Table of Contents

When moving from prototype to production, CNC companies support scalability by optimizing processes, ensuring precise quality control, and leveraging advanced machining technologies.

CNC manufacturing is a critical step for businesses seeking to turn innovative ideas into scalable products.

From initial prototypes to full-scale production, partnering with experienced CNC companies ensures efficiency, accuracy, and reduced time-to-market.

Understanding the Journey: From Prototype to Production

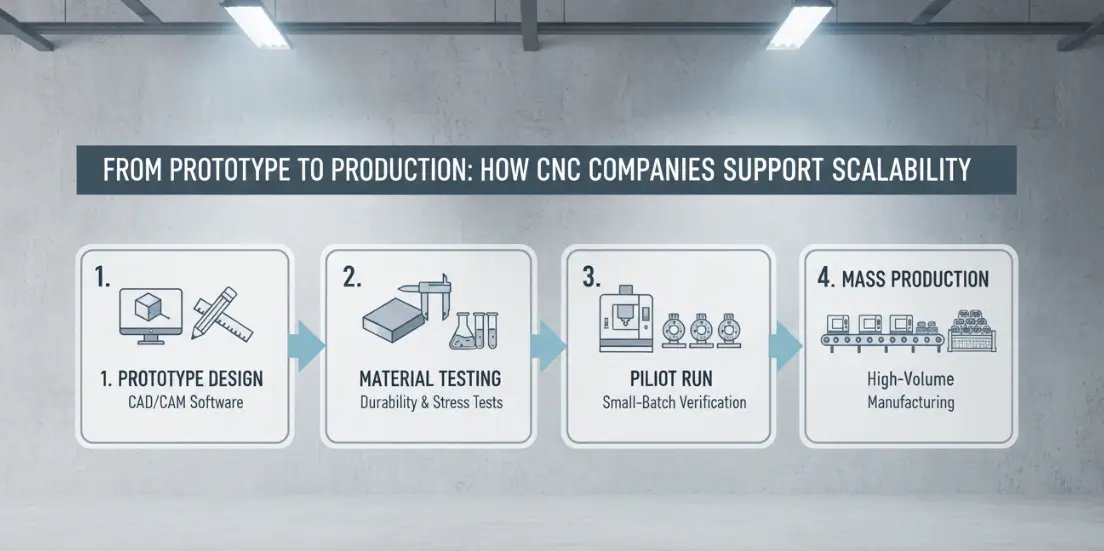

The journey from prototype to production involves a structured process of design validation, material selection, pilot runs, and full-scale manufacturing optimization.

Transitioning from a single functional prototype to large-batch production requires systematic planning and technical coordination.

Each phase—design, testing, verification, and ramp-up—determines whether the final product can achieve scalable efficiency.

1.Key Steps in CNC Prototyping and Production

The first step in moving from prototype to production is precise design and engineering validation.

- Prototype Design & Engineering (2025 data): Over 85% of top CNC suppliers integrate CAD/CAM simulations to predict manufacturability issues before machining. Design validation ensures that complex geometries can be produced consistently at scale.

- Material Verification & Testing: Materials are tested for tensile strength, thermal resistance, and surface finish to guarantee repeatable production quality. Leading suppliers like Shenzhen Precision CNC (est. 2015, ISO 9001) track material batches to ensure compliance with specifications.

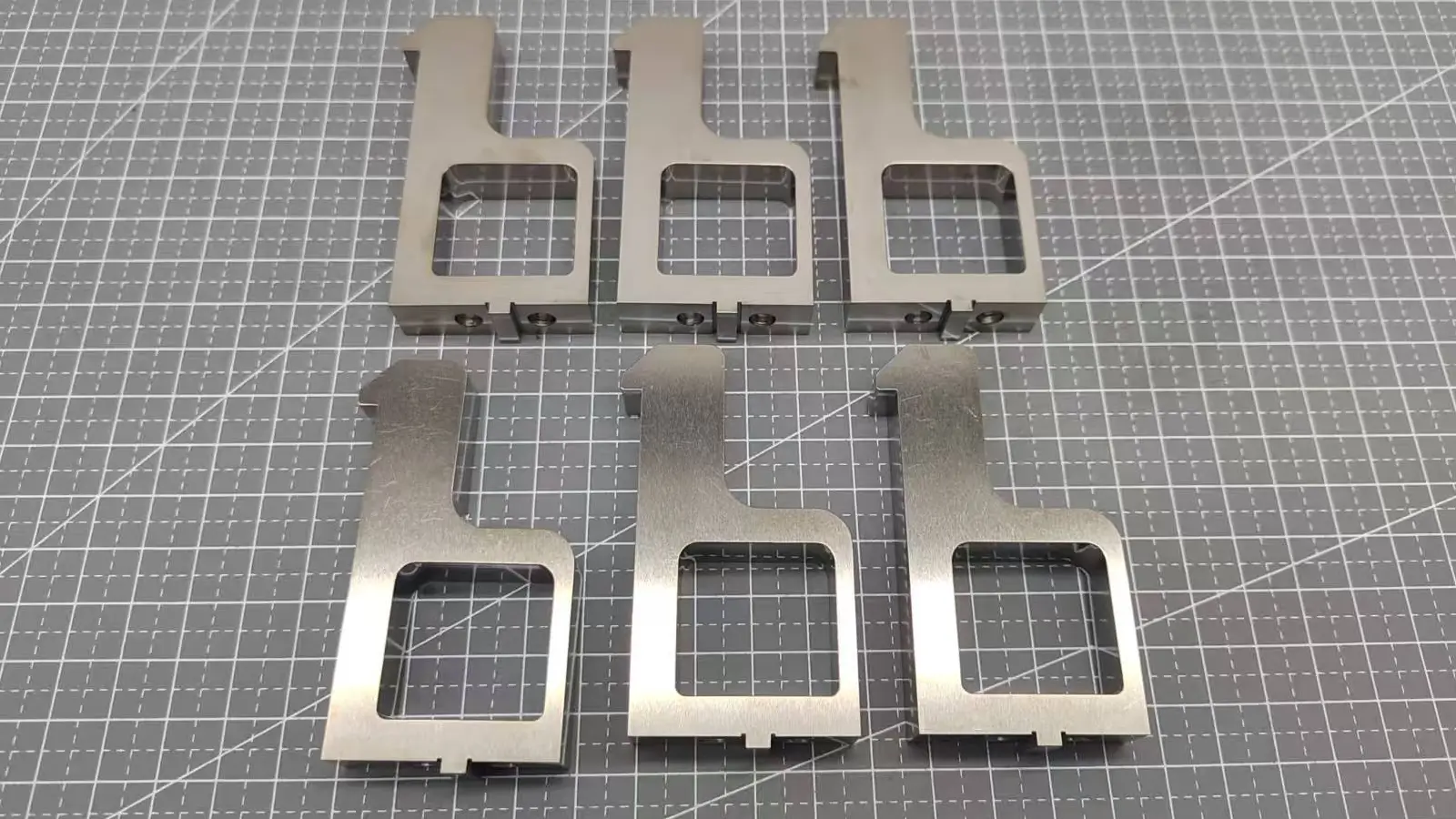

- Pilot Production Runs: Small-scale runs validate both the design and manufacturing process. Companies often produce 50–200 units to identify bottlenecks, reduce errors, and streamline workflows before committing to full-scale production.

2.Typical Challenges in Scaling CNC Manufacturing

Maintaining precision, efficiency, and cost-effectiveness are the most common challenges when scaling CNC production.

- Tolerance Management: Achieving ±0.01 mm precision requires meticulous calibration of CNC machines and tooling.

- Lead Time Optimization: Advanced suppliers reduce prototype-to-production lead time by up to 40% through automated tooling and workflow planning.

- Cost Control: Strategic material management and supplier collaboration can cut waste by 15–20%, directly improving scalability and profitability.

How CNC Companies Enable Scalability?

CNC companies enable scalability by standardizing workflows, implementing automation, and using digital tools to maintain efficiency and quality across production stages.

To move efficiently from prototype to production, modern CNC manufacturers rely on technology-driven processes that improve accuracy and throughput while reducing human error.

1.Process Optimization for High-Volume Production

CNC companies ensure scalability by implementing process optimization and standardized workflows.

- Automated Tooling Systems: Suppliers like Ecoreprap (China, est. 2013) utilize robotic tool changers to reduce machining cycle time by 30%.

- Lean Manufacturing Principles: ISO 9001-certified manufacturers apply lean methods to minimize downtime and maximize throughput.

- Digital Twin Simulation: 70% of leading CNC suppliers use virtual simulations to anticipate and mitigate potential production issues before full-scale runs.

2.Quality Control Measures at Each Stage

Consistent quality is critical to ensure that scaled production meets prototype specifications.

- Inspection Technology: CMM (Coordinate Measuring Machines) and laser scanners maintain ±0.01 mm tolerance accuracy.

- Material Traceability: Batch tracking ensures that chemical composition and mechanical properties meet design requirements.

- Continuous Monitoring: Shenzhen Precision CNC employs Statistical Process Control (SPC) to monitor production in real time, reducing defect rates below 0.5%.

3.Technology and Equipment That Support Scalability

Advanced equipment and software are essential to move from small prototypes to mass production efficiently.

- 5-Axis CNC Machines: Allow production of complex parts with high repeatability.

- ERP-Integrated CNC Systems: Coordinate production schedules, manage inventory, and optimize resource allocation.

- High-Speed Machining Centers: Reduce cycle times without compromising precision, supporting larger batch production.

Best Practices to Ensure Smooth Transition from Prototype to Mass Production

The best practices for scaling from prototype to production involve choosing capable suppliers, optimizing costs, and continuously validating process stability.

Working with an experienced CNC partner ensures your prototype design translates effectively into production-scale efficiency.

1.Supplier Selection and Collaboration Strategies

Choosing the right CNC partner is key to achieving scalable production.

- Experience & Portfolio: Companies like Ecoreprap have delivered over 5,000 prototypes across automotive, aerospace, and electronics industries.

- Certifications: ISO 9001, IATF 16949, and CE-certified suppliers guarantee consistent process quality.

- Communication & Transparency: Regular project updates, CAD/CAM feedback loops, and clear reporting reduce errors by 25% and accelerate project timelines.

2.Cost and Time Efficiency Tips

Efficient planning and resource management can significantly reduce costs and lead times during scale-up.

- Bulk Material Ordering: Purchasing raw materials in larger quantities can reduce unit costs by 10–15%.

- Tooling Standardization: Reusing jigs and fixtures across batches accelerates setup time and reduces tooling errors.

- Outsourcing Non-Core Processes: Finishing operations such as anodizing, plating, or heat treatment can be outsourced to specialized vendors to save time and maintain focus on core CNC processes.

3.Case Study: Successful Scaling of a CNC Prototype

A Shenzhen-based electronics manufacturer successfully scaled a prototype to mass production in just 8 weeks through strategic collaboration with Shenzhen Precision CNC (est. 2015, ISO 9001).

- Prototype Stage: 10 units produced for functional testing.

- Pilot Run: 200 units validated for process scalability and surface finish.

- Mass Production: 5,000 units manufactured within 6 weeks while maintaining ±0.01 mm tolerances.

- Outcome: Cost per unit decreased by 12%, lead time shortened by 30%, and production defects dropped below 0.5%.

Leveraging CNC Expertise for Scalable Manufacturing

Partnering with experienced CNC companies ensures predictable results, lower risks, and stable long-term production scalability.

Manufacturers who collaborate with professional CNC teams benefit from strategic process management, technical reliability, and operational transparency—key advantages in competitive industries.

1.Why Experienced CNC Companies Are Essential?

Partnering with experienced CNC companies reduces risks and ensures predictable scaling outcomes.

- Process Knowledge: Experienced suppliers anticipate and solve common scaling issues before they impact production.

- Industry Expertise: Manufacturers familiar with automotive, aerospace, and electronics standards can meet tight tolerances and regulatory requirements efficiently.

- Technology Advantage: Access to the latest CNC machinery, automation, and ERP systems ensures consistency across large production runs.

2.Tips for Businesses Planning to Scale CNC Production

Planning and preparation are key to moving from prototype to large-scale manufacturing.

- Early Supplier Engagement: Involve CNC suppliers during the design phase to avoid costly redesigns.

- Prototype Testing and Iteration: Validate functionality, durability, and manufacturability in small batches.

- Data-Driven Production Decisions: Use production metrics from pilot runs to inform large-scale batch planning.

- Continuous Communication: Maintain regular updates with suppliers to quickly address any deviations or challenges.

3.Measuring Success in Scalable CNC Production

Tracking key metrics ensures that scaling efforts remain efficient and cost-effective.

- Production Lead Time: Measure from initial prototype to full-scale batch delivery.

- Yield Rate: Percentage of units meeting quality standards.

- Cost per Unit: Monitor material, labor, and overhead costs to optimize scalability.

- Customer Feedback: Use end-user performance data to inform iterative improvements.

Conclusion

CNC companies play a crucial role in helping businesses scale from prototype to mass production by combining precision, automation, and process optimization.

By choosing certified and experienced CNC suppliers, companies can ensure smoother transitions, shorter lead times, and consistent quality.

From design validation to high-volume manufacturing, CNC technology continues to be the foundation of modern scalable production.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.