Table of Contents

Engineers often underestimate how dramatically a material’s inherent mechanical and thermal properties influence prototype accuracy, stability, and overall reliability.

In CNC machining, the interaction between tool, spindle, feed parameters, and material behavior determines how close the final prototype will match its intended design.

When a material expands under heat, deflects under pressure, or resists cutting forces, the finished part inevitably reflects these reactions.

Based on Ecoreprap’s hands-on experience producing more than 70,000 CNC prototypes since 2012, material selection consistently ranks as the most decisive factor for dimensional accuracy, surface quality, and repeatability.

Material hardness directly dictates CNC surface quality

Because harder materials generate greater cutting resistance and tool wear.

Hardness is one of the first variables engineers evaluate, as it determines how smoothly the cutter interacts with the workpiece.

Key observations from prototype machining:

- Hard metals like stainless steel increase tool friction, creating higher cutting temperatures.

- Aluminum alloys (such as 6061 and 7075) maintain a balanced hardness level, allowing stable cutting and smooth surface finishes (Ra 1.6–3.2 µm).

- Plastics like ABS or PMMA are softer and can deform under tool pressure, making precise surface textures more difficult to maintain.

- Extremely hard engineering plastics, such as PEEK, require optimized tool paths to avoid burning marks.

Ecoreprap Hard-Material Machining Capabilities

- CNC fleet: 38 machining centers, including 5-axis DMG Mori units.

- Hard-material tolerance capability: ±0.01 mm on aluminum, ±0.015 mm on stainless steel.

- Experience machining 7075 aluminum, PEEK, and tool steel for industrial-grade prototypes.

- All materials undergo hardness verification via Rockwell or Brinell testing for batch consistency.

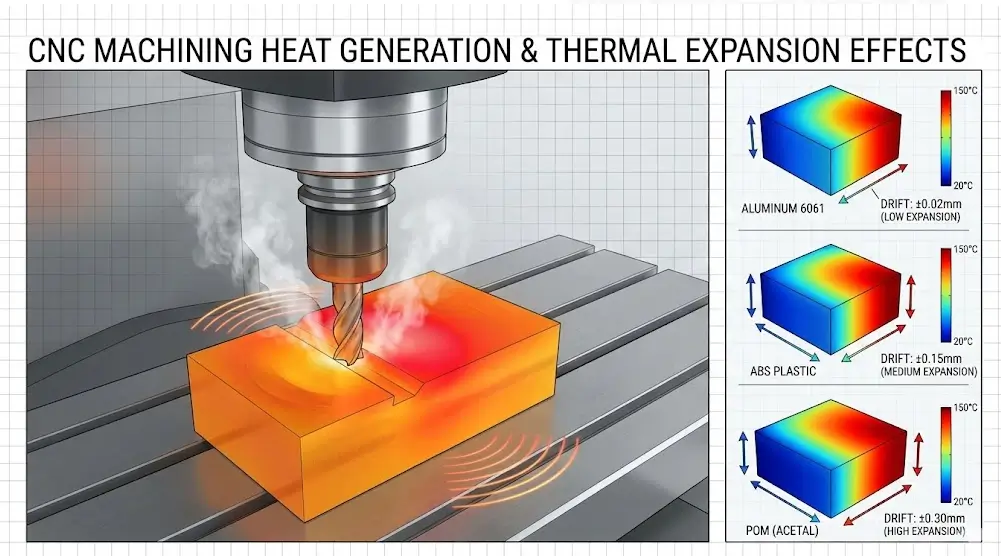

Thermal stability directly influences CNC dimensional accuracy

Because materials expand or contract when exposed to heat generated during machining.

Heat is a natural byproduct of CNC cutting, and certain materials respond more predictably than others.

Metals conduct heat efficiently, while plastics may soften or distort.

Thermal behavior affects prototypes in the following ways:

- High thermal expansion coefficients increase tolerance deviation during long tool paths.

- Plastics like ABS exhibit more thermal deformation, resulting in dimensional inconsistency in thin-walled features.

- POM (Delrin) shows excellent thermal stability, making it ideal for precision gears and sliding components.

- Aluminum maintains stable thermal behavior, enabling tight tolerances across larger prototype surfaces.

Ecoreprap Thermal-Behavior Assessment

- Heat deformation inspection using Keyence surface scanners.

- Material data sheets integrated into CAM programming for predicted expansion compensation.

- Over 12 years of testing correlation between feed rates, tool heat, and material shift on ±0.02 mm prototypes.

- Experience handling long prototypes where thermal drift is especially critical (robotic arm housings, automation fixtures).

Material machinability directly determines prototype efficiency

Because machining-friendly materials allow cleaner cuts and shorter production times.

Machinability refers to how easily a material can be cut without excessive tool wear, vibration, or surface burning.

Materials with poor machinability often require slower speeds, custom tool geometries, or multiple finishing passes.

Machinability trends observed in CNC prototypes:

- Aluminum 6061 offers one of the highest machinability ratings among metals, enabling precise and cost-efficient prototype production.

- Stainless steel demands reduced feed rates, increasing machining time by 25–40% compared with aluminum.

- POM machines cleanly with crisp edges and exceptional surface flatness.

- PEEK requires controlled temperatures and sharp tooling to maintain surface integrity.

Ecoreprap Machinability Optimization Practices

- Proprietary cutting parameter database built from 10+ years of production logs.

- Tool life tracking for each material category (metal, engineering plastic, high-performance polymer).

- Multi-axis tool path simulation for complex prototypes with pockets, threads, and deep grooves.

- Adaptive roughing and controlled finishing to balance speed and stability.

Mechanical strength directly affects prototype functionality

Because materials with different tensile properties withstand load and stress differently.

When prototypes are intended for mechanical or functional testing, the strength requirement becomes a decisive factor in material choice.

Performance differences caused by material strength:

- Aluminum 7075 delivers high structural integrity, suitable for load-bearing frames or fixtures.

- ABS offers adequate impact strength but is not ideal for heavy mechanical loads.

- POM provides excellent wear resistance in motion-intensive prototypes.

- PEEK maintains strength even at high temperatures, often used in aerospace test components.

Ecoreprap Functional Prototype Capabilities

- Tensile testing data available for all stocked materials.

- Functional prototype pass rate: 98.7% in 2024–2025 evaluation cycles.

- Support for small-batch testing runs using identical material sources for consistency.

- Experience delivering prototypes for robotics, automotive assemblies, and industrial automation.

Surface finish quality directly depends on material behavior

Because different materials respond differently to cutting geometry and feed speed.

Surface quality affects not only the appearance but also the assembly and friction performance of CNC prototypes.

Surface-related insights from Ecoreprap’s machining experience:

- Aluminum yields smooth finishes with fine tool marks that can be polished easily.

- PMMA requires specialized tools to achieve optical-level clarity.

- ABS can show tool ripples if machining direction and feed rate are not optimized.

- POM produces clean edges suitable for sliding components without additional finishing.

Ecoreprap Surface-Finish Standards

- Surface finish capability: Ra 0.8–3.2 µm depending on material.

- In-house polishing and bead-blasting for metal and plastic prototypes.

- CAM-simulated feed-path control for uniform finish across curved surfaces.

- Inspection performed using Mitutoyo roughness testers.

Comparing common CNC materials helps engineers select the right option

Because each material offers unique advantages and constraints.

Here is a simplified comparison engineers often use when evaluating CNC prototype materials:

Aluminum 6061 / 7075

- Balanced strength and machinability

- Good thermal stability

- Best for functional and structural prototypes

ABS

- Low cost and lightweight

- Easy to machine but less stable in thin features

- Suitable for enclosures, housings, and early-stage models

POM (Delrin)

- Exceptional dimensional stability

- Low friction and high stiffness

- Ideal for gears, sliders, precision mechanisms

PEEK

- High heat resistance (up to ~260°C)

- High strength-to-weight ratio

- Used for aerospace or medical prototypes requiring extreme performance

Ecoreprap Multi-Material Expertise

- Stock availability: 30+ metals and plastics including aluminum, POM, ABS, PMMA, nylon, PEEK.

- Material traceability with batch identification.

- Engineers available to compare performance across multiple materials for clients.

Selecting the correct material ensures prototype reliability

Because the material choice determines testing accuracy, assembly fit, and product validation outcomes.

Material selection should follow a structured decision process to avoid tolerance issues, deformation, or unintended failure during prototype evaluation.

Recommended steps for choosing CNC material:

- Define the prototype’s purpose: appearance, assembly, or functional load-testing.

- Determine tolerance requirements (e.g., ±0.01–0.02 mm).

- Match mechanical properties with intended stress or motion scenarios.

- Consider thermal behavior if the part involves long tool paths.

- Evaluate machinability to balance cost, time, and surface finish expectations.

Ecoreprap Material Recommendation Support

- One-to-one engineering advice for material selection.

- Sample-based comparison with performance predictions.

- Practical guidance built from more than a decade of CNC project experience.

- In-house prototype validation to ensure material suitability before batch production.

Conclusion

Material selection shapes CNC prototype performance because every mechanical, thermal, and machining-related property influences accuracy, stability, and appearance.

Through Ecoreprap’s long-term CNC prototyping experience, consistent results demonstrate that choosing the correct material is the strongest predictor of prototype success.

By understanding hardness, thermal expansion, machinability, strength, and surface behavior, engineers can better match materials to prototype function and achieve reliable, repeatable machining outcomes.

With comprehensive CNC capabilities, multi-material expertise, and data-supported machining standards, Ecoreprap supports engineers in making informed decisions throughout the prototyping process.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.