From prototyping to mass production, CNC machining has become a central pillar of modern manufacturing processes.

One of the most asked questions about CNC machining is how it performs compared to manual processes. Manual machining has an important place in the industry and in the rapid prototyping of small batches. CNC machining offers faster and more efficient manufacturing strategies. In this article, we compare the two to help you make the best choice for custom prototyping and end-use production parts.

Related read: Types of lathe tools used in CNC turning

CNC Machining Principles

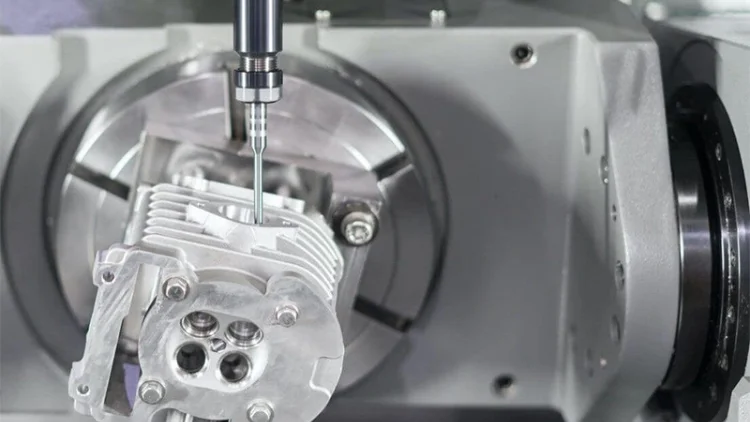

CNC machining utilizes computer programming to control the movement of the machine tool, allowing precise and complex machining tasks to be automated. The operator first creates a detailed design drawing on the computer, which is then converted into G-codes. These codes instruct the machine tool to perform specific actions such as cutting, drilling, and milling.

CNC machining requires digital files containing cutting and machining instructions. To accomplish this, engineers and machinists build a library of digital tools to interact with the CNC machine. The design process usually begins with CAD (Computer Aided Design) software. The 3D model created by the CAD software determines the properties and dimensions of the final part.

The main advantages of automated machining are its high accuracy, efficiency, and consistency. Since the machines are controlled by computers, they can produce a large number of identical parts in a short period of time, reducing human error.

For more on CNC machining, you can check out: How does CNC machining work?

Manual Machining Principles

Manual machining relies on the skill and experience of the operator to control the movement of the machine tool. Operators manually operate equipment, such as lathes, mills, and drill presses, to accomplish machining tasks.

While manual machining may be more time-consuming than CNC machining, it offers irreplaceable advantages in specific situations. For example, manual machining can provide greater flexibility when producing small batches or when flexible adjustments are required.

In addition, manual machining is usually less expensive because it does not require expensive computers and software support. By directly observing and adjusting the machining process, the operator can make the necessary modifications and adjustments on-site.

What Are the Pros of CNC Machining vs Manual Machining?

1. High precision and accuracy

CNC machining offers unparalleled precision and accuracy. Computer-controlled machines can execute complex and delicate designs, minimizing errors and ensuring that every part produced is the same and meets exact specifications.

2. Consistency

One of the major advantages of CNC machining is the ability to produce high-volume parts of consistent quality. Once the design and program are set, the machine can produce the same part over and over again without variation, which is vital for industries that demand high standards.

3. Efficiency

CNC machines run faster than manual machines. They can work continuously around the clock with minimal supervision, which greatly increases productivity, reduces production time, and minimizes human misalignment. This efficiency reduces production costs and speeds up project turnaround times.

4. Complexity and versatility

CNC machining can handle highly complex designs that are difficult or impossible to achieve with manual machining. The ability of CNC machining to produce complex geometries and fine parts makes it well-suited to the advanced manufacturing needs of the aerospace, automotive, and medical industries.

5. Safety

CNC machining offers a safer working environment compared to manual machining. Operators are not required to be in close proximity to cutting tools and moving parts, which reduces the risk of accidents and injuries. Safety features and enclosures further enhance the protection of workers.

CNC Machining VS Manual Machining Cost

1. Overall Cost

CNC machining generally has a lower overall cost compared to manual machining. Various factors contribute to the cost of the machining process, including scrap rates, labor costs, maintenance expenses, and total part production. Analyzing these factors in depth often reveals that CNC machining can be more cost-effective in the long run.

2. Low Scrap Rates and Maintenance Costs

CNC machining is known for its precision, resulting in lower scrap rates for each production run. This high level of accuracy reduces the amount of wasted material, which directly lowers costs.

In contrast, manual machining tends to have higher labor costs and maintenance requirements. The need for skilled operators and frequent adjustments in manual machining adds to the overall expenses and limitations of this method.

3. Increased Industrial Demand

The high scrap rates, labor costs, and maintenance needs associated with manual machining make it a more expensive option. On the other hand, the demand for CNC-machined parts is rising globally due to their high precision and low scrap rates.

Industries that require complex and accurate parts, such as aerospace, automotive, and medical, are increasingly turning to CNC machining to meet their needs efficiently and cost-effectively.

More about: How much does CNC machining cost?

CNC Machining Applications

CNC machining is widely used across various industries due to its precision, efficiency, and ability to handle complex designs. Some common applications include:

Aerospace Industry

CNC machines produce high-precision components such as turbine blades, engine parts, and structural components, ensuring safety and performance in aircraft.

Automotive Industry

Used to manufacture engine parts, transmission components, and custom car parts. The high precision and consistency of CNC machines improve the quality and performance of automotive components.

Medical Industry

Create complex and precise medical devices and implants, including prosthetics, surgical instruments, and orthopedic devices, meeting stringent medical standards.

Electronics Industry

CNC machining produces intricate parts for electronic devices, such as heat sinks, enclosures, and connectors, ensuring high performance and reliability.

Tool and Die Making

CNC machining is essential for creating precise molds and dies used in manufacturing processes, allowing for mass production of consistent and accurate parts.

Manual Machining Applications

Manual machining, while more labor-intensive and less precise than CNC machining, still holds value in certain applications, especially where flexibility and craftsmanship are required. Some applications include:

Custom and One-Off Parts

Manual machining is ideal for producing custom parts or small batches where design flexibility and quick adjustments are necessary.

Repair and Maintenance

Manual machining is often used for repairing and maintaining equipment, where precise fitting and adjustments are required.

Artisanal and Craftsmanship Work

Manual machining allows for greater artistic control and craftsmanship, making it suitable for creating unique and intricate designs.

Prototyping in Early Stages

Manual machining can be useful for initial prototyping, where quick changes and modifications are needed before finalizing the design for mass production.

Conclusion

If you only want to produce a one-off product for a customized project, manual machining may be a better option. However, for regular production or high-precision parts, you should choose CNC machining.

CNC machines have replaced most of the manual machine tool market. Even so, machines such as manual mills are still preferred by some operators due to their lack of programming requirements and ease of setup. However, when mass production is required, CNC machine tooling services are the best option.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.