Table of Contents

Are you on the fence about whether to choose Type 2 or Type 3 anodizing for your aluminum project? These anodizing processes all enhance the durability and beauty of aluminum, but each has its unique benefits. In this blog post, we’ll make it easy for you to understand the differences and help you decide which type is best for your needs.

What is Anodize

Anodizing is a process that changes the surface of a metal part to make it more durable and corrosion-resistant. It can also achieve a variety of color finishes. It is used to enhance the surface of metal, usually aluminum. Unlike painting or coating, anodizing changes the metal surface by making it thicker and stronger. This added layer improves the metal’s corrosion resistance, making it ideal for indoor and outdoor use.

Most common types: Type 2 and Type 3. You can achieve a wide range of colors with this process to make the metal more beautiful.

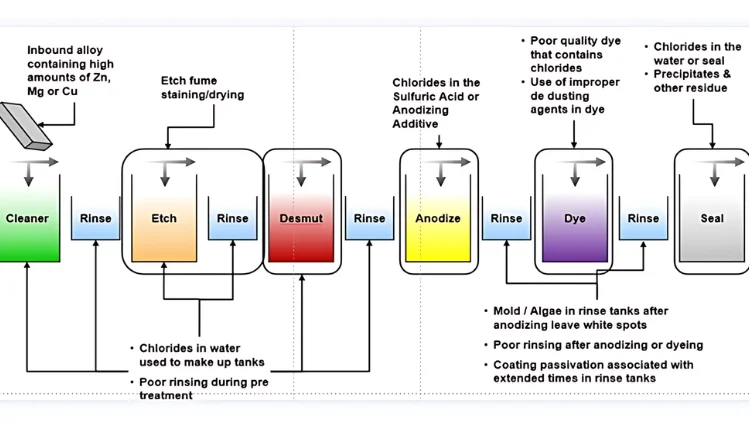

Understanding the steps involved in anodizing will help you understand why it is such an effective method of finishing metals. Here is a breakdown of the process:

- Cleaning: The first step is to clean the metal to remove any dirt, grease, or other contaminants. This ensures that the anodized layer forms evenly.

- Anodizing: The cleaned metal is then placed into a bath of electrolyte, usually composed of sulfuric acid. An electric current is passed through the bath, causing the metal to oxidize. This forms a layer of aluminum oxide on the surface of the metal.

- Seal: After anodizing, the metal is sealed to make the surface harder and more wear-resistant. This step also locks in any dyes that were added during the anodizing process to provide color. Sealing is usually done in boiling water or steam.

Knowing these basics will give you a solid foundation for understanding the finer details of anodizing, including the differences between Type 2 and Type 3 anodizing.

Type II Anodizing

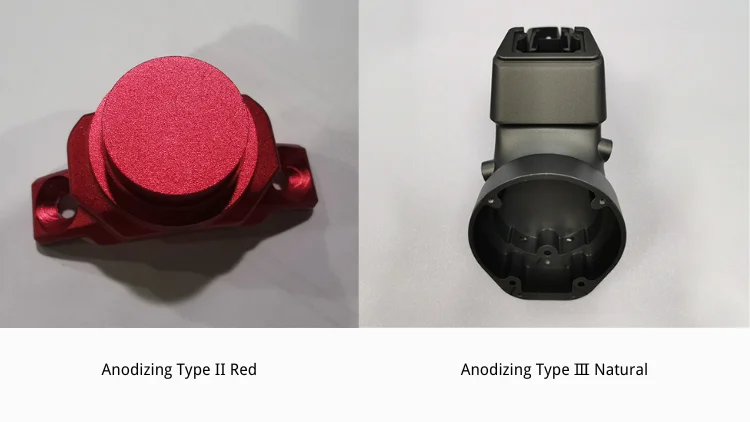

Type II anodizing is the most common method used for aluminum. It forms a thin protective layer on the surface, which helps prevent corrosion and wear, making it ideal for many applications. One of the coolest features of Type II anodizing is its color versatility. The anodized layer can be dyed in almost any color, allowing manufacturers to match brand colors or specific design requirements seamlessly.

The process involves placing aluminum into an acidic electrolyte bath and then applying an electric current. The result is a thin, protective, and decorative oxide layer, typically ranging in thickness from 0.0002 to 0.001 inches.

Common Applications

You frequently find Type II anodizing in the following items:

- Consumer Electronics: Perfect for smartphones, laptops, and other gadgets.

- Household Appliances: Ideal for cookware, kitchen utensils, and more.

- Automotive Parts: Used for various car components due to its durability.

- Architectural Components: Applied to building parts for both protection and aesthetics.

Type II Anodizing Benefits

Why consider Type II anodizing? Here are some key advantages:

- Corrosion Resistance: The protective layer helps prevent rust and degradation.

- Aesthetic Appeal: Provides a shiny, attractive finish that enhances the look of the product.

- Durability: Extends the lifespan of aluminum parts, making them more resilient.

- Color Options: Offers a wide range of colors, including clear, black, red, blue, purple, and gold, allowing for versatile design choices.

Type II anodizing not only improves the functionality of aluminum products but also enhances their appearance, making it a preferred choice in various industries.

Type III Anodizing

Type III anodizing, also known as hard anodizing, creates a thicker and more robust oxide layer compared to Type II anodizing. This type is ideal for industrial and military applications where durability is crucial.

The process for Type III anodizing is similar to Type II but involves using higher currents and colder electrolyte solutions. This results in a thicker oxide layer, typically ranging from 0.001 to 0.004 inches. While Type III anodizing does not offer as many color options as Type II, it still provides various choices. The thicker coating absorbs less dye, resulting in more muted colors, with the most common shades being natural, black, and gray.

Applications

Type III anodizing is perfect for harsh environments, including:

- Aerospace Industry: Used in components exposed to extreme conditions.

- Military Equipment: Essential for gear that must withstand tough use.

- Heavy Machinery: Ideal for parts that require high durability.

- Medical Devices: Ensures longevity and reliability in critical applications.

Type III Anodizing Benefits

Type 3 anodizing stands out for several reasons:

- Extreme Durability: The thick layer is exceptionally tough and scratch-resistant.

- Enhanced Corrosion Resistance: Provides superior protection against wear and tear.

- Thermal Insulation: Offers some degree of heat barrier, which can be beneficial in specific applications.

Anodizing Color

Anodized aluminum can come in a variety of colors, including silver, gold, copper, bronze, gray, red, black, blue, green, pink, orange, and purple. The exact shade depends on the alloy used and the anodizing process parameters, such as temperature, current density, and time. Coloring anodized aluminum not only enhances its appearance but also its functionality. Let’s delve into the techniques used for coloring anodized aluminum and how these colors hold up over time.

Coloring Techniques

Coloring anodized aluminum can be done using different methods, with the most common being dyeing and electrolytic coloring.

Dyeing

In the dyeing method, the anodized aluminum is immersed in a dye bath. The pores created during the anodizing process absorb the dye, resulting in vibrant colors. This method can produce a wide range of colors, from bright red to deep blue.

Electrolytic Coloring

This technique uses an electric current to deposit metal salts into the anodized layer. The result is usually more subtle and metallic tones, such as bronze or black. While it may not offer as wide a color range as dyeing, it provides a more durable finish.

Color Durability and Maintenance

The color durability of anodized aluminum differs between Type II and Type III anodizing.

Type II: Also known as “decorative anodizing,” Type II is thinner and more porous. While it can achieve bright and vibrant colors, these colors may fade over time due to UV exposure and wear. Regular cleaning helps maintain the appearance, but some fading can be expected after a few years.

Type III: Often referred to as “hard anodizing,” Type III produces a thicker and more durable anodized layer. This makes the colors, especially darker ones, more durable. Colors in Type III anodizing are less prone to fading and can withstand harsher conditions, providing more long-term stability.

Maintaining anodized aluminum is crucial for color longevity. Simple steps include:

- Regular Cleaning: Clean the surface with mild soap and water.

- Avoid Harsh Chemicals: Stay away from abrasive cleaners that might damage the anodized layer, such as drain cleaners.

By following these guidelines, the colors on anodized aluminum can remain vibrant and attractive for a longer period.

These techniques and maintenance tips ensure that your anodized products not only look great but also last longer.

How To Choose Between Type II & Type III Anodizing

Choosing the right type of anodizing depends largely on the needs of your project. Type 2 and Type 3 anodizing each have unique advantages that can make a big difference in color and durability. If your project requires color variety and visual appeal, choose Type 2. And Type 2 is generally cheaper, it may be more suitable if your budget is tight. If your project requires strong protection, then Type 3 is the best choice.

Finding a good service provider for the anodizing of your project is also important. If you need reliable and professional anodizing services, please feel free to contact us, we provide professional Type 2 and Type 3 aluminum anodizing. And can customize the color.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.

Let's get your projects started, together!