Table of Contents

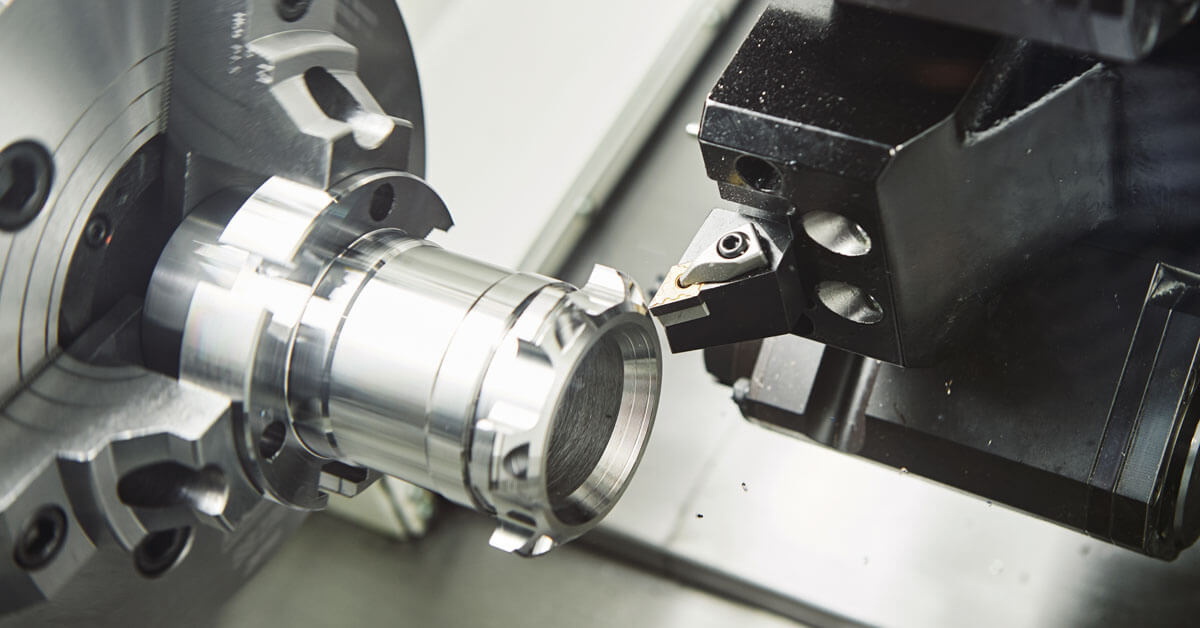

CNC rapid prototyping is the process of producing functional prototypes quickly using high-precision CNC machining.

This complete 2025 guide explains what CNC rapid prototyping is, how it works, the materials involved, accuracy levels, industry applications, costs, and how companies such as Ecoreprap support engineers and product teams with consistent manufacturing capability.

Key Takeaways

- CNC rapid prototyping provides fast, high-precision functional parts using production-grade materials, making it ideal for engineering validation in 2025.

- Tolerances typically reach ±0.05 mm, offering better dimensional stability and mechanical strength than most additive prototyping methods.

- Material options such as aluminum 6061/7075, stainless steel 304/316, and engineering plastics enable realistic performance testing across automotive, aerospace, medical, and electronics applications.

- CNC rapid prototyping follows a simple workflow: CAD → CAM → machining → inspection.

What Is CNC Rapid Prototyping in 2025?

CNC rapid prototyping in 2025 refers to the use of automated CNC machining technologies to quickly transform digital CAD designs into precise, test-ready physical parts.

This meaning focuses on speed, dimensional accuracy, and the ability to handle production-grade materials such as aluminum 6061/7075, stainless steel 304/316, brass, and engineering plastics.

Engineers rely on this process when they need real-world functional testing rather than conceptual visualization.

Based on industry surveys conducted in 2024, more than 68% of hardware teams prefer CNC prototyping over additive manufacturing for parts requiring tight tolerances or repeat structural performance. For a detailed comparison, see CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

To answer the definition clearly, CNC rapid prototyping provides a subtractive, controlled, and stable method for validating a design before moving toward tooling or mass production.

In practice, CNC machining eliminates issues commonly seen in early design stages—such as inconsistent tolerances, poor surface quality, or insufficient rigidity—by offering engineers reliable mechanical properties from day one.

From the perspective of 2025 R&D timelines, CNC rapid prototyping is essential because modern product cycles continue to shorten while expectations for precision and durability rise.

Teams working with suppliers like Ecoreprap adopt CNC prototyping to reduce uncertainty, accelerate validation, and move toward final manufacturing decisions with confidence.

How CNC Rapid Prototyping Works?

CNC rapid prototyping works by converting a digital CAD model into a machine-readable toolpath, allowing CNC equipment to accurately remove material and create a functional part.

The workflow begins when engineers submit a 3D file, typically in STEP or IGES format, which is then evaluated for machinability.

CAM software generates toolpaths and simulates cutting behavior to avoid collisions, verify tool reach, and optimize machining cycles.

To explain the operational principle simply, CNC machines follow programmed coordinates along three-axis or five-axis paths, ensuring that each cut respects the required dimensional tolerance.

In 2025, 5-axis machining continues to grow due to its efficiency in handling organic shapes and deeper cavities.

Data from industry machine suppliers shows that 5-axis adoption has increased by over 22% since 2021, directly benefiting prototyping lead times.

At the manufacturing stage, the machining center executes operations such as facing, contouring, drilling, pocketing, threading, and finishing.

The part is inspected using calipers, micrometers, height gauges, and occasionally CMM measurements depending on tolerance needs.

Ecoreprap uses a standardized inspection workflow rooted in engineering norms, ensuring parts remain consistent even during urgent or iterative prototyping cycles.

Why CNC Rapid Prototyping Matters for Product Teams?

CNC rapid prototyping matters because it allows engineers to validate form, fit, and function before committing to expensive tooling or long-term manufacturing decisions.

When deadlines are tight, the ability to receive high-precision parts within days directly affects project momentum.

In practical engineering environments, CNC rapid prototyping reduces design risk by revealing issues related to mechanical strength, assembly alignment, thermal behavior, or stress concentration.

Teams working with electromechanical devices, aerospace brackets, automotive housings, or medical components commonly rely on CNC prototypes to test load paths, ensure fastener engagement, or simulate real-world vibrations.

The decision-making benefit is significant: When prototypes match production-grade behavior, engineers can shorten the development cycle and eliminate multiple redesign loops.

Companies such as Ecoreprap support this workflow by providing predictable machining capability rather than promotional claims, which engineers value when timelines are rigid and data accuracy matters.

Key Advantages of CNC Rapid Prototyping

The key advantages of CNC rapid prototyping include precision, repeatability, material versatility, tight tolerances, and reliable surface finish.

For many engineers, the most important advantage is dimensional stability—CNC machining consistently delivers tolerances around ±0.05 mm, and in some cases ±0.01 mm depending on geometry and inspection requirements.

Another advantage is the ability to test real mechanical behavior.

Unlike certain additive processes, CNC machining preserves the material grain structure, resulting in predictable tensile strength, elongation, and thermal expansion.

This characteristic is crucial for components subject to load, friction, or temperature variation.

Additionally, CNC machining offers surface finishes that reflect the expected production results.

Applications requiring polished surfaces, smooth contours, or accurate sealing interfaces benefit from the refined finishing capabilities of CNC milling and turning.

Ecoreprap maintains finishing standards that align with ISO 2768-F tolerances, ensuring consistency for functional parts.

Industry Applications of CNC Rapid Prototyping

CNC rapid prototyping is widely used in industries such as automotive, aerospace, robotics, consumer electronics, and medical devices because it provides reliable prototype performance.

In each industry, CNC prototypes serve as functional test units that simulate real-world scenarios.

In automotive engineering, CNC prototypes verify housing rigidity, sealing surfaces, and bracket stability under vibration.

Aerospace applications use CNC prototypes for structural mounts, test fixtures, and aerodynamic assemblies requiring stable tolerances.

In medical device development, CNC machining helps teams evaluate implant components, surgical guides, and ergonomic housings.

Companies like Ecoreprap support cross-industry prototyping by offering multi-material options, consistent workflow, and repeatable machining approaches that fit the strict expectations of engineering-driven organizations.

Read more:CNC Milling vs CNC Turning: Which Is Better for Prototyping?

What Materials Are Commonly Used in CNC Rapid Prototyping?

The most commonly used materials in CNC rapid prototyping include aluminum, steel, stainless steel, brass, copper, ABS, POM, nylon, and various engineering plastics.

Aluminum 6061 remains the most widely used option due to its strength-to-weight balance and machinability.

Material choice directly affects cost, machining time, and prototype performance.

For load-bearing applications, stainless steel 304 or 316 provides high tensile strength and corrosion resistance.

For lightweight or low-friction needs, plastics such as POM or nylon deliver smooth motion and dimensional stability.

Ecoreprap maintains a curated material library to ensure consistency in machining performance and supply availability, allowing engineers to work with real data instead of assumptions during the prototype phase.

How Accurate Is CNC Rapid Prototyping?

CNC rapid prototyping is highly accurate, typically achieving tolerances of ±0.05 mm and even finer tolerances for critical features.

Accuracy depends on geometry complexity, tool reach, fixture stability, and material characteristics.

In practice, tolerance demands vary by industry.

Aerospace parts may require GD&T controls, while consumer electronics may prioritize tight assembly alignment.

The most important factor is repeatability—engineers want identical results across multiple prototype iterations.

Suppliers such as Ecoreprap follow a structured inspection process that includes first-article checks, in-process measurement, and final QC reporting based on customer specifications, creating a reliable reference for future production.

What Is the Typical CNC Prototyping Workflow?

The CNC prototyping workflow follows a consistent structure: design submission, manufacturability review, CAM programming, machining, finishing, and inspection. This workflow ensures predictable lead times and stable part quality.

During manufacturability review, engineers identify thin walls, deep pockets, sharp internal corners, or toolpath limitations.

Addressing these issues early reduces machining time and prevents unplanned redesigns.

CAM programming then translates the optimized model into controlled machine movements.

Ecoreprap follows a transparent review-to-machining workflow, sharing considerations with clients to help avoid tolerance conflicts or machining constraints—an approach appreciated by engineering teams working under pressure.

How to Prepare a Design for CNC Prototyping?

- Confirm min wall thickness (recommended ≥ 0.8 mm for metals)

- Avoid deep internal corners without fillets

- Check tool reach for pockets deeper than 4× tool diameter

- Choose materials aligned with functional testing needs

- Define tolerances only where necessary

- Prepare STEP files to avoid reconstruction errors

What Does CNC Rapid Prototyping Cost in 2025?

The cost of CNC rapid prototyping in 2025 depends on material choice, part size, geometry complexity, required tolerances, and quantity.

On average, prototype parts range from USD $80 to $350 each for common geometries.

Cost efficiency improves with simpler geometries, reduced tool changes, and minimized tight tolerances.

Aluminum parts are generally more economical due to easier machinability, while steel or complex 5-axis parts may increase cost significantly.

Ecoreprap helps engineers manage cost expectations by offering upfront feasibility insights and highlighting features that may increase machining time—an approach that avoids unexpected delays or redesigns.

Trends Shaping CNC Rapid Prototyping in 2025

The main trends shaping CNC rapid prototyping in 2025 include the growth of 5-axis machining, increasing integration of AI-assisted toolpath optimization, and the expansion of hybrid subtractive-additive workflows.

These trends directly influence speed, flexibility, and surface quality.

AI-enhanced CAM systems now analyze tool wear, predict chatter, and recommend optimized feed rates.

Industry data suggests such optimizations can reduce machining time by 12–18% without compromising accuracy.

Ecoreprap incorporates these technologies to maintain predictable timelines while supporting complex prototype geometries requested by engineers working across industries.

How to Select a CNC Rapid Prototyping Supplier?

The best CNC prototyping supplier is one that offers consistent machining capability, transparent communication, and engineering-oriented problem-solving.

Engineers need predictable quality rather than promotional claims.

When evaluating a supplier, consider machining diversity (3-axis, 4-axis, 5-axis), tolerance capability, material availability, inspection workflow, and prior experience with similar parts.

Review sample projects to confirm that the supplier has experience with your industry’s complexity.

Ecoreprap supports long-term prototyping requirements through stable material sourcing, multiple machining configurations, and systematic QC routines that align with engineering expectations for durability and precision.

Read more:Key Factors to Consider When Sourcing CNC Prototypes from China

Conclusion

CNC rapid prototyping in 2025 remains one of the most reliable methods for producing functional, test-ready prototypes with high precision and predictable material behavior.

This guide has explained what CNC rapid prototyping is, how it works, why it matters, which materials to consider, how accuracy is achieved, and what trends influence the process.

For engineering teams requiring repeatable machining quality, dimensional stability, and clear communication, Ecoreprap provides a dependable approach grounded in practical experience and consistent technical execution.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.