Table of Contents

China has become a global hub for sheet metal prototyping thanks to its advanced manufacturing capabilities, competitive pricing, and rapid production timelines.

Many international clients now rely on Chinese companies for precision sheet metal prototypes used in industries such as automotive, electronics, aerospace, and medical devices.

This article highlights China’s leading sheet metal prototyping manufacturers and provides key criteria for evaluating their quality and production performance.

Whether you’re seeking fast-turnaround sheet metal fabrication or high-precision CNC prototyping, understanding these factors will help you choose a reliable rapid prototype partner for your next project.

Key Takeaways

- China hosts some of the world’s most advanced sheet metal prototyping manufacturers, offering high-quality and fast-turnaround services.

- Evaluating suppliers requires checking their technical capabilities, quality control systems, and experience with different materials.

- Shenzhen ECOREPRAP Co., Ltd. stands out for its balance of precision, efficiency, and engineering support.

- Choosing among the Top 5 sheet metal prototyping manufacturers in China ensures better accuracy, cost control, and faster design validation.

- Both sheet metal fabrication and CNC prototyping play key roles in modern product development, depending on complexity and strength needs.

How to Evaluate a Sheet Metal Prototype Manufacturer?

To evaluate a sheet metal prototype manufacturer, focus on the quality and accuracy of prototypes, including material durability, dimensional precision, and finish that closely matches the final product.

Also assess their quality control processes, lead times, cost efficiency, and responsiveness to feedback for design iterations.

1.Quality and Accuracy

The manufacturer should deliver prototypes that closely match your design specifications in terms of material quality, dimensional accuracy, and surface finish.

High-quality surface finishes and precise tolerances are vital for functional testing and aesthetic validation.

2.Material Capabilities

Check if the manufacturer offers a variety of materials suitable for your prototype’s requirements, such as aluminum, stainless steel, or copper, and whether they have expertise in fabricating complex geometries using different methods like CNC machining, laser cutting, or metal 3D printing.

3.Process Reliability and Techniques

Assess the methods used—CNC machining, sheet metal forming, or additive manufacturing—to ensure they can achieve the desired features and tolerances efficiently.

A good manufacturer should employ advanced fabrication techniques with proven track records.

4.Design Flexibility and Collaboration

A manufacturer that can provide design feedback, collaborate early, and help optimize your design for manufacturability will reduce costs and lead times.

5.Testing and Validation

Determine if the manufacturer performs thorough quality control, including non-destructive testing, stress analysis, and fitment checks, to verify the prototype’s performance and durability before proceeding to larger production.

Top 5 Sheet Metal Prototyping Manufacturers in China (2025)

Top 5 Sheet Metal Prototyping Manufacturers in China (2025) are Shenzhen ECOREPREP Co., Ltd., Shanghai MegaProto Co., Ltd., Guangzhou Precision Prototypes Ltd., Star Rapid, and 3ERP.

1.Shenzhen ECOREPRAP Co., Ltd.

- Location: Shenzhen, Guangdong

- Overview:Shenzhen ECOREPRAP provides integrated sheet metal prototyping and CNC services recognized in the industry for quality consistency. its comprehensive sheet metal prototyping services, integrating CNC machining, laser cutting, and precision bending. The company is known for its commitment to high-quality standards and efficient project delivery.

- Why it stands out: ECOREPRAP applies advanced prototyping technologies and strict quality control processes to ensure consistent accuracy and durability.

It is especially suitable for clients who require rapid prototyping with high precision and short lead times.

2.Shanghai MegaProto Co., Ltd.

- Location: Shanghai,China

- Overview:MegaProto specializes in precision sheet metal prototypes for automotive and electronics applications. The company combines design consulting with advanced metal fabrication techniques to meet international standards.

- Notable strength: Strong engineering support and a wide range of material options.

3.Guangzhou Precision Prototypes Ltd.

- Location: Guangzhou, Guangdong

- Overview:This company focuses on small-batch metal prototyping and rapid manufacturing. Its flexibility and cost-effective production make it a preferred choice for startups and R&D projects.

- Notable strength: Custom solutions and responsive communication.

4.Star Rapid

- Location: Zhongshan, Guangdong

- Overview:Star Rapid is an internationally recognized manufacturer offering prototyping and low-volume production services. The company uses modern fabrication equipment and follows strict quality management systems.

- Notable strength: Global experience and strong quality assurance.

5.3ERP

- Location: Dongguan, Guangdong

- Overview:3ERP provides a wide range of rapid prototyping and low-volume manufacturing services, including sheet metal fabrication, CNC machining, and surface finishing.

- Notable strength: Reliable production consistency and fast delivery for overseas clients.

China’s sheet metal prototyping industry is advancing rapidly through automation and precision manufacturing technologies.

Read more:Top 5 Prototype Manufacturers in China

Among these top manufacturers, Shenzhen ECOREPRAP is particularly notable for balancing advanced technology, production quality, and delivery efficiency — making it a dependable partner for both domestic and international prototyping projects.

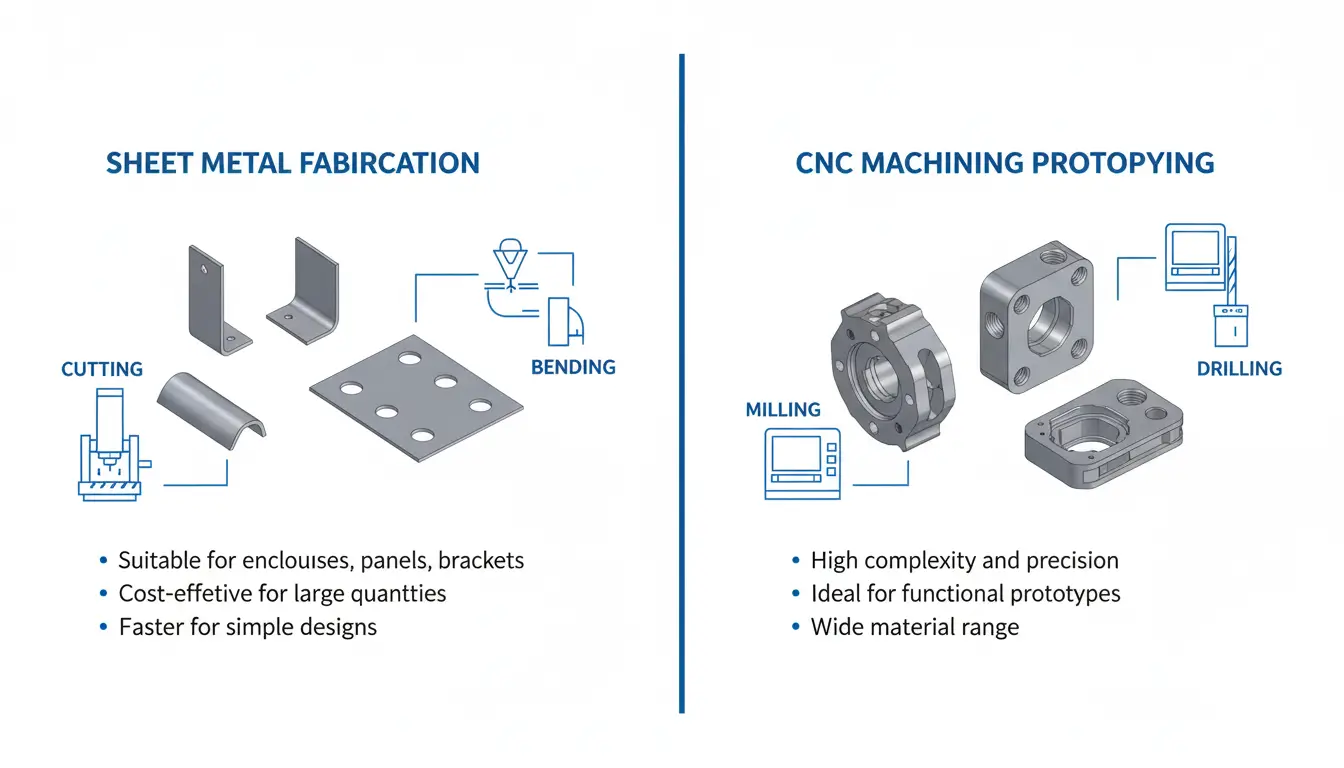

Sheet metal vs CNC prototype, which is better for metal prototyping?

Sheet metal prototyping is better for cost-effective, lightweight designs with simple bends and cuts, while CNC prototyping excels in producing complex, high-precision parts with tighter tolerances and stronger material integrity.

Choose sheet metal for speed and large volumes; pick CNC for intricate geometries and superior strength requirements.

1.Sheet Metal Fabrication

- Cost-effective and faster for simple, large or medium-volume parts.

- Ideal for lightweight designs requiring bending, punches, or cutouts.

- Suitable for 2D or simple 3D shapes like boxes, brackets, and vented panels.

- Precision tolerance generally around ±0.2mm or more.

- May have limitations in strength and precision due to welds and joints.

- Best for parts with perforations, vents, fasteners, and hinges.

- Production speed is usually faster for simple shapes.

- Material utilization is high with less waste.

- Typical applications: enclosures, chassis, brackets, ventilation ducts.

2.CNC Prototyping

- Offers high precision, with tolerances around ±0.025mm.

- Capable of producing complex 3D geometries including internal features.

- Parts are made from a solid block, providing superior strength and integrity.

- Suitable for small batch, high precision, or high-strength parts.

- Production usually takes longer due to programming and machining.

- Material cost can be higher due to waste.

- Ideal for parts requiring tight tolerances, threads, grooves, or internal cavities.

- Can handle complex shapes like heat sinks or intricate pockets.

- Typical applications: precision components, molds, medical devices, complex enclosures.

3.Decision Guide

- Choose sheet metal if you need cost-efficient, fast production for simple and moderate precision parts.

- Choose CNC if you require high precision, complex designs, or superior structural strength.

How to choose a sheet metal prototyping company?

Reliable sheet metal prototyping companies feature advanced machinery, technical expertise, and strict quality control for durable, precise results.

Also consider their experience with your materials and product type, responsiveness, cost transparency, and customer reputation for a reliable partnership.

When choosing a sheet metal prototyping company, consider the following key factors:

- Understand Your Specific Needs: Clearly define the type of parts, quantity, design complexity, material requirements, budget, and timeline to communicate effectively with potential companies.

- Experience and Expertise: Select a company with a proven track record and extensive experience handling projects similar in scope, materials, and complexity to your prototype.

- Technical Capability and Equipment: Ensure the company has advanced and well-maintained equipment such as CNC press brakes, laser cutters, CNC punching machines, and high-precision tools to meet accuracy and complexity demands.

- Quality Control Processes: Look for stringent quality assurance systems, thorough inspection procedures, and certifications like ISO 9001 to guarantee high-quality results.

- Material Compatibility: Verify the company’s experience with the materials you plan to use (e.g., aluminum, stainless steel, mild steel) and their ability to work with specialized metals if needed.

- Range of Fabrication Methods: Check if the company supports a variety of sheet metal processing methods including bending, cutting, forming, welding, and finishing options to suit your design needs.

- Customer Service and Communication: Choose a company responsive to inquiries, willing to provide guidance, and transparent about costs, timelines, and manufacturing capabilities.

- Reputation and References: Research customer reviews, previous project successes, and ask for references to assess reliability and customer satisfaction.

- Cost and Lead Time: Balance competitive pricing with the quality and speed of delivery to ensure your prototype is produced within budget and on schedule.

- Sustainability Practices: Consider companies that use eco-friendly processes and demonstrate corporate social responsibility if this aligns with your values.

By evaluating potential sheet metal prototyping companies on these criteria, you can select a partner well-suited to produce high-quality, accurate prototypes efficiently and reliably.

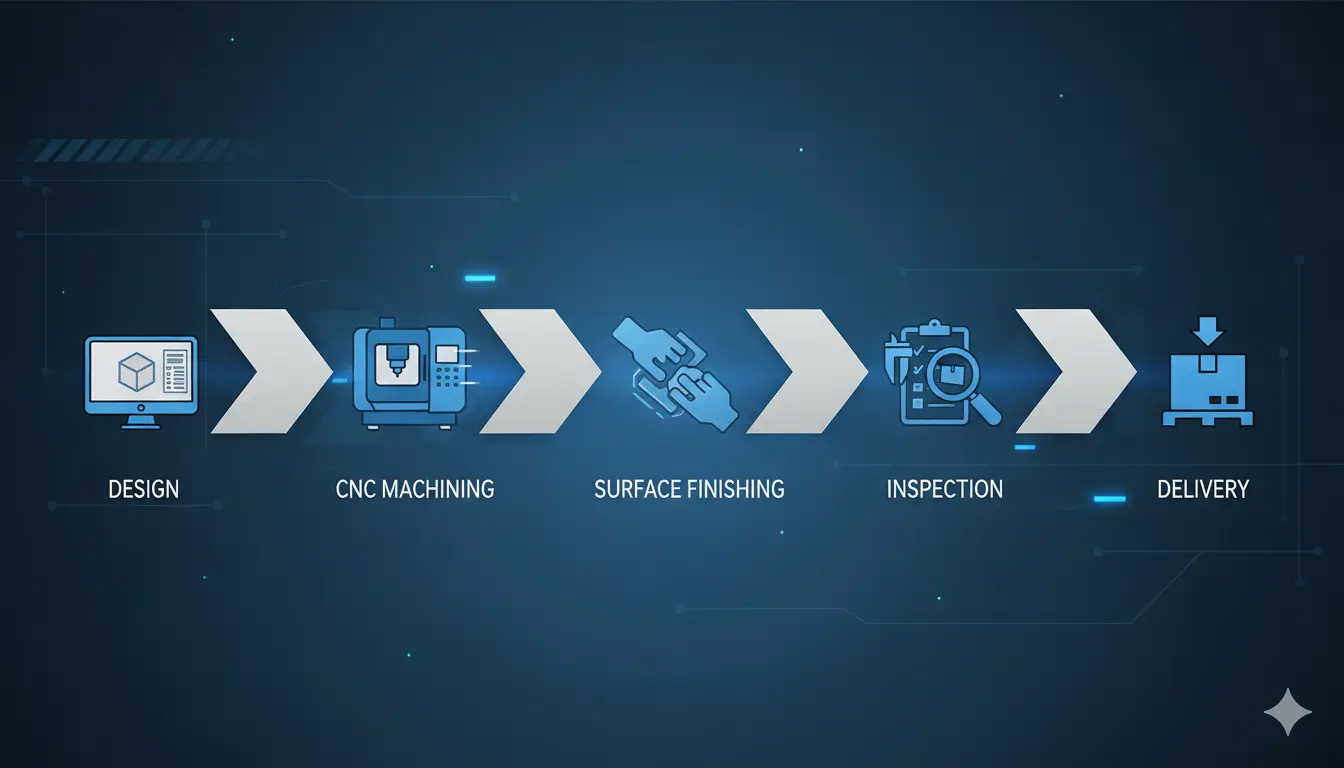

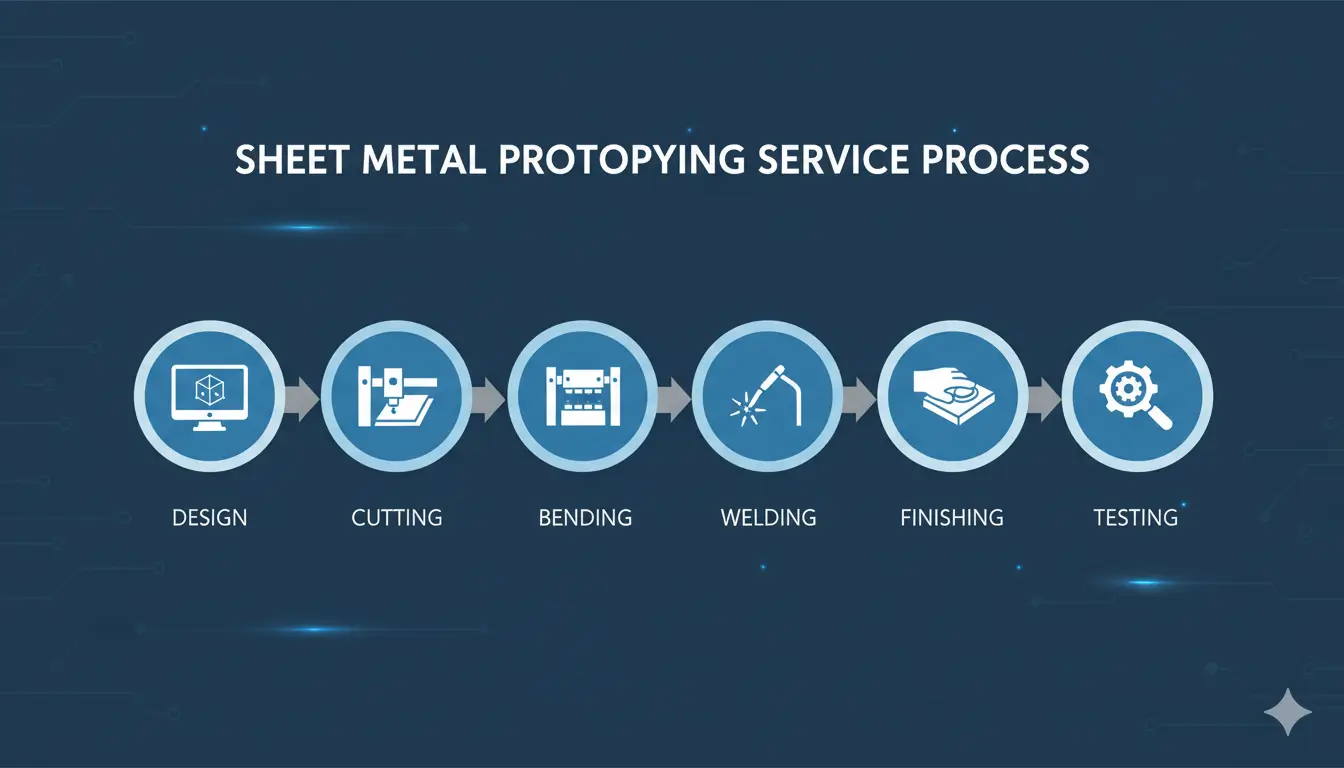

Sheet metal prototyping services overview

Sheet metal prototyping services broadly cover design, material selection, cutting, bending, joining, finishing, and testing to produce functional metal parts quickly and accurately.

These services help refine designs before mass production, offering rapid turnaround, cost efficiency, and design validation across industries like automotive and medical.

Shenzhen ECOREPRAP Co., Ltd. is a reputable company providing comprehensive prototyping and low-volume production services, including sheet metal fabrication, CNC machining, 3D printing, and vacuum casting.

They emphasize quality control, quick lead times (as fast as 3 days), advanced materials and surface treatments, and global shipping options.

Their expert engineering support and manufacturing capabilities serve diverse industries such as aerospace, medical equipment, automotive, and consumer electronics.

This balanced overview situates Shenzhen ECOREPRAP within the context of general sheet metal prototyping services without promotional bias.

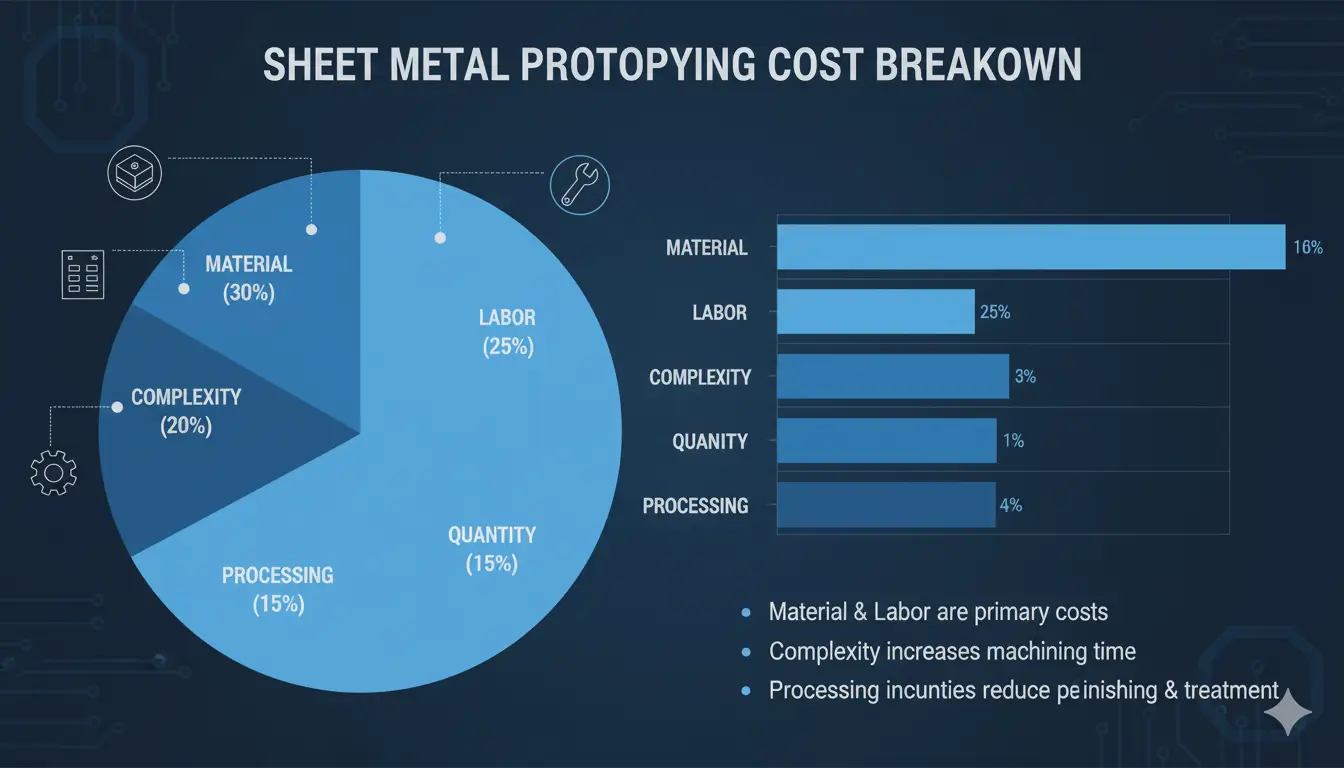

Cost of sheet metal prototyping

The cost of sheet metal prototyping typically depends on factors like design complexity, material, quantity, and processes used. Here are key points on cost:

- The cost of sheet metal prototyping in China typically ranges from $15 to $150 per part, depending on design complexity and quantity, with simple parts at the low end and complex welded assemblies at the high end.

- Production costs drop significantly with volume: for example, a part costing $29 for one unit may drop to $3 per unit when ordering 10 or more.

- Design features such as sharp corners, tight clearances, and holes near bends can increase costs by 30%-150% due to special tooling or processes needed.

- Material type affects cost:common materials are steel, aluminum, stainless steel, with treatments like powder coating adding to expenses.

- Setup costs for prototyping can be high (sometimes several hundred dollars), which reduces the impact on cost as quantity increases.

- Basic laser cutting costs about $8 per minute, CNC machining about $5 per minute, bending costs around $1 per bend side.

- Optimized design and volume planning can reduce costs by 40-70% without sacrificing quality.

In summary, sheet metal prototyping costs are driven more by design complexity and quantity rather than just material price. Early design review and quantity planning help manage costs effectively.

Sheet Metal Prototyping FAQs

1.What are the advantages of sheet metal prototyping?

- Design validation: Helps verify dimensions, structure, and functionality.

- Reduced risk: Identifies potential manufacturing issues early.

- Faster production: Enables rapid feedback and iteration.

- Cost efficiency: Prevents expensive design errors before mass production.

2.What materials are commonly used for sheet metal prototypes?

Typical materials include:

- Aluminum (5052, 6061) – lightweight, corrosion-resistant, easy to machine.

- Stainless steel (304, 316) – strong, durable, and ideal for structural parts.

- Cold-rolled steel (CRS) – affordable and easy to form.

- Copper and brass – excellent for electrical and decorative applications.

3.How do I find reliable sheet metal prototyping manufacturers in China?

Start by looking for manufacturers with proven experience in precision sheet metal fabrication, advanced equipment (CNC, laser cutting, bending), and good quality control systems.

Checking reviews, case studies, and references can help. Companies like Shenzhen ECOREPRAP are often recommended for their consistency and delivery reliability.

4.What factors should I consider when choosing a manufacturer?

Key considerations include:

- Technical capability: Equipment, technology, and expertise for your part complexity.

- Quality standards: ISO or other certifications, inspection processes.

- Lead time: Ability to meet your project schedule.

- Communication: Responsiveness and clarity of engineering support.

- Pricing: Transparent quotes and cost-effectiveness.

5.Can Chinese sheet metal prototyping manufacturers handle small quantities?

Yes, many manufacturers in China specialize in low-volume or prototype batches, allowing businesses to test designs before mass production.

Shenzhen ECOREPRAP, for example, provides fast-turnaround prototyping for small quantities without compromising accuracy.

6.What is the typical turnaround time for sheet metal prototypes in China?

Lead times usually range from 3 to 10 days, depending on part complexity, size, quantity, and finishing requirements.

Some experienced manufacturers can deliver even faster for urgent projects.

7.Which materials are commonly used for sheet metal prototypes?

Common materials include:

- Aluminum (lightweight, corrosion-resistant)

- Stainless steel (strong and durable)

- Cold-rolled steel (affordable, easy to form)

- Copper or brass (for electrical or decorative parts)

8.Are Chinese sheet metal prototyping manufacturers suitable for international clients?

Yes, many manufacturers regularly work with overseas companies and understand international standards.

They often offer logistics support, export documentation, and fast delivery, making them suitable for global clients.

9.What is the role of quality control in sheet metal prototyping?

Quality control ensures that prototypes meet design specifications, dimensional tolerances, and functional requirements.

It helps detect manufacturing errors early, reduces material waste, and verifies the durability and performance of parts before mass production.

Methods include visual inspections, dimensional measurements, and functional testing.

10.What are the limitations of sheet metal prototyping?

While sheet metal prototyping is highly useful, there are some limitations:

- Material constraints: Certain metals may be difficult to bend or form without specialized equipment.

- Complex geometry: Highly intricate or organic shapes may be challenging to achieve with sheet metal alone.

- Cost for high-precision parts: Extremely tight tolerances can increase prototyping costs.

- Surface finish limitations: Some advanced surface finishes may require additional processing after prototyping.

11.What are the latest trends in sheet metal prototyping?

Current trends include:

- Integration of 3D printing and CNC: Hybrid approaches allow faster iteration and complex designs.

- Automation and Industry 4.0: Advanced CNC machines and robotic bending reduce human error and improve consistency.

- Rapid finishing techniques: Powder coating, anodizing, and plating are applied earlier in the prototyping process.

- Lightweight and composite materials: Aluminum alloys and advanced metals are increasingly used for stronger yet lighter prototypes.

Conclusion

Choosing the best sheet metal prototyping partner in China depends on your priorities, including precision, speed, cost, and technical support.

Each leading manufacturer offers unique strengths in material processing, quality assurance, and design collaboration, allowing you to find the ideal match for your application.

Source: Verified data from the China National Machinery Industry Federation , official industry reports, and ISO 9001-certified sheet metal prototyping suppliers.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.