Table of Contents

When sourcing CNC prototypes from China, success depends on choosing experienced suppliers with proven quality control, precise machining capabilities, proper certifications, and clear communication.

By understanding the key factors and following a structured approach, companies can reduce risk, save cost, and ensure prototype accuracy for their product development.

Understanding CNC Prototyping and China’s Market Advantage

CNC prototyping in China provides fast, cost-effective, and high-precision solutions for global manufacturers.

With advanced machinery and competitive pricing, Chinese suppliers have become a preferred choice for companies across automotive, aerospace, and electronics industries.

1.What Is CNC Prototyping and Why It Matters?

CNC prototyping refers to the process of creating physical product samples directly from CAD designs using computer-controlled machines.

It allows engineers to test functionality, evaluate materials, and optimize product designs before mass production.

Chinese suppliers offer a range of capabilities, including 3-axis to 5-axis CNC machining, rapid turnaround times, and compatibility with metals and plastics like Aluminum 6061, Stainless Steel 304, and ABS.

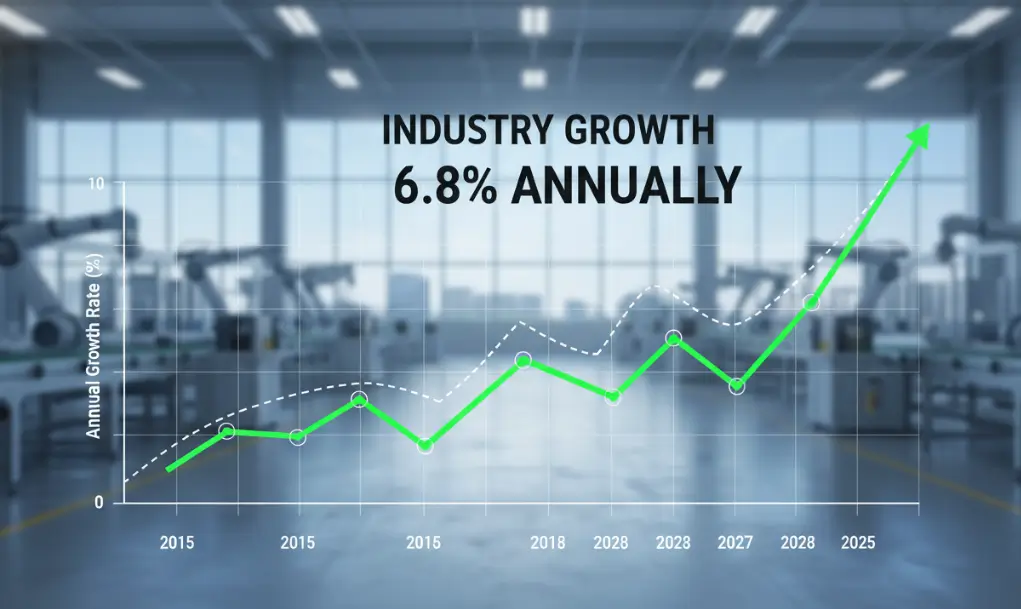

2.Growth of China’s CNC Prototyping Industry (2020–2025)

China’s CNC prototyping sector has grown steadily, with an estimated annual growth rate of 6.8% from 2020 to 2025.

Major hubs like Shenzhen, Suzhou, and Guangzhou have concentrated clusters of CNC machine shops, providing cost advantages of 20–40% compared to Europe or the US.

The combination of skilled labor, mature supply chains, and modern machinery makes China an attractive sourcing destination.

3.Why Foreign Companies Choose Chinese CNC Suppliers?

- Foreign companies are increasingly choosing Chinese CNC suppliers because of:

- Cost efficiency: Production cost reductions of up to 40% for prototypes.

- Fast lead times: Standard CNC prototypes can be delivered in 5–7 days, with mass production ready within 2–4 weeks.

- High precision: Advanced 5-axis machines and precision tolerances of ±0.01 mm ensure quality prototypes.

- Scalability: Easy transition from prototype to small batch production without changing suppliers.

Key Factors to Consider When Sourcing CNC Prototypes from China

The most important factors when sourcing CNC prototypes include quality control, supplier reliability, certifications, materials, communication, and IP protection.

Addressing these elements reduces risk and ensures the success of your prototype project.

1.Quality Control and Inspection Standards

Quality control is the cornerstone of successful prototyping. Suppliers should implement robust inspection procedures:

- ISO 9001 and ISO/TS 16949 certified processes.

- CMM (Coordinate Measuring Machine) inspection and tolerance testing (±0.01 mm).

- On-site audits and third-party quality reports.

In our experience, suppliers who consistently provide CMM inspection reports significantly reduce prototype defects and alignment issues.

2.Material Selection and Machining Capabilities

Choosing the correct material and verifying supplier machining capabilities are critical:

- Common materials: Aluminum 6061, Stainless Steel 304, ABS, POM.

- Precision requirements: ±0.05 mm for functional prototypes.

- Supplier capability assessment: Ask for prior sample projects and machining portfolio.

Experienced suppliers will guide material selection based on product functionality, durability, and cost efficiency.

3.Supplier Certification and Compliance

Verified certifications indicate reliability and adherence to international standards:

- CE and RoHS certifications for safety compliance.

- ISO 9001 or ISO/TS 16949 for quality management.

- Verification of audit date (preferably within the last 12 months).

Always request certification copies and verify authenticity to minimize sourcing risk.

4.Communication and Project Management

Transparent communication ensures prototypes meet design expectations:

- Set clear timelines and regular updates (weekly reports recommended)

- Use project management tools such as Asana, Trello, or Monday.com

- Experience shows that responsive suppliers typically reply within 24 hours, reducing misunderstandings and delays

5.Intellectual Property Protection

Protecting your designs is essential when collaborating internationally:

- Sign a Non-Disclosure Agreement (NDA) before sharing CAD files.

- Mark patents clearly and discuss proprietary components with the supplier.

- Work with suppliers who have a history of handling confidential projects.

Step-by-Step Guide to Finding Reliable CNC Prototype Suppliers in China

To minimize risks and ensure high-quality prototypes, follow these practical steps based on our sourcing experience:

Step 1 – Identify Verified CNC Prototype Manufacturers

- Use platforms like Alibaba Verified, Made-in-China Premium Suppliers.

- Check company registration, years of operation (5+ years recommended), and track record.

- Evaluate reviews and project portfolios.

Step 2 – Request Sample Prototypes and Evaluate Precision

- Specify critical tolerances and surface finish.

- Compare prototype quality across 2–3 suppliers.

- Review CMM or 3D scanning reports to confirm dimensions.

Step 3 – Evaluate Quotation and Lead Time

- Compare prices and delivery times transparently.

- Typical lead time: 5–7 days for prototypes, 2–4 weeks for small batch production.

- Ensure tooling fees and additional costs are clearly outlined.

Step 4 – Sign a Clear Manufacturing Agreement

- Detail quality acceptance standards, delivery schedule, and NDA terms.

- Include QC checklist and required inspection reports.

- Set dispute resolution procedures in advance.

Following these steps ensures your sourcing process is structured, transparent, and efficient.

Common Mistakes to Avoid When Sourcing CNC Prototypes

Avoiding common pitfalls can save significant time and cost:

1.Ignoring Tolerances in Technical Drawings

Even minor deviations can compromise functionality.

Always provide precise CAD files with tolerance specifications.

2.Choosing the Lowest Quote Without Verifying Capabilities

Low prices may indicate inferior quality or outdated equipment.

Verify machinery, experience, and references.

3.Not Signing an NDA or IP Agreement

Sharing designs without protection can lead to intellectual property theft.

NDA and proper contracts are essential.

Conclusion

When sourcing CNC prototypes from China, success depends on certified, experienced suppliers, quality control, precise machining, and clear communication.

Companies that carefully evaluate these factors can save costs, accelerate development, and produce functional prototypes that meet international standards.

Ecoreprap team has over 10 years of CNC prototyping experience in China

Delivering thousands of prototypes for clients across automotive, aerospace, and electronics industries.

Contact us today for a free consultation to ensure your prototype projects succeed.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.