Table of Contents

As a fundamental geometric parameter in engineering and manufacturing, Diameter is a core element of the GD&T (Geometric Dimensioning and Tolerancing) system. It defines the overall dimensions of a circular or spherical feature, which directly affects the assembly, functionality and manufacturing process of the part.

This article systematically introduces the definition of Diameter, labeling rules, application scenarios and machining guidelines, and clarifies its difference from Radius, Radius of curvature and other confusing concepts.

Key Points:

- Diameter is a core GD&T parameter defining the size of circular features, symbolized by “⌀”. It is distinct from Radius (R) as it represents the full width across the center (⌀ = 2R).

- Accurate diameter specification is vital for ensuring assembly compatibility (e.g., shaft-hole fits), guiding tool selection (e.g., drill bits), and optimizing functional aspects like structural strength and fluid flow.

- Achieving precise diameters involves a controlled machining process (tool selection, parameter setting) and verification with appropriate measurement tools, ranging from simple calipers to high-precision CMMs, depending on the tolerance requirements.

1. What is Diameter?

A Diameter measures the linear distance across a circular or spherical feature.The term “Radius” is defined as the length of a line segment that passes through the center of a circle or sphere and connects two points on its circumference.

The symbol used to represent the Radius is “⌀,” and the Radius is equal to twice the Radius (⌀ = 2R). In geometry, the Diameter determines the overall span of a circular feature and is a key parameter for describing the dimensions of holes, shafts, spheres, etc.

2. Labeling of Diameter in Engineering Drawings

The Diameter symbol “⌀” is the unique identifier in engineering labeling and consists of a perfect circle in which a 45° straight line extends beyond the circle. It is clearly distinguished from the Radius symbol “R”. In the GD&T system, the rules for the labeling of Diameters are both related to and specific to conventional dimensioning, and the following are the core points:

2.1. Specific Labeling Rules

Specific rules include the use of Diameter symbols and dimensioning rules:

2.1.1. The Use of Diameter Symbols

The symbols are expressed as follows:

The Diameter symbols are uniformly used as “⌀” (U+2300), which is different from “φ” in conventional dimensioning, and this symbol needs to be strictly regulated in the GDT frame.

2.1.2. Dimension Annotation Rules

Basic dimension annotation:

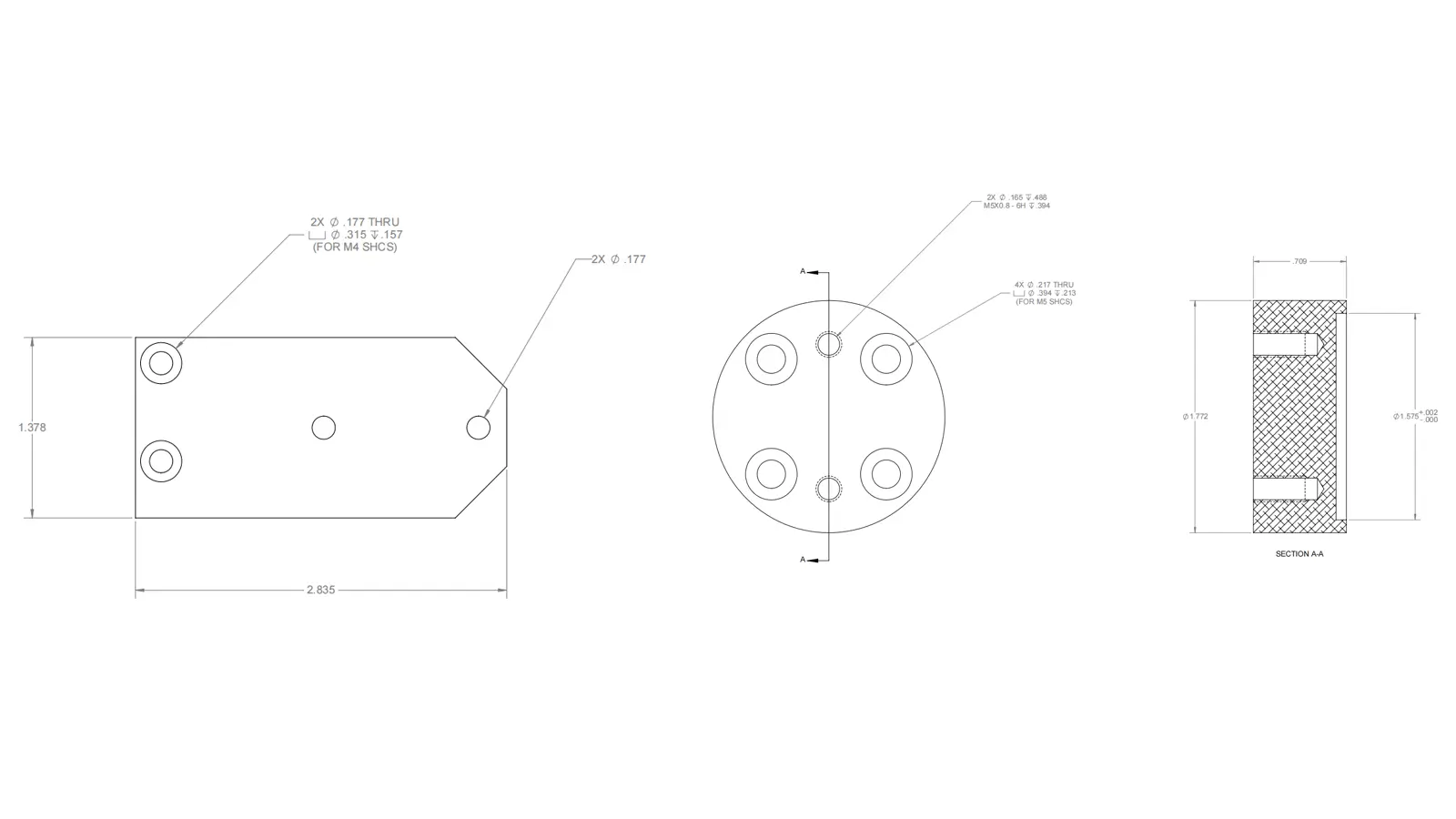

Diameter dimensions need to add “⌀” before the number, such as “⌀50”, and the dimension line must pass through the center of the circle, with arrows pointing to both sides of the circumference (same as conventional engineering drawings).

In the case of multiple holes of the same Diameter, the dimension is labeled as “n×⌀D” (e.g., “4×⌀10”), which is the same as the conventional labeling.

Association of tolerances with dimensions:

When dimensions need to be associated with a form and position tolerance, it is necessary to make it clear in the dimension line or in the tolerance box frame:

Example: the shaft Diameter is labeled as “⌀20±0.05 Ⓒ”, where ” Ⓒ” denotes the Diameter Inclusion Principle (Envelope Principle), i.e., the actual element must lie within the ideal cylindrical surfaces with Diameters of 20.05mm and 19.95mm.

2.2. Annotation Example Comparison Table

| Scenario | Labeling Structure | Interpretation |

| Single 2D hole | ⌀20mm | A 2D hole with a Diameter of 20mm, without tolerance or datum requirements. |

| Multiple spherical features | 4×S⌀50mm±0.02mm | 4 spherical features with a Diameter of 50mm and a tolerance of ±0.02mm. |

| Hole with datum positioning | ⌀35mm Ⓑ | A hole with a Diameter of 35mm, positioned centered on datum B. |

| Cylindrical feature with straightness | ⌀18mm Ⓒ ║ 0.03mm | A cylindrical feature with a Diameter of 18mm, whose axis straightness is within 0.03mm relative to datum C. |

3. Applications of Diameters

Diameters find extensive application in mechanical engineering, electronics, aerospace, and other fields.They are the basis for defining feature dimensions, selecting tools, and ensuring assembly compatibility.

3.1. Main Functions of the Diameter Feature

Function 1: Dimension Definition and Assembly Compatibility

Diameter directly determines the overall dimensions of holes, shafts, and cylindrical parts, and ensures an exact fit, e.g., a ⌀20 mm shaft forms a clearance fit with a ⌀20 mm hole.

Function 2: Tool Selection and Processing Reference

Diameter guides the selection of cutting tools, e.g., ⌀10mm holes require ⌀10mm drills and processing parameter settings to enhance productivity.

Function 3: Structural Strength and Fluid Dynamics Optimization

In piping and mechanical components, the Diameter has an impact on both fluid flow and structural load carrying capacity, e.g., a pipe with a Diameter of 50mm will have a determining effect on the fluid flow rate, and the Diameter of a mechanical shaft will affect its torque resistance.

3.2. Application Scenarios of Diameter Characteristics

As a fundamental parameter in engineering design, the dimensional accuracy of Diameter features is directly linked to the realization of functional requirements and structural reliability across various application scenarios. This correlation will be elaborated on in detail through the following four dimensions:

Bolt and shaft connection

For example, ⌀12mm bolt holes in the flange need to be matched to the bolt Diameter in order to ensure the strength of the connection; the hole Diameter is usually 0.1-0.2mm larger than the bolt for mounting.

Bearing and bushing mounting

For example, the bearing bore (e.g., ⌀30mm) must precisely match the shaft Diameter to prevent rotational play, and the outer Diameter (e.g., ⌀55mm) needs to align with the housing bore for secure positioning.

Piping and fluid system design

For example, ⌀100mm water pipe with balanced flow rate and pressure loss based on hydrodynamic calculations to meet transmission requirements.

Electronics and Consumer Products

For example, The Diameter of a round battery compartment (e.g., ⌀25mm) needs to be matched to the battery size, and the Diameter of the screw holes in the product’s enclosure ensures fastener compatibility.

4. Diameter Processing Guidelines

Accurate Diameter control is essential for meeting design requirements.The following processes and techniques ensure dimensional accuracy and surface quality during the machining process.

4.1. Diameter Machining Process

Step 1: Tool selection

Selection of machining tools is based on the size of the machining Diameter and the characteristics of the workpiece material.

For smaller Diameters or conventional materials, high-speed steel drills can be used; for processing of large Diameters, carbide end mills are more suitable; if you need to achieve high-precision aperture requirements, you need to use reamers and other fine processing tools.

Step 2: Workpiece clamping and centering

Use vise, special fixtures and other tools to clamp the workpiece firmly, and with the help of measuring instruments such as a percentage meter, align the machine coordinate system accurately with the workpiece datum.

At the same time, use the center punch to mark the center of the hole on the workpiece to provide a clear guide for subsequent machining.

Step 3: Parameter setting

According to the material properties of the workpiece and the machining Diameter, set the spindle speed scientifically to balance the cutting efficiency and the machining quality, and reduce the surface defects.

Reasonably determine the feed rate and flexibly adjust it according to the hardness of the material to ensure the stability of the machining process.

Reserve appropriate cutting allowance for subsequent reaming, grinding and other finishing processes to lay the foundation to ensure that the final high precision requirements.

Step 4: Machining execution

When CNC machining, according to the needs of the machining process, the use of linear interpolation instructions for drilling; milling holes in the process, the tool Radius compensation function is enabled to enhance the machining accuracy.

Manual machining follows the principle of pre-drilling and then expanding the hole, gradually processing the hole Diameter to the specified size, and maintaining a smooth feed during operation to prevent the tool from breaking due to uneven force.

Step 5: Inspection and Finishing

Use calipers, micrometers, plug gauges and other measuring tools to accurately measure the processed Diameter size. If the surface quality is not up to standard, use sandpaper or grinder to polish the surface to ensure that the surface roughness and other parameters meet the design requirements.

4.2. Keys for Diameter Machining

Key 1: Tool alignment and runout control

Calibrate the coaxiality of tool and spindle with runout meter to avoid ellipse (eccentricity) of the hole.

Key 2: Material adaptation parameters

For steel parts: Use cutting oil for cooling to minimize tool wear;

For aluminum: Increase cutting speed and apply air cooling to prevent chip adhesion;

For cast iron: Perform dry cutting or use emulsion cooling to avoid graphite smearing.

Key 3: High-Precision Machining

For IT6-IT7 accuracies (e.g., ⌀10H6), use the drill-hinge or drill-grind process: drill to ⌀9.8 mm, then ream to ⌀10 mm, or grind with a cylindrical grinder.

Key 4: Error Prevention

Set the safety height in the CNC programming to avoid overcutting due to sharp tool movements.

Measure the Diameters one at a time (e.g., 0.5mm depth for each entry) to correct for deviations during manual machining.

Key 5: Tool Wear Management

Regularly check drill cutting edges and replace or resharpen when dull; use indexable insert tools for large Diameters (⌀>50mm) to reduce costs.

5. How to Measure The Diameter

The diameter is present on every CNC drawing that includes holes or cylindrical features.

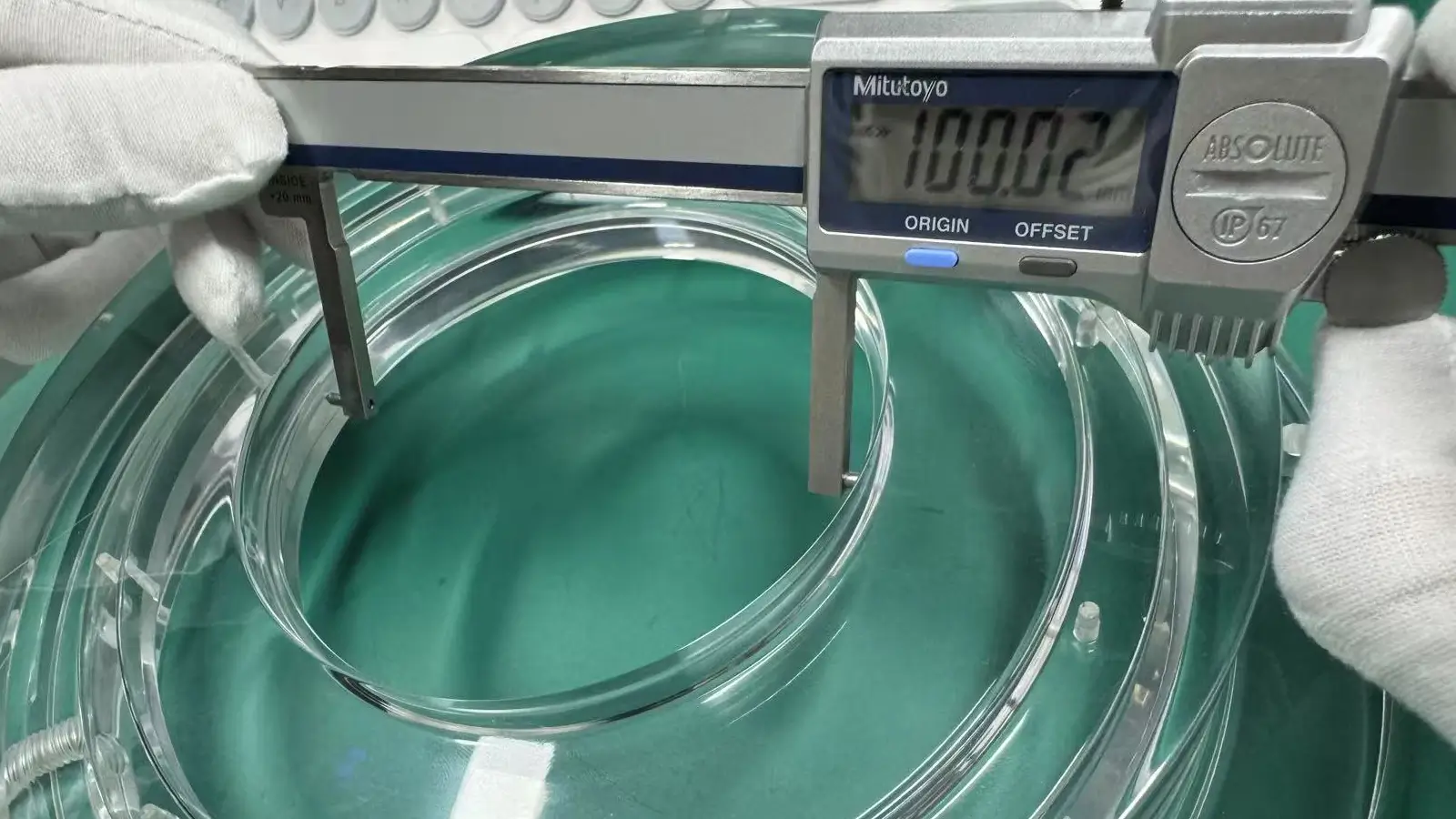

In CNC working shop, we use Vernier Caliper, Outside Micrometer,Inside Micrometer, CMM (Coordinate Measuring Machine) and Optical Comparator / Vision System to check the diameter based on different sturcture and tolerance requirement.

5.1. Vernier Caliper

A vernier caliper is simple and easy-use to measure the outside and inside diameter, and depth.

It is a great tool for quick cheks with typical accuracy around ±0.02mm.

5.2. Outside Micrometer

The outside micrometer is for precise measurement of external features like shafts and round pins.

Micrometers offer excellent accuracy—usually ±0.01mm or better—but they’re best suited for simple cylindrical shapes.

5.3. Inside Micrometer

Like an outside micrometer, an inside micrometer is also for precise measurement, but for internal diameters of holes.

They’re ideal for medium to large holes where higher accuracy is needed.

5.4 CMM (Coordinate Measuring Machine)

A CMM can measure the diameter, center location, and even roundness.

It’s a highly automated, extremely accurate method (up to ±0.002mm), making it perfect for complex parts or when customers require full inspection reports.

5.5. Optical Comparator / Vision System

These are non-contact tools that project or capture a magnified image of a part’s profile.

Optical compartor is ideal for small, thin-walled, or flexible parts, especially when contact tools like calipers and micrometers might distort them.

Optical systems are highly accurate—around ±0.005mm—and great for visual quality checks.

Comparison Table – Diameter Measurement Tools

| Tool | Accuracy | Contact / Non-Contact | Recommended Use | Key Features |

| Vernier Caliper | ±0.02 mm |  Contact Contact | General outside & inside diameters | Fast and portable |

| Outside Micrometer | ±0.01 mm ~ 0.001 mm |  Contact Contact | High-precision outside diameters | Stable and accurate |

| Inside Micrometer | ±0.01 mm ~ 0.003 mm |  Contact Contact | Precision internal diameters | Ideal for deep or large holes |

| CMM (Coordinate Measuring Machine) | ±0.002 mm |  Contact (probe) Contact (probe) | Tight-tolerance parts, report output | Auto-fitting and digital measurement |

| Optical Measuring System | ±0.005 mm ~ 0.001 mm |  Non-contact Non-contact | Small parts, transparent parts, software-compatible | Non-contact, image magnification |

6. Diameter VS Radius

In the field of mechanical design and manufacturing, although there is a close mathematical connection between Diameter and Radius, they play very different roles in technical applications.

From the definition and notation, to the characterization, engineering application and tool selection, both of them show significant differences. The following table systematically compares the differences and connections between Diameter and Radius in six key dimensions to help understand their core roles in different scenarios.

Please read our blog: Radius in GD&T Explained

Technical Characteristics Comparison Table of Diameter and Radius

| Aspect | Diameter (⌀) | Radius (R) |

| Definition | Distance through the center, ⌀ = 2R. | Distance from center to circumference, R = ⌀/2. |

| Symbol | Prefixed with “⌀” (e.g., ⌀20mm). | Prefixed with “R” (e.g., R10mm). |

| Feature description | Overall size of circles/spheres (e.g., hole Diameter). | Curvature of arcs/spheres (e.g., fillet Radius). |

| Application focus | Assembly fit (e.g., shaft-hole matching). | Transition curvature (e.g., stress relief fillets). |

| Tool reference | Directly guides drill/reamer size. | Guides ball-end mill or forming tool Radius. |

7. Other Concepts Easily Confused with Diameter

In addition to Radius, the following concepts are often confused with Diameter:

7.1. Perimeter

Definition: the circumference of a circle, calculated as C = π × ⌀.

Source of confusion: Novices often confuse Diameter with circumference—for example, misinterpreting “⌀10mm” as a circumference measurement.In fact, Diameter is a linear dimension and circumference is a perimeter measure.

7.2. Bore and Diameter

Definitions:

-Bore refers to the inside Diameter of a hollow structure, such as a pipe or a hole.

-Diameter is a general term for both internal and external dimensions, including the outside Diameter of a shaft or the inside Diameter of a hole.

Bore Diameter is a specific subset of Diameter.

Bore refers specifically to the inner diameter of holes, cavities, or cylindrical objects—such as the inner diameter of a bearing, the inside diameter of a cylinder, a hydraulic cylinder barrel, the bore of a gear, the inner diameter of a bushing, or the inside diameter of a pipe (especially after precision machining).

Bores are typically associated with precision fits.

On the other hand, Diameter is a much broader term. It refers to the width of any circular cross-section and can be either rough or precise, depending on the application.

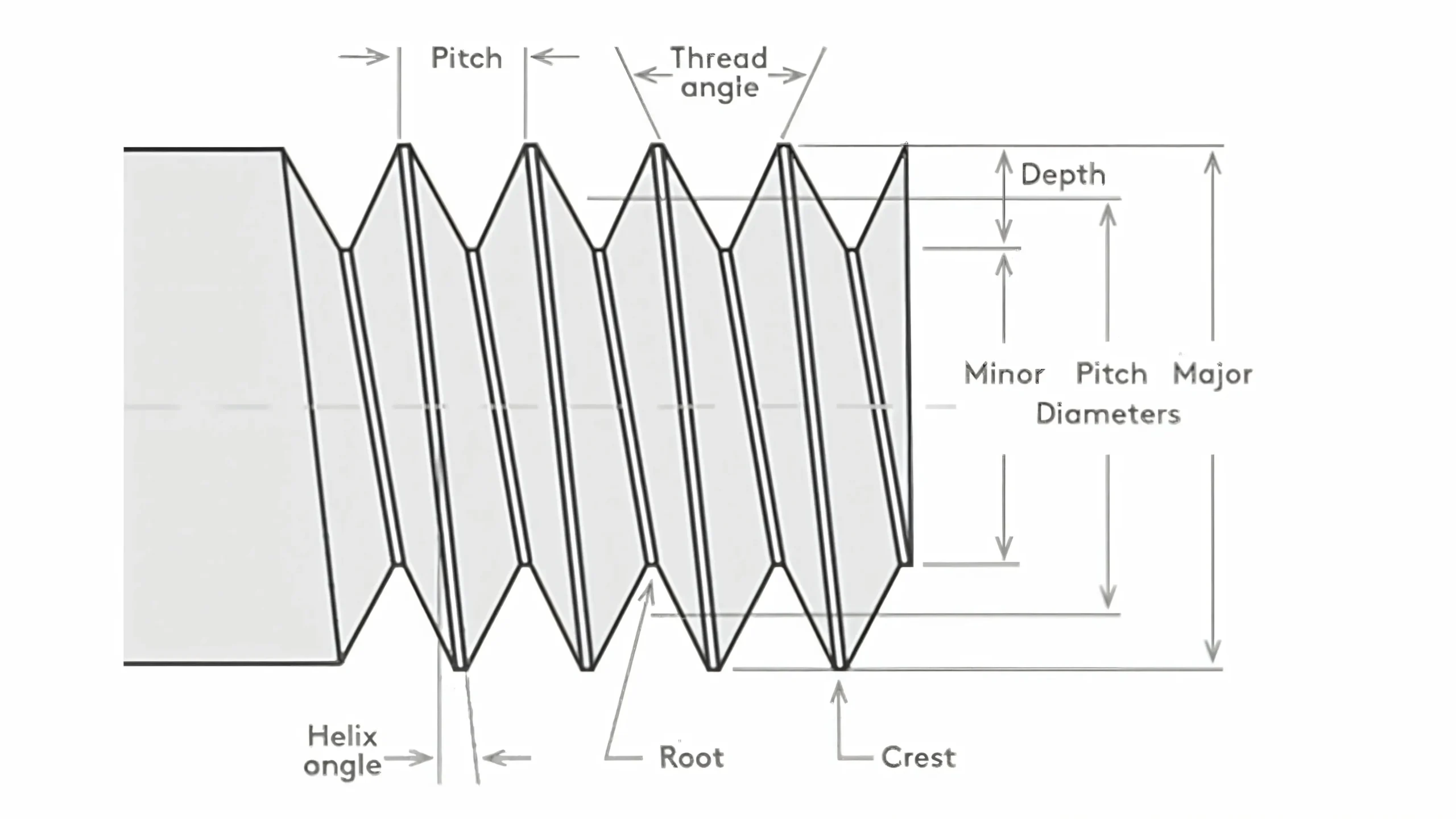

7.3 Pitch Diameter

All pitch diameters are a type of diameter, but not all diameters are pitch diameters.

The pitch diameter is a specific diameter within a thread—it’s not the outer diameter or the inner diameter, but rather the effective diameter where the thread engagement actually happens.

When it comes to threads, there are three common types of diameters:

Major Diameter: This is the largest diameter of the thread, typically the outside of an external (male) thread.

Minor Diameter: This is the smallest diameter, usually at the root of an internal (female) thread.

Pitch Diameter: Also called the effective diameter, this lies between the major and minor diameters. It’s the diameter at which the thread flanks of a mating screw and nut make contact. This is the most critical dimension for thread fit, affecting how tightly the threads engage, the accuracy of the fit, and the strength of the connection.

Take an M10 thread for example,

Major Diameter ≈ 10.00 mm

Pitch Diameter ≈ 8.98 mm (approximate)

Minor Diameter ≈ 8.16 mm

8. Conclusion

Diameter is the cornerstone of geometric definition in engineering, dominating feature size, assembly accuracy and manufacturing processes. Mastering its labeling rules, application scenarios and machining techniques is central to ensuring product quality.

Distinguishing between Diameter and related concepts (e.g. Radius, circumference) can avoid design and manufacturing errors and promote the development of precision engineering and industrial standardization.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.