Table of Contents

Datum target makes crucial effects on manufacturing and inspection processes in Geometric Dimensioning and Tolerancing(GD&T) when a feature’s entire surface is unsuitable for creating a datum. This article will comprehensively explain the concept of datum target.

Key Takeaways:

- A Datum Target is a specific point, line, or area on a part used to establish a measurement reference when the entire surface is too irregular, warped, or large to serve as a reliable datum feature itself.

- Datum Targets are identified on drawings by a unique symbol—a circle split by a line. The symbol specifies the datum letter, target number, and the size/shape of the target area (point, circle, or rectangle), connected to the feature with a leader line.

- Datum Targets are the physical application points for the “3-2-1” principle, which uses three targets on the primary datum, two on the secondary, and one on the tertiary to fully constrain a part in space, creating a repeatable coordinate system for manufacturing and inspection.

- The core function of Datum Targets is to ensure consistent and repeatable fixturing and measurement for parts with complex geometries, reducing errors caused by part-to-part variation, distortion, or surface imperfections.

1. What is Datum Target in GD&T?

A datum target in Geometric Dimensioning and Tolerancing(GD&T) can be a specific point, line, or certain area on surfaces or edges of a part.

Usually, an entire surface would be selected as a datum for reference, but when the surface is complex or irregular as a whole, it is unsuitable for creating a datum. This is where a datum target comes into play.

Datum targets define a precise location on a part where measurement and inspection equipment can make contact, ensuring consistent and repeatable measurement.

By restraining the contacting position between the feature and measurement machine, datum targets serve as additional information to figure out the datum. And engineers usually use multiple datum targets to establish the datum.

2. How to Show Datum Target on Engineering Drawings?

The indications of datum targets are different from that of datums. It is important to pinpoint the target position accurately and indicate the crucial information of the datum target’s type.

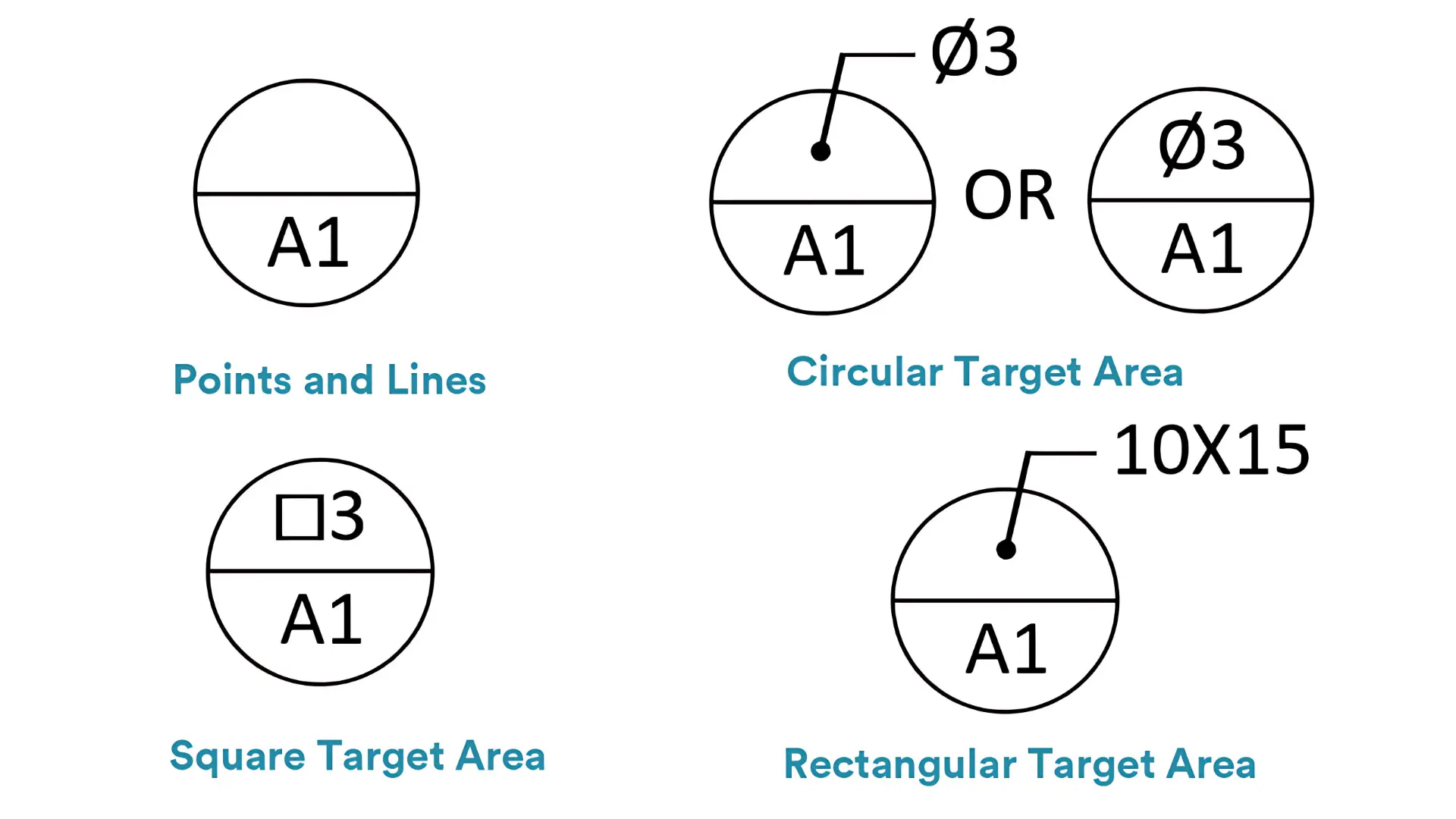

2.1. Datum Target Symbol

The datum target symbol is a circle with a horizonal line inside at the half to divide it into two even portions.

The lower portion contains a letter with a number right beside. The letter is associated with the datum which the datum target locates on. And the number is sequential to distinguish each datum target, but not related to priority. However, as we all know, letters A, B, and C are sorted by priorities.

The utter portion is relative to the dimension of the datum target. If the datum target is a point or a line, is it left blank. If the datum target is a limited area, the utter portion will contain the shape and size information of the area.

If the area is a circle, the diameter size will be contained inside the utter half with a diameter symbol left, or will be pointed to the utter half by a bent line.

If the area is a rectangular target area, the side length will be pointed to the utter portion, usually with the width left and the length right.

If the area is a square target area, the utter portion will contain a square symbol left and the side length right.

2.2. Datum Targets on an Engineering Drawing

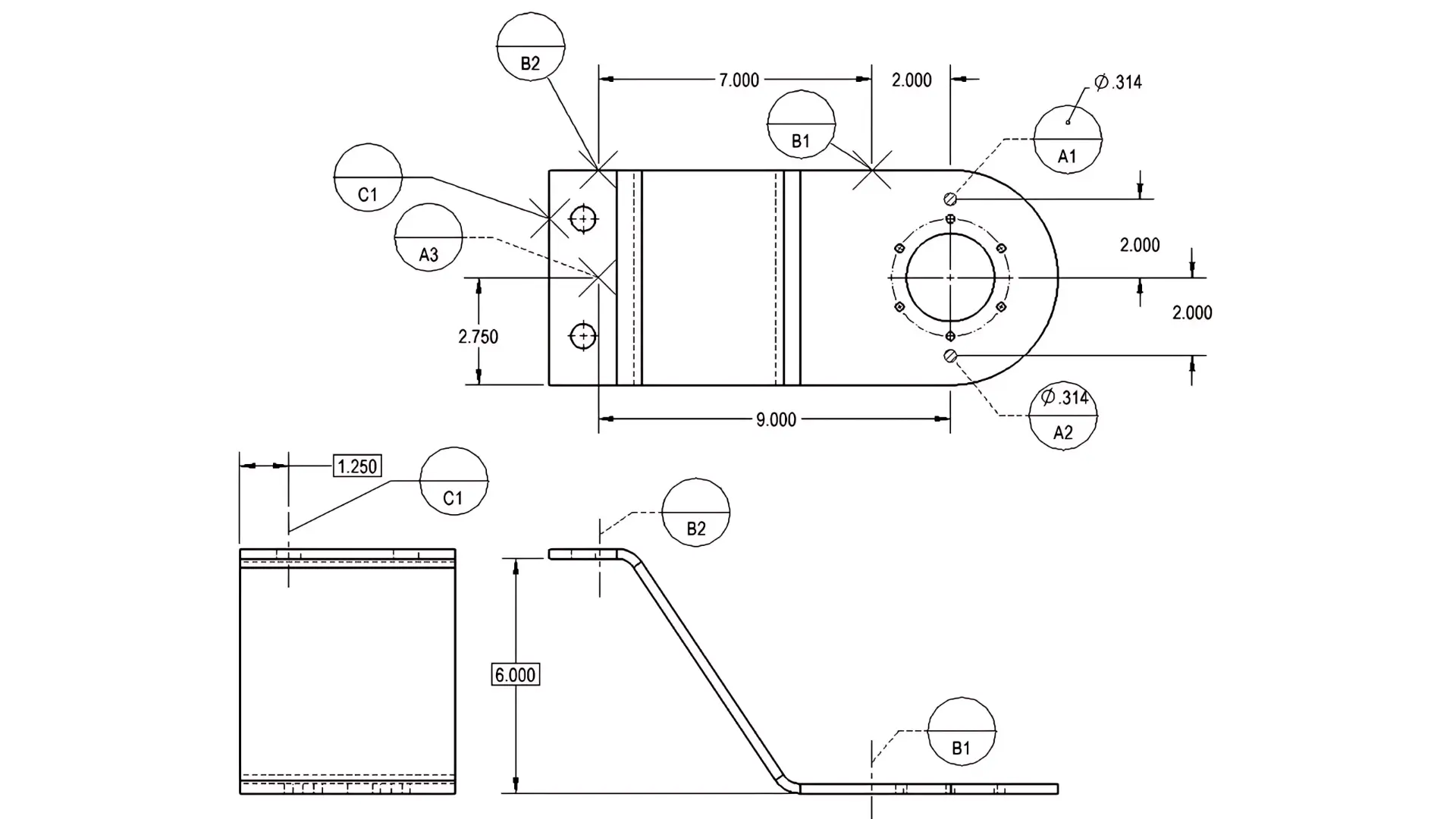

Datum targets are indicated on engineering drawings by datum target radial lines and different indicational symbols.

2.2.1. Datum Target Radial Line

Datum targets are usually connected with a radial line that points to the datum feature. Datum target radial lines are either solid or dashed.

If the line is solid, the datum target is on the drawing side of the feature. While a dashed line suggests that the datum target is on the opposite side of the drawing.

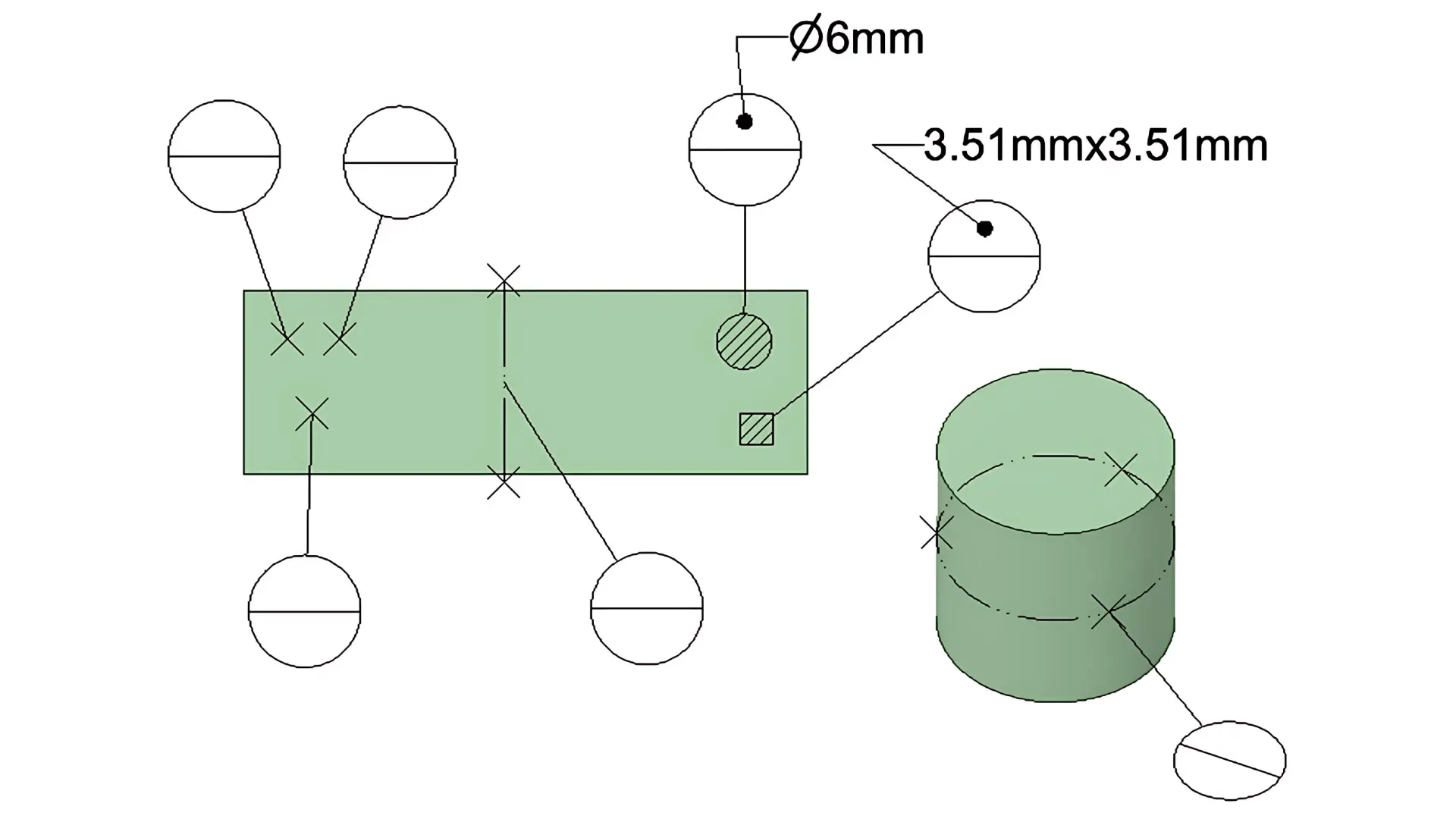

2.2.2. Datum Targets Points

Just as the datum target “A3” above shows, a datum target point is identified on an engineering drawing by its X-shaped symbol. The single point where a X-shaped symbol locates on refers to the contacting position between the datum simulator and the part.

And to locate the point accurately, a datum target point will be dimensioned directly in a direct view of the surface. If there is no direct view, the point will be dimensionally located on two adjacent views.

2.2.3. Datum Target Lines

The datum targets B1, B2, and C1 above are all datum target lines. The indicational symbol of datum target lines is similar to that of datum target points, also a X-shaped symbol.

The X-shaped symbol is indicated on the drawing to show the line’s location on the part. Furthermore, the datum target line will also be indicated on another view by the dimensionally located dotted line to accurately show the line contacting position between the datum simulator and the part.

What’s more, datum target lines would be indicated commonly by the edge of a cylindrical gauge pin. And if required, the length of the line can also be indicated on the drawing.

2.2.4. Datum Target Areas

The datum targets A1 and A2 above are both datum target areas. Usually, datum target areas are indicated by crosshatched area on engineering drawings.

If the datum target area is a circle, then the crosshatched area is also a circle. If the datum target area rectangular, then then crosshatched area is rectangular.

3. 3-2-1 Method Used for Datum Target

As we have explained above, an irregular surface of a feature cannot be used as a datum as a whole. In such a case, datum targets are applied to establish a datum reference frame with 3-2-1 location method.

A datum reference frame usually has six degrees of freedom. They are respectively linear translations in the X, Y and Z axes, and rotations around the three axes. By constraining the part to datum targets, the 3-2-1 method can gradually eliminate these degrees of freedom and then accurately fix the feature location.

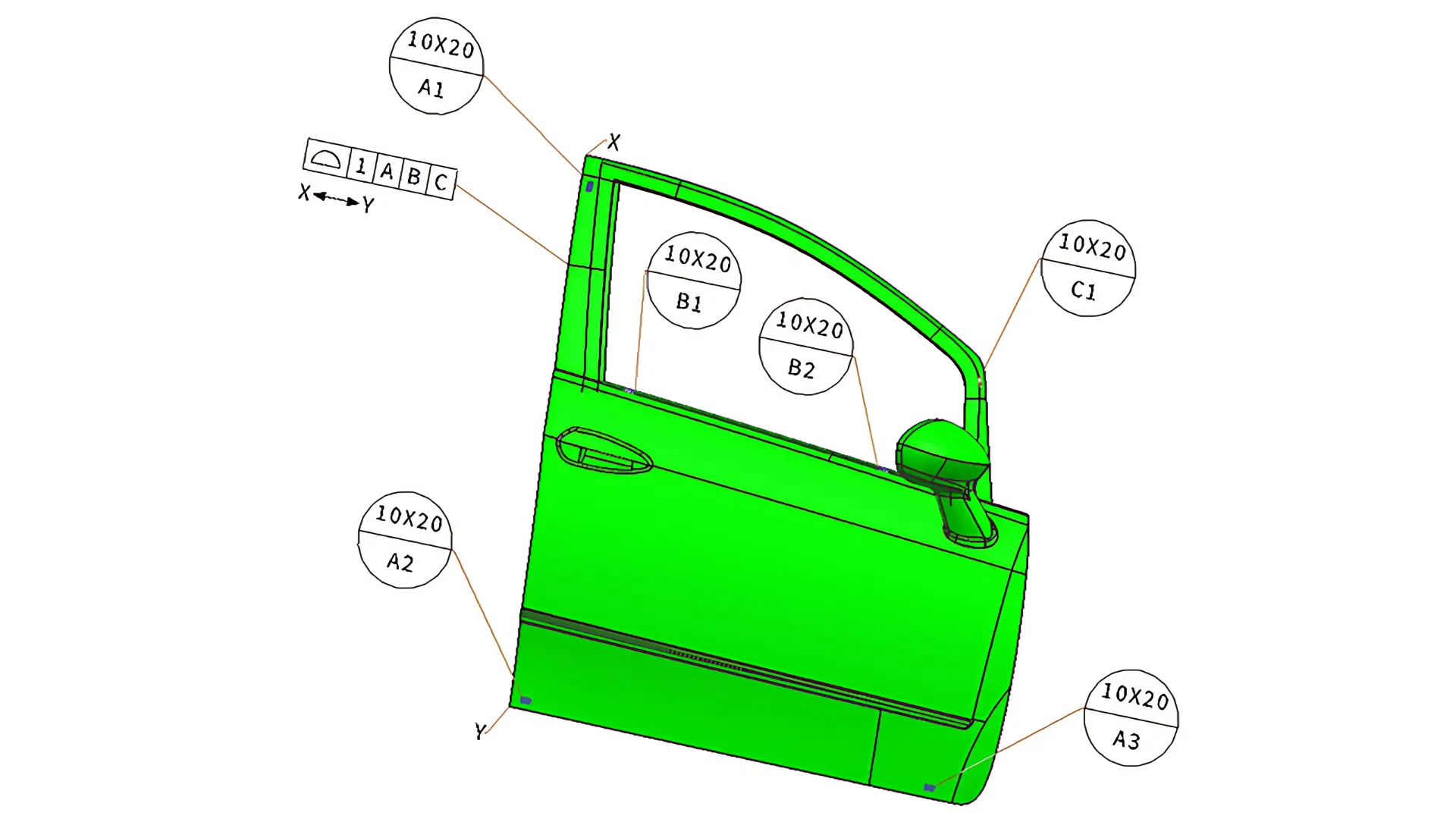

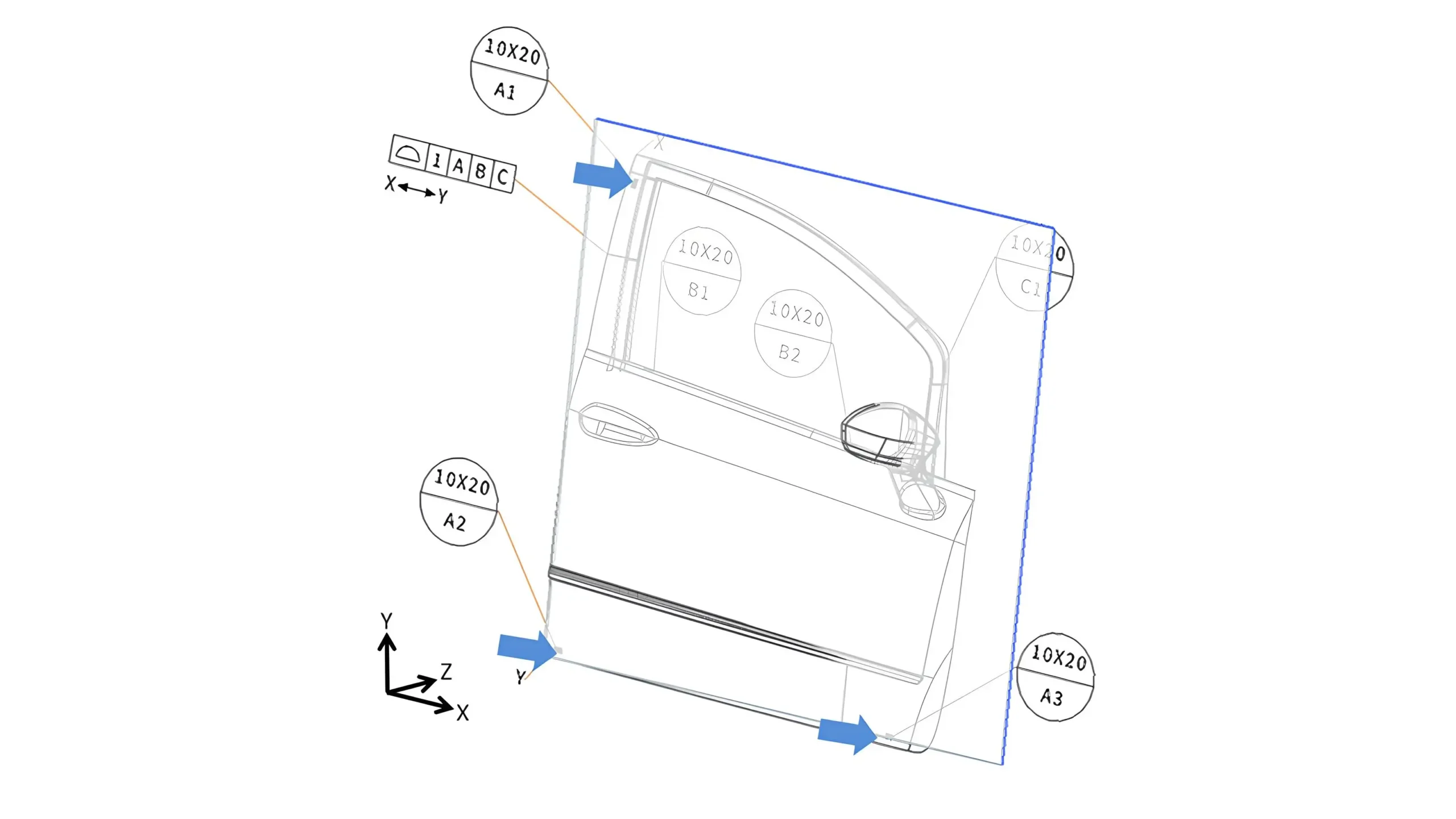

Here we will take an entire surface of an automotive part as an example.

One: 3 Datum Targets on the Primary Datum

The first step to establish the datum reference frame is to select the primary datum and choose 3 positions for datum targets on the datum.

Usually, the largest surface of the part would be selected as the primary datum. And the 3 datum targets would be located as far apart as possible for stability.

In this example, since the surface is large enough, we use 3 datum target areas for simulated datums. They are datum targets A1,A2 and A3 in Figure 1.

Therefore, the translation in the Z-axis and rotations around the X-axis and Y-axis are eliminated by these three datum targets on the primary surface.

Primary datum plane defined by three datum target areas (A1, A2, A3)

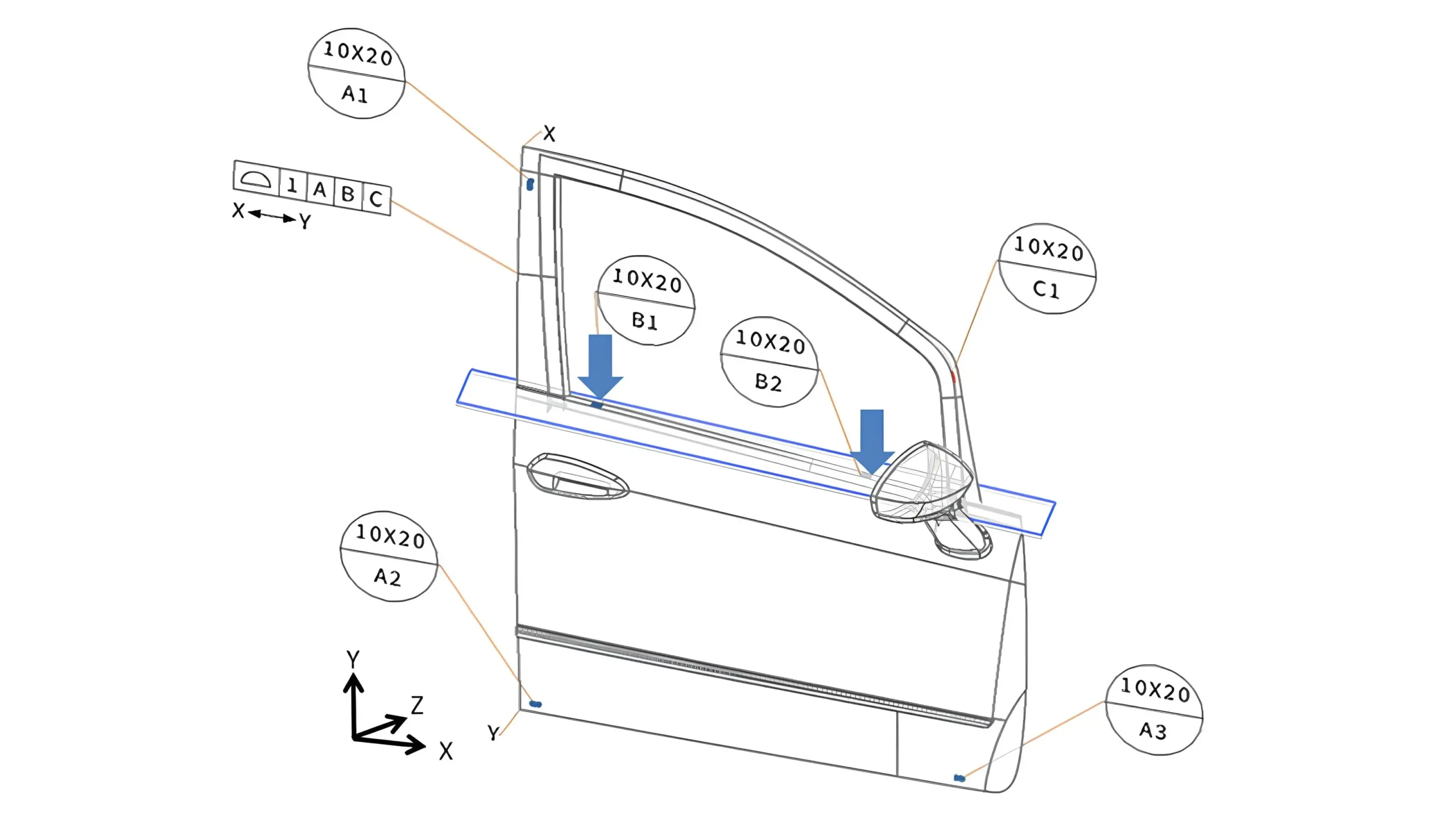

Two: 2 Datum Targets on the Secondary Datum

And then the second largest surface which is perpendicular to the primary datum would be select as the secondary datum usually. At the same time, two datum targets are to be selected on the secondary datum.

In this case the two datum targets are B1 and B2 in Figure 2, with which translation in the Y-axis and rotation around the Z-axis are eliminated.

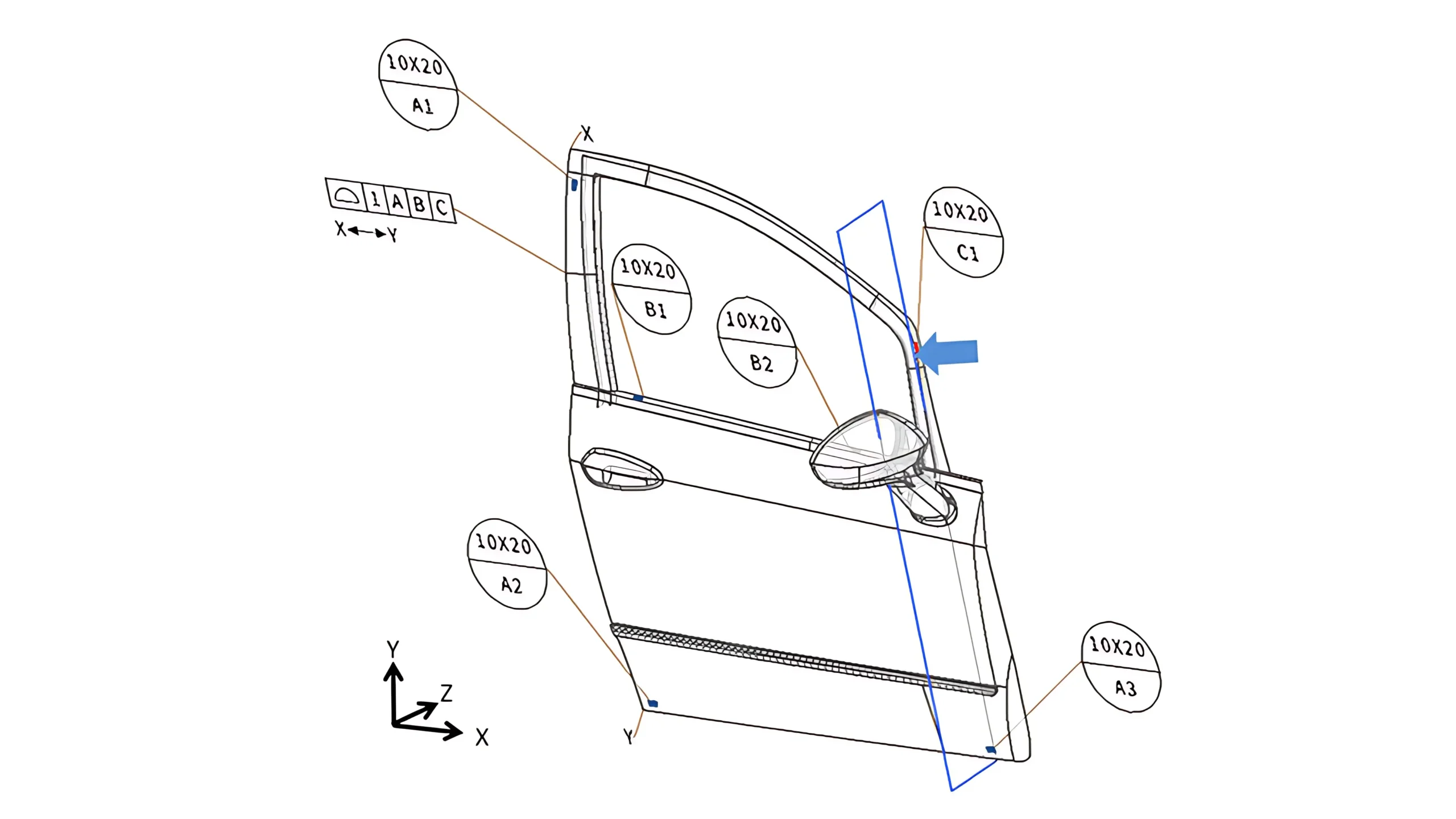

Three: 1 Datum Targets on the Tertiary Datum

Finally, a surface which is perpendicular to both the primary and secondary datums would be selected as the tertiary datum, and just one datum target is required on the surface.

Datum target area C1 in the Figure 3 is the one in this example. It is used to eliminate the translation in the X-axis.

4. What are Functions of Datum Target?

There is no denying that Geometric Dimensioning and Tolerancing(GD&T) benefits much from datum targets. The main functions of datum targets are as follows.

- To Establish Datum Reference Frame

Using multiple datum targets can establish datum reference frame to simulate ideal geometric features. With the stable coordinate system established, datum targets define precise locations on a part where measurement and inspection machines can make contact. Thus, consistent and repeatable measurements are made sure.

- To Address Complex Geometries

If an irregular or otherwise shaped inappropriately plane is defined as a datum, a significant error is easy to appear during processing or inspection. Datum targets come into play in such situation. They offer a way to establish datums that accurately represent the intended design, especially for cast, forged, or molded parts.

- To Reduce Variability

By specifying exact points or areas for contact, datum targets minimize measurement errors and inconsistencies that can arise from variations in part geometry. Meanwhile, contact press would be dispersed to reduce variability that might be caused by distortion of thin parts.

5. Datum Target VS Datum Feature

Datum features are real, physical, and tangle features of a part, like an entire surface or feature of size. They are used to serve as reference for making measurements.

Datum features are applied to establish datums for an entire feature, especially for surfaces with regular form or features with high accuracy. But note that datum features are not perfect and ideal.

Besides, the symbol of datum features are different from that of datum targets. They are indicated as capital letters in boxes and are connected with the specific datum feature by a black triangle.

Compared with datum features, datum targets are not complete and entire features. They are just points, lines, or areas that are used to simulate the datum feature. Datum targets come into play when an entire surface is too irregular or large to be defined as a datum.

Both datum features and datum targets are the contacting position between measuring machines and the part. Datum targets make crucial effects on irregular, flexible, and large components, or the parts that needs less contacting area.

6. Conclusion

In essence, datum targets provide practical means to establish datums for features that are not suitable to serve as datums. If you meet any problem on datum target, contact with us directly.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.