Table of Contents

Spotface is a kind of common hole in engineering and manufacturing, making huge effect on providing even and flat seat for fastener heads or washers. And it is very easy to confuse a spotface hole with a counterbore hole, which is also applied to accommodate fasteners.

In this article, we will explain the definition, callout, and applications of spotface. Additionally, we will also illustrate some key differences between spotface holes and counterbore holes.

Key Takeaways:

- Spotface creates shallow, flat seating surfaces on rough or uneven materials for fastener heads and washers, ensuring proper contact and load distribution while preventing tilting and uneven stress.

- Spotface is shallow (provides flat seat only) while counterbore is deeper (completely accommodates fastener heads below surface). Spotface focuses on surface preparation, counterbore on fastener concealment.

- Spotface is essential for bolt installation on cast surfaces (engine blocks), bearing seating in gearbox housings, sealing surface preparation for hydraulic systems, and any application requiring flat mounting on irregular surfaces.

- Spotface requires proper tool selection (adjustable, carbide, or multi-tooth cutters), controlled parameters (50-70% drilling speed, 0.05-0.15mm/rev feed rate), and strict perpendicularity maintenance during operation.

1. What is Spotface?

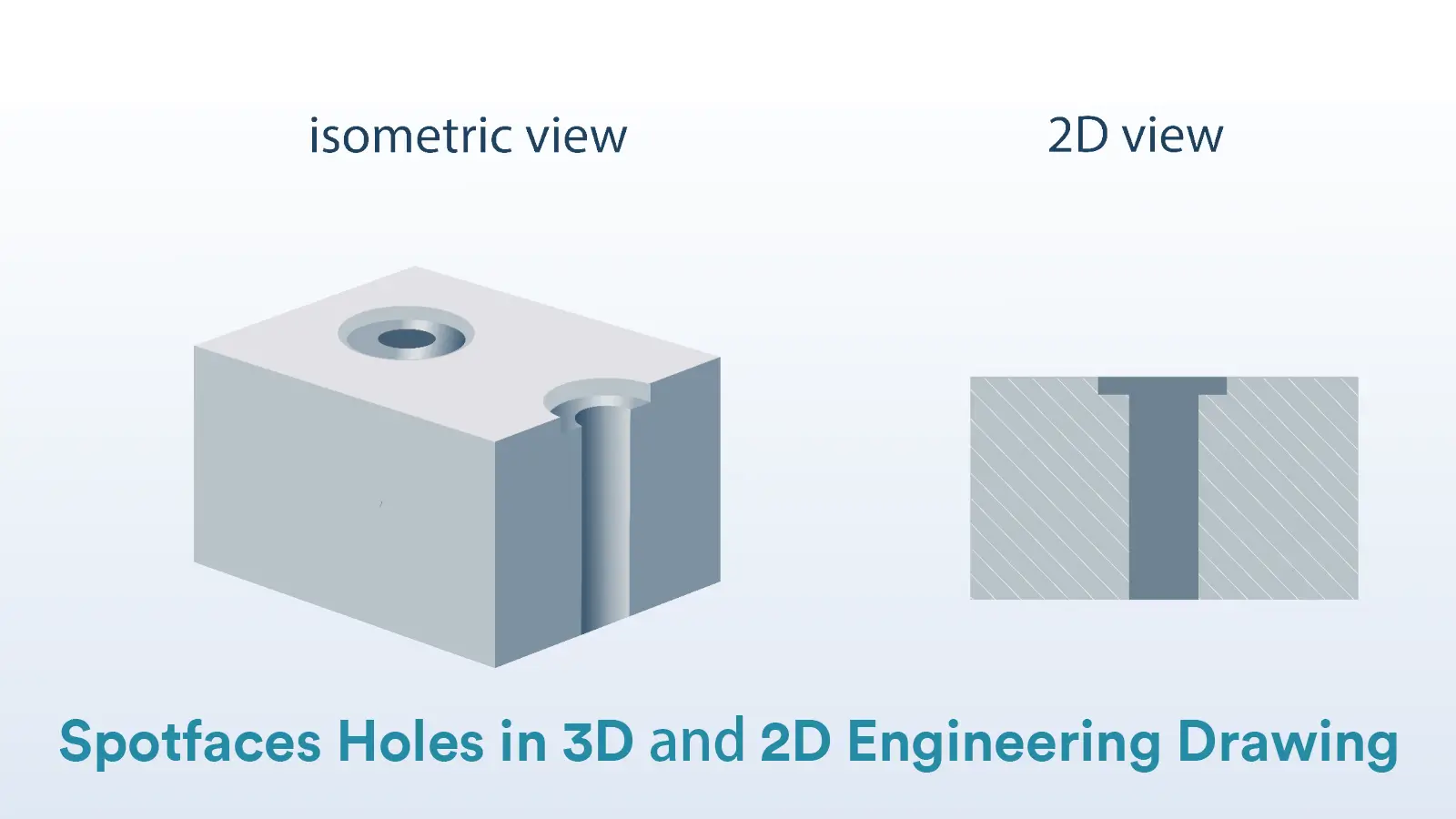

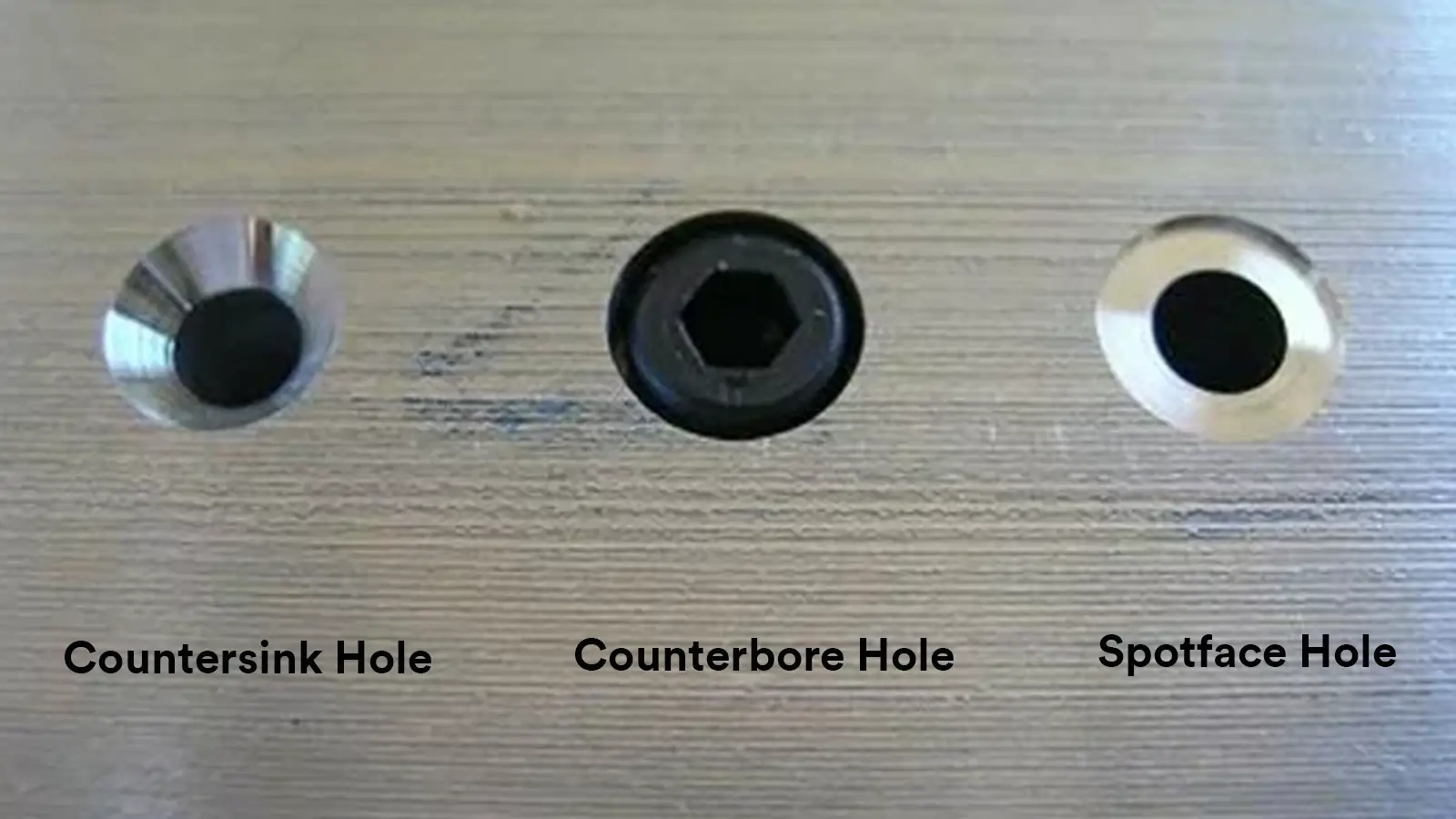

As one of the common holes in engineering and manufacturing, spotface is a very shallow circular or cylindrical hole with a flat bottom and is larger than the coaxial pilot hole connected below it.

It is a machining feature drilled on the surface of a workpiece to provide a flat and even support base for the head of a bolt, nut and other fastener, or a lock washer.

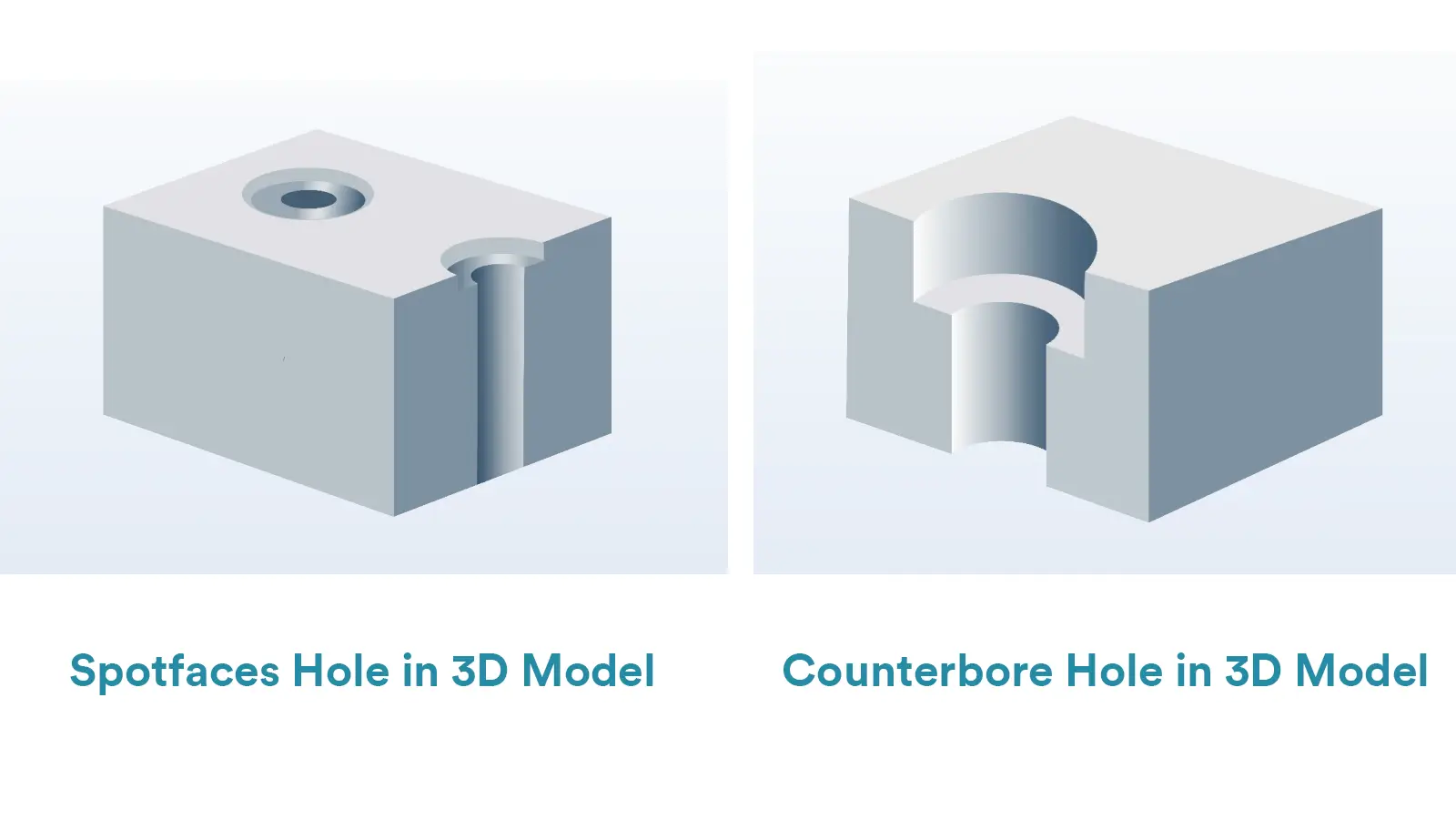

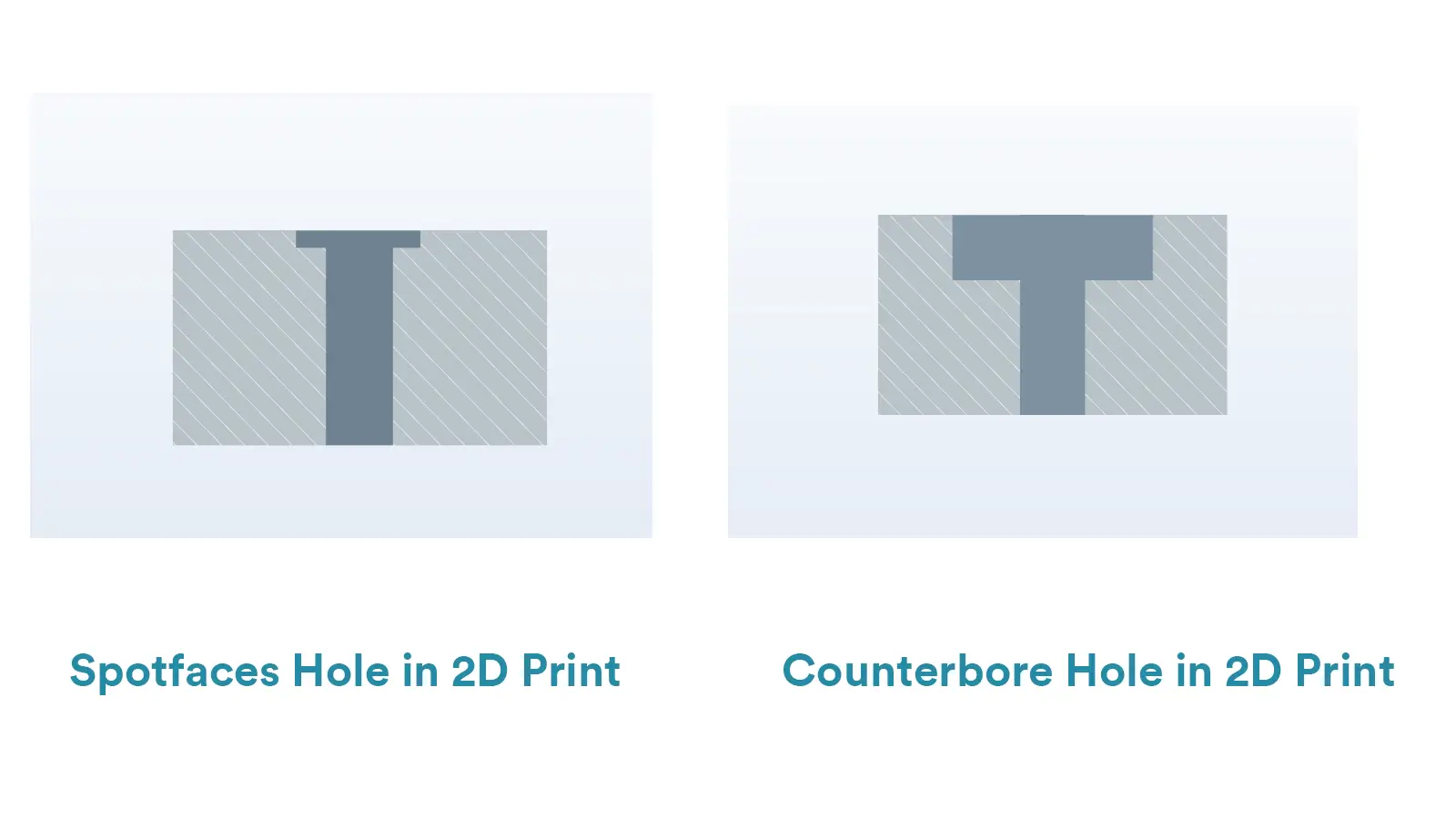

A spotface hole is much similar to a counterbore hole. A counterbore hole is also a flat-bottomed cylindrical hole. But spotface holes are much shorter in depth, which can be seen as the compressed version of counterbore holes. Therefore, the main function of a spotface is different from that of a counterbore.

As a shallow flat-bottomed hole, spotface is applied to provide only a flat mounting surface for mating pats. However, much deeper than spotface, counterbore is applied to provide a flat and recessed mounting surface for fastener heads to be completely accommodated within.

2. Spotface Callout in Engineering Drawings

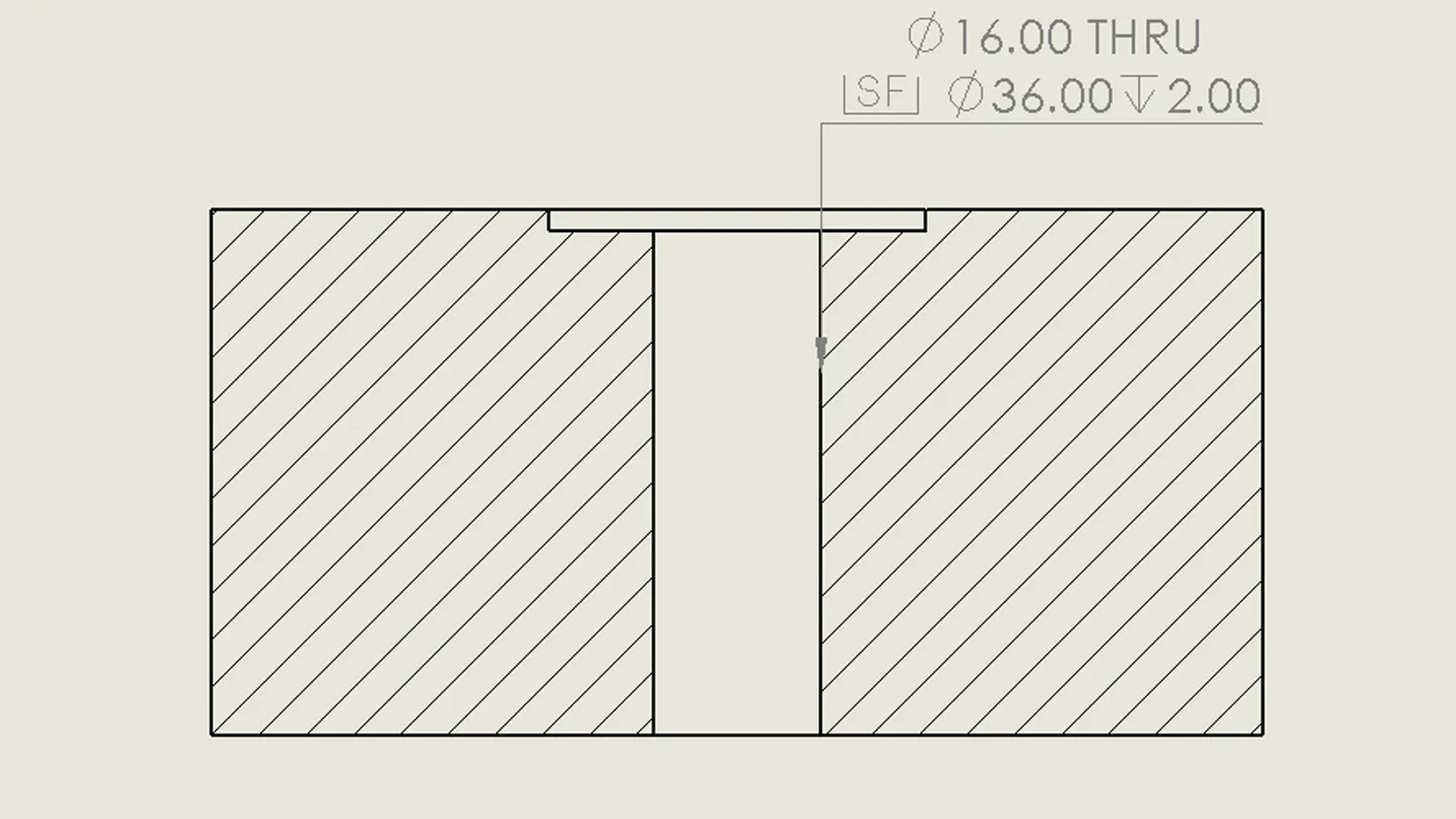

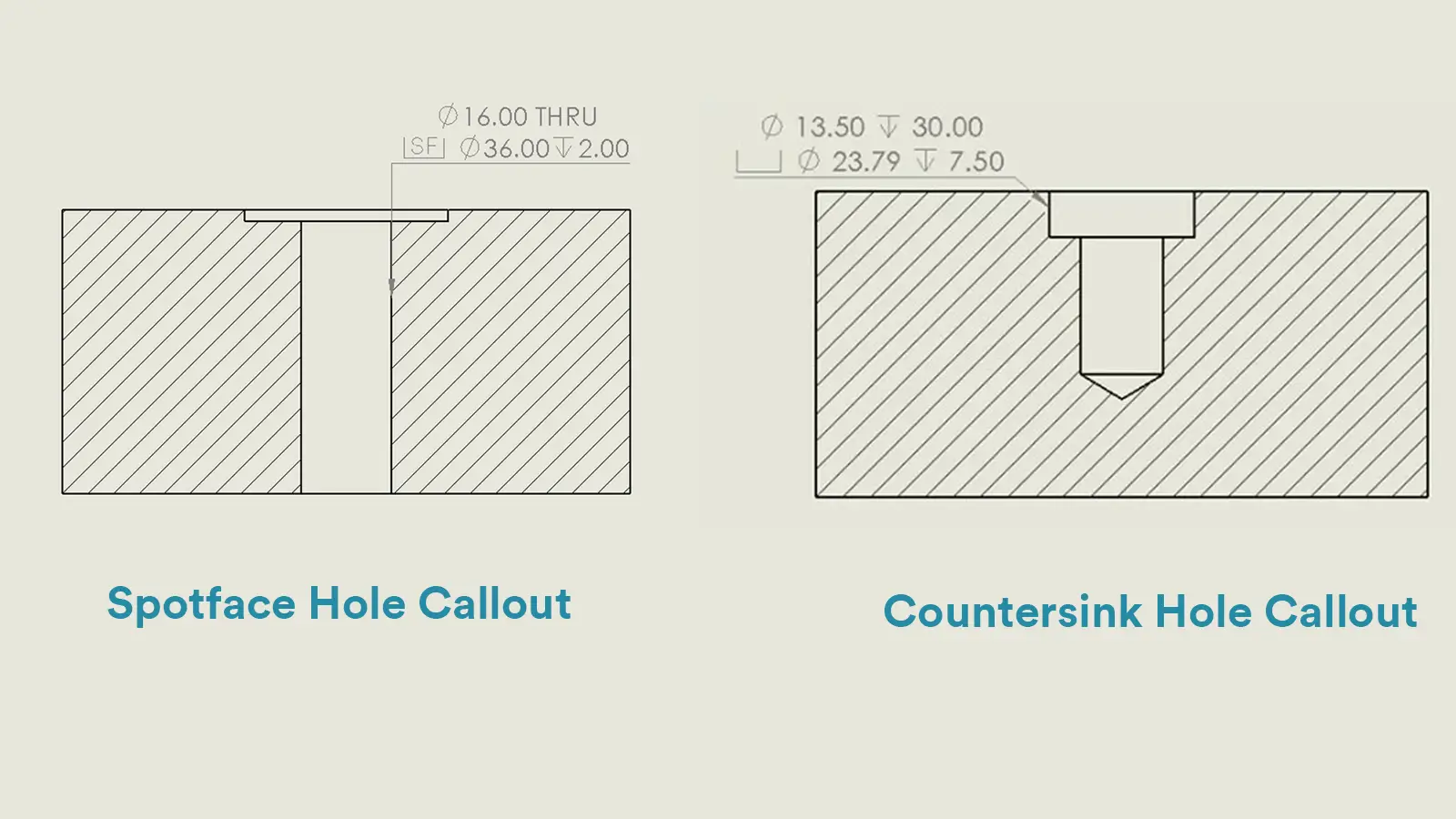

The spotface symbol is a rectangle opening at the top and entertaining letter “SF” as the abbreviation of spotface within. It means that the spotface symbol is similar to the counterbore symbol, just with an addition of the letters “SF”.

And the spotface callout in engineering drawings are also similar to that of the counterbore. Generally, there would be two rows of indications of the measured holes.

The first row indicates the information of the thru hole, including the number of the measured holes and the tolerance zone. The first factor is an Arabic number with the symbol of multiplication(“ⅹ”) to indicate the amount of the controlled holes.

The second factor is the symbol of the diameter and the dimension zone of the holes. The permissible dimension can either be indicated by the basic dimension with the tolerance zone or directly by the permissible dimension zone.

The second row shows the information of the spotface hole, including the spotface symbol and dimension zone on diameter and depth. The first factor of this row is the symbol of spotface, an opening rectangle with the letters “SF” inside.

The second factor is the diameter symbol with the permissible diametric dimension zone.

And the third factor is the depth symbol with the acceptable dimension zone on the depth of the measured spotface holes.

The dimension zone can also either be indicated by the basic dimension with the tolerance zone or directly by the acceptable dimension zone. But note that the information should be indicated in the uniform form.

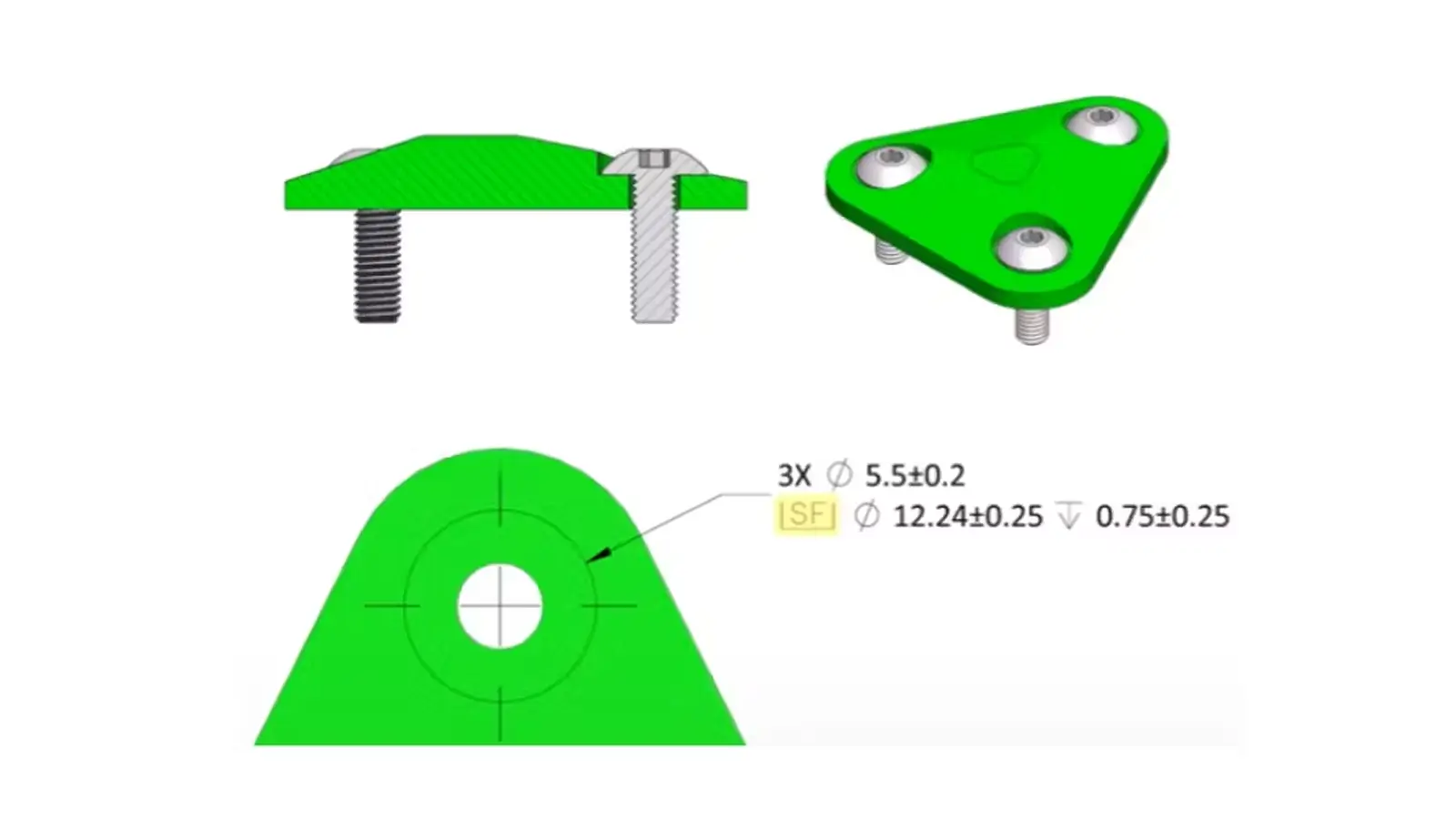

Then the two rows of indications would be connected with the circular line of the measured holes by a leader arrow. Below is an example of spotface callout in engineering drawings:

3. Applications of Spotface Holes

Spotface holes are commonly used in fields of automobile manufacturing, aerospace and other general machining. As a shallow flat-bottomed hole, spotface plays a critical role in providing a secure mounting surface for those mating parts in situation where the surface around the holes is coarse, inclined or uneven.

If a fastener seat is rough, uneven or curved, the fastener in the hole would have to take on uneven stresses, which would certainly damage the fastener or make the fastener be inclined, loose or distorted. That is where a spotface hole comes into play.

3.1. Main Functions of Spotface Holes

Function 1: The primary function of a spotface hole is to create a smooth and flat seat for the head of a fastener or a lock washer to sit on securely and steadily. With a flat mounting seat machined on the surface, the head of the fastener can sit firmly and flatly, which can prevent the fastener head from sinking into the material and then influencing the fastener’s functions or distorting the material.

Function 2: The other function of a spotface hole is to ensure the good contact between the fastener and its mating part. If the mounting surface around the hole is certainly uneven, the gap between the fastener and the material may cause acute vibration and wearing. By providing a flat seat, a spotface can make the fastener contact with its mating part well and then can reduce the unnecessary vibration and wearing, elevating the stability and reliability on the whole.

Function 3: Beside from the above two functions, a spotface hole also plays a role in controlling the perpendicularity. By amending the surface around the hole flat, a spotface can keep the fastener head perpendicular to the central axis, which can prevent uneven load or improper mating due to the inclination.

3.2. Examples of Spotface Applications

Spotface is commonly applied to automobile manufacturing, aerospace and many other machining industries, especially on the rough, uneven, or curved surface of the components. Below we list some concrete examples of spotface applications.

Bolt or Screw Installation: As we all know, in the situation where a bolt should be installed on the rough surface of a cast, the hole periphery may be uneven or have burrs, requiring a spotface to provide a flat mounting seat.

For instant, machining a spotface for the bolt hole on engine blocks can ensure the bolt head fit snugly, thus avoiding uneven preload due to surface irregularities. And machining spotfaces for bolt holes on steel-structured connecting plates can prevent washer deformation caused by roughness.

Bearing or Bushing Installation: Spotface holes are popularly used in the cases where the bearing housings or bushings must fully seat against the base to ensure alignment.

For instant, machining a spotface for outer rings of bearings on gearbox housings can prevent tilting and then extend service life of the components.

Sealing Surface Machining: Commonly, most sealed components like hydraulic valve blocks require the surrounding surface to be flat to avoid leaks. Spotface machining is one of the most common methods to deal with such a problem.

For instant, machining a spotface for the bolt hole on the flange of a hydraulic pipe can ensure even compression of gaskets.

4. Guides for Spotface Machining

This part will introduce the procedure of spotface machining and some key tips for considerations. In general, machining spotface by CNC is more automatic and accurate, but operating the drill press by hand is one of the common means too.

4.1. Procedure of Spotface Machining

Step 1: Select the appropriate spotface tool based on the drawing requirements, ensuring the diameter of the spotface cutter is bigger than that of the bolt head or the washer.

The common types of spotface tools include adjustable spotface cutter(suitable for various diameter needs), solid carbide spotface cutter(used for high-hardness materials), and multi-tooth spotface cutter(used for improving machining efficiency).

Step 2: Securely fix the workpiece to prevent vibration or misalignment and mark the center point of the hole based on the drawing.

Step 3: Set the proper spindle speed, feed rate and cutting depth. Usually, the spindle speed is better to be lower than drilling speed(typically 50%-70% of drilling speed) to avoid tool chatter and the feed rate should be slow and steady(like 0,05-0.15mm/rev) to ensure surface finish.

Step 4: Machining the spotface hole. If you choose to use CNC machines, you should just program the tool path and then the machines would automatically complete spotface machining, which is accurate on depth and diameter control.

If you choose to spotface by manual machining, you should install the spotface cutter into the drill chuck and align it with the center point. And then start the drill press to slowly feed the tool to the required depth. Note to keep the tool perpendicular to the workpiece surface during the operation.

Step 5: Remove the edge burrs with a file or deburring tool after machining.

4.2. Key Tips for Spotface Machining

Tip 1: Ensure that the spotface cutter is coaxial with the hole’s center; otherwise, eccentricity may occur or the surface may be uneven. If the spotface is eccentric, the spotface tool should be re-aligned or the workpiece should be secured firmly again.

Tip 2: Use cutting fluid such as emulsion when machining steel or stainless steel to prevent overheating.

Tip 3: For high finish requirements, reduce the feed rate or use a finishing spotface cutter. If the spotface surface is rough, the feed may excessive or the tool has worn too much.

Tip 4: Depth can be precisely controlled by machine scale or CNC program to avoid overcutting.

Tip 5: For tool chipping, it may be caused by excessive speed or material hardness. Reducing speed or using carbide tool can resolve such a problem.

5. Spotface VS Counterbore

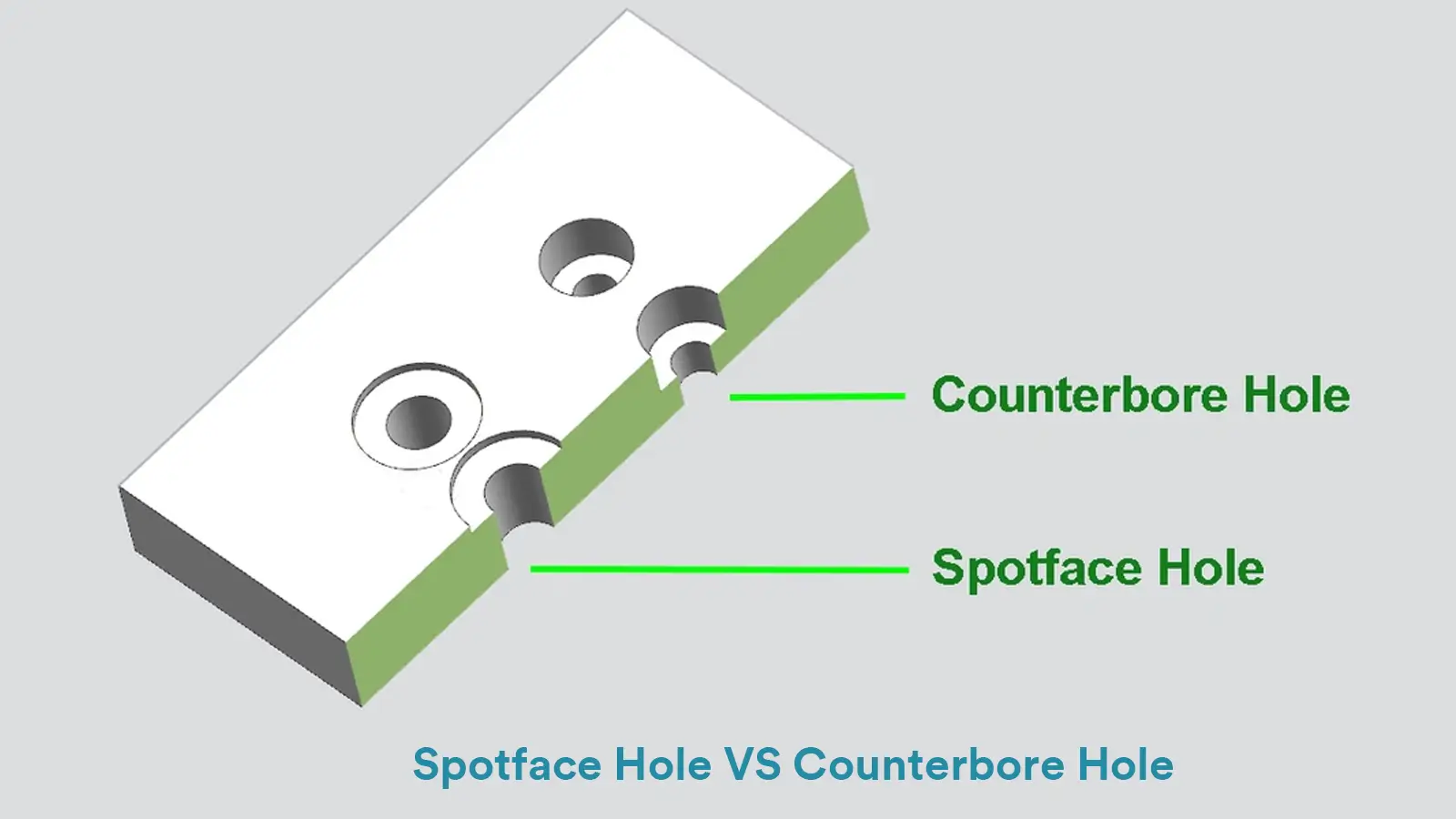

In fact, the spotface is very similar to counterbore. They are both cylindrical hole with a flat bottom and are both coaxial with the thru hole. And their diameter are both larger than the thru hole’s diameter.

More importantly, they are both used to accommodate the fastener heads. However, there are key distinctions between them in some aspects.

5.1. On the Depth

The primary essential difference between spotface and counterbore lies on the depth. They are mostly similar on the form, but the spotface’s depth is much shorter than that of the counterbore.

Spotface is just shallow enough to provide a flat seat for the fastener head, while the depth of a counterbore hole should at least as long as the height of the fastener head(usually deeper enough to completely accommodate the fastener head or even with a lock washer).

5.2. On the Function

One of the main differences between spotfaces and counterbores is their respective functions. Although they are both used to accommodate the fastener heads, the concrete forms are different.

Spotface is just applied to provide a flat mounting surface for fastener heads or lock washers, while counterbore is required to completely hide the fastener heads inside(beneath the workpiece surface).

In short, by using a spotface, the fastener head would still stand out on the material surface. But if a counterbore is used, the fastener head would be encompassed below the surface completely to avoid creating assembly restrictions.

5.3. On the Surface Finish

Although both the spotface and counterbore are cylindrical holes with a flat bottom, a spotface usually has a smoother and falter surface finish. The main reason it that the primary purpose of a spotface is to provide a level mounting surface to achieve stability and even loading, while a counterbore can accept certainly rough walls without affecting functionality.

5.4. On the Application

Spotfaces are commonly applied in castings or rough machined parts to provide a flat mounting seat to prevent wobbling or improper seating of the fastener.

Whereas counterbores are commonly used in situation where the fastener heads must be completely recessed to avoid interference with other parts. The common applications include switch panels, PCB, and home appliance housing, etc.

Below is the callout symbol in the 2d drawings of spotface and counterbore difference.

6. Other Types of Holes in Machining

Apart from spotface holes and counterbore holes, there are also other various types of holes in machining. Below we list some of the common holes.

Through Hole: Just as the name implies, a through hole is a kind of hole that is machined through the material entirely, opening from one side to the other side.

Blind Hole: Opposite to a through hole, a blind hole does not completely go through the material. Only machined to a specified depth, a blind hole will not reach opening to the other side of the workpiece.

Countersink Hole: A countersink hole is a cone-shaped hole machined at the mouth of a coaxially cylindrical pilot hole. The countersink angle is specified to accommodate the particular cone-shaped fastener head.

Visit our bog: Counterbore vs Countersink:What is The Difference?

Tapered Hole: Opposite to a countersink hole, a tapered hole is also a conical hole, but its diameter is gradually larger from the entrance to the bottom.

7. Conclusion

In this article we have comprehensively explain the knowledge of spotface, including its definition, callout, machining method, applications, and comparison with counterbore. But if you are still confused about spotface or any other types of holes, please contact with us directly.

8. FAQs

8.1. Are spotface and counterbore machined by different tools?

There are particularly specialized tools for both spotface machining and counterbore machining. But in some cases, they may be machined by the same tools, such as endmills or reamers.

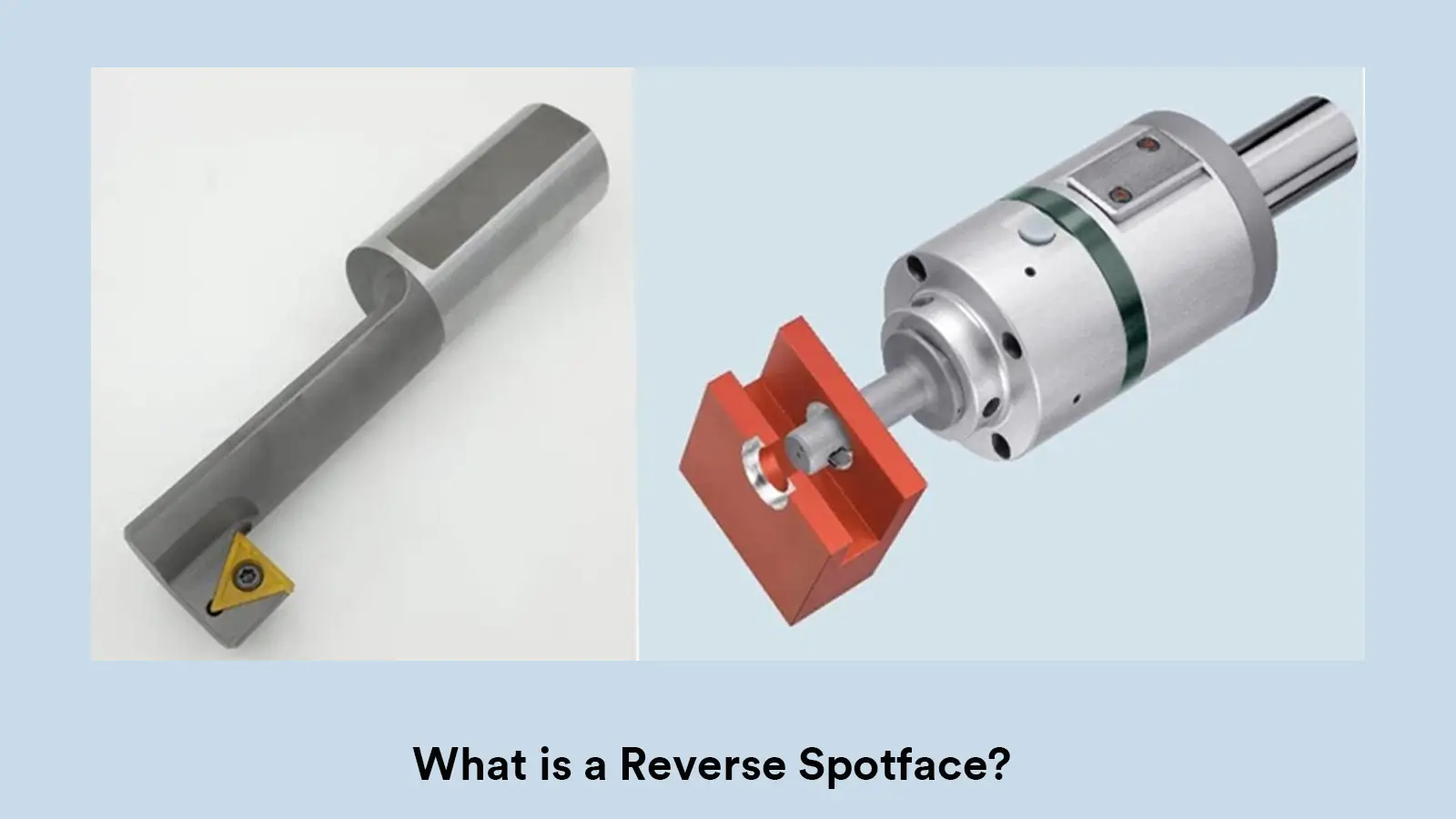

8.2. What is a reverse spotface?

A reverse spotface is totally similar to a regular spotface in form. The difference is that a reverse spotface is machined on the back side of the part typically when it is difficult to drill a spotface on the front side of the part or due to the space limitations.

A reverse spotface is also called back spotface.

8.3. What are reverse spotface tools?

Compared with regular spotface tools, reverse spotface tools have longer reach to access the reverse side of the part. In addition, to handle specific materials or tolerances, they may also have indexable inserts or custom geometries.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.