CNC robots are suitable for flexible machining. CNC machining is more suitable for high-precision machining.

What Is CNC Machining?

- Milling: CNC milling involves removing material from a workpiece to create the desired shape.

- Turning: CNC lathes are used to create cylindrical parts.

- Drilling: CNC drilling involves making precise holes in the workpiece.

- Cutting: CNC cutting allows for very precise cutting of materials such as metal, plastic, and wood.

- Grinding: CNC grinding machines use rotating grinding wheels to remove material and polish a smooth surface on the workpiece.

- 3D Printing: This process creates parts layer by layer, allowing for complex geometries that are difficult to achieve with traditional methods.

What Is CNC Robotics?

CNC Machines And Robots: What Are The Differences?

CNC machines and robots each have their own unique strengths and can fulfill different aspects of manufacturing. While they may look similar at a glance, they have different functions and shine in different areas.

Precision and Accuracy

CNC machines are designed for tasks that require tight tolerance control. They can produce highly accurate parts over and over again, making them ideal for applications where precise measurements and consistency are critical.

In the aerospace industry, for example, CNC machines create complex components that must adhere to strict specifications to ensure safety and performance.

Robots, while precise, are often used in situations where flexibility is more important than extreme accuracy.

They are well suited for tasks that require adaptability, such as assembling complex products or performing quality inspections.

Robots can adjust their actions based on real-time feedback from sensors, making them highly versatile in dynamic environments.

Versatility and Flexibility

Robots excel in versatility and flexibility. They are capable of performing a wide range of tasks, from welding and painting to packaging and palletizing.

Robots can be easily reprogrammed to adapt to new tasks, making them invaluable in industries that require frequent line changes, such as electronics manufacturing and automotive assembly.

CNC machines, on the other hand, are specialized for specific tasks. Once set up for a specific operation, they perform efficiently but lack the flexibility to easily switch between different types of tasks.

Reprogramming CNC machines is a complex process that often requires significant downtime, which makes them unable to adapt to frequent changes in production requirements.

Task Complexity

CNC machines are best suited for complex machining operations that require consistent precision.

They specialize in tasks such as milling, turning, and drilling that require extreme precision in material removal. These machines can machine complex parts with fine details.

Robots are well suited for tasks that involve multiple steps, such as assembly and material handling.

They can perform sequential operations, move parts from one station to another, assemble parts, and even perform quality checks.

This capability makes robots the best choice for production lines that manufacture complex products through a series of automated steps.

Control and Programming

CNC machine tools are programmed using G-code, a language that specifies precise tool movements and operations.

G-code programming focuses on precise coordinates, speeds, and feeds to ensure a high degree of control and accuracy in the machining process.

Robots use a variety of programming languages, including proprietary robotics languages as well as more common languages such as Python and C++.

In addition, robots can incorporate artificial intelligence and machine learning algorithms to adapt their behavior based on sensory input and changing conditions.

This adaptability allows robots to handle more complex and varied tasks, making them suitable for environments where conditions may change frequently.

Related Reading: mill vs lathe machine: what’s the difference?

CNC Machines And Robots: What’s The Connection?

CNC machines and robots can be integrated to perform complex manufacturing tasks more efficiently. By combining the machining precision of a CNC machine with the versatility of a robot, manufacturers can automate the entire production line, from material handling to final assembly.

Material Handling Automation

Robots can automate the loading and unloading of materials into and out of CNC machine tools, thereby reducing manual labor and speeding up the production process. For example, a robot can pick up raw materials, place them into a CNC machine for processing, and then transfer the finished part to the next station.

Increased Production Flexibility

CNC machine tools are highly accurate but lack flexibility. Robots make up for this by performing a variety of tasks, such as moving parts between different CNC machines or assembling components. This combination enables manufacturers to quickly adapt to changing production requirements and customize workflows.

Improved Quality Control

Robots equipped with sensors can perform detailed inspections of parts produced on CNC machines. They can detect defects or deviations from specifications, ensuring that only high-quality products reach the market. This automated quality control reduces waste and improves the overall reliability of the product.

Streamlining the Assembly Process

After parts are machined on a CNC machine, robots can take over assembly tasks. They can handle precision or complex assemblies that require accuracy and repeatability. This integration simplifies the production process and reduces the time and cost of manual assembly.

Robotics Commonly Used in CNC Machining

Robots used in CNC machining come in many forms, each designed to handle a specific task. Here are some of the most commonly used robots in the CNC machining environment:

Articulated Robots

Articulated robots have rotating joints that allow them to move in multiple planes, making them very versatile. They are commonly used for tasks such as welding, material handling, and assembly.

Cartesian Coordinate Robots

Cartesian coordinate robots move along a linear path in the X, Y, and Z axes. They are often used for tasks requiring high precision, such as CNC machining and 3D printing.

Scara Robotics

SCARA (Selective Compliance Articulated Robotic Arm) robots are ideal for pick-and-place tasks, assembly, and packaging. They are compact in design, fast, and highly accurate.

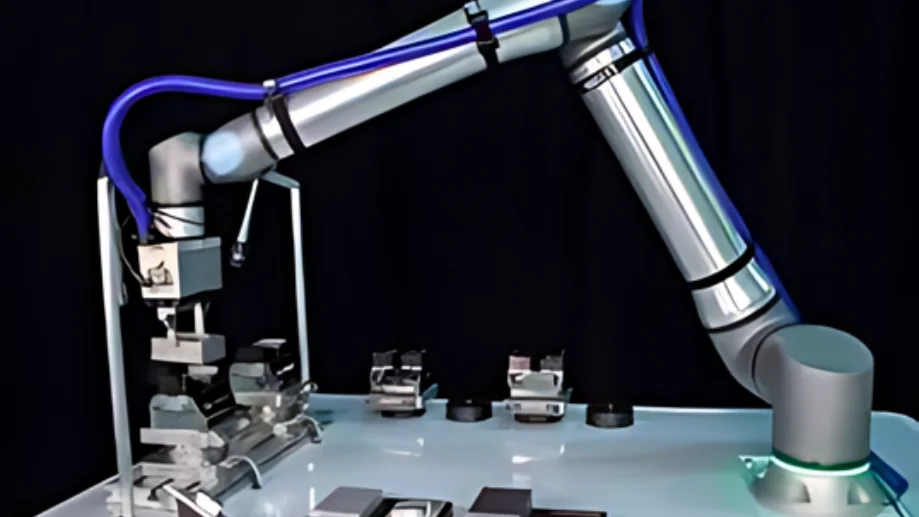

Collaborative Robots (Cobots)

Collaborative robots are designed to work alongside human operators. They are used for tasks that require human-robot collaboration, such as assembly and quality inspection.

Related Reading: types of CNC machines you need to know

Common CNC Robot Parts Manufactured Using CNC Machining

CNC machining can be used to manufacture a variety of robot parts, ensuring high precision and durability. Here are some common parts manufactured through CNC machining:

Robotic Arms

The structural parts of a robotic arm, including joints and connectors, are often machined to precise specifications. These parts need to be robust and reliable to handle repetitive tasks.

End-effector

End-effector or robot “hands” come in many forms, such as grippers, torches, and suction cups. CNC machining ensures that these parts perform specific tasks with high precision.

Motor Housings

Motor housings are used to protect the motors that drive the robot’s movements. They are machined to precise dimensions to ensure proper fit and function.

Will CNC Robots Replace CNC Machines?

Should You Choose a Robot or a CNC Machine?

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.