Table of Contents

When choosing the right knurling method, tool, and parameters, several key material properties—hardness, toughness, thermal conductivity, and work-hardening tendency—play a decisive role.

Understanding how these properties affect the knurling process helps ensure a clean pattern, stable performance, and long tool life.

Key Takeaways:

Soft materials like aluminum and brass are perfect for form knurling (squeezing)

Hard materials like stainless steel and titanium require cut knurling (slicing)

1. How Material Properties Impact on Knurling?

1.1. Hardness: The Deciding Factor

Hardness is the material’s ability to resist localized permanent deformation (like indentation). It is the single most important variable in choosing your knurling method.

- Low Hardness (e.g., Aluminum, Brass):

These materials are highly ductile and easily yield to pressure, making them ideal candidates for Form Knurling (pressure-based). The knurling process itself will increase the surface hardness through cold working.

- High Hardness (e.g., Stainless Steel, High-Strength Steel):

These materials resist squeezing. Forcing Form Knurling on them will cause rapid tool wear, possible chipping, and potential machine damage. Therefore, high-hardness materials must use Cut Knurling, which uses sharp edges to slice the material into the desired pattern.

Hardness is the critical boundary between choosing a Form knurling or cut knurling process.

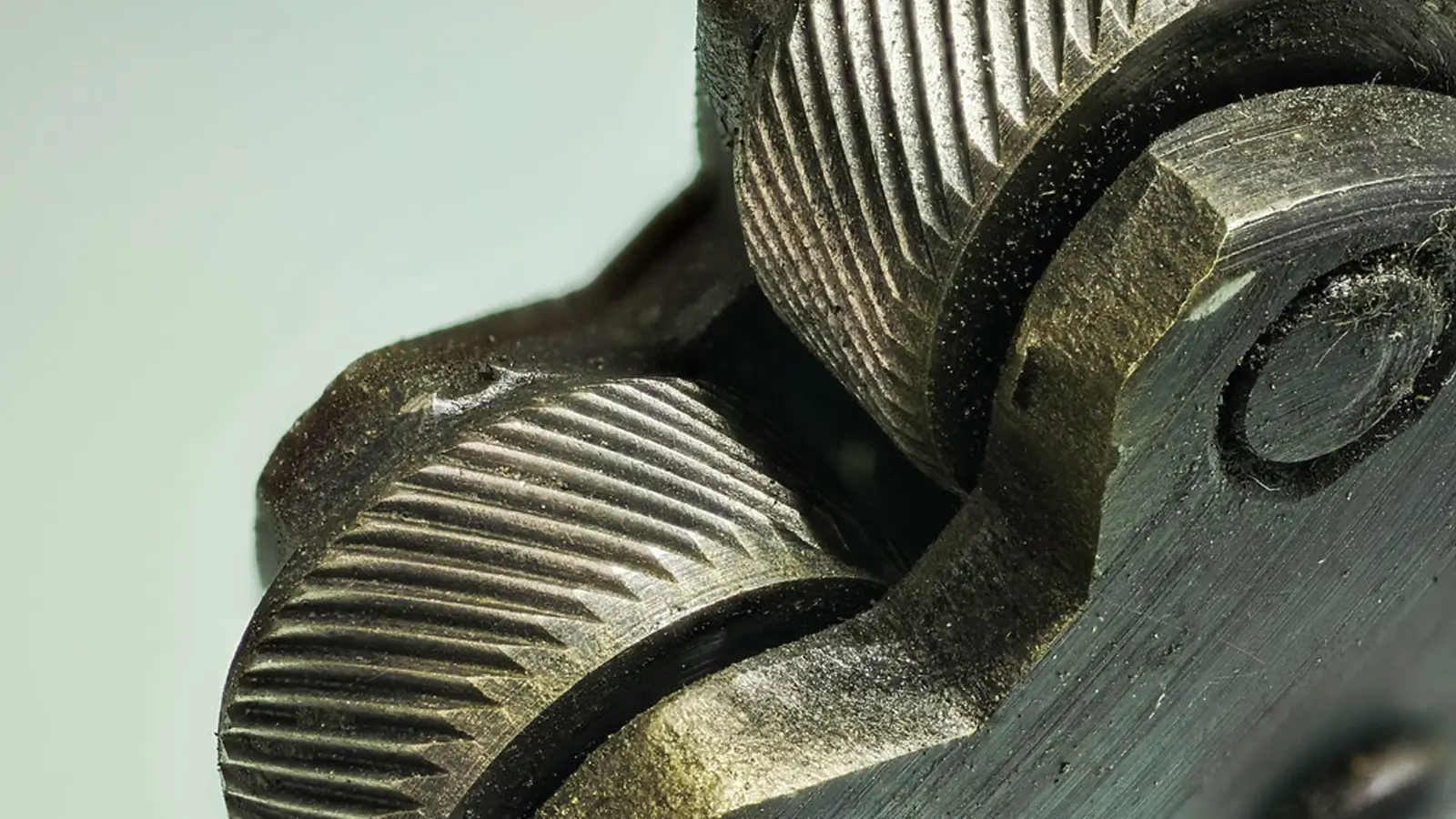

1.2. Toughness: Managing the Chips

Toughness is a material’s capacity to absorb energy before fracturing. In knurling, this impacts how the material “behaves” under stress and how chips are handled.

- High Toughness (e.g., Mild Steel, some Stainless Steels):

The material won’t break easily when cut, leading to long, stringy chips. This is a common issue in Cut Knurling, as chips can tangle around the tool and workpiece, damaging the final pattern.

- Low Toughness (e.g., Cast Iron, Brass):

These brittle materials snap easily, creating small, manageable fragments that are easily evacuated. This is highly beneficial for Cut Knurling.

When using Cut Knurling on highly tough materials, it is essential to use high-pressure coolant and optimized cutting parameters to effectively break and clear the chips.

For Form Knurling, high toughness is positive as it resists cracking under pressure.

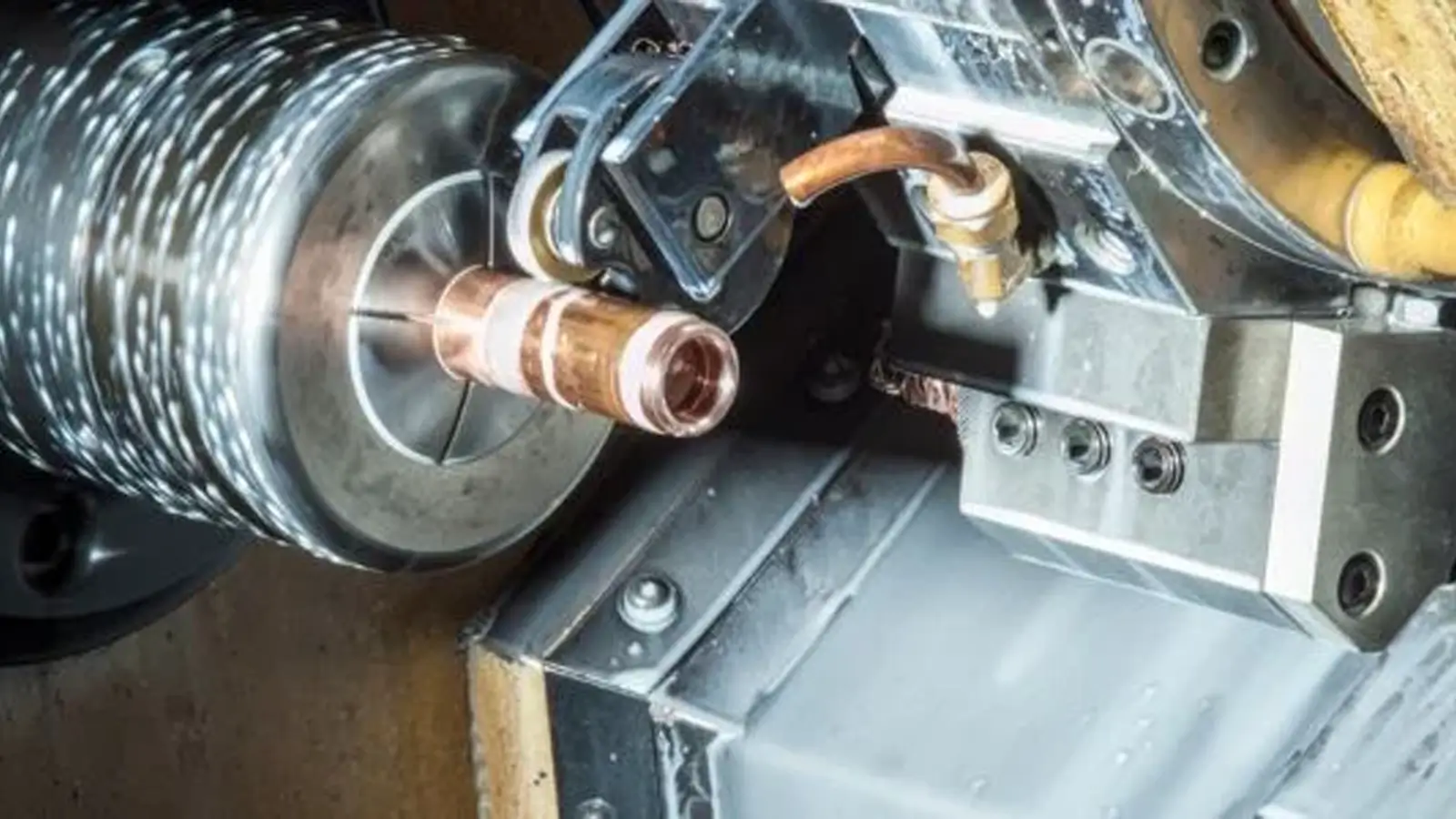

1.3. Thermal Conductivity: Keeping the Heat Down

Thermal conductivity is how well a material transfers heat. In knurling, especially Cut Knurling, this directly affects tool longevity and part quality.

- High Conductivity (e.g., Aluminum, Copper):

Heat generated during machining is quickly dissipated into the bulk of the part or carried away by the coolant. This keeps the tool temperature lower, extending tool life and reducing the risk of thermal deformation.

- Low Conductivity (e.g., Stainless Steel, Titanium):

Heat is trapped in the cutting zone (the point of contact between tool and workpiece). This rapid temperature rise accelerates tool wear, can cause the cutting edge to fail, and may lead to surface discoloration or slight changes in the part’s structure.

When processing low-conductivity materials, you must employ high-performance cutting fluids, use lower cutting speeds to manage temperature, and select heat-resistant tool materials.

1.4. Work Hardening Tendency: Fighting Back

Work hardening is the phenomenon where a material’s strength and hardness increase due to plastic deformation (either squeezing or cutting).

- High Tendency (e.g., Austenitic Stainless Steel like 304):

Even minor friction or pressure from the tool rapidly hardens the surface. This is detrimental to Form Knurling—the knurl wheel has an increasingly difficult time squeezing an already hardened surface.

In Cut Knurling, a low feed rate or incorrect speed causes the tool to rub the surface, accelerating hardening and making subsequent cuts much harder, thus increasing tool wear.

- Low Tendency (e.g., Mild Steel, Brass):

Work hardening is negligible, posing few issues.

For materials with a high work-hardening tendency (like 304 Stainless Steel), you must use an aggressive strategy in Cut Knurling: “High Feed, Deep Cut.”

This ensures the tool quickly cuts beneath the previously formed hardened layer, preventing further hardening and ensuring a clean pattern.

2. Which Materials Can Be Knurled?

The feasibility of knurling any material depends on its ductility (plasticity), hardness, toughness, and the chosen method (Form or Cut).

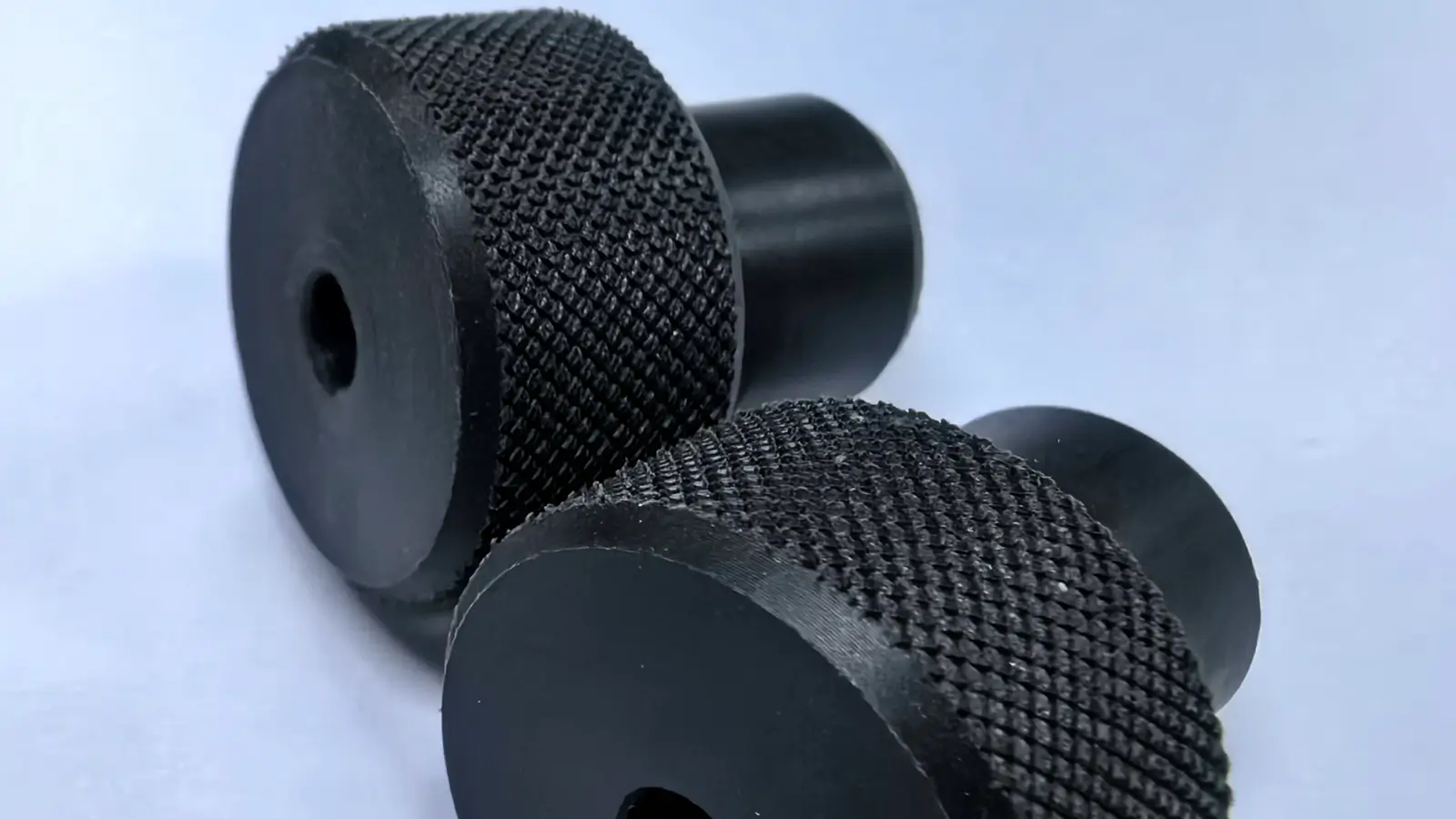

2.1. Soft, Ductile Metals (Form Knurling Preferred)

These materials have excellent plasticity, making them ideal for the efficient Form Knurling (squeezing) process.

- Aluminum Alloys (e.g., 6061):

Aluminum is one of the most common materials for knurling.

Form Knurling is often prioritized for its speed. The main challenge is its gummy nature, which can cause material to stick to the tool and result in fuzzy edges.

Use ample, high-pressure coolant and choose fine-pitch tools to reduce squeezing force for Aluminum Alloys knurling.

- Brass and Bronze:

Excellent plasticity and easy to form, often yielding the best knurling results. Brass is the benchmark material for testing knurling parameters.

For brass and bronze knurling, control pressure carefully, especially on slender parts, to avoid bending.

- Copper:

Very soft and easy to knurl, but pressure must be strictly managed to prevent excessive deformation.

- Mild Steel / Free-Cutting Steel:

Moderate strength and ductility, serving as the standard industrial material for both Form and Cut Knurling.

If using Form Knurling for mild steel, ensure balanced pressure to avoid bending long parts.

If cutting knurling for mild steel, prioritize good chip evacuation.

2.2. Medium-to-High Hardness Metals (Cut Knurling Essential)

These materials are challenging and usually require the Cut Knurling (slicing) method.

- Stainless Steel (e.g., 304, 316):

These present the highest challenge due to their high hardness and extreme work-hardening tendency. Form Knurling is almost impossible.

You must use Cut Knurling with a specialized tool, maintaining low RPM and a high feed rate.

This “aggressive” approach slices below the hardened layer, ensuring a clear pattern. A medium-to-coarse pitch (like m≥ 0.5mm) is often used.

- Alloy Steels (e.g., 4140, 8620):

Can be knurled in their soft (annealed or non-hardened) state. Fully hardened or quenched steel is extremely difficult to knurl.

2.3. Non-Metallic Materials

- Thermoplastics (e.g., Nylon, POM/Delrin):

The core challenge is their poor thermal conductivity. Friction heat can cause melting or severe deformation.

You must use Cut Knurling or special thermal processes, maintaining extremely low spindle speeds and ensuring adequate cooling to dissipate heat. Coarse patterns are usually chosen for better grip.

- Wood:

Primarily limited to dense hardwoods for decorative purposes, usually involving an embossing process rather than traditional CNC knurling.

Almost all metals and many plastics can be successfully knurled by selecting the right process. When in doubt, follow this simple rule:

Materials Suitable for Knurling and Process Recommended

| Material Type | Common Materials | Recommended Knurling Process | Machining Performance | Key Considerations |

|---|---|---|---|---|

| Carbon Steel | AISI 1018, 1045 | Both Form and Cut Knurling Suitable | Good plasticity, clear pattern definition | High hardness may reduce toughness and generate heat |

| Stainless Steel | 303, 304, 316 | Cut Knurling Preferred | Good ductility but prone to work hardening | Use cut knurling tools with sufficient coolant |

| Aluminum Alloy | 6061, 7075 | Form Knurling Optimal | Good ductility, relatively soft | Control pressure to prevent pattern deformation |

| Brass | HS9, H62, C3604 | Form Knurling | Excellent plasticity, very good knurling results | Minimal burrs, significantly enhanced material |

| Copper | T2, C110 | Form Knurling | Good ductility, smooth surface | Prone to material loading, requires ample lubrication |

| Bronze | QSn6.5-0.1, C93200 | Form or Cut Knurling | Good pattern formation but less wear-resistant | Use hardened knurl wheels when possible |

| Plastic | Nylon, POM, ABS | Form Knurling | Feasible but requires low pressure and speed | Prevent melting and thermal deformation |

| Titanium Alloy | Ti-6Al-4V | Cut Knurling | High strength but limited ductility | Prone to cracking, ensure continuous feed |

| Magnesium Alloy | AZ91D | Form Knurling | Easy to form but prone to surface issues | Recommend light pressure knurling |

3. Summary

The decision to use Form or Cut Knurling is the key to success. Form Knurling is faster and cost-effective for soft materials; Cut Knurling is mandatory for hard or work-hardening materials to ensure pattern clarity and prevent tool failure.

Related blog:

- The Complete Guide to Knurling: Types, Uses, and Design Tips

- Types of Knurling Tools and How to Choose the Right One

- CNC Knurling vs Conventional Knurling: Key Differences, Features, and How to Choose

- How Material Properties Affect Knurling: Choosing Between Form and Cut Knurling

- Types of Knurling Patterns and How to Choose the Right Knurling Type

- Knurling Process: Form Knurling vs. Cut Knurling

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Form Knurling vs. Cut Knurling

Cut Knurling is for Precision; Form Knurling is for Speed: Choose cut knurling when dimensional accuracy is critical, as it doesn’t change the workpiece diameter.

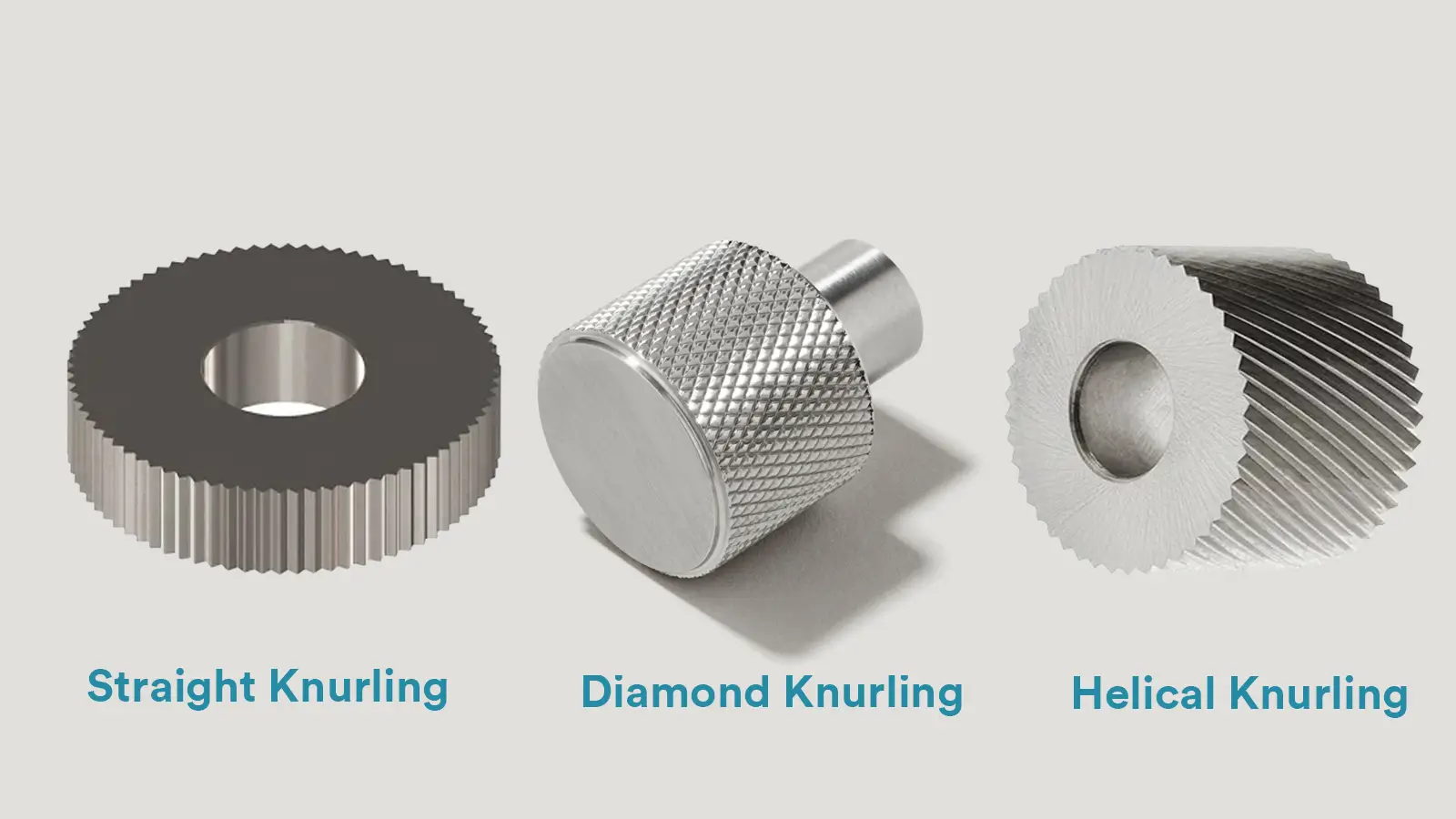

Types of Knurling Patterns

The most common types of knurling textures are Straight Knurling, Diagonal (Helical) Knurling, and Diamond Knurling.

CNC Knurling vs Conventional Knurling

For high-precision, repeatable results in medium to large batches, CNC knurling is unmatched.

Types of Knurling Tools

Form knurling tools excel in high-volume production for efficiency, while cut knurling tools provide accuracy for tight tolerances.