Table of Contents

Knurling, a critical process in modern CNC machining, primarily relies on two core methods: Form Knurling (Roll Knurling) and Cut Knurling.

Knurling, a critical process in modern CNC machining, primarily relies on two core methods: Form Knurling (Roll Knurling) and Cut Knurling.

These two techniques are based on fundamentally different physical principles, leading to significant differences in applicability, precision, and final part characteristics.

Key Takeaways:

- Form knurling displaces material through pressure (plastic deformation), while cut knurling removes material through a shearing action (like machining). This is the core difference is in the mechanism.

- Material hardness is the primary deciding factor.Use form knurling for soft, ductile materials like aluminum and brass. You must use cut knurling for hard, tough, or work-hardening materials like stainless steel and titanium.

- Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter. Choose form knurling for high-volume production where speed is the priority, accepting that the part diameter will increase.

1. What is Form Knurling?

Form Knurling is also known as roll knurling. In our blog, we will use form knurling.

Form Knurling is a chipless, plastic deformation process. The principle involves using high-hardness knurling wheels to exert pressure on the workpiece surface, causing the material to undergo plastic flow instead of being removed. The material is displaced sideways and upwards, forming the raised pattern.

Process Features:

- No chips generated.

- Applies immense radial force to the workpiece.

- Alters the final dimensions of the part (typically causes an increase in Outer Diameter – OD).

- Processing typically requires forced feeding (applying sufficient force to press the knurling wheel into the part).

Advantages:

- Extremely high processing efficiency.

- Zero chip production.

- Increases surface hardness and wear resistance due to the cold-working effect.

Disadvantages:

- Increases the final OD, requiring the workpiece diameter to be reduced beforehand to compensate for material expansion.

- Primarily applicable to medium- to low-hardness materials, such as aluminum, brass, and mild steel.

- Requires very high rigidity from the CNC machine structure.

2. What is Cut Knurling?

Cut Knurling is a chip-forming process. It uses knurling tools with sharp teeth to create the pattern by cutting and removing material, similar to a turning operation on a lathe.

Process Features:

- Chips are generated, requiring coolant flushing for evacuation.

- The applied radial force is very low.

- Does not fundamentally change the original Outer Diameter (OD) of the workpiece.

- The machining method resembles turning, allowing for precise feed rate control synchronized with spindle speed.

Advantages :

- Extremely high control over final dimensions; minimal change to the OD.

- Suitable for high-strength steels and stainless steels (harder materials).

Disadvantages:

- Production efficiency is slightly lower than form knurling.

- Requires chip management (swarf control).

3. Form Knurling vs. Cut Knurling Features Comparison Table

| Feature | Form Knurling | Cut Knurling |

|---|---|---|

| Machine Requirement | High rigidity (must withstand high squeezing force) | Relatively lower rigidity required |

| Dimensional Accuracy | Medium; OD increases, requiring precise pre-calculation | High; OD remains stable, easier tolerance control |

| Surface Quality/Hardness | Surface hardness increases (cold working) | Surface hardness remains largely unchanged |

| Production Efficiency | Extremely high; quick pattern formation in one pass | Medium; requires longer cutting time |

| Applicable Materials | Soft materials (Aluminum, Brass, Mild Steel) | Hard materials, High-Strength Steel, Stainless Steel |

| Main Challenges | Prone to burrs/flaking; easily causes bending in slender parts | Chip entanglement risk; faster tool wear |

4. How to Choose the Optimal Knurling Process

The decision-making logic for selecting the knurling process should follow these steps:

4.1. Primary Consideration: Material Hardness and Characteristics

If the material is hard (e.g., stainless steel, hardened steel, titanium), or the part is thin-walled/slender, Cut Knurling is mandatory.

If the material is soft (e.g., aluminum, brass, mild steel, plastic) and the part structure is rigid, both methods are viable; proceed to the next step.

4.2. Secondary Consideration: Dimensional Accuracy and Tolerance

If the knurled part requires precise mating with other components and strict OD tolerance: Choose Cut Knurling.

If the knurl is only for grip, tolerance is loose, and OD expansion can be compensated for by adjusting the pre-machining diameter: Choose Form Knurling.

4.3. Final Consideration: Production Volume and Cost

If the production volume is high and the material is suitable for forming: Choose Form Knurling for superior speed and production efficiency.

If the volume is small, chip handling must be avoided, or machine rigidity is low: Choose Cut Knurling.

5. Summary

Form Knurling (Roll Knurling) is Preferred: It is the most economical and efficient choice for high-volume production of rigid, soft material parts where tight OD tolerance is not the priority.

Cut Knurling is Essential: It is the only appropriate choice when processing hard materials, thin-walled components, or when there are rigorous demands for dimensional accuracy and surface quality.

This knurling process guide helps manufacturers and engineers understand the key differences between form knurling and cut knurling methods, enabling informed decisions for optimal results in CNC machining applications.

Related blog:

- The Complete Guide to Knurling: Types, Uses, and Design Tips

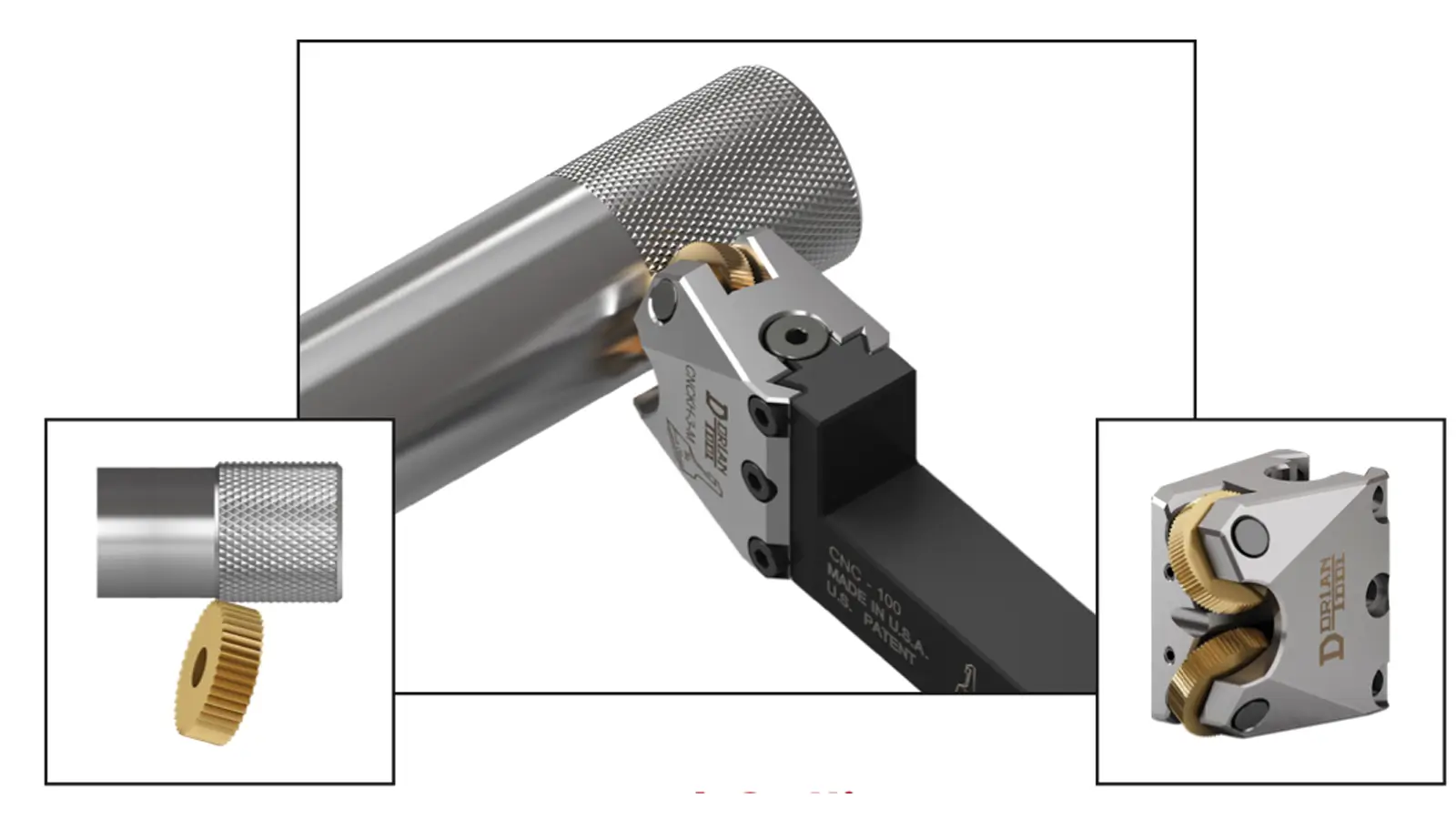

- Types of Knurling Tools and How to Choose the Right One

- CNC Knurling vs Conventional Knurling: Key Differences, Features, and How to Choose

- How Material Properties Affect Knurling: Choosing Between Form and Cut Knurling

- Types of Knurling Patterns and How to Choose the Right Knurling Type

- Knurling Process: Form Knurling vs. Cut Knurling

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Form Knurling vs. Cut Knurling

Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter.

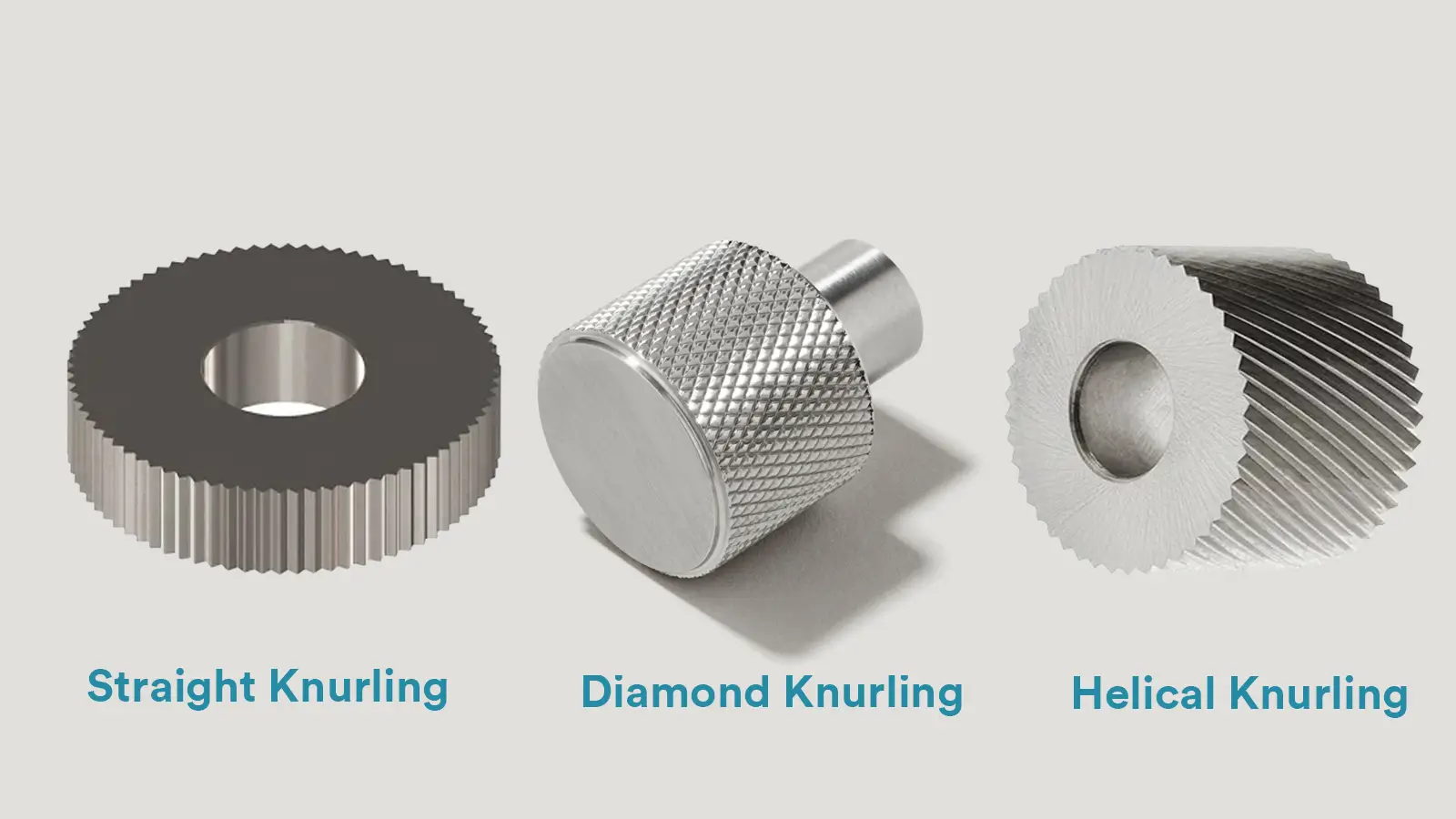

Types of Knurling Patterns

The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

CNC Knurling vs Conventional Knurling

For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched.

Types of Knurling Tools

Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances.