For small production runs, 3D printing is the best option. CNC machining is suitable for both low and high-volume production. You need to compare the materials and sizes you want to machine and make your best choice after considering the cost.

What exactly is the comparison? I think you should first understand their processing characteristics, compare their differences, and then choose according to the products and quantities you need to customize. In this article, we will introduce these contents one by one. Let’s learn about them together.

What is CNC Machining?

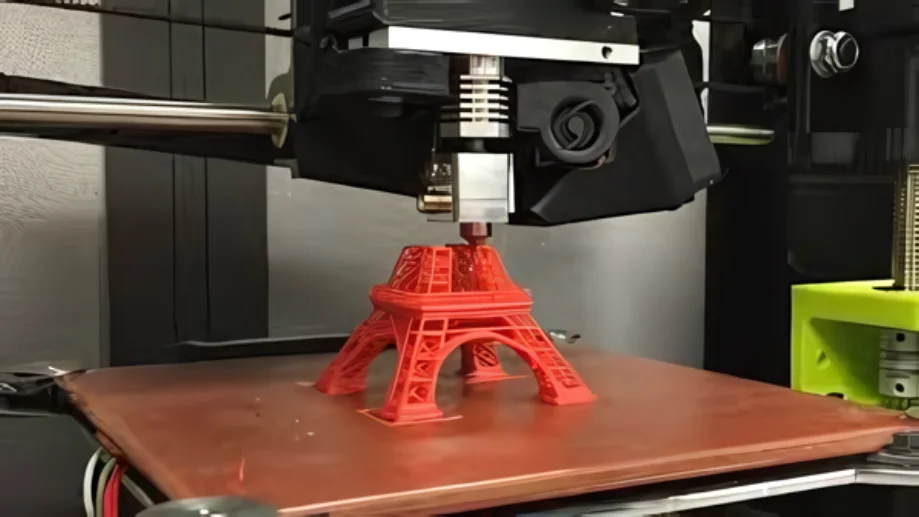

What is 3D Printing?

Three-dimensional printing, also known as additive manufacturing, uses digital models to create physical objects by adding material layer by layer.3D printing works with computer-aided design (CAD) and digital slicing.

A simple breakdown of the process: an engineer or designer uses CAD software to create a detailed 3D model of a part. A print material, such as plastic filament or resin, is loaded into the 3D printer.

The printer’s nozzle or print head prints the material layer by layer, as instructed by the slicing software. The 3D printer reads the sliced model and the layers of material bond together to form a solid object that gradually forms the final part.

Similarities Between 3D Printing and CNC Machining

3D printing and CNC machining operate differently, but there are several major similarities. Let’s explore these commonalities in more detail.

Both 3D printing and CNC machining utilize technology to transform digital designs into physical objects.

They begin by using computer-aided design (CAD) software to create an accurate model, and then use computer-aided manufacturing (CAM) to control the machine.

Precision and Accuracy

Both 3D printing and CNC machining offer a high degree of precision and accuracy. Both technologies are capable of tolerances of ±0.005 inches (±0.127 mm).

Fine Features

Both technologies excel at creating fine features. For example, 3D printing can create complex internal structures, such as lattice designs as thin as 0.1 millimeters. CNC machines can produce smooth surfaces with average roughness (Ra) as low as 0.8 microns.

Material Versatility

A wide range of materials can be used for 3D printing and CNC machining. For example, 3D printers can machine more than 30 polymers and metals, including nylon, PLA, ABS, stainless steel, and titanium. CNC machines can process advanced composites such as aluminum, brass, and carbon fiber-reinforced plastics.

Prototyping and Production

Both 3D printing and CNC machining allow for prototyping and small production runs. For example, prototypes can be produced in 24-48 hours using 3D printing, while CNC machining can take from a few hours to a few days, depending on the complexity of the process.

The time required for small-volume production using 3D printing typically ranges from a few days to a week, while CNC machining ranges from a few days to a few weeks, depending on the material and complexity of the process.

Automation and Efficiency

Automation is a key feature of both 3D printing and CNC machining. Once setup is complete, both processes can be highly automated. The need for constant monitoring is reduced and human error is minimized. For example, CNC machines can run unattended for hours or even overnight, resulting in increased productivity.

Related Reading: How to Avoid Over-Extrusion in 3D Printing

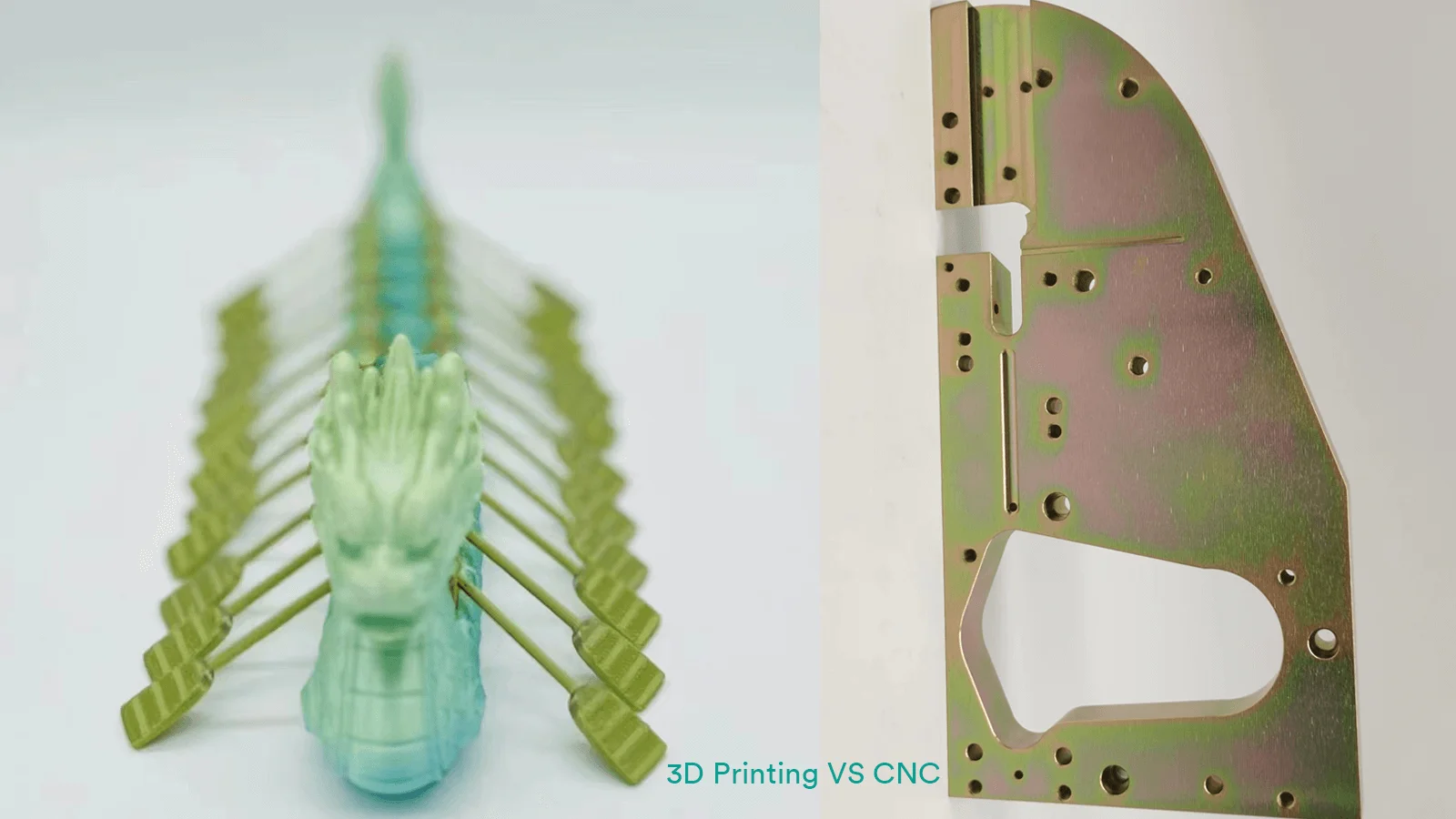

3D Printing Vs. CNC Machining: What’s The Difference?

3D printing and CNC machining are both powerful manufacturing technologies, but they differ in several key areas. Let’s dive into the specifics.

Cost

3D printing is often more cost-effective for small production runs and prototypes. The main costs are related to the printer, materials, and electricity.

For example, entry-level professional 3D printers cost between $2,000 and $5,000, while high-end models can exceed $100,000. Material costs for common filaments such as polylactic acid (PLA) or acrylonitrile butadiene styrene (ABS) range from $20 to $50 per kilogram.

CNC machining is often expensive, especially for small production runs, due to high machine and setup costs. CNC machines can cost from $50,000 to over $500,000 dollars.

In addition, material costs are high, especially for metals. Setup costs, including programming and fixture making, can also add up, making CNC machines less cost-effective for low-volume production.

Precision

The general tolerance of 3D printing is between ±0.1 mm and ±0.2 mm. Higher-end 3D printers can achieve finer resolutions, but layer lines can still affect the final surface finish, so post-processing is required for high-precision applications.

CNC machining tolerances can be accurate to ±0.005 inches (±0.127 mm) or better. The smooth surface produced directly by the machine reduces the need for post-processing, making it ideal for parts requiring high precision.

Speed

3D printing can produce a prototype in 24-48 hours. However, the actual print time depends on the size and complexity of the part. For example, printing a small object may take a few hours, while a larger, more complex part may take several days.

Once the CNC machining setup is complete, parts can be produced much faster. Simple parts can be machined in a few hours, while more complex parts may take a day or two. The overall time includes setup time, which can be long for complex designs.

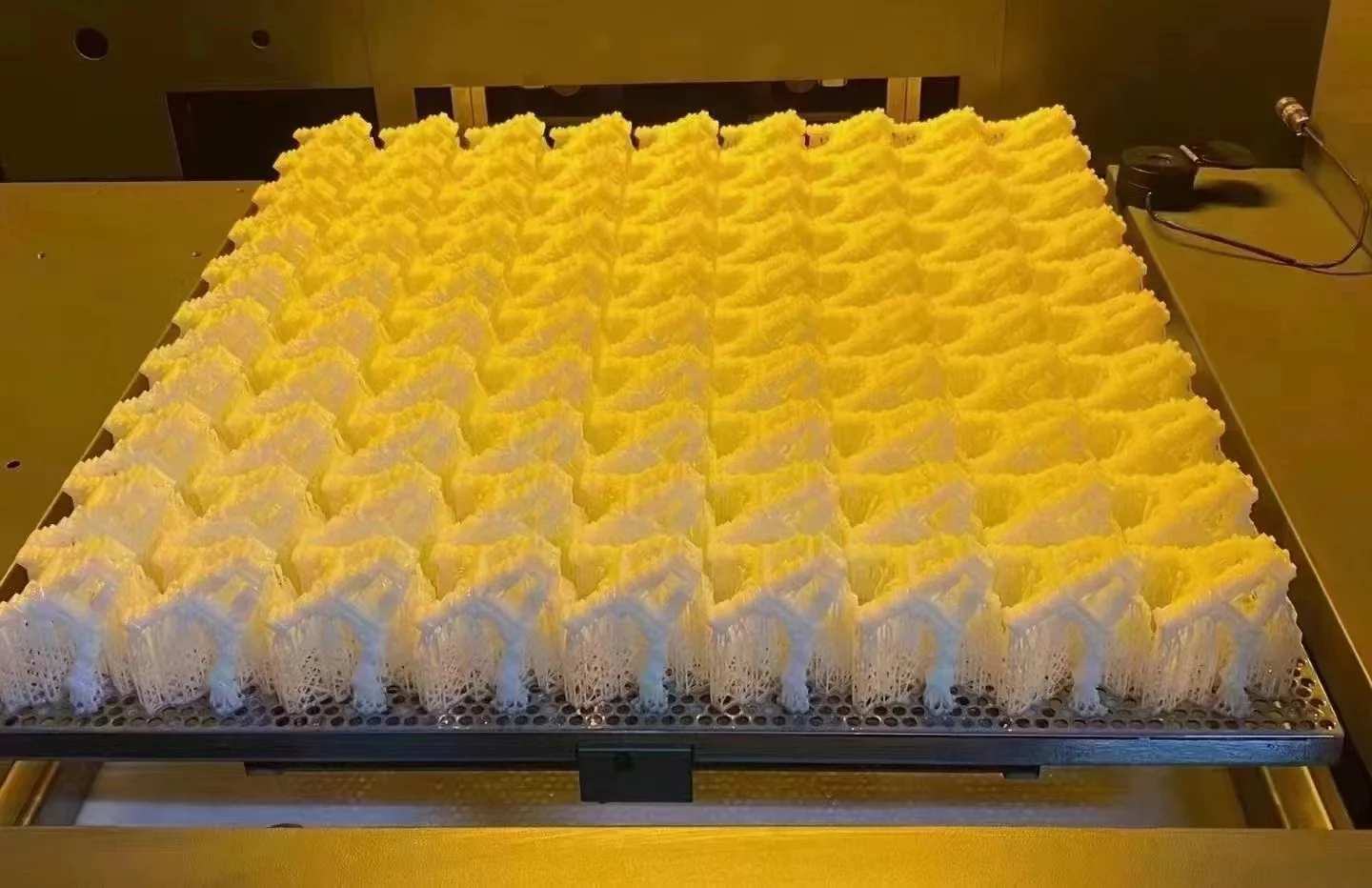

Volume

3D printing is well suited to small production runs, typically up to 100 pieces. Beyond this volume, the time and cost per part are reduced compared to other manufacturing methods.

CNC machining is better suited for small and large production runs. Although setup costs are higher, the cost per part decreases significantly as production volume increases. CNC machining is typically used for mass production of a few to several thousand parts.

Materials

3D printing is done through processes such as selective laser sintering (SLS) or direct metal laser sintering (DMLS). 3D printing materials include a variety of plastics (PLA, ABS, PETG), resins, and metals (titanium, and stainless steel).

CNC machining can process a wide variety of materials, including metals (aluminum, brass, steel), plastics (nylon, acrylic, polycarbonate), and composites. The choice of material affects the machining process, tool selection, and the final performance of the part.

Comparison Table

| Feature | 3D Printing | CNC Machining |

| Cost | Lower initial costs for small runs | Higher initial costs, cheaper per part in large volumes |

| Accuracy | Tolerances typically ±0.1 mm to ±0.2 mm | Tolerances as tight as ±0.005 inches (±0.127 mm) |

| Speed | Prototypes in 24-48 hours | Parts produced in hours to days, depending on complexity |

| Volume | Best for low-volume (up to 100 units) | Suitable for low to high-volume production (few units to thousands) |

| Material | Plastics, resins, metals | Metals, plastics, composites |

| Surface finish | Grained, rough, and stepped; features are often blurred | Can deliver very high surface quality by using longer cut times |

Related Reading: 3D Printing Tips: How to Fix Elephant Foot?

3D Printing vs CNC Machining: Which is Best for Prototyping?

Electronic enclosures often feature snaps, hinges, or other interlocking joints and fasteners. These features can be produced using FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering) 3D printing or CNC (Computer Numerical Control) machining. Each method has its own set of advantages and considerations.

Benchtop FDM is typically the most affordable option in terms of cost, with material costs ranging from about $10 to $30 per part.

CNC machining and SLS are more expensive, with CNC machining costs ranging from $50 to $200 per part, including setup, and SLS costs around $50 to $100 per part.

Speed is a big advantage of benchtop FDM, which can produce prototypes in 1-3 days, while SLS is a little slower, usually producing parts in less than a week. CNC machining takes the longest, with lead times typically 1-2 weeks due to the setup and machining processes required.

For low-volume production, tabletop FDM is best suited to efficiently handle production runs of 1 to 100 pieces without significant setup costs. sLS and CNC machining are better suited for high-volume production.

| Factor | CNC Machining | Desktop FDM | SLS |

| Cost | $50 to $200 per unit | $10 to $30 per unit | $50 to $100 per unit |

| Common Materials | ABS, Nylon, Polycarbonate | PLA, ABS, Nylon | Nylon |

| Delivery Time | 1-2 weeks | 1-3 days | Less than a week |

| Accuracy | ± 0.125 mm | ± 0.500 mm | ± 0.300 mm |

| Volume | Suitable for 100 to several thousand units | Ideal for 1 to 100 units | Suitable for low to medium volumes |

What If You’re Making Metal Brackets And Mechanical Parts?

Creating metal brackets and mechanical parts requires careful consideration of the manufacturing process to ensure accuracy, durability, and cost-effectiveness. Let’s dive into the specifics of manufacturing these parts using CNC machining and metal 3D printing such as DMLS.

CNC machining is typically more expensive. Machine costs range from $50,000 to $500,000, setup costs range from $100 to $500 per job, and material costs range from $5 to $30 per pound for metals such as aluminum, steel, or titanium. Unit costs vary depending on complexity but typically range from $50 to $500.

Direct metal laser sintering (DMLS) 3D printers cost even more, ranging from $100,000 to over $1 million. The material cost of metal powders such as stainless steel or titanium is about $100 to $200 per kilogram, and unit costs typically range from $100 to $600 due to expensive materials and equipment.

Once set up, CNC machining can produce parts relatively quickly. Simple parts can be machined in a few hours, while more complex parts can take a day or two, with a typical turnaround time of 1-2 weeks, including setup and machining time.

Metal 3D printing is a bit slower due to the layer-by-layer build process. Small parts may take a few hours, while larger, more complex parts may take several days. Turnaround time is typically 1-2 weeks, taking into account printing and post-processing time.

| Factor | CNC Machining | Metal 3D Printing (DMLS) |

| Cost | $50 to $500 per unit | $100 to $600 per unit |

| Common Materials | Aluminum, Steel, Titanium | Stainless Steel, Titanium, Inconel |

| Delivery Time | 1-2 weeks | 1-2 weeks |

| Accuracy | ±0.005 inches (±0.127 mm) | ±0.1 mm to ±0.2 mm |

| Volume | Suitable for low to high volumes | Suitable for low to medium volumes |

3D Printing Vs. CNC: How To Choose?

Choosing between 3D printing and CNC machining requires careful consideration of several factors, including cost, speed, accuracy, quantity, and material selection. Each method has unique advantages and is therefore suitable for different applications.

For small production runs, 3D printing is the best choice, often efficiently processing up to 100 units. Beyond that, the time and cost per part are not as competitive with CNC machining.

CNC machining is suitable for both small and large production runs, and can efficiently handle production runs from a few to several thousand units, with the cost per part decreasing as production volume increases.

When considering material options, 3D printing typically uses PLA, ABS, PETG, and nylon. CNC machining can use a wide range of metals and plastics, including aluminum, steel, titanium, and nylon.

Request A Quote For Your Parts

ECOREPREP specializes in CNC machining and 3D printing, offering rapid prototyping and low-volume production services in a wide range of materials and finishes.

Whether you need precision parts through CNC machining or rapid prototyping through 3D printing, you can count on ECOREPREP. There is no part too complex or quantity too small for our capabilities.

If you need CNC and 3D printing machining, you can contact us and our engineers will provide Design for Manufacturing (DFM) feedback on your design to ensure the best results.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.