Table of Contents

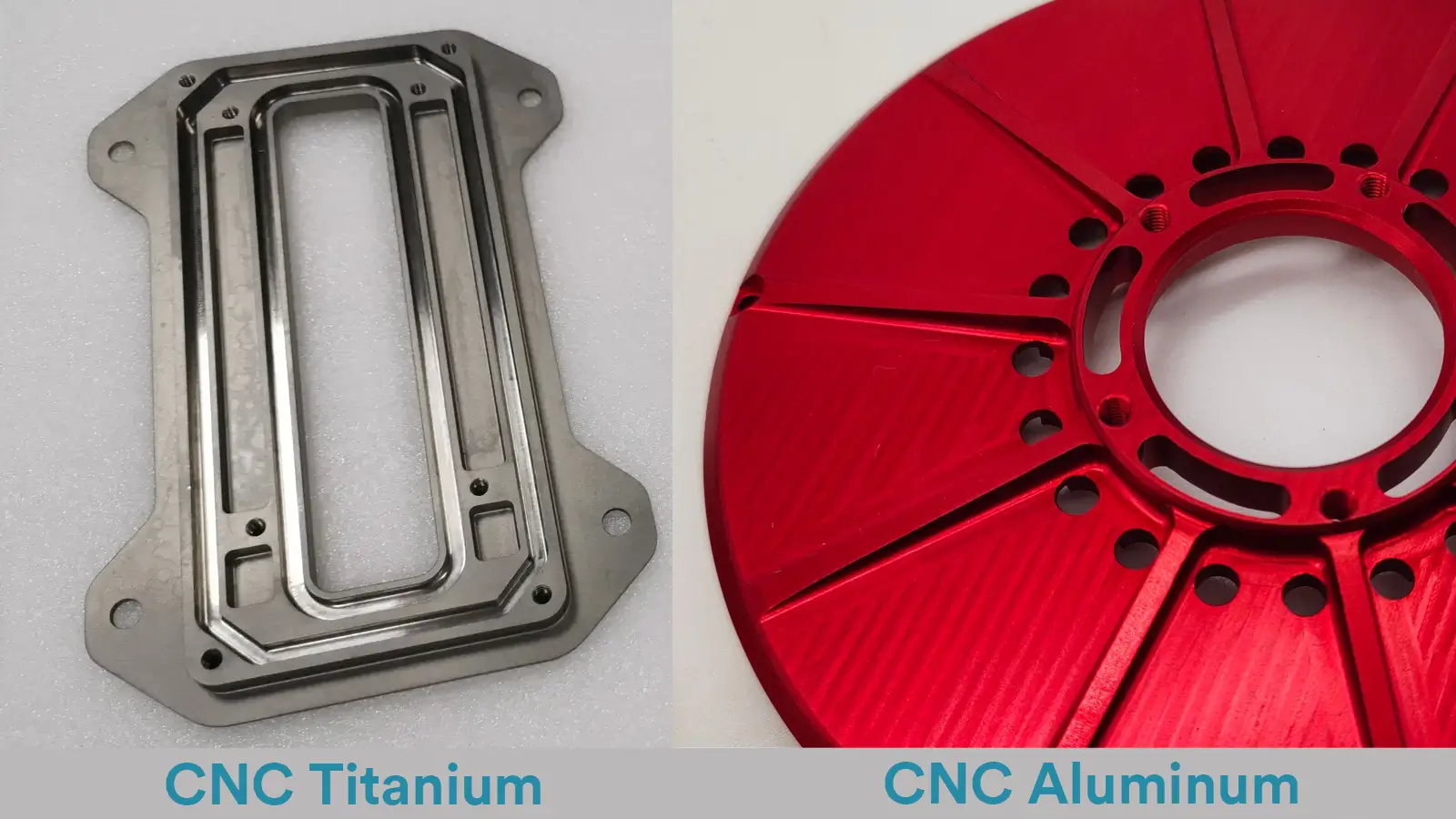

In CNC machining, aluminum alloys are widely chosen for low cost and high machining efficiency, while titanium alloys provide superior strength, fatigue resistance, and corrosion performance—at 3–6× higher manufacturing cost. Material selection depends on whether performance or cost is the primary constraint.

Engineers, designers, and procurement professionals often ask: “Titanium or aluminum?” Both are lightweight, high-performance metals, but they differ fundamentally in strength, weight, cost, machinability, and applications. Choosing the wrong material can lead to unnecessary cost, over-engineering, or even failure risks.

This guide compares titanium alloys (e.g., Ti-6Al-4V / TC4 / Grade 5) and aluminum alloys (e.g., 6061-T6 and 7075-T6) from an engineering perspective, providing insights to balance performance, weight, and budget.

Key Takeaways:

- Titanium alloys (Ti-6Al-4V) deliver far superior strength, fatigue resistance, and corrosion performance—but at 3–6× higher manufacturing cost of aluminum CNC machining.

- While 7075-T6 aluminum and Grade 5 titanium have comparable strength-to-weight ratios, titanium clearly outperforms in fatigue life, high-temperature stability (>300 °C), corrosion resistance, and stress-corrosion immunity, making it irreplaceable for aerospace, medical, and high-reliability parts.

- Aluminum is easy to machine at high speeds with excellent heat dissipation, making it ideal for prototyping and mass production. Titanium acts as a “heat trap,” requiring slower speeds, specialized tooling, and high-pressure cooling—significantly increasing cycle time, tooling cost, and process complexity.

- Choose aluminum when cost, speed, and scalability are the priority and loads are moderate. Choose titanium when weight savings, fatigue resistance, corrosion resistance, or biocompatibility are critical and design space is limited.

1. Key Mechanical Properties Comparison

To make a clear comparison, let’s look at the most common types: Ti-6Al-4V (Grade 5/TC4) for titanium, and 6061-T6 and 7075-T6 for aluminum.

| Property | Titanium (Ti-6Al-4V / Grade 5) | Aluminum 7075-T6 | Aluminum 6061-T6 | Engineering Insight |

|---|---|---|---|---|

| Density | 4.43 g/cm³ | 2.81 g/cm³ | 2.70 g/cm³ | 6061 is lightest, 7075 mid-range, Ti heaviest. Ti is heavier but offers higher specific strength. |

| Tensile Strength | 900–1100 MPa | 540–570 MPa | 290–310 MPa | Ti strongest (~1.8× 7075, ~3.5× 6061). |

| Yield Strength | 830 MPa | 470 MPa | 240–275 MPa | Ti resists permanent deformation best. |

| Elastic Modulus | 110 GPa | 71 GPa | 68.9 GPa | Ti is stiffer, ideal for precision and thin-walled structures. |

| Specific Strength (σ/ρ) | 203–248 MPa·cm³/g | 192–203 MPa·cm³/g | 107–115 MPa·cm³/g | Ti and 7075 have similar high specific strength; 6061 lower. |

| Elongation | 8–14% | 5–11% | 8–18% | 6061 most ductile; Ti and 7075 comparable. |

| Hardness | HRC 30–36 | HB 150–160 | HB 95–100 | Ti hardest, 6061 easiest to machine. |

| Corrosion Resistance | Excellent (self-passivating) | Good (needs coating) | Good | Ti superior; 6061 naturally better than 7075. |

| Thermal Stability | Long-term 500°C | Long-term 150°C | Long-term <150°C | Ti maintains strength at high temps; aluminum degrades >150°C. |

| Thermal Conductivity | 6.7 W/m·K | 130 W/m·K | 167 W/m·K | Aluminum excellent for heat dissipation; Ti poor. |

| Coefficient of Thermal Expansion | 8.6×10⁻⁶/K | 23.6×10⁻⁶/K | 23.6×10⁻⁶/K | Ti highly dimensionally stable under temperature changes. |

| Material Cost | 8–12× base | 2–3× base | 1× base | 6061 cheapest; Ti most expensive. |

| CNC Machinability | Difficult: low speed, high tool wear | Moderate: higher speed | Easy: high speed, long tool life | Ti machining requires advanced tooling and cooling; 6061 easiest. |

2. Density & Weight

Titanium density (~4.5 g/cm³) is higher than aluminum (~2.7 g/cm³) but lower than steel (~7.8 g/cm³). For the same load, thinner titanium sections can match or outperform aluminum in weight.

Choose aluminum for lightweight-only designs; choose titanium for strength + lightweight optimization.

3. Typical Strength Comparison

At standard operating temperatures, CNC titanium stands in a league of its own.

| Material | Tensile Strength (MPa) |

|---|---|

| 6061-T6 Aluminum | ~310 |

| 7075-T6 Aluminum | ~570 |

| Ti-6Al-4V (Grade 5) | ~900 |

At room temperature, Grade 5 titanium (Ti-6Al-4V) shows significantly higher tensile strength than both 6061-T6 and 7075-T6 aluminum alloys.

4. Specific Strength (Strength-to-Weight Ratio)

Specific strength is defined as tensile strength divided by density. Based on the typical tensile strength values of aluminum and titanium alloys, we can compare them as follows:

| Material | Tensile Strength σb (MPa) | Density ρ (g/cm³) | Specific Strength σb/ρ (MPa·cm³/g) |

|---|---|---|---|

| 6061-T6 Aluminum | ≈ 310 | 2.70 | ≈ 115 |

| 7075-T6 Aluminum | ≈ 570 | 2.81 | ≈ 203 |

| Ti-6Al-4V (Grade 5) | ≈ 900 | 4.43 | ≈ 203 |

From a specific strength perspective, Ti-6Al-4V (Grade 5) is essentially on par with 7075-T6 aluminum, and clearly superior to 6061-T6.

In real-world structural design, when space is limited but high strength is required, 6061-T6 often falls short, while titanium is “just right.”

Although 7075-T6 aluminum and Grade 5 titanium have similar specific strength, titanium consistently wins in high-end applications, for several key reasons:

| Performance Aspect | 7075-T6 Aluminum | Grade 5 Titanium |

|---|---|---|

| Fatigue performance | Moderate | Significantly superior |

| High-temperature stability | Degrades rapidly | Stable above 300°C |

| Corrosion resistance | Coating-dependent | Naturally corrosion resistant |

| Medical / biocompatibility | Not suitable | Naturally biocompatible |

| Stress corrosion sensitivity | High | Extremely low |

In practical engineering applications, titanium’s advantages in fatigue resistance, high-temperature performance, corrosion resistance, and long-term reliability make it irreplaceable in aerospace, medical, and high-reliability structural components.

5. Stiffness and Elastic Modulus

| Material | Elastic Modulus (GPa) |

|---|---|

| Titanium alloys | ~110 |

| Aluminum alloys | ~70 |

Aluminum is “softer” and more prone to deflection (bending) under load. Precision CNC machined titanium parts are stiffer, making them ideal for high-precision assemblies, thin-walled load-bearing structures, and parts under long-term stress.

6. Corrosion Resistance and Environmental Adaptability

Aluminum’s protection depends on its oxide film, which is sensitive to salt spray, seawater, and chemical agents. In our titanium CNC service experience, we’ve even seen 7075-T6 begin to oxidize during the machining process itself. To protect it, you almost always need post-processing like anodizing, powder coating, or painting.

In contrast, titanium CNC parts generate a naturally stable TiO2 passivation film that is practically immune to:

- Seawater and marine environments.

- Chlorides and harsh chemicals.

- Human body fluids (saline).

Because of this, the “total life-cycle cost” of titanium is often lower in corrosive environments because you save on maintenance and replacement.

7. Machining Challenges and CNC Cost Realities: Titanium vs. Aluminum

7.1 Characteristics of Aluminum CNC Machining

In the world of manufacturing, aluminum is known for its exceptional “machinability.”

Low Resistance: Cutting through aluminum requires very little force, meaning less load on the machine and tools. The process is fast and fluid, making it perfect for high-speed, high-volume production.

Superior Heat Dissipation: Aluminum has high thermal conductivity. Heat generated during cutting quickly escapes through the chips and the part itself. This keeps the tool edge cool, significantly extending tool life and ensuring a stable process.

Maximum Efficiency: Because we can use aggressive cutting speeds and feed rates, aluminum parts are finished quickly. When you combine low material costs with fast cycle times and minimal tool wear, aluminum offers the best value for budget-conscious projects.

7.2 Characteristics of Titanium CNC Machining

By contrast, CNC titanium machining is a different league of difficulty, primarily due to its low thermal conductivity.

The “Heat Trap”: Unlike aluminum, titanium acts like an insulator. Heat doesn’t dissipate; it stays concentrated right at the cutting edge of the tool. This causes temperatures to skyrocket instantly.

Chemical Reactivity & Hardening: At high temperatures, titanium tends to “stick” to the cutting tool. It also has a habit of “work hardening”—becoming harder as it’s being cut. This is incredibly demanding on tools; even a small error can lead to chipped edges, rapid wear, or dimensional inaccuracies.

Precision Requirements: To manage this, titanium CNC machining services must use specialized high-performance tools and high-pressure cooling systems (often through-spindle cooling). We also have to use more conservative cutting speeds to manage heat and stress. While this ensures a high-quality part, it naturally extends the production time and increases the final cost.

CNC Comparison Table: Aluminum vs. Titanium

| Machining Aspect | Titanium Alloy | Aluminum Alloy | Impact |

|---|---|---|---|

| Cutting speed | Medium–low (30–60 m/min) | High (200–500 m/min) | Aluminum is 3–5× more efficient |

| Tool life | Short (rapid wear) | Long | Titanium tooling cost is much higher |

| Cutting force | High (requires rigid machines) | Low | Titanium demands more expensive equipment |

| Cooling requirement | High-pressure cooling required | Standard cooling sufficient | Titanium systems are more complex |

| Surface quality | Prone to work hardening | Generally excellent | Titanium needs tighter process control |

For an identical design, a custom CNC titanium part will typically cost 3 to 6 times more to manufacture than an aluminum one.

This price difference isn’t just about one factor; it’s the combination of higher raw material prices, longer machining hours, specialized tooling, and the expertise required to manage the process.

However, if your project demands extreme strength, fatigue resistance, and a lifetime of corrosion protection, titanium is a wise investment. This is why it remains the irreplaceable standard for aerospace, medical implants, and high-reliability engineering.

8. Raw Material Costs

In any titanium CNC machining project, the price of the raw material is one of the most significant factors in the final quote. Because the refining processes and supply chains for aluminum and titanium are so different, their price points are worlds apart.

Aluminum Raw Materials: Generally very affordable, typically ranging from $2 to $5 USD/kg, depending on the specific alloy and market demand.

Titanium Raw Materials: Depending on the grade and form (bar, plate, or sheet), high-performance alloys like Ti-6Al-4V (Grade 5) can range from $20 to $50 USD/kg.

Industrial Grades: Even standard industrial-grade titanium usually sits between $8 and $30+ USD/kg.

On average, titanium raw material is 4 to 10 times more expensive than aluminum. This means that for a titanium CNC machining supplier, the material cost represents a much larger percentage of the project budget than it would for aluminum.

9. Total Cost Comparison

When evaluating wholesale CNC machining titanium vs. aluminum, it is helpful to look at the “big picture” of the manufacturing cycle.

| Cost Factor | Aluminum Alloy | Titanium Alloy |

|---|---|---|

| Raw material price | Low | High |

| CNC machining time | Short | Long |

| Tool consumption | Low | High |

| Surface finishing | Often required | Optional |

| Service life | Moderate | Extremely long |

When all cost elements are considered together, titanium parts naturally carry a much higher upfront manufacturing cost—but often deliver greater long-term value in demanding applications.

10. Surface Treatment: Titanium vs. Aluminum

10.1 Common Surface Treatments for Aluminum

Aluminum is one of the most versatile metals for finishing. Because it is relatively soft and prone to scratching, surface treatments are often mandatory. Common surface treatment for aluminum include andozing, Alodine coating, and powder coating.

Anodizing (Type II & Type III): An electrochemical process that thickens the natural oxide layer.Type II (Decorative) offers vibrant colors (red, blue, black) and good corrosion resistance. Type III (Hardcoat) creates a thick, ceramic-like surface that is extremely wear-resistant.

Chromate Conversion Coating (Alodine/Chem-Film): Best for parts that need to remain electrically conductive while gaining a layer of corrosion protection. Often used as a primer for painting.

Related blog: Chromate Conversion Coating (Alodine) Guide

Powder Coating: Provides a thick, durable, and colorful protective layer. It hides machining marks effectively, making it great for consumer-facing enclosures.

10.2 Common Surface Treatments for Titanium

Titanium is naturally beautiful and corrosion-resistant, so treatments are usually focused on reducing friction (galling) or medical identification.

Anodizing (Type I, II, & III): Unlike aluminum anodizing which uses dyes, titanium anodizing uses interference refraction. By changing the thickness of the oxide layer, the metal reflects light in different colors (gold, purple, teal) without any pigments.

It is bio-compatible (safe for implants) and does not chip or peel.

11. Typical Applications and Selection Guide

11.1 When to Choose Aluminum

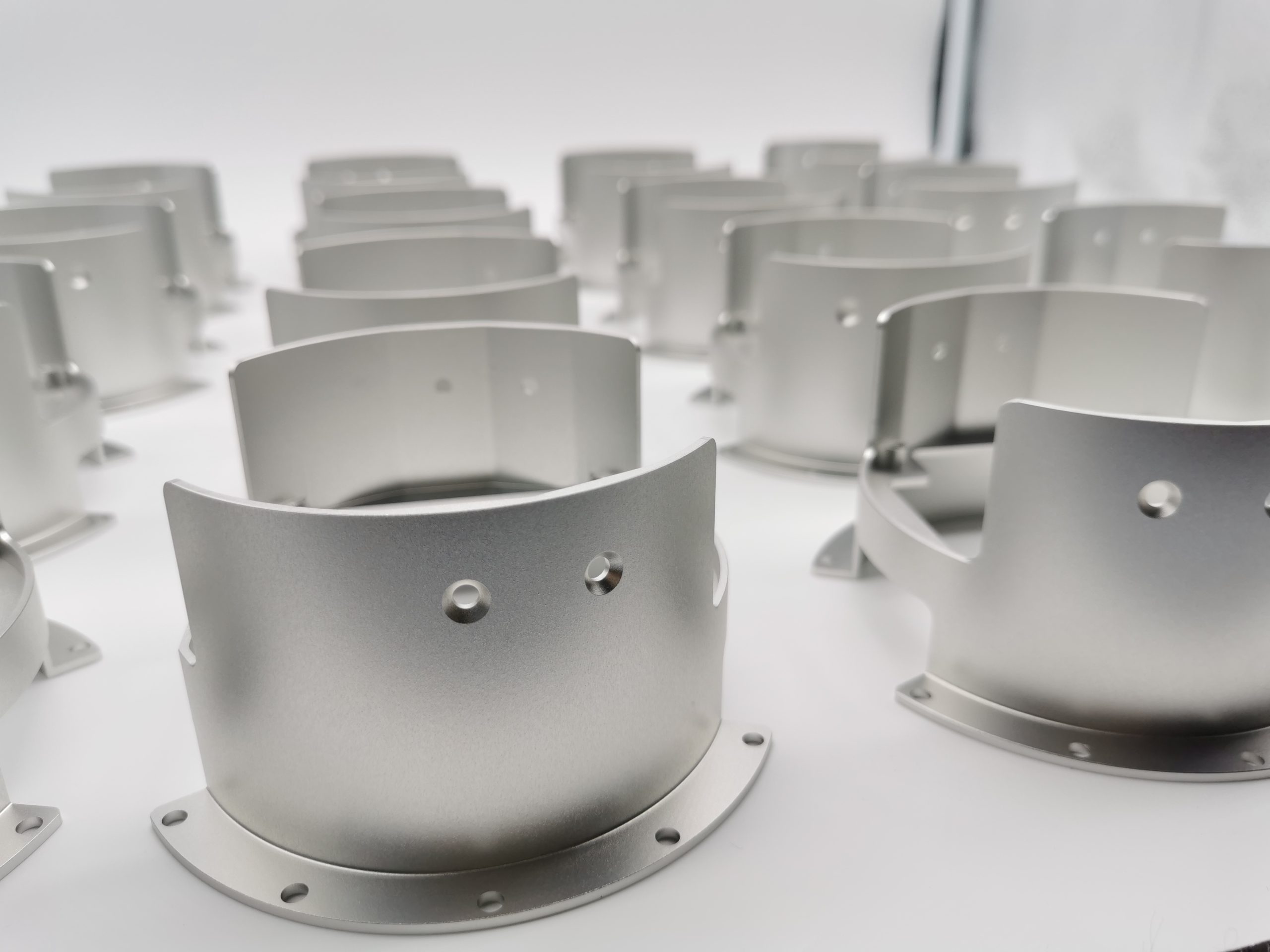

When cost control is highly critical, aluminum alloys are usually the most rational choice. With low raw material cost, high CNC machining efficiency, and minimal tool wear, aluminum is ideal for budget-constrained projects or value-oriented product designs.

In medium- to high-volume production, aluminum’s advantages become even more pronounced. Its ability to support high cutting speeds and mature, stable machining processes allows manufacturers to maintain consistency while significantly reducing unit cost. This is one of the key reasons aluminum is widely used across consumer and industrial products.

Below is medium batch aluminum parts made by aluminum.

If a part is mainly subjected to non-extreme loads, without high fatigue cycles, elevated temperatures, or aggressive corrosion, aluminum alloys can fully meet strength and service-life requirements. In such cases, choosing titanium often leads to unnecessary cost increases without proportional performance benefits.

For consumer electronics housings, industrial enclosures, support frames, and protective structures, aluminum offers an excellent balance of weight, machinability, and surface finishing flexibility.

When the design provides sufficient structural margin—such as adequate wall thickness or space for ribs—aluminum’s lower strength rarely becomes a limiting factor.

In practical CNC machining, 6061 and 7075 are the most commonly used aluminum grades:

6061 is known for its balanced mechanical properties, corrosion resistance, and excellent machinability.

7075 is preferred when higher structural strength is required, while still maintaining acceptable machinability.

Aluminum-Focused Applications

| Application Category | Specific Scenario | Material Choice & Core Rationale |

| Cost-sensitive mass production | Consumer electronics frames | Primary: 6061 aluminum – best balance of cost, machinability, and surface finishing Secondary: 7075 aluminum |

| Automotive non-critical structural parts | Primary: 6061 aluminum – excellent formability, joinability, and cost control Secondary: 7075 aluminum | |

| General industrial equipment housings | Primary: 6061 aluminum – good protection, lightweight, cost-efficient Secondary: low-grade steel | |

| Thermal management–driven applications | Heat sinks, heat exchangers | Primary: 6061 aluminum – excellent thermal conductivity, ideal for complex fins |

| LED lighting substrates | Primary: 6061 aluminum – industry standard for heat dissipation and surface treatment | |

| High-power electronics enclosures | Primary: 6061 aluminum – effective heat dissipation and scalable manufacturing Secondary: 7075 aluminum (when higher strength is required) | |

| Maximum machining efficiency | Rapid prototyping | Primary: 6061 aluminum – outstanding machinability and fastest turnaround Secondary: plastics (3D printing) |

| Frequent design iterations | Primary: 6061 aluminum – low machining cost and fast revisions | |

| Tight delivery schedules | Primary: 6061 aluminum – high material removal rate and stable processing Secondary: 7075 aluminum | |

| Moderate-load structures | UAV non-load-bearing components | Primary: 6061 aluminum – lightweight, easy to machine, cost-effective Secondary: carbon fiber composites |

| Sports equipment frames | Primary: 6061 aluminum – balanced strength, toughness, formability, and cost *Secondary: 7075 aluminum / carbon fiber* | |

| Furniture structural parts | Primary: 6061 aluminum – good surface appearance and value Secondary: stainless steel |

11.2 When Titanium Becomes Necessary

When a design simultaneously demands high strength and lightweight construction, and structural requirements cannot be met by increasing cross-sectional size, titanium alloys often become the only viable engineering solution. Their exceptionally high specific strength provides clear advantages in weight-restricted structures.

In applications subjected to long-term cyclic loading, titanium’s superior fatigue resistance significantly reduces failure risk. This is a major reason titanium is widely used in aerospace, motorsports, and high-reliability mechanical systems.

For corrosive environments—such as seawater, chemical media, or high-humidity conditions—titanium’s naturally stable oxide layer delivers outstanding corrosion resistance, often without any additional coating. This translates into lower maintenance and lifecycle costs.

In medical devices and human-contact applications, titanium alloys are essentially the industry standard. Their excellent biocompatibility, low allergenic response, and long-term stability make them the preferred material for implants and high-end medical equipment.

Additionally, when design space is extremely limited and load capacity cannot be increased through thicker walls or larger dimensions, titanium’s high strength and reliability become decisive advantages.

In CNC machining, the most widely used and mature titanium grade is Ti-6Al-4V (Grade 5 / TC4). It offers the best overall balance of strength, toughness, corrosion resistance, and supply stability, making it the default choice for most titanium components.

Titanium-Focused Applications (Based on Real Project Experience)

| Application Category | Specific Scenario | Material Choice & Core Rationale |

| High performance & reliability | Aerospace primary load-bearing structures | Primary: Titanium (Ti-6Al-4V) – highest specific strength and fatigue resistance Secondary: 7075 aluminum for secondary load areas |

| Racing critical components (suspension, linkages) | Primary: Titanium (Ti-6Al-4V or high-strength β alloys) – extreme strength-to-weight and impact resistance Secondary: 7075 aluminum | |

| High-end sports equipment (professional bicycle frames) | Primary: Titanium (Ti-3Al-2.5V) – excellent vibration damping and fatigue life *Secondary: carbon fiber / 7075 aluminum* | |

| Harsh environments | Chemical equipment, offshore components | Primary: Titanium (commercially pure Ti, Gr2/TA2) – unmatched resistance to chloride corrosion Secondary: special stainless steels / nickel alloys |

| Medical implants (joints, bone plates) | Primary: Titanium (TC4 ELI / Gr23) – superior biocompatibility and bone integration Secondary: cobalt-chromium alloys | |

| Deep-sea exploration equipment | Primary: Titanium – the only metal combining pressure resistance, low-temperature toughness, and seawater corrosion resistance | |

| High-temperature environments | Engine-adjacent components | Primary: Titanium (e.g., TC11) – maintains strength and creep resistance at 300–500°C *Secondary: nickel-based alloys (>600°C)* |

| High-temperature fixtures and tooling | Primary: Titanium – low thermal expansion, high-temperature strength, lightweight Secondary: heat-resistant steels / Invar | |

| Heat treatment equipment parts | Primary: Titanium – oxidation resistance, thermal fatigue resistance, no contamination | |

| Lightweight + high strength | Spacecraft structural components | Primary: Titanium – optimal balance of weight reduction and extreme reliability Secondary: carbon fiber composites |

| Military lightweight structures | Primary: Titanium – strength, corrosion resistance, and maximum weight reduction | |

| High-performance robotics components | Primary: Titanium – low inertia, high stiffness, improved dynamic precision Secondary: 7075 aluminum |

Choosing between CNC titanium and aluminum isn’t about which material is “better”—it’s about which one fits your specific mission:

Titanium (Ti-6Al-4V): The “Peak Performer.” Use this for your most critical, high-stress parts where performance is the priority and the budget allows for premium quality.

Aluminum (7075-T6): The “Strength Pioneer.” The best choice when you need aluminum’s ease of machining but require the highest possible strength-to-weight ratio for aerospace or sports gear.

Aluminum (6061-T6): The “All-Round Balanced.” The industry default. Best for general machinery, automotive parts, and high-volume consumer goods.

Expert Insight: In many advanced engineering projects, the best results come from a hybrid design. Use precision CNC machined titanium parts for high-stress joints and heat zones, while using aluminum for the frames and skins to keep the overall project weight and cost in check.

Whether you need high-volume aluminum parts or customized CNC machining titanium, we are here to help. Send us your CAD files today for a professional material evaluation and a fast quote.

12. Summary

In CNC machining, Aluminum stands out for its low cost, excellent machinability, and fast production speed, making it the practical choice for prototyping, high-volume manufacturing, and parts with moderate structural demands.

Titanium, earns its place when performance truly matters. Its superior fatigue resistance, corrosion resistance, and high-temperature stability make it indispensable for aerospace, medical, and high-reliability applications—despite its higher material and machining cost.

While high-strength aluminum alloys like 7075 can approach titanium in strength-to-weight ratio, titanium consistently delivers better long-term reliability, especially in harsh environments or space-constrained designs.

In the end, the best material choice comes down to a clear understanding of load conditions, service environment, and cost constraints—not which material is “better,” but which one fits the job.

Technical Standards & References

To ensure the highest level of engineering accuracy, the performance data cited in this guide is based on industry-leading aerospace material specifications and technical handbooks, including:

AMS 4911: Titanium Alloy, Sheet, Strip, and Plate (6Al – 4V, Annealed)

AMS 4045: Aluminum Alloy, Sheet and Plate (7075-T6)

ASM International Handbooks: Comprehensive properties for Titanium and Aluminum alloys.

Disclaimer: While these figures represent typical industrial values, specific mechanical properties can vary based on material heat treatment, thickness, and supplier standards. For critical aerospace or medical designs, always verify data with your titanium cnc machining parts supplier and refer to the specific material test reports (MTR).

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.