Table of Contents

If you’re in the market for CNC prototyping, you’ve probably heard the buzz about China’s services.

Let me cut through the noise—after 8 years working with over 50 suppliers (and getting burned by more than a few), I can tell you: China’s CNC prototyping scene isn’t just about cheap prices.

It’s about precision, speed, and a supply chain that can turn your CAD file into a physical prototype faster than most Western shops.

But here’s the catch: not all suppliers are created equal.

In this guide, I’ll share what actually matters when choosing a CNC prototyping service in China, why ECOREPRAP stands out from the pack, and how to avoid the “too good to be true” traps that cost my clients tens of thousands last year.

Why Choose CNC Prototyping Services in China?

Let’s start with the basics: CNC prototyping is the backbone of product development.

It’s how you turn a design into a tangible part to test fit, function, and manufacturability.

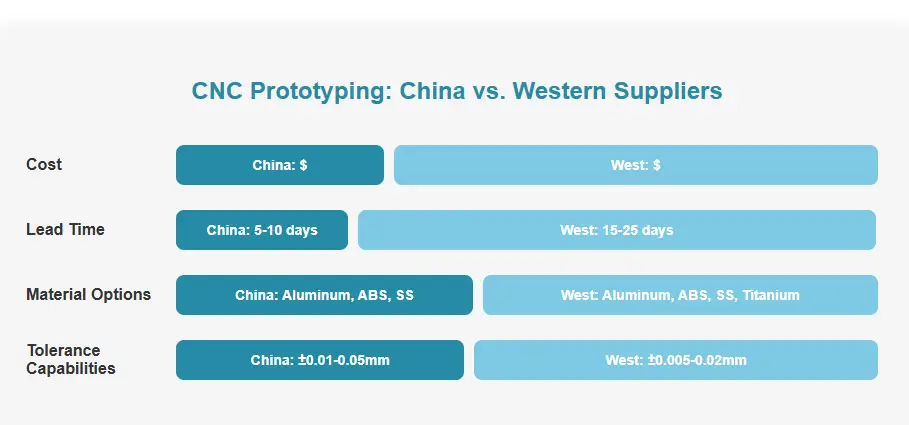

But why China? Let me break it down with numbers from my own projects.

1.The CNC Prototyping Edge: Precision, Speed, Versatility

First, the tech itself. Precision CNC prototyping in China isn’t just marketing fluff.

I’ve had parts made with tolerances as tight as ±0.005mm—on par with what I paid 3x more for in Germany.

Learn more about the typical CNC machining tolerance and the tight CNC machining tolerance.

How? Chinese shops invest heavily in high-end machines: Haas, DMG Mori, and even custom-built setups for complex geometries.

Speed is another killer advantage. A client needed a prototype for a medical device last quarter.

Their local US supplier quoted 3 weeks; the Chinese shop (ECOREPRAP, as it happens) turned it around in 5 days.

Why the difference? It’s not just longer workdays—it’s the ecosystem.

Tooling, materials, and skilled operators are all within a 100km radius in manufacturing hubs like Shenzhen and Suzhou.

Need a last-minute material switch?

They can source it overnight, while Western shops might wait a week for delivery.

Materials? Name it, they’ve got it. From standard aluminum 6061 and ABS to exotic stuff like PEEK and titanium.

I once needed a prototype in a specialized food-grade plastic—my US supplier said 6 weeks, China had it in 10 days.

The secret? China’s role as the world’s manufacturing hub means they’re already handling these materials for mass production, so prototyping is just a small step.

2.Why China’s Suppliers Beat the Competition?

Cost is obvious, but let’s talk specifics. A CNC prototype that costs $500 in the US might be $150-$200 in China. But here’s what most “gurus” won’t tell you: it’s not just labor. It’s the scale. Chinese shops run 24/7, so they spread fixed costs over more parts. They also have in-house secondary processes—anodizing, painting, assembly—that Western shops often outsource, adding time and cost.

Supply chain resilience is another factor. Remember the 2021 chip shortage?

My clients who relied on European suppliers for prototypes got stuck for months.

Those working with Chinese suppliers? They pivoted.

One found a local alternative material that met specs, another rerouted through a different port.

China’s manufacturing ecosystem is like a well-oiled machine—when one part creaks, another part compensates.

Experience matters too. Chinese CNC shops have been making prototypes for every industry under the sun for decades.

They’ve seen the mistakes, the edge cases, the “I didn’t think of that” moments.

A junior engineer at a US shop might scratch their head at your complex design; a Chinese shop foreman has probably made something similar last week.

How to Choose the Right CNC Prototyping Supplier in China?

Here’s where most people mess up. They Google “CNC prototyping China,” pick the first result with a flashy website, and wonder why their parts are garbage.

After vetting over 50 suppliers, I’ve learned that the best ones aren’t always the loudest.

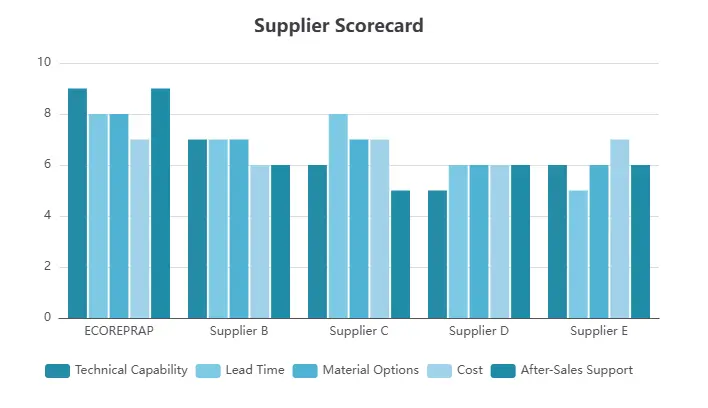

1.Key Factors When Selecting a Supplier

1)Technical Capability (Not Just Machines)

A shop can have all the fancy equipment, but if the programmers and operators don’t know what they’re doing, you’ll get scrap.

Ask for a sample part similar to yours.

I once had a supplier send me a “precision” prototype that had visible tool marks—they used the wrong cutting speed.

ECOREPRAP, on the other hand, included a inspection report with every dimension measured, which told me they cared about quality.

2)Material Sourcing

Avoid suppliers who can’t tell you where their materials come from.

Cheap aluminum might look the same, but it can warp during machining.

A good supplier will share material certifications—especially important for industries like aerospace or medical.

ECOREPRAP, for example, sources from Tier 1 suppliers and keeps certificates on file, which saved me a headache during a client’s FDA audit.

3)Production Capacity (Can They Scale?)

You might only need 10 prototypes now, but what if your product takes off?

I had a client who loved their small Chinese supplier for prototypes, but when they needed 1,000 parts for pre-production, the shop couldn’t deliver.

ECOREPRAP has both prototyping cells and production lines, so they can scale without dropping quality.

4)Lead Time Transparency

Beware of suppliers who promise “3-day delivery” without seeing your design.

Complex parts take time.

A good supplier will break down the timeline:

1 day for programming, 2 days for machining, 1 day for finishing.

ECOREPRAP once told me a part would take 7 days when others said 3—turns out, they were the only ones who noticed a design feature that required extra setup.

They delivered on day 7; the others would have missed the deadline or cut corners.

5)After-Sales Support

Mistakes happen.

The question is, how does the supplier fix them?

I had a supplier send parts with the wrong thread size.

They blamed my drawing and refused to redo them.

ECOREPRAP, when they messed up a surface finish on a prototype, overnighted replacements at their cost.

That’s the difference between a vendor and a partner.

2.Supplier Evaluation Checklist

Use this to grade potential suppliers (I’ve saved this as a template after too many bad experiences):

- Can provide 3+ client references in your industry

- Shares detailed process documentation (programming, machining, inspection)

- Has certifications relevant to your industry (ISO 9001, ISO 13485 for medical, etc.)

- Offers design for manufacturability (DFM) feedback before starting

- Provides a clear quote with no hidden fees (look for “setup charges” or “material surcharges”)

- Has a dedicated project manager (not just a sales rep)

- Uses cloud-based inspection reports (so you can check progress remotely)

- Offers secondary processes in-house (anodizing, plating, etc.)

- Has a clear rework/return policy in writing

Top CNC Prototyping Manufacturers & Suppliers in China

Let’s cut through the clutter. After years of trial and error, these are the suppliers I actually recommend to clients.

1.ECOREPRAP: The Gold Standard for Complex Projects

ECOREPRAP isn’t the biggest supplier in China, but they’re the one I trust with my most critical projects.

Here’s why:

Capabilities: They specialize in complex geometries—think aerospace brackets with undercuts, medical devices with micro-machined features.

Their 5-axis CNC machines handle parts up to 1000x800mm, and they have a cleanroom for sensitive components.

Materials: From basics like aluminum and stainless steel to high-performance plastics (PEEK, PTFE) and even composites.

They once sourced a rare magnesium alloy for a client’s lightweight prototype when no one else could.

Pricing: Mid-range, but worth it. For a typical aluminum prototype (100x100mm), they’re around $120-$180, which is 30% cheaper than US shops but 10-15% more than the cheapest Chinese suppliers.

You’re paying for quality control—their first-pass yield is 95% vs. 70% for budget shops.

Certifications: ISO 9001, ISO 13485, and AS9100 for aerospace.

They’re also ITAR registered, which is a must if you’re working on defense-related projects.

Turnaround: Standard prototypes in 5-7 days, rush orders in 2-3 days (with a 50% premium, but sometimes you need it).

What really sets them apart?

Their DFM feedback. I sent them a client’s design last month that had a thin wall section prone to warping.

Most suppliers would have just made it; ECOREPRAP suggested a slight redesign that maintained functionality but made machining easier.

The client saved 20% on costs and got a better part.

2.Other Worthy Contenders

1)RapidDirect

Good for simple prototypes and low-volume production.

They’re big, so they can handle large orders, but their attention to detail suffers on complex parts.

Pricing is similar to ECOREPRAP, but lead times are longer (7-10 days standard).

2)Prototek China

Strong on materials, especially plastics.

They have a wide range of 3D printing options too, which is useful if you need both CNC and additive prototypes.

Their weakness? They outsource secondary processes, so lead times can be unpredictable.

3)CNC Masters

Budget option—great for non-critical parts.

Prices are 20-30% lower than ECOREPRAP, but tolerances are looser (±0.02mm max).

I use them for early-stage prototypes where fit isn’t critical, but never for final validation.

Learn more:Top 5 Prototype Manufacturing Suppliers in China

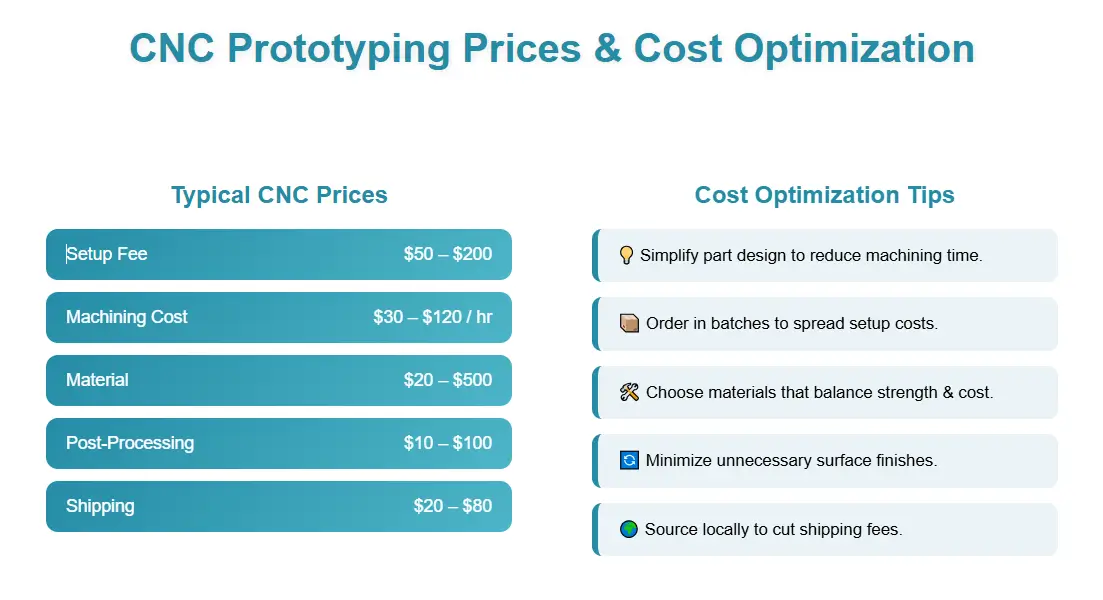

CNC Prototyping Prices & Cost Optimization

Let’s talk money. The first question clients ask is, How much will this cost? The answer?

It depends—but I’ll show you how to avoid overpaying.

1.What Drives CNC Prototyping Costs?

Material Choice: Aluminum 6061 is the cheapest (around $50-$100 for a small part), while titanium can be 5x that.

But don’t cheap out if you need specific properties.

A client once tried to use aluminum instead of stainless steel for a marine prototype—it corroded during testing, costing them more in rework than the material upgrade would have.

Part Complexity: A simple block with a few holes is cheap.

A part with 3D contours, tight tolerances, or internal features? Expect to pay more. Programming time goes up, and machining takes longer.

ECOREPRAP once quoted me $300 for a part with a 0.5mm tolerance that another shop said $150 for—turns out, the cheaper shop couldn’t actually hold that tolerance, so the $150 would have been wasted.

Batch Size: Making 1 prototype costs more per unit than making 10.

The setup time is the same, so spreading that over more parts lowers the per-unit cost.

For example, 1 aluminum part might be $150, but 10 could be $80 each.

Finishing: Anodizing adds $20-$50 per part, painting $30-$70, and plating even more.

If you don’t need the finish for testing, skip it to save money.

2.How to Optimize Costs Without Sacrificing Quality?

1)Design for Machinability

Work with your supplier on DFM.

Simple changes—like rounding sharp corners or increasing wall thickness—can cut costs by 30%.

ECOREPRAP’s engineers are great at this; they once redesigned a client’s part to reduce the number of setups from 3 to 1, saving $120 per unit.

2)Avoid Over-Tolerancing

Not every feature needs ±0.01mm.

If a hole just needs to fit a bolt, ±0.1mm is fine.

Tighter tolerances mean slower machining and more scrap.

I had a client specify ±0.02mm on a decorative part—no functional reason.

Loosening it to ±0.1mm cut the cost by 40%.

3) Consolidate Parts

Can one CNC-machined part replace two or three assembled parts?

It might cost more for the single part, but you’ll save on assembly time and reduce failure points.

4)Choose the Right Material Early

Don’t prototype in aluminum if the final part will be steel.

The properties are different, and you might miss issues.

But if you’re just testing form, a cheaper material is fine.

5)Order in Batches

If you know you’ll need multiple prototypes over time, order them together.

The per-unit cost drops, and you’ll have spares if one gets damaged during testing.

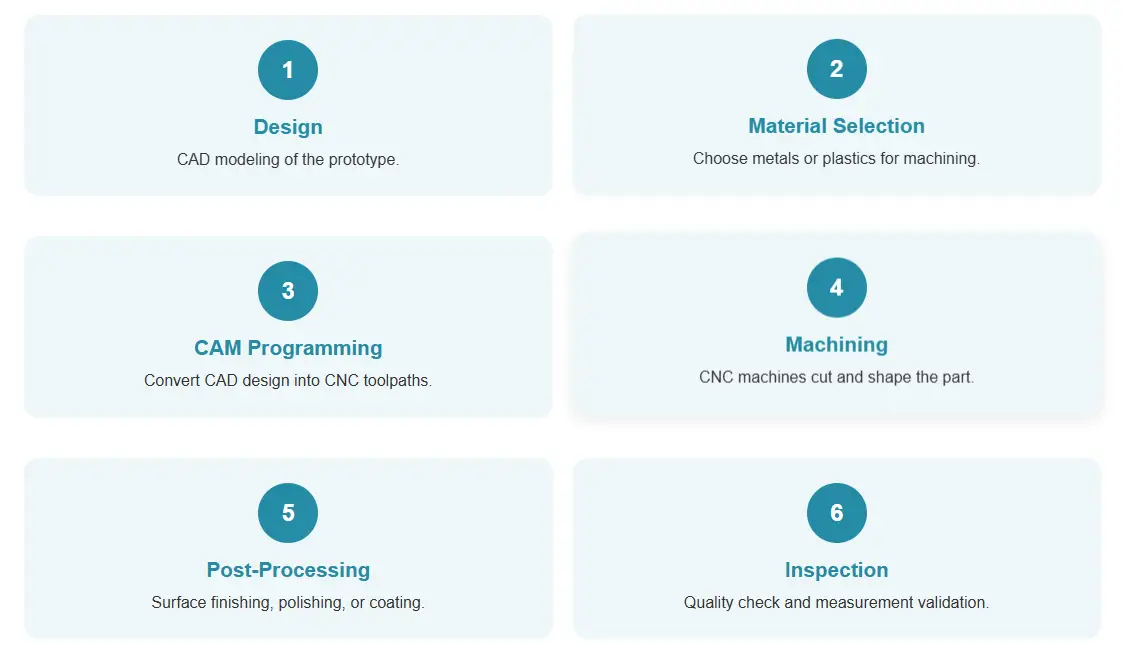

Step-by-Step CNC Prototyping Process

Ever wondered what happens to your CAD file after you hit “send”? Let me walk you through the process—knowing this helps you spot red flags.

1.From Design to Prototype

1)Design Submission & DFM Review

You send your CAD file (STEP or IGES is best—avoid PDFs).

A good supplier will review it for manufacturability.

ECOREPRAP does this within 24 hours, flagging issues like thin walls, impossible tolerances, or features that require special tooling.

This is where bad suppliers cut corners—they’ll skip the review to start machining faster, leading to mistakes later.

2)Quotation & Material Selection

Based on the design, the supplier sends a quote with material options, lead time, and cost.

Make sure the quote specifies tolerances, finish, and inspection methods.

I once got a quote that said “aluminum part” with no details—turns out, they used a cheap alloy that wasn’t suitable for my client’s needs.

3)Programming

The CNC programmer converts your CAD file into G-code—the instructions for the machine.

This is critical for complex parts.

ECOREPRAP uses Mastercam and GibbsCAM, which are industry standards, and they’ll sometimes send a simulation video so you can see how the part will be machined.

4)Material Preparation

The raw material is cut to size (called “stock preparation”).

For expensive materials, a good supplier will minimize waste by nesting parts.

I had a supplier once use a 12x12in sheet for a 2x2in part—ECOREPRAP would have fit 20 parts on that sheet, saving material cost.

5)Machining

The part is machined on CNC mills, lathes, or 5-axis machines, depending on the design.

Operators check dimensions periodically—ECOREPRAP uses in-process inspection with digital calipers and CMMs for critical features.

6)Post-Processing

Secondary operations like deburring (removing sharp edges), heat treatment, or finishing (anodizing, painting) are done.

This is where many shops outsource, but ECOREPRAP does most in-house, which keeps quality consistent.

7)Inspection & Quality Control

The final part is measured against your drawing.

ECOREPRAP provides a full inspection report with photos and measurements.

Cheap shops skip this—they’ll send the part and hope you don’t check.

8)Delivery

The part is packed (properly—ECOREPRAP uses anti-static bags for electronics parts) and shipped.

They use DHL or FedEx for reliability, whereas some shops use cheaper carriers that lose parts.

Case Studies & Use Cases

Talk is cheap—let’s look at real projects where ECOREPRAP delivered when others failed.

1.Case Study 1: Aerospace Bracket with Tight Tolerances

A client needed a prototype bracket for a drone. The design had a 0.01mm tolerance on a critical hole to fit a sensor.

Their first supplier sent parts that were 0.03mm off—they blamed the machine.

ECOREPRAP’s approach: They checked the design first and noticed the hole was near a thin section, which could warp during machining.

They suggested a small fillet to strengthen the area, then used a specialized cutting tool for the hole.

Their first sample was within 0.008mm of spec.

The client went from failed tests to successful validation in one iteration.

2.Case Study 2: Cost Reduction for Consumer Electronics

A client had a smartphone case prototype that was costing $250 each from a US supplier.

They needed 5 prototypes for testing.

ECOREPRAP suggested switching from stainless steel to aluminum (the client only needed to test fit, not durability) and simplified a decorative groove that didn’t affect function.

The result? $80 per part, 5 prototypes for $400 instead of $1,250.

The client saved enough to fund an extra round of user testing—and the aluminum prototypes worked just as well for fit checks.

These cases aren’t anomalies—they’re the result of a supplier that cares about your success, not just shipping parts.

ECOREPRAP doesn’t just machine prototypes; they solve problems.

That’s why I keep going back.

FAQs About CNC Prototyping Services in China

Let’s tackle the questions I get asked most often—these are the ones that trip up even experienced buyers.

1. How do I verify a Chinese CNC supplier’s quality before ordering?

Don’t just take their word for it. Ask for a “first article inspection report” (FAIR) from a recent project similar to yours. It should include measurements, photos, and material certificates.

ECOREPRAP sends these voluntarily, but most suppliers will drag their feet—if they can’t provide one, walk away.

You can also order a small, simple test part first (like a block with a few holes) to check their tolerance control and finish quality.

It’s a small investment to avoid a big headache.

2. What’s the typical lead time for CNC prototyping in China, and how can I speed it up?

Standard lead times are 5-10 days, but rush orders can be 2-3 days with a 30-50% premium. To speed things up:

- Provide a complete CAD file (STEP/IGES, not a 2D drawing)

- Specify tolerances only for critical features (no “±0.01mm everywhere” unless needed)

- Pre-approve material options so the supplier doesn’t wait for your OK

ECOREPRAP has a “rush team” that prioritizes urgent orders, but even they’ll tell you if a deadline is impossible—unlike some shops that promise the moon and miss by a mile.

3. Which materials are best for CNC prototyping in China?

It depends on your needs:

- For fit/function tests: Aluminum 6061 (cheap, easy to machine) or ABS plastic

- For strength tests: Stainless steel 304 or titanium (if weight matters)

- For high-temperature applications: Inconel or PEEK plastic

- For medical use: Titanium Grade 23 or PEEK (both biocompatible)

ECOREPRAP’s material experts can recommend alternatives if your first choice is expensive or hard to machine.

For example, they once suggested aluminum 7075 instead of titanium for a drone part—it was lighter and cheaper, with enough strength for prototyping.

4. How do I handle communication issues with Chinese suppliers?

Language barriers are real, but avoidable.

Look for suppliers with English-speaking project managers, not just sales reps.

ECOREPRAP assigns a dedicated PM to each project who responds to emails within 4 hours and can hop on a Zoom call to review drawings.

Also, use visual aids: mark up CAD files with notes, send photos of similar parts, and confirm measurements in both metric and imperial if needed.

I once had a client avoid a mistake by circling a critical dimension in red on the drawing—sometimes a picture is worth 1000 words.

5. What’s the difference between prototyping and low-volume production in China?

Prototyping focuses on speed and accuracy to test a design, while low-volume production (10-500 parts) balances quality with cost.

Prototyping might use general-purpose tools, while production uses custom fixtures for consistency.

ECOREPRAP seamlessly transitions from prototype to production—they’ll reuse the same CNC programs and inspectors, so you don’t get “surprises” when scaling up.

A client once tried to switch suppliers for production and ended up with parts that didn’t match the prototype—sticking with ECOREPRAP avoids that hassle.

6. How can I ensure my intellectual property is protected?

This is a valid concern, but manageable. Sign a non-disclosure agreement (NDA) before sharing designs—ECOREPRAP has standard NDAs and will customize them if needed.

Avoid sharing more than necessary: send only the drawings for the part, not your entire product roadmap.

Also, work with established suppliers with a track record—fly-by-night shops are the ones to worry about.

I’ve never had an IP issue with ECOREPRAP in 5 years, and they’ve handled everything from consumer gadgets to aerospace parts.

Final Thoughts: Why ECOREPRAP Stands Out in China’s CNC Crowd

After years of navigating China’s CNC prototyping landscape, I’ve learned that the best suppliers aren’t just about machines or prices—they’re about partnership.

ECOREPRAP gets this.

They don’t just take your order; they invest in your success by:

- Asking tough questions to improve your design

- Being honest about what’s possible (and what’s not)

- Standing behind their work with rework guarantees

- Growing with you from prototype to production

Sure, you can find cheaper suppliers in China. But as I’ve seen too many times, saving $50 on a prototype can cost you $5,000 in rework, delays, or failed tests.

ECOREPRAP isn’t the cheapest option—but they’re the one that will make you look good to your boss, your clients, or your investors.

If you’re ready to stop chasing low prices and start getting reliable prototypes, reach out to ECOREPRAP.

Tell them I sent you—they’ll know to bring their A-game. And if you want to compare other options, use the checklist in this guide.

Either way, you’ll be ahead of 90% of buyers who just pick the first supplier they find.

Remember: A great CNC prototype isn’t just a part—it’s the first step toward a successful product. Choose wisely.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.