Table of Contents

In today’s competitive market, quick rapid prototyping in China enables companies to cut time-to-market by 40–60% compared to Western alternatives.

It supports multiple design iterations, functional testing, and early cost optimization. Choosing the right prototyping partner can save weeks of development time and prevent costly errors during mass production.

Discover the 10 Best Rapid Prototyping Manufacturers in China to accelerate your product development.

These manufacturers offer 3D printing, CNC machining, injection molding, and vacuum casting.

These capabilities support rapid iterations, helping bring your ideas from concept to reality quickly.

Key Takeaways

| Feature | Details |

|---|---|

| Top Providers | WayKen, 3ERP, ECOREPRAP, TiRapid, Star Rapid, SuNPe, APT Mold, SEAL-RP, CreateProto, RpProto |

| Key Technologies | CNC machining, 3D printing, injection molding, vacuum casting, sheet metal fabrication, rapid tooling |

| Materials Used | Plastics (ABS, PLA, PC, Nylon), Resins, Metals (Aluminum, Steel, Titanium), Composites, Ceramics, Wax, Wood |

| Industries Served | Automotive, Aerospace, Medical Devices, Electronics, Consumer Products, Industrial Equipment |

| Lead Time | 3–7 days (depending on complexity) |

| Cost Advantage | 40–60% cheaper than Western alternatives |

Why Choose Chinese Quick Prototyping Companies?

Chinese quick prototyping companies offer affordable, fast, and flexible solutions thanks to lower labor costs and efficient manufacturing processes.

Their advanced technology and skilled workforce ensure high-quality, customizable prototypes.

Key benefits include:

- Cost-Effectiveness – Lower labor and manufacturing costs reduce development expenses.

- Speed and Efficiency – Rapid turnaround times enable faster product iteration.

- Advanced Manufacturing Capabilities – Access to CNC machining, 3D printing, injection molding, and more.

- Scalability – Easy transition from prototyping to mass production.

- Industry Experience – Extensive experience across electronics, automotive, medical, and consumer products.

- Customization and Flexibility – Tailored services to meet specific prototype requirements.

- Global Logistics – Established export infrastructure ensures smooth international shipping.

What are 10 Best Quick Rapid Prototyping Companies in China?

Best quick rapid prototyping companies in China include Ecoreprap, WayKen, 3ERP, Star Rapid, Prototech Asia, Deep Mould, Nice Rapid, RP Prototype Limited, SuNPe, and Start Prototyping.

1. WayKen Rapid Manufacturing

- Certification: ISO 9001:2015

- Materials & Processes: CNC Machining, 3D Printing, Vacuum Casting, Injection Molding

- Industry Focus: Automotive, Aerospace, Medical Devices, Consumer Electronics

- Lead Time: 3–9 days

2. 3ERP (3E Rapid Prototyping Limited)

- Certification: ISO 9001:2015

- Materials & Processes: CNC Milling & Turning, Rapid Tooling, High Pressure Die Casting

- Industry Focus: Automotive, Medical, Aerospace, Consumer Electronics

- Lead Time: 3–7 days

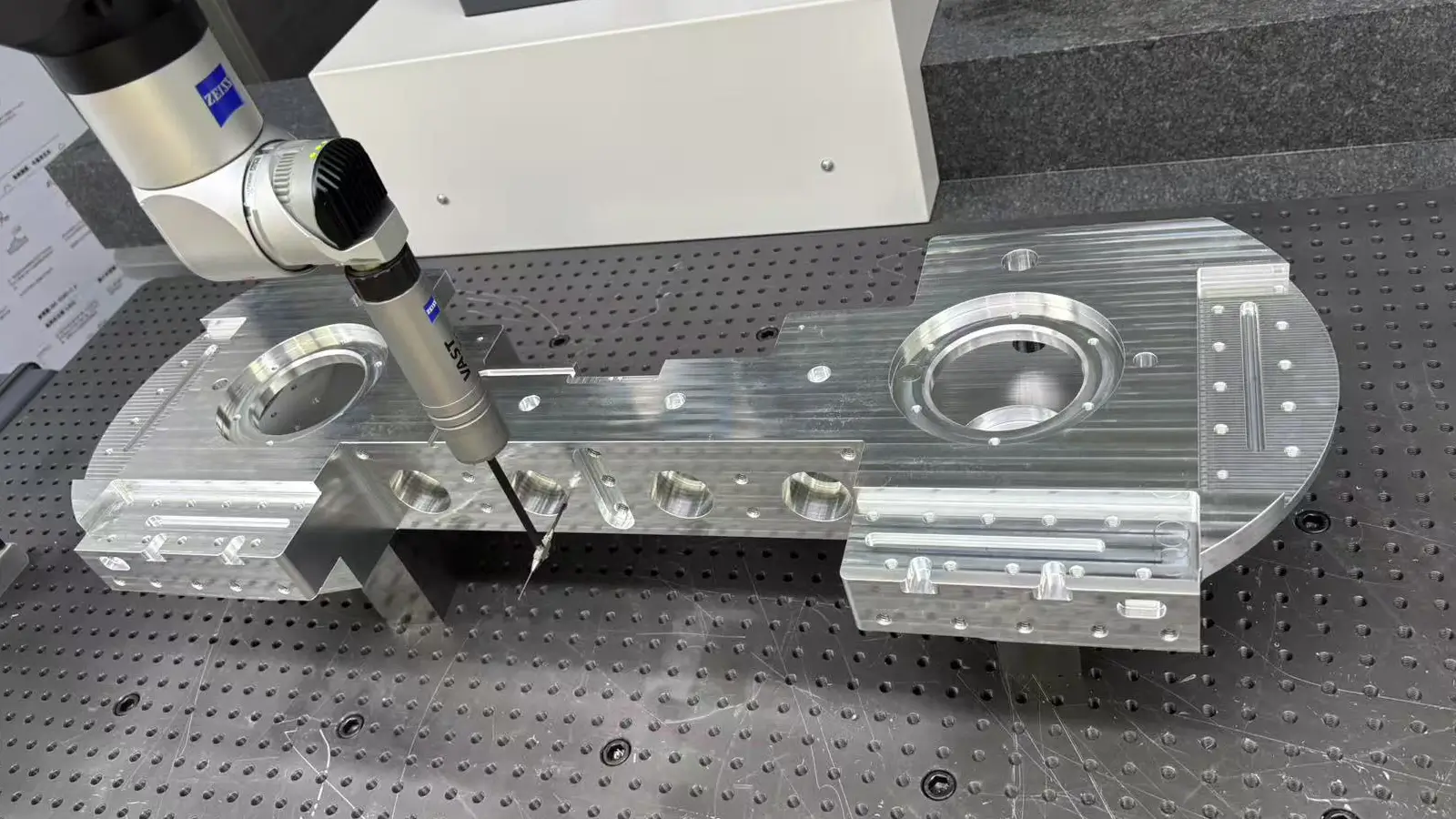

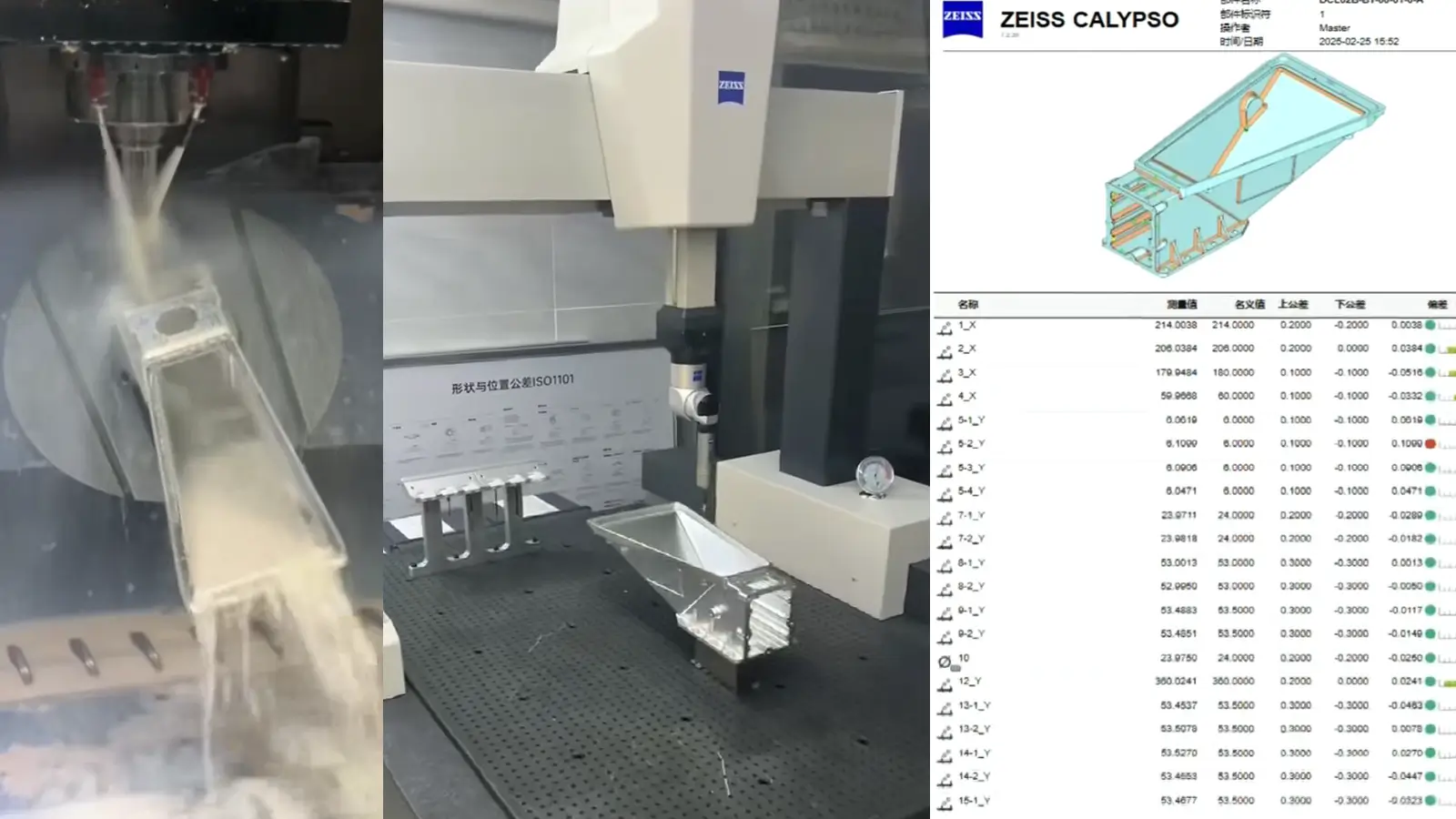

3. ECOREPRAP

- Certification: ISO 9001, ISO 13485, CE, and FDA

- Materials & Processes: CNC Machining, 3D Printing, Urethane Casting, Injection Molding

- Industry Focus: Robotics, Electronics, Consumer Products

- Lead Time: 3–5 days

4. TiRapid

- Certification: ISO 9001, RoHS

- Materials & Processes: 5-Axis CNC Machining, Micro Parts, Large-Size Parts

- Industry Focus: Aerospace, Automotive, Industrial Equipment

- Lead Time: 3–7 days

5. Star Rapid

- Certification: Not specified

- Materials & Processes: CNC Machining, Injection Molding, Vacuum Casting, Sheet Metal

- Industry Focus: Automotive, Medical, Consumer Electronics

- Lead Time: 5–10 days

6. SuNPe PROTOTYPE

- Certification: Not specified

- Materials & Processes: CNC Machining, Injection Molding, Vacuum Casting

- Industry Focus: Automotive, Electronics, Consumer Products

- Lead Time: 4–8 days

7. APT Mold Manufacturing Co., Ltd

- Certification: Not specified

- Materials & Processes: CNC Machining, Injection Molding, Rapid Tooling

- Industry Focus: Automotive, Electronics, Consumer Products

- Lead Time: 4–7 days

8. SEAL-RP

- Certification: Not specified

- Materials & Processes: 3D Printing, CNC Machining, Vacuum Casting

- Industry Focus: Automotive, Aerospace, Medical Devices

- Lead Time: 5–10 days

9. CreateProto

- Certification: Not specified

- Materials & Processes: CNC Machining, 3D Printing, Rapid Tooling

- Industry Focus: Consumer Electronics, Medical Devices

- Lead Time: 3–7 days

10. RpProto

- Certification: Not specified

- Materials & Processes: CNC Machining, Vacuum Casting, Sheet Metal, Injection Molding

- Industry Focus: Automotive, Aerospace, Consumer Electronics

- Lead Time: 4–8 days

Read more:5 Best sheet metal prototyping manufacturers in China

How to Choose Rapid Prototyping Companies in China?

When evaluating rapid prototyping services, key considerations include technical capabilities, material versatility, certifications, and industry coverage. Based on the top 10 companies:

1.ECOREPRAP

- Certifications: ISO 9001, CE, FDA

- Materials & Processes: CNC machining, 3D printing, urethane casting, injection molding

- Industry Focus: Electronics, robotics, consumer products, general industrial prototypes

- Overview: ECOREPRAP provides multiple prototyping technologies and can work with a variety of materials. The company holds recognized quality and safety certifications, and its services are representative of typical industry lead times for rapid prototyping.

2.WayKen Rapid Manufacturing / 3ERP

- Materials & Processes: CNC, injection molding, vacuum casting, rapid tooling

- Industry Focus: Electronics, automotive, consumer products, general industrial prototypes

- Overview: These companies offer multiple manufacturing processes and are capable of handling projects requiring different technologies or materials. Their quality management is supported by ISO 9001 or equivalent certifications.

3.CreateProto / Star Rapid

- Materials & Processes: CNC machining, 3D printing, injection molding, vacuum casting

- Industry Focus: Electronics, consumer products, general industrial prototypes

- Overview: These companies are experienced in general prototyping and provide flexible options for projects with standard requirements. Certification and quality management systems vary by provider.

Read more:5 Best Prototype Manufacturers in China

Key Comparison Points

- Technical Range: ECOREPRAP and WayKen / 3ERP provide a wide range of prototyping technologies suitable for diverse applications.

- Material Flexibility: Most top companies support multiple materials and finishes suitable for electronics, consumer products, and general industrial prototypes.

- Industry Coverage: Electronics, consumer products, and industrial prototypes are commonly served across the top providers.

- Certifications: ISO 9001 is common. ECOREPRAP also holds CE and FDA certifications, relevant for quality and safety compliance.

What Are Common Quick Prototyping Technologies in China?

China’s rapid prototyping industry uses a variety of advanced technologies to produce precise, cost-effective prototypes for multiple industries. The main technologies include:

- 3D Printing (Additive Manufacturing) – Ideal for complex shapes, concept models, and functional prototypes in plastics and metals.

- CNC Machining – Precision milling, turning, and drilling of metals and plastics for functional prototypes.

- Injection Molding (Rapid Tooling) – Soft tooling or aluminum molds for small-batch prototypes.

- Vacuum Casting – Produces small runs of polymer parts with good surface finish.

- Sheet Metal Fabrication – Laser cutting, bending, stamping for metal prototypes.

- Sand Casting & Die Casting – Quick metal prototypes for testing or functional use.

- Surface Finishing & Assembly – Painting, plating, anodizing, polishing, and assembly for near-final appearance.

- Electronics Prototyping – PCB prototyping and component assembly in specialized facilities.

What materials are commonly used in rapid prototyping?

| Material Type | Specific Materials | Suitable Technologies | Applications |

|---|---|---|---|

| Plastics | ABS, PLA, PC, Nylon, POM, PEEK | 3D Printing, CNC Machining, Injection Molding | Durable functional prototypes, consumer products |

| Resins | Photopolymers (acrylics, flexible polyurethane) | SLA 3D Printing | High-precision models, concept prototypes |

| Metals | Aluminum, Stainless Steel, Titanium, Copper | CNC Machining, Metal 3D Printing, Casting | Strong functional prototypes, mechanical parts |

| Composites | Carbon fiber, Glass fiber | CNC, 3D Printing | Lightweight functional prototypes |

| Ceramics & Wax | Ceramic powders, Wax | SLA, Casting | Molds, master patterns |

| Paper/Metal Foils/Plastics | Laminated object manufacturing | 3D Printing, Layered Prototyping | Architectural, visual models |

| Wood | Natural or treated wood | CNC Machining | Visual models, furniture prototypes |

How long does rapid prototyping take?

| Technology | Prototype Type | Typical Lead Time |

|---|---|---|

| 3D Printing | Simple parts | Hours to 3 days |

| CNC Machining | Mechanical parts | 3–7 days |

| Injection Molding / Rapid Tooling | Plastic parts | 5–10 days |

| Vacuum Casting / Silicone Rubber | Functional prototypes | 2–6 weeks |

| Complex Mechanical / Electronics | Multi-component prototypes | 4–12 weeks |

Applications of Quick Rapid Prototyping in China

| Category | Industries & Applications |

|---|---|

| Consumer | Electronics (smartphones, wearables), Consumer Goods & Appliances, Fashion & Jewelry |

| Industrial | Automotive (panels, brackets), Aerospace & Defense, Industrial Equipment & Machinery |

| Healthcare & Research | Medical Devices, Surgical tools, Prosthetics, Education & Research |

| Design & Innovation | Architecture & Construction, Startups & Innovation Labs |

China’s manufacturing ecosystem integrates rapid prototyping with scalable production, enabling faster product development.

How to protect intellectual property when working with Chinese manufacturers?

Protect your innovations with these steps:

- Register IP in China – Patents, trademarks, and copyrights with CNIPA.

- Use NDAs – Sign clear agreements before sharing sensitive designs.

- Work with Trusted Manufacturers – Choose reputable companies and conduct audits.

- Limit Disclosure – Share only necessary information for production.

- Include IP Clauses in Contracts – Define ownership, confidentiality, and dispute resolution.

- Monitor & Enforce Rights – Regularly check for infringements and act legally.

- Use Technology Protection Measures – Serial numbers, holograms, or digital watermarks.

- Leverage Legal & Customs System – Register IP with Chinese Customs to prevent counterfeit imports.

- Build Long-Term Relationships – Trust and collaboration reduce leakage risks.

- Consult IP Professionals – Work with IP lawyers familiar with Chinese regulations.

What is the difference between quick rapid prototyping and mass production?

Quick rapid prototyping focuses on creating small quantities of functional or visual models quickly to test and refine designs.

Mass production involves large-scale manufacturing of finalized products with consistent quality and efficiency.

While prototyping prioritizes speed and flexibility, mass production emphasizes cost-effectiveness and volume.

Stage 1: Concept and Design Validation

- Recommended Approach: Quick Rapid Prototyping

- Reason: At this early stage, you need fast, low-cost physical models to test design concepts, functionality, and ergonomics. Rapid prototyping allows quick iterations and refinements before committing to costly tooling or large production runs.

Stage 2: Pre-Production and Pilot Runs

- Recommended Approach: Small Batch Production or Rapid Tooling

- Reason: Once the design is validated, producing a small batch helps test manufacturing processes, quality control, and market response. This bridges the gap between prototyping and full-scale production, reducing risks.

Stage 3: Mass Production

- Recommended Approach: Full-Scale Manufacturing

- Reason: When the product design is finalized and demand volume is confirmed, mass production minimizes unit costs and ensures consistent quality and supply to meet market needs.

What is the cost of rapid prototyping in China?

China’s rapid prototyping services are 30–70% cheaper than Western alternatives due to lower labor, material, and equipment costs.

Typical costs are:

| Technology | Material | Lead Time | Typical Cost | Notes |

|---|---|---|---|---|

| 3D Printing | ABS, PLA | 1–3 days | $50–$200 | Simple models, concept validation |

| CNC Machining | Aluminum, Steel | 3–7 days | $100–$2000 | Functional prototypes, precision parts |

| Injection Molding | ABS, PC | 5–10 days | $200–$1500 | Small batch production, soft tooling |

Cost Factors:

- Material Costs: SLA $0.4/g, SLS Nylon $0.7/g, CNC billets $3–$200/kg.

- Labor Costs: $8–$30/hour for skilled workers, up to $50 for complex work.

- Equipment Costs: Basic CNC $20–30/hour, 5-axis CNC $35–50/hour.

- Complexity & Order Size: Larger, more detailed parts cost more; small batches cost more per unit.

What are the common challenges in quick rapid prototyping?

Common challenges in quick rapid prototyping include balancing speed with accuracy, as fast production can sometimes compromise precision.

Material limitations may restrict prototype functionality or durability compared to final products.

Additionally, communication gaps between designers and manufacturers can lead to misunderstandings and delays in the prototyping process.

If your goal is to quickly validate a concept or design

1.Quick Rapid Prototyping (QRP) Decision Guide

Evaluate rapid prototyping in China based on your product needs:

- Goal: Fast Concept Validation – Quickly produce models to check design, functionality, and ergonomics before mass production.

- Material Requirements:QRP materials may differ from final production; suitable for appearance or preliminary testing.

- Budget Constraints:QRP allows multiple iterations at lower cost; ideal for startups and labs.

- IP Protection Concerns:Sign NDAs, stage disclosure, and define IP ownership clearly.

- Short Lead Time Needed:QRP can deliver initial prototypes within days to weeks, accelerating time-to-market.

2.Final Recommendation

- In most cases, QRP is worth trying, especially in the early stages of product development.

- Prerequisites:

- Clearly define testing goals

- Control iteration costs

- Protect intellectual property

- For high-performance parts or strict final-material requirements, use QRP for concept validation, then move to full-scale production.

Conclusion

Choosing the right rapid prototyping partner in China is essential for efficient and cost-effective product development. The Top 10 Quick Rapid Prototyping Manufacturers in China offer:

Fast turnaround times and cost savings

Diverse prototyping technologies

Experience across multiple industries

Global logistics support

By evaluating certifications, material capabilities, lead times, and IP protection practices, you can maximize the benefits of working with Chinese rapid prototyping companies while minimizing risks.

Verified data from the China Association of Machinery Industry (CAMI) Rapid Prototyping Database, official industry reports on Chinese manufacturing and prototyping, and ISO 9001-, CE-, RoHS-, and FDA-certified rapid prototyping suppliers.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.