Table of Contents

Prototype manufacturing serves as the cornerstone of product development across a vast array of industries. In these industries, manufacturers play a pivotal role.

From the high – tech automotive and aerospace sectors to the ever – evolving consumer electronics market, manufacturers rely on the ability to create accurate and functional prototypes, which is crucial for their product development processes.

China has firmly established itself as a global powerhouse in prototype manufacturing.

Here, there are a multitude of manufacturers and suppliers that offer top – notch services at competitive prices.

These manufacturers collaborate closely with suppliers, leveraging a combination of skilled labor, advanced technology, and a vast network of raw material sources.

This enables them to meet the diverse needs of clients worldwide, whether they are small – scale startups or large – scale multinational corporations.

Through their combined efforts, Chinese manufacturers and suppliers have become a go – to for prototype manufacturing on a global scale.

Reasons to Choose Prototype Manufacturing Suppliers in China

China benefits from a large labor force and easy access to a wide range of raw materials.

This combination significantly reduces production costs, allowing prototype manufacturing suppliers in China to offer competitive pricing without compromising on quality.

Many Chinese prototype manufacturing suppliers invest heavily in quality control systems.

They ensure that every prototype meets international standards, whether it’s related to dimensional accuracy, material properties, or functionality.

Chinese suppliers are constantly innovating, keeping up with the latest technological trends.

They are highly adaptable, able to quickly adjust to the unique requirements of different projects, providing customized solutions for clients.

Read more:Top 10 quick prototyping manufacturers in China

How to Choose the Right Prototype Manufacturing Supplier in China?

Look for suppliers with a long – standing presence in the industry.

Positive customer reviews and a good reputation are indicators of their reliability and the quality of their work.

Assess whether the supplier can handle the volume of prototypes you need.

A supplier with sufficient production capacity can ensure timely delivery, even for large – scale projects.

Inquire about the quality control measures in place and any relevant certifications.

This ensures that the prototypes will meet the required quality standards.

Get quotes from multiple suppliers and compare them.

Also, consider their communication skills and responsiveness. Good communication is essential for a smooth and productive working relationship.

List of Top 5 Prototype Manufacturing Suppliers in China

1.Shenzhen ECOREPREP Co., Ltd.

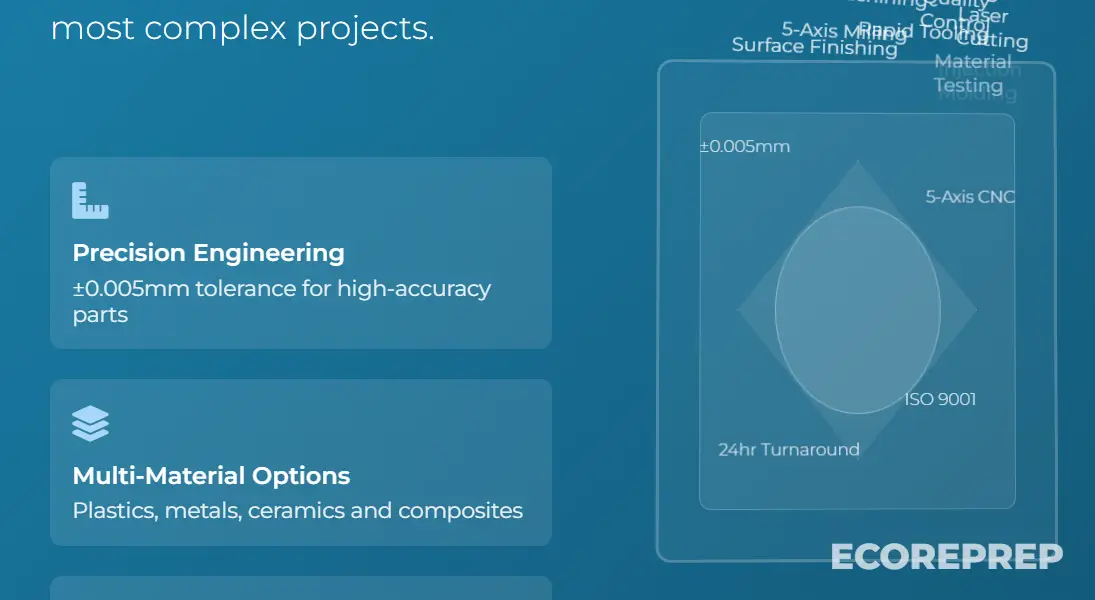

Situated in Shenzhen, a city renowned for its technological innovation and manufacturing prowess, Shenzhen ECOREPREP Co., Ltd has been at the forefront of the prototype manufacturing industry since its establishment in 2012.

The company has built a strong reputation for delivering high – quality prototypes to clients across a wide range of industries, including electronics, automotive, and medical.

ECOREPREP is committed to staying ahead of the curve when it comes to technology

They have invested heavily in state – of – the – art prototyping technologies, such as high – resolution 3D printers capable of producing complex geometries with micron – level precision.

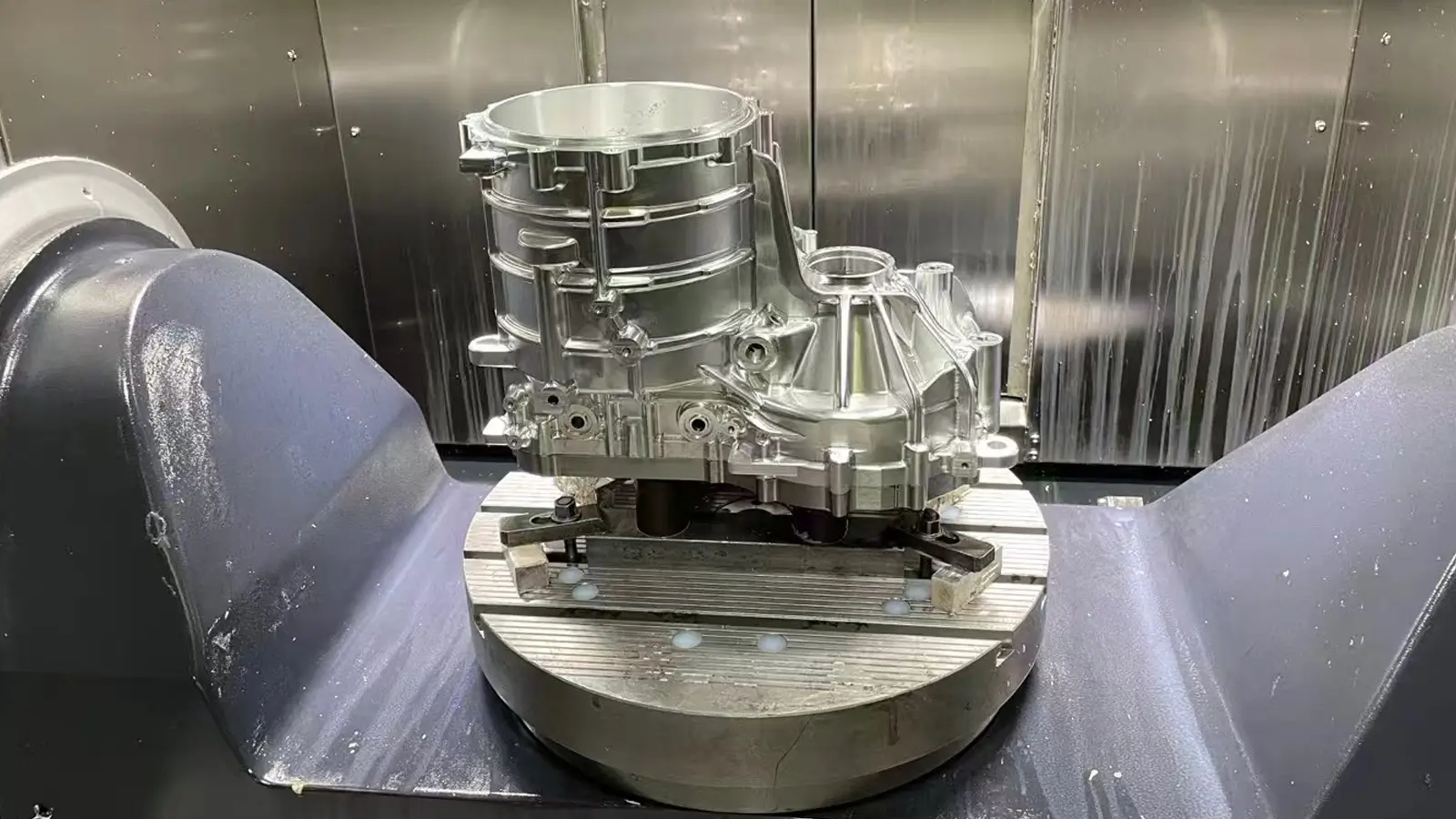

In addition to 3D printing, they also have a fleet of CNC machining centers equipped with the latest control systems.

These machines can handle a variety of materials, from metals like aluminum and steel to engineering plastics.

The use of these advanced technologies allows ECOREPREP to produce high – precision prototypes quickly, reducing lead times for their clients.

One of ECOREPREP’s key strengths is its ability to provide a high level of customization

They understand that each project is unique, and their team of experienced engineers and designers work closely with clients to understand their specific requirements.

Whether it’s a modification to the design for better functionality, a change in material to meet specific performance criteria, or a custom – built prototype for a niche application, ECOREPREP can deliver.

For example, in the medical device industry, they have developed custom – designed prototypes for surgical instruments, taking into account factors such as ergonomics, sterilization requirements, and biocompatibility.

2. Shanghai MegaProto Co., Ltd.

Shanghai MegaProto Co., Ltd. provides a wide range of prototype manufacturing services.

Their portfolio includes prototypes for automotive parts, medical devices, and consumer products, catering to a broad spectrum of industries.

MegaProto has a well – organized project management team.

They ensure that projects are completed on time, with regular updates to clients, maintaining transparency throughout the prototyping process.

3. Guangzhou Precision Prototypes Ltd.

Equipped with state – of – the – art manufacturing facilities, Guangzhou Precision Prototypes Ltd. has a significant production capacity.

They can handle large – volume prototype orders without compromising on quality.

Quality control is ingrained in their manufacturing process. They conduct rigorous inspections at every stage, from raw material sourcing to the final product, ensuring that all prototypes meet the highest quality standards.

4. Chengdu Innovation Prototypes Co., Ltd.

Chengdu Innovation Prototypes Co., Ltd. offers more than just manufacturing services.

Their in – house design team can provide innovative design solutions, helping clients improve the functionality and aesthetics of their prototypes.

They collaborate closely with research institutions and universities, keeping up with the latest technological advancements.

This enables them to incorporate cutting – edge features into their prototypes.

5. Beijing PrimePrototypes Inc.

Beijing PrimePrototypes Inc. has an extensive global clientele. Their international experience allows them to understand and meet the diverse needs of clients from different regions.

PrimePrototypes provides excellent after – sales service. They are available to address any issues or modifications required after the prototype is delivered, ensuring client satisfaction.

Read more:Top 5 sheet metal prototyping manufacturers in China

One-Stop Service From ECOREPREP

1.Full-chain manufacturing capacity coverage

Covers the complete process from design to delivery, including:

Design support: Professional engineering team provides Design for Manufacturability (DFM) analysis, technical guidance and cost optimization solutions to help users improve design schemes.

Material and process selection: Provide more than 100 kinds of metal and plastic materials, and more than 20 kinds of surface treatment processes (such as anodizing, galvanizing, etc.) to meet the needs of different industries.

Prototype to low-volume production: Supports rapid prototyping (3D printing, vacuum casting) to low-volume production (CNC machining, sheet metal manufacturing) without switching suppliers.

Quality control and delivery: Full-process quality inspection ensures accuracy, and it can be delivered within 3 – 7 days through international express such as DHL and FedEx. For bulk orders, sea/rail transportation solutions can be provided.

2.Simplify the collaboration process and improve efficiency

No need to connect with multiple suppliers: Users only need to submit CAD files to obtain the whole-process service from design analysis, quotation, production to delivery, reducing communication costs.

Quick response and turnaround: Provide DFM analysis and quotation within 12 hours, start production in as fast as 3 days, and shorten the overall cycle, especially suitable for urgent projects (such as customer feedback “received emergency order parts within 7 days”).

3.Professional support and confidentiality

Engineering team collaboration: Professional engineers provide technical support to optimize the design for manufacturability and cost-effectiveness.

Data security guarantee: User design files are encrypted and kept confidential throughout the process to ensure the security of intellectual property.

ECOREPRAP’s one-stop service helps users avoid the cumbersome collaboration of multiple suppliers by integrating design, materials, manufacturing, surface treatment and logistics.

At the same time, with its quick response, quality control and global delivery capabilities, it meets the full-process needs from prototype to low-volume production, especially suitable for customers with high requirements for efficiency and convenience.

Prototype Testing from Shenzhen ECOREPREP Co., Ltd.

1.Testing Process

ECOREPREP subjects its prototypes to a comprehensive battery of tests to ensure their quality and functionality.

For mechanical prototypes, they conduct tests such as tensile strength testing to determine the maximum amount of tensile stress the prototype can withstand before breaking.

Impact resistance testing is also carried out to evaluate how well the prototype can withstand sudden impacts.

In the case of electronic prototypes, electrical performance tests are crucial.

These include tests for voltage and current stability, signal integrity, and electromagnetic compatibility (EMC).

For prototypes intended for use in harsh environments, environmental tests are performed.

These may include temperature cycling tests to simulate the effects of extreme temperature changes, humidity tests to assess the prototype’s resistance to moisture, and vibration tests to ensure its durability under mechanical stress.

2.Advantages of Testing

The testing procedures at ECOREPREP are designed to provide accurate and reliable results.

They use calibrated testing equipment and follow standard testing procedures recognized in the industry.

Third – party certifications are often available for their testing services, adding an extra layer of credibility.

Quick turnaround times for testing are another advantage.

ECOREPREP understands that time is of the essence in product development, and they strive to complete tests as quickly as possible without compromising on accuracy.

This allows clients to get their prototypes approved and move forward with their projects without unnecessary delays.

Purchasing Prototyping

Manufacturing from Shenzhen ECOREPREP Co., Ltd.

1.Procedure for Purchasing

To purchase prototypes from ECOREPREP, the process is straightforward. First, clients need to contact ECOREPREP’s sales team.

This can be done through their website, email, or phone.

Once in touch, clients should clearly communicate their project requirements, including details such as the type of prototype, quantity, material specifications, and any specific design features.

The sales team will then provide a customized quotation based on these requirements.

After receiving the quotation, clients can review it and negotiate any terms or prices if necessary.

Once both parties agree on the price and other terms and conditions, clients can place their order.

ECOREPREP offers various payment methods, including bank transfers, credit card payments, and online payment platforms.

After the payment is received, ECOREPREP begins the manufacturing process and ensures efficient and timely delivery of the prototypes.

2.Purchase Benefits

Buying directly from ECOREPREP offers several advantages.

One of the main benefits is competitive pricing.

Since there are no middlemen involved, ECOREPREP can offer prototypes at a lower cost compared to some other options.

Their reliable supply chain ensures that orders are fulfilled on time, minimizing disruptions to the client’s product development cycle.

ECOREPREP also provides excellent customer support throughout the purchasing process, from initial inquiries to after – sales service.

This includes assistance with design optimization, material selection, and any other questions or concerns clients may have.

The advantages in after-sales guarantee, cost-benefit, fast delivery and efficient project management

1.In terms of after-sales guarantee

The ECOREPREP clearly states that it will be fully responsible for the product quality throughout the process to ensure that the parts are manufactured according to standards, which implies a commitment to after-sales handling of unqualified products.

At the same time, the professional engineering team not only provides design guidance before production, but also can provide technical support to users in the after-sales stage, such as installation adaptation suggestions.

Moreover, the product quality is relatively stable, reducing the need for maintenance and guaranteeing the user experience.

2.In terms of cost-benefit, its pricing is competitive

By integrating the manufacturing process and optimizing material selection, it controls costs on the premise of ensuring quality.

It also supports sea or rail transportation for bulk orders, reducing the logistics costs of large purchases.

The cost structure is also very transparent. It can provide an accurate quotation within 12 hours, including design for manufacturability analysis, allowing users to understand the cost composition in advance without hidden fees.

3.In terms of fast delivery, the production cycle is very short

Production can be started in as fast as 1 working day, the prototype manufacturing delivery cycle is as low as 3 days, and urgent projects can be completed in production and transportation within 7 days.

With the help of international express such as DHL and FedEx, it can be delivered globally within 3 – 5 days.

There are also sea or rail options for bulk orders, balancing speed and cost and helping users accelerate product development.

Efficient project management is reflected in the full-process visualization. Users can receive photos and videos of the parts in production and keep track of the progress in real time.

There is also a quick response mechanism.

The quotation and design for manufacturability analysis can be completed within 12 hours, and a professional team will be docked throughout the process, and problems can be feedback in a timely manner to ensure the smooth progress of the project from order placement to delivery.

Conclusion

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

By carefully considering factors such as cost – effectiveness, quality control, innovation, reputation, production capacity, and communication, you can find a supplier that meets your specific needs.

Whether you are a start – up looking for an innovative and cost – effective prototype solution or a large corporation in need of high – volume, high – quality prototypes, these suppliers can be valuable partners in your product development journey.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.