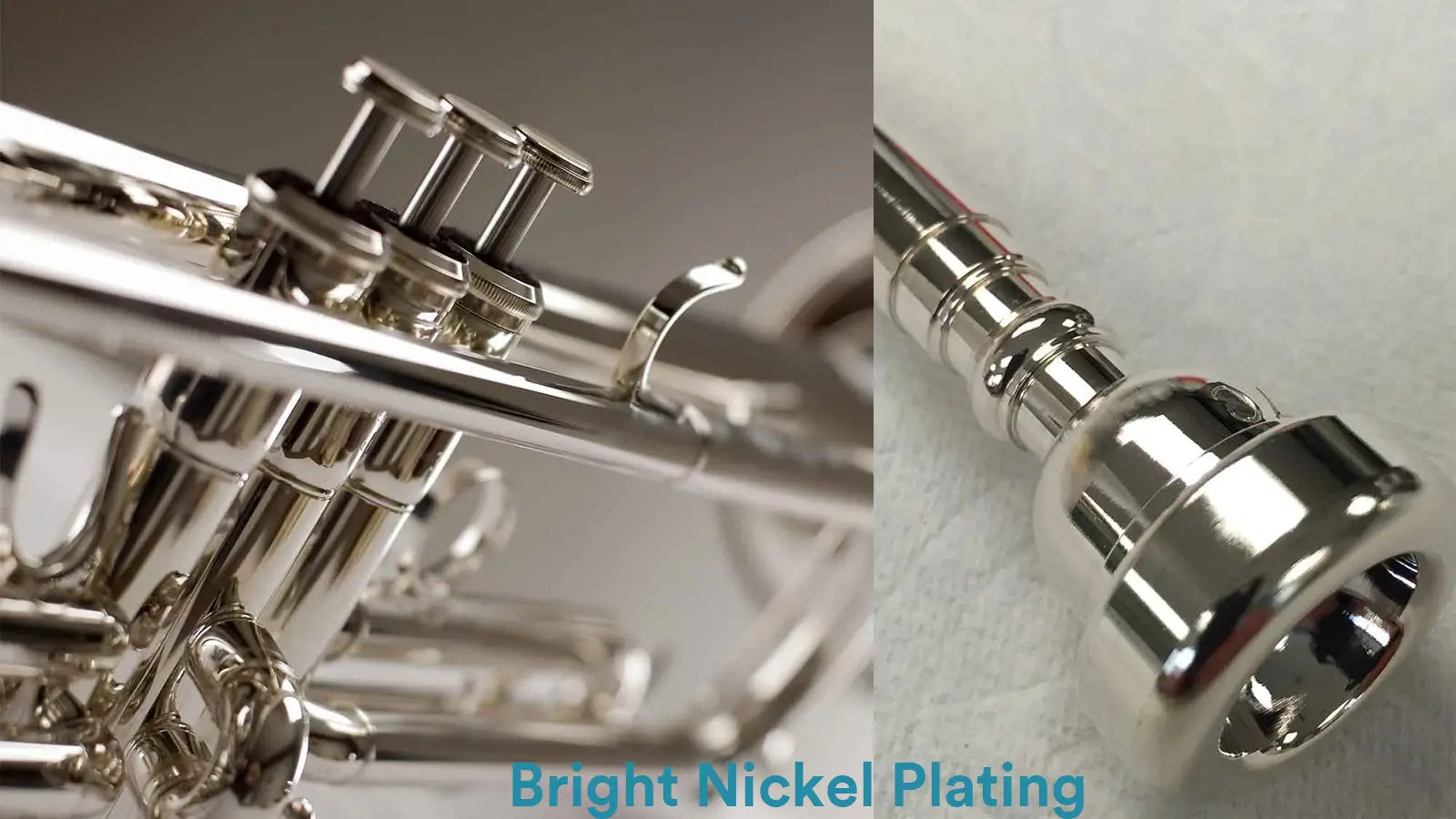

Below is a bright nickel coating photo.

5.1. Top 5 Differences between Decorative Chrome Plating and Bright Nickel Plating

Below are top 5 Differences between Decorative Chrome Plating and Bright Nickel Plating.

On Composition and Function

For Decorative Chrome Plating: In fact, decorative chrome plating is usually the top coating on the part. It is a multiple coating system within which a copper coating is plated bottom and a bright nickel coating is medium, just under the thin chrome coating.

The decorative chrome coating is very thin, usually just 0.25–1.0 μm. It is the bright nickel coating beneath that provides the primary protection from corrosion.

As the topcoat, its main function is to protect the underlying nickel layer from tarnishing or discoloration, since nickel would dull over time when exposed to air.

The extreme hardness of the chrome layer also provides superior resistance to wear and scratches.

For Bright Nickel Plating: Different from decorative chrome plating, bright nickel plating is usually a single coating. And it is much thicker than decorative chrome coating, commonly up to 5–25 μm. However, it can also be plated on a copper coating for better surface performance.

Bright nickel coating acts as the core protective barrier that provides excellent rust and corrosion resistance and meanwhile makes the surface highly glossy.

On Appearance and Color

For Decorative Chrome Plating: The color of decorative chromium coating is cool and brilliant silver-white, often with signature bluish cast. It delivers a much stronger and more dazzling mirror-like finish that looks harder and shinier. More importantly, its color and gloss can maintain longer than that of bright nickel plating.

For Bright Nickel Plating: The color of bright nickel layer iswarm silver with a slight yellowish or golden sheen. While highly reflective, bright nickel plating is a bit softerand less glossy than decorative chrome coating.

On Hardness and Durability

For Decorative Chrome Plating: The chrome layer exhibits very high hardness, typically ranging from800to 1200 HV, and offers excellent wear resistance. It can effectively resist abrasion and scratching, maintaining good surface integrity even under friction.

For Bright Nickel Plating: The nickel layer has relatively low hardness, generally between 150 and 300HV, and provides inferior wear resistance compared to chrome. It is more prone to wear when subjected to high level of friction or mechanical stress.

On Corrosion Resistance

For Decorative Chrome Plating: Chromium readily forms a denseand passive oxide film in air, making it highly resistant to alkalis, sulfides, nitric acid, and most organic acids.

It offers good corrosion resistance in atmospheric conditions and neutral environments. However, its anti-corrosion performance is relatively weaker in aggressive conditions such as strong acids or strong alkalis.

In addition, although the nickel coating provides the main bulk of the protection, the chrome acts as a final seal, preventing the nickel from direct exposure to environment, which significantly extends the overall corrosion resistance and tarnish-free life.

Therefore, the corrosion resistance of decorative chrome plating is overall much better than that of bright nickel plating.

For Bright Nickel Plating: Nickel exhibits excellent chemical stability in air, water, and many corrosive conditions. It caneffectively protect the underlying metal substrate from corrosion. Notably, in environments containing aggressive ions such as chloride (Cl⁻), nickel coating often demonstrates superior corrosion resistance compared to chrome plating.

On Cost

For Decorative Chrome Plating: The process of decorative chrome plating demands a high level of surface smoothness on the substrate. It needs multiple plating processes.

Moreover, the process generates toxic wastewater and fumes containing hexavalent chromium, requiring costly environmental treatment. And the chromium metal itself is also expensive. As a result, the overall cost is relatively high.

For Bright Nickel Plating: Bright nickel plating is comparatively simpler and less demanding in terms of pre-treatment to the substrate. Therefore, its cost is generally lower than that of chrome plating.

Comparison Table: Decorative Chrome Plating vs Bright Nickel Plating

| Feature | Decorative Chrome Plating | Bright Nickel Plating |

|---|---|---|

| Composition | Multi-layered: Bright Nickel (undercoat) + Very thin Chromium (topcoat) | A single bright nickel layer |

| Primary Function | Protects the nickel from oxidizing/tarnishing; provides extra wear and scratch resistance | Provides smoothness, gloss, and the main corrosion resistance |

| Color Tone | Cooler, bright white with a slightly bluish-silver mirror finish | Warmer, silvery-yellowish with a slight golden hint |

| Luster | Extremely glossy, more intense mirror effect | Highly glossy, smooth |

| Corrosion Resistance | Excellent; the chrome layer prevents the nickel from tarnishing or rusting easily | Good; the primary protective layer, but prone to tarnishing over time |

| Hardness | Better; the chrome topcoat is very hard and highly scratch-resistant | Good, but less wear-resistant than chrome |

| Cost | Higher | Lower |

| Porosity | Higher(due to the thin coating and micro-cracks) | Lower(especially in multi-layer nickel systems) |

| Ductility | Prone to cracking due to high brittleness | Good, with moderate ductility |

5.2. Pros and Cons of Decorative Chrome Plating and Bright Nickel Plating

Advantages of Decorative Chrome Plating

- Exceptionally high gloss and mirror-like finish

- Excellent corrosion and wear resistance

- Relatively easy to clean andresistant to fingerprint

- More resistant to discoloration

Disadvantages of Decorative Chrome Plating

- Thin and porous, relying on the underlying layer for corrosion protection

- Prone to cracking due to high brittleness

- Hexavalent chromium is toxic, leading to significant environmental and regulatory pressures

Advantages of Bright Nickel Plating

- Good corrosion resistance

- Soft, aesthetically pleasing luster

- Mature process with relatively low cost

Disadvantages of Bright Nickel Plating

- Low hardness, susceptible to scratching

- Easier to tarnish or darken over time with prolonged exposure

- Nickel may cause skin sensitization or allergic reactions upon contact

5.3. How to Choose between Decorative Chrome Plating and Bright Nickel Plating?

Decorative chromium plating is widely used on bright decorative components of household appliances and electronics, as well as on automotive parts such as door handles, wheel covers, and faucets. It can provide high aesthetic appeal and moderate wear resistance.

Bright nickel plating is primarily used on hardware components and electronic component leads. It can enhance both the decorative appearance and the corrosion resistance and solderability of the parts. It is commonly applied to applications where wear resistance is not that critical.

| Requirement | Recommended | Reason |

|---|---|---|

| Need the brightest, whitest mirror finish | Decorative Chrome | It provides the cool-toned bluish cast and most intense mirror shine. |

| Budget is a primary concern | Bright Nickel | It costs less and still offers good luster and corrosion protection. |

| High resistance to scratches and tarnishing is critical | Decorative Chrome | The chrome topcoat is hard and non-tarnishing. |

| Prefer a warm, traditional metal luster | Bright Nickel | It has a soft, warm silver or slightly yellowish tone. |

| Need the strongest long-term corrosion resistance | Decorative Chrome | The chrome layer seals and protects the core nickel barrier more effectively. |

6. Hard Chrome Plating vs Electroless Nickel Plating

Hard chrome plating and electroless nickel plating are two types of surface finishing techniques used to enhance the corrosion resistance, durability, hardness, and specific appearance.

However, the two methods differ in several ways. It is important to choose the proper one for the components.

Hard chrome plating parts are shown below.

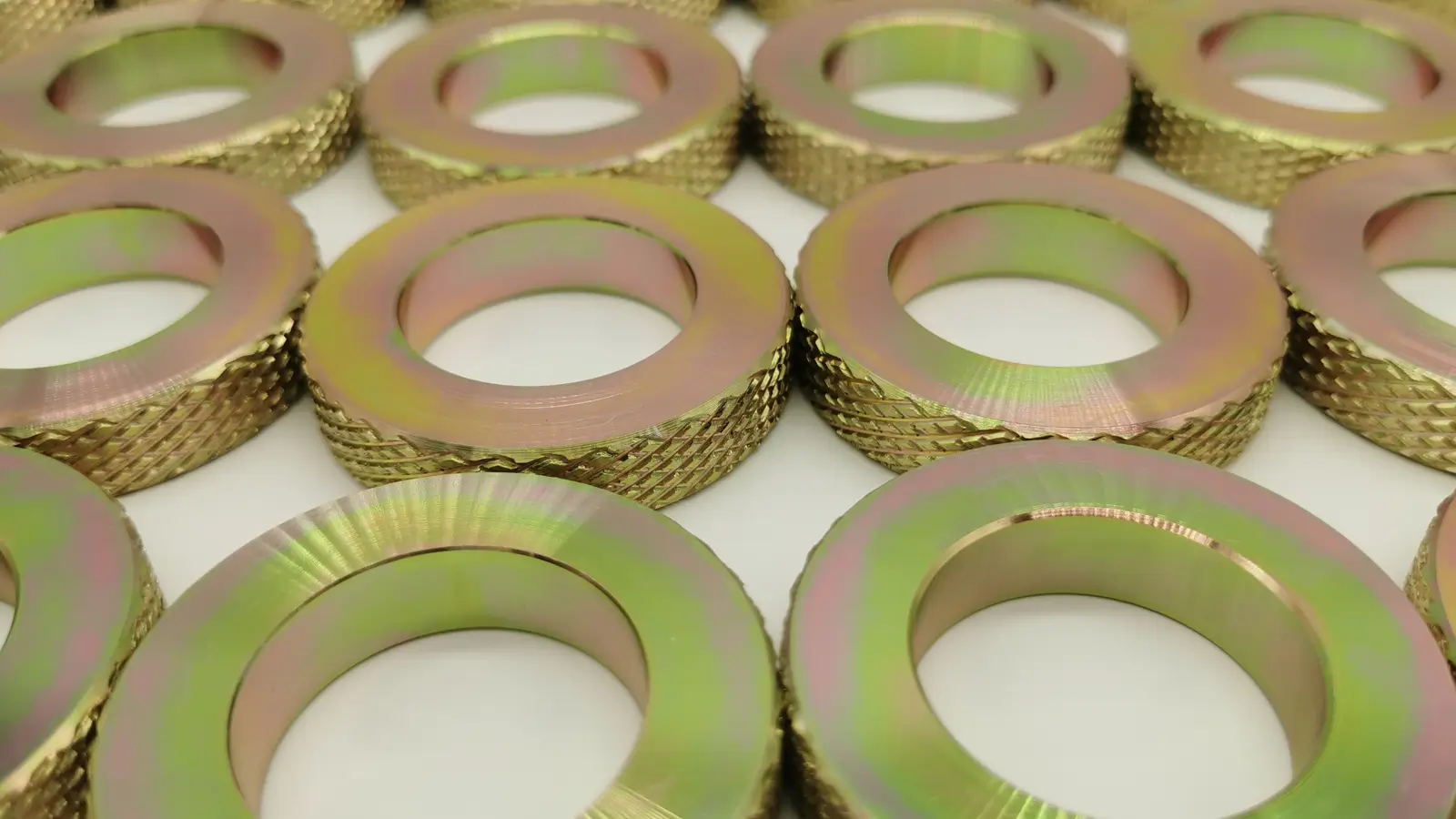

Electroless Nickel Plating on Steel Photo is shown below.

6.1. Top 5 Differences between Hard Chrome Plating and Electroless Nickel Plating

On Plating Process and Composition

Hard Chrome Plating is formed through electrolytic deposition, during which an external electric current is applied to a chromic acid electrolyte.

Then, chromium ions gain electrons at the part surface , are reduced to metallic chromium, and deposit as a solid layer. The workpiece must be electrically conductive.

In addition, hard chrome plating is a pure chromium coating.

For Electroless Nickel Plating, it is formed through chemical reduction, during which the reducing agent in the solution chemically reduces nickel ions to metallic nickel.

The nickel deposits as a solid coating on the catalytically active surface. This is an autocatalytic chemical reaction that proceeds without any external electrical current.

It forms a nickel-phosphorus or nickel-boron alloy coating. The most common type is nickel-phosphorus alloy.

On Plating Uniformity

For Hard Chrome Plating: Hard chrome plating offers poor coating uniformity due to its reliance on current distribution, leading to uneven thickness on complex-shaped parts.

For Electroless Nickel Plating: Since it relies on autocatalytic chemical reactionbut not current distribution, electroless nickel plating can produce a coating with highly uniform thickness, even on parts with extremely complex geometries.

Therefore, the plating uniformity of electroless nickel coating is exceptional, and it is its most outstanding advantages.

On Appearance

For Hard Chrome Plating: It appears steel-white or silver with slightly bluish tone. And it is generally semi-bright to matte or satin, requiring grinding or polishing to become highly glossy and mirror-like.

In addition, it has micro cracks within the coating and is certainly rough.

For Electroless Nickel Plating: It is silvery white with subtle yellowish or pale goldentint, slightly warmer compared to hard chromecoating. And it is usually bright or semi-bright.

The surface appears smooth and uniform, resembling the refined look of stainless steel. If the deposit contains high phosphorus content, the color may appear slightly darker or more subdued.

On Hardness and Durability

For Hard Chrome Plating: It stands out for its extremely high hardness and brilliant wear resistance. Its hardness is about 800-1000 HV, andcan be up to 1100-1300 HVafter heat treatment within 400-500℃.

Therefore, it is suitable for parts that should hold up high level of loading and abrasion.

For Electroless Nickel Plating: The hardness of low-phosphorus nickel coating is about 400-500 HV, while that of high-phosphorus nickel plating is about 500-600 HV, even up to 800-1000 HVafter heat treatment within 300-400℃.

Its wear resistance is much better than that of electroplating nickel coating, but is still slightly worse than that of hard chrome plating.

On Corrosion Resistance

For Hard Chrome Plating: Hard chrome coatings typically contain micro-cracks that often extend all the way to the substrate, creating pathways for corrosive media to reach the base metal.

Its corrosion resistance relies on the part itself and multiple coatings. As a result, hard chrome generally provides inferior corrosion resistance compared to electroless nickel plating.

For Electroless Nickel Plating: The nickel-phosphorus alloycoating is dense and amorphous without pores. It can effectively isolate the substrate from corrosive environments.

This structure gives it excellent corrosion resistance. Additionally, the phosphorus content significantly influences this property. High-phosphorus nickel deposits offer the best corrosion resistance.

Comparison Table: Hard Chrome Plating vs Electroless Nickel Plating

| Feature | Hard Chrome Plating | Electroless Nickel Plating |

|---|---|---|

| Process | Electroplating | Electroless plating |

| Coating Composition | Pure chromium | Nickel-phosphorus alloy |

| Coating Structure | Micro-cracked or micro-porous | Amorphous (when P > 8%) or crystalline, no pores |

| Appearance | Bright white with a bluish tint | Silvery-white with a slight yellowish hue |

| Hardness (HV) | Very high: 800–1000+ | High: 400–600; Up to 800–1000 after heat treatment |

| Wear Resistance | Excellent | Good |

| Corrosion Resistance | Good | Excellent |

| Uniformity | Poor | Excellent |

| Thickness | 5-100μm | 1-50μm |

| Adhesion | Very good | Very good |

| Environmental Friendliness | Very poor | Good |

6.2. Pros and Cons of Hard Chrome Plating and Electroless Nickel Plating

Advantages of Hard Chrome Plating

- Extremely high hardness

- Extremely excellentwear resistance

- Can be used to repair part

Disadvantages of Hard Chrome Plating

- Not environmentally friendly

- Poor uniformity

Advantages of Electroless Nickel Plating

- Excellent uniformity

- Good corrosion resistance

- Can be plated on non-conductive parts

Disadvantages of Electroless Nickel Plating

- Low plating efficiency

- Nickel is allergenic

6.3. How to Choose between Hard Chrome Plating and Electroless Nickel Plating?

Hard chrome plating is particularly used on components within high loading conditions, such as hydraulic piston rods, cylinder bores, crankshafts, and camshafts.

What’s more, it is also commonly applied to molds and tools such as cold-working dies, punches, and cutting tools for its excellent wear resistance. In addition, it can be used to restore worn parts.

Electroless nickel plating is particularly used on precise parts with complex geometries such as gears, valves, internal pipe surfaces, and deep-hole components.

In addition, it can also be applied to electronics such as printed circuit boards (PCBs), connectors, and sensors.

| Requirement Priority | Preferred Technique | Reason |

|---|---|---|

| High hardness and wear resistance | Hard Chrome | Electroless nickel plating cannot match the hardness of hard chrome. |

| Complex geometry, uniform coating thickness | Electroless Nickel | Hard chrome suffers from non-uniform current distribution, leading to significant thickness variation on complex parts. |

| High corrosion resistance | Electroless Nickel | Hard chrome contains micro-cracks that can initiate substrate corrosion. |

| Thick deposit for repair | Hard Chrome | Electroless nickel deposits are prone to cracking and high internal stress when applied thickly. |

| Strict environmental regulations | Electroless Nickel | Hard chrome plating uses toxic hexavalent chromium, resulting in high compliance and waste treatment costs. |

7. Conclusion

Both chrome plating and nickel plating can provide certain corrosion resistance and abrasion resistance, as well as specific finishing appeal. However, they are distinguishing on some aspects, making them suitable for particularly different applications.

8. Frequently Asked Questions about Chrome Plating and Nickel Plating

Q: Can Chrome Plating and Nickel Plating be Used Together?

A: Yes! They are plated together especially for decorative chrome plating, within which a bright nickel coating should be plated under a thin chrome coating.

Q: Does chrome plating always require a nickel underlayer?

A: For decorative chrome plating, a nickel underlayer is typically required, which provides the primary corrosion protection. But hard chrome plating is usually plated directly onto the base material.

Q: How to repair scratched chrome-plated or nickel-plated parts?

A: Minor scratches can often be polished out while deep scratches generally require re-plating. Chrome plating is hard to strip and rework, while nickel can be chemically removed and rework more easily.

Q: Which coating is mostdurable in outdoor or humid environments?

A: Electroless nickel plating is most resistant to corrosion. It is most durable in environments with prolonged exposure to moisture and salt spray.

Q: Which plating is better for partswith complex shapes or deep holes?

A: Electroless nickel plating delivers highly uniform coating thickness even on intricate geometries such as internal bores, threads, and recessed features. It is the best choice for complex-shaped components.

Q: Can chrome plating be used for productscompliant to RoHS?

A: Only trivalent type of chromium plating is compliant to RoHS. But if budget is limited, nickel plating is a preferable alternative.

Q: Which plating is more suitable for parts under heat exposure?

A: Hard chrome maintains its hardness and wear resistance at elevated temperatures, whereas nickel plating would oxidize and discolor under heat.

Q: Which plating is better for electronic parts?

A: Nickel plating is more conductive and is commonly used for electrical contacts or solderable surfaces, while chrome has poorer conductivity and higher resistance after oxidation.

Q: Which is more durable in conditions within high level of abrasion?

A: Hard chrome plating is much more wear-resistant due to its high hardness and low coefficient of friction.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is Nickel Plating?

Nickel plating coats a thin nickel layer via electroplating or chemical methods. Two main types are Electroplating Nickel (EN) and Electroless Nickel Plating (ENP).

Zinc Plating - Everything You Shall Know

Zinc Plating are classifed into Hot-Dip Galvanizing, Electro Zinc Plating,Mechanical Zinc Plating and Electroless Zinc Plating.

What is Chrome Plating?

Chrome plating is a type of popularly used finishing method for various applications. There are many common things in our life that are plated with a chrome coating

Aluminum Alloy Anodizing-MIL-PRF-8625F

Aluminum anodizing is systematically classified under MIL-PRF-8625F into six distinct Types (I, IB, IC, II, IIB, III) and two Classes (1: non-dyed, 2: dyed).