Table of Contents

As a powerful system widely used in engineering and manufacturing, Geometric Dimensioning and Tolerancing(GD&T) precisely confines the form, size, orientation, and location of features on a part.

We are going to explain GD&T Runout Tolerances, including GD&T Circular Runout and GD&T Total Runout. Circular runout would be introduced first.

Key Takeaways:

- Circular runout simultaneously controls both radial (perpendicular to axis) and axial (parallel to axis) deviations during 360° rotation around a datum axis, ensuring rotational stability and reducing vibration in cylindrical components.

- Circular runout features two distinct tolerance zones – concentric rings for radial runout (controlling circularity and concentricity) and parallel circles for axial runout (controlling flatness and perpendicularity) – both referenced to the same datum axis.

- It can be measured using dial indicators for cost-effective inspection, CMM for automated precision, or specialized roundness testers for high-accuracy rotational analysis.

- Circular runout serves as a synthetic tolerance that controls circularity, concentricity, and perpendicularity simultaneously, making it more comprehensive than individual form or location tolerances for rotating parts.

1. What is Circular Runout in GD&T?

Circular runout GD&T plays a crucial role in ensuring the good quality and proper function of cylindrical parts. This part focuses on its definition and tolerance zone to detailed explain what is circular runout in GD&T.

1.1. Circular Runout GD&T Definition

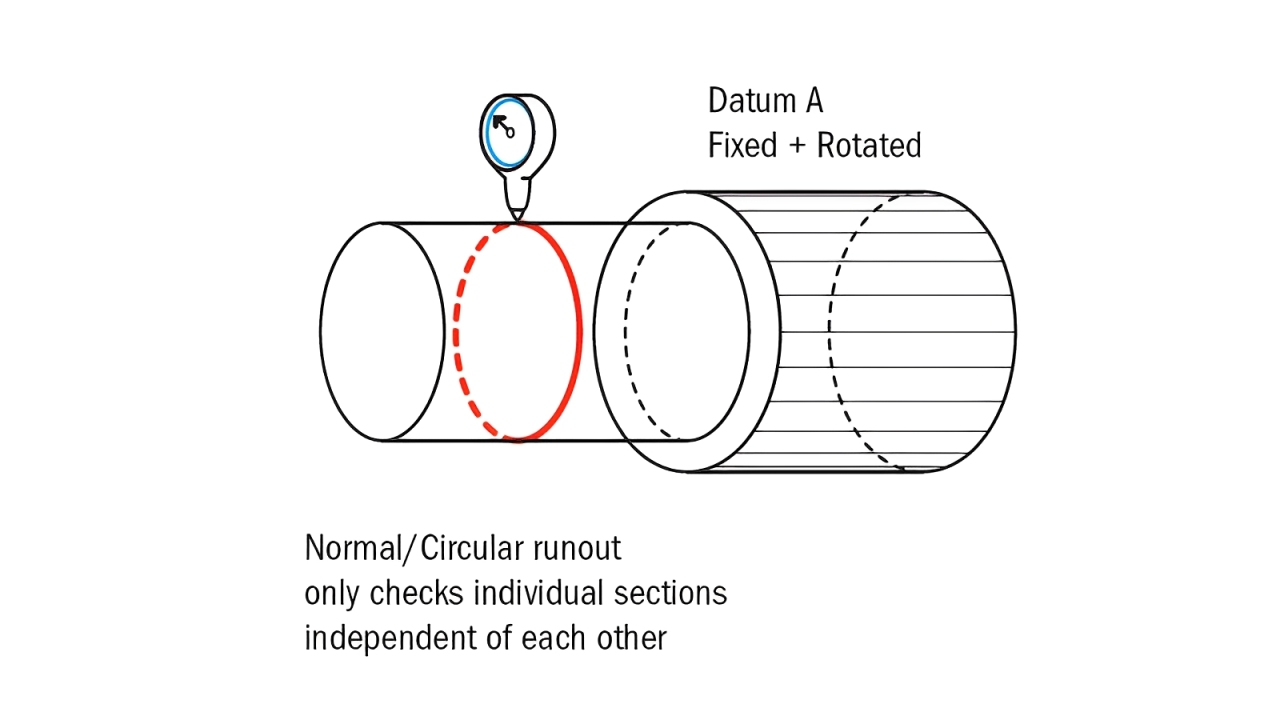

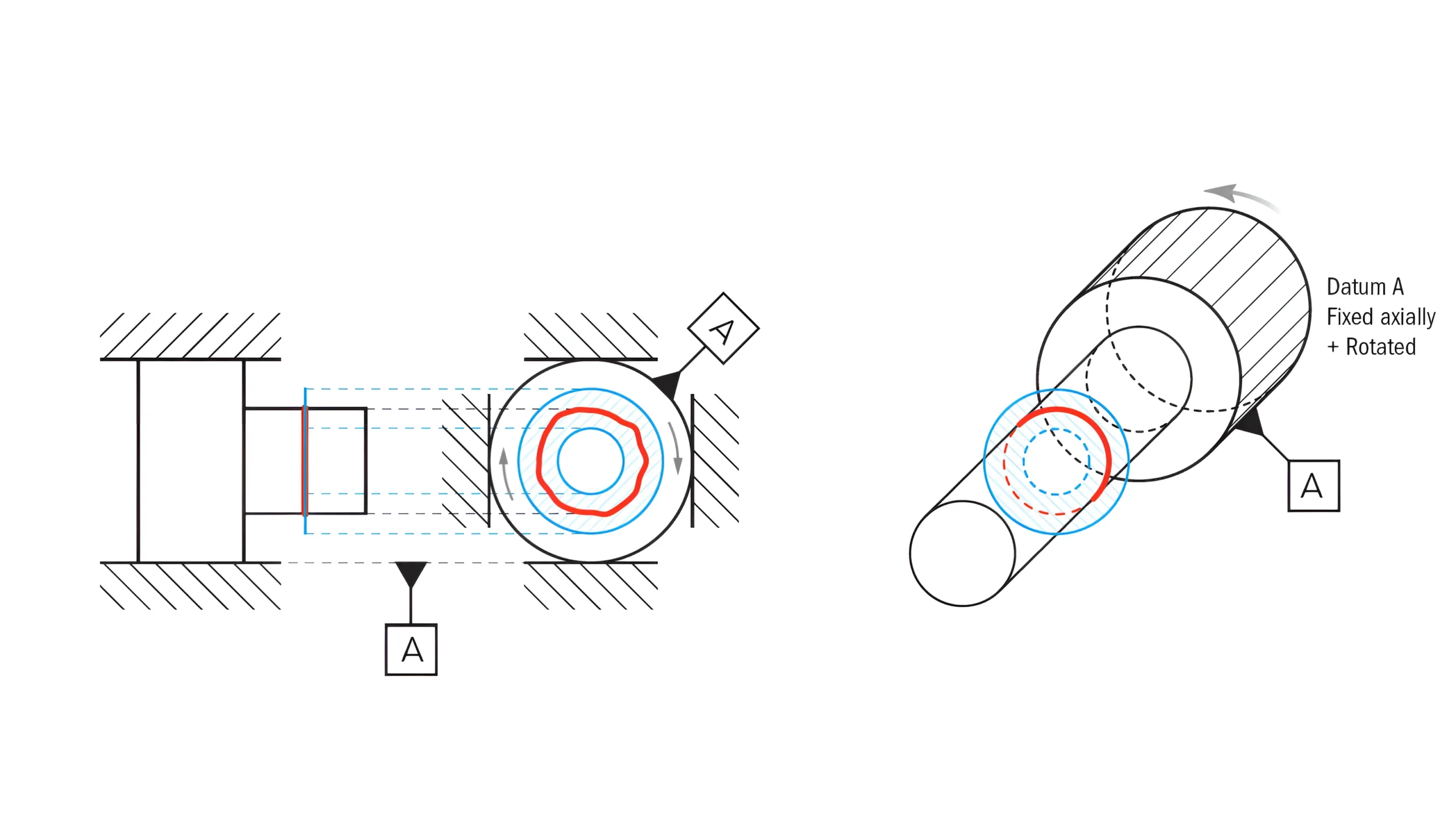

Circular runout GD&T is a geometric tolerance used to control the variation of a part’s circular profile as it rotates 360° around the datum axis. By controlling the radial and axial runout of any cross-section, the GD&T circular runout controls the circular and concentrical deviation at the same time.

In short, circular runout GD&T confines how much the measured feature of a part swings referring to a datum feature(usually the cylindrical plane or the central axis).

And the controlled factors of circular runout include any out-of-roundness, eccentricity, and other deviations from a perfect circle, as well as the runout direction, as the feature rotates around its central axis.

1.2. Circular Runout GD&T Tolerance Zone

As the circular runout GD&T controls both the radial runout and the axial runout, the tolerance zones are classified into two types.

For radial runout, the tolerance zone is an area of a concentric ring. It controls that any cross-section that is perpendicular to the datum axis must lie within the zone between two concentric circles when rotating around the datum axis.

The center of these two concentric circles is the intersection of datum axis and the measured plane. And the tolerance value is the width of the concentric ring.

By confining the measured cross-section within this tolerance zone, the measured feature’s deviation on circularity, concentricity and axis’ straightness is controlled at the same time.

More importantly, note that the two concentric circles’ dimension is not essentially refined by the standard itself, but indirectly controlled by the size of feature and tolerance value.

As for axial runout, the tolerance zone consists of two parallel circles that are both theoretically perpendicular to the datum axis. The circumference line of the head surface or the end surface must lie within these two parallel circles when the measured feature rotating around the datum axis.

And the tolerance value is the width of these two parallel circles, which controls the permissible variation along the axial direction during rotation.

By controlling the measured feature within this tolerance zone, the measured surface’s flatness and perpendicularity to the datum axis are controlled at the same time.

In addition, though the tolerance zone of circular runout would vary due to the different measured elements, one indication of circular runout tolerance can control both the radial and axial runout at the same time since the datum axis and tolerance value of radial tolerance zone are similar to that of axial tolerance zone.

2. Radial Runout VS Axial Runout

Circular runout GD&T commonly controls the radial runout and axial runout at the same time. They are both used to control the runout deviation of the measured feature, but are different on the measuring direction and measured element.

For radial runout, the measuring direction is perpendicular to the datum axis, controlling the measured feature’s deviation along the radial direction. And the measured feature is usually any perpendicular cross-section of the part’s cylindrical surface.

By controlling the radial deviation referring to the datum axis, radial runout controls the circularity and concentricity of the part’s cylindrical surface. The main function of radial runout is maintaining the rotating balance of the part, thus to reduce the part’s vibration and abrasion when rotating.

And radial runout is commonly applied to parts that require control on rotational symmetry and concentricity, such as shaft parts, wheels, outer diameters of gear, and outer rings of bearing.

Compared with radial runout, the axial runout’s measuring direction is parallel to the datum axis, controlling the measured feature’s deviation along the axial direction when rotating around the datum axis. The measured feature is usually the head or end surface of the part.

By controlling the axial deviation referring to the datum axis, axial runout controls the measured feature’s flatness and perpendicularity to the datum axis. The main purpose is to reduce the measured feature’s waving and inclination, and then to ensure the sealing and fitting.

Axial runout is usually applied to parts that needs to keep perpendicular to its axis, such as end faces of flange, turbine disks, and optical lenses.

3. How to Show Circular Runout GD&T on Engineering Drawings?

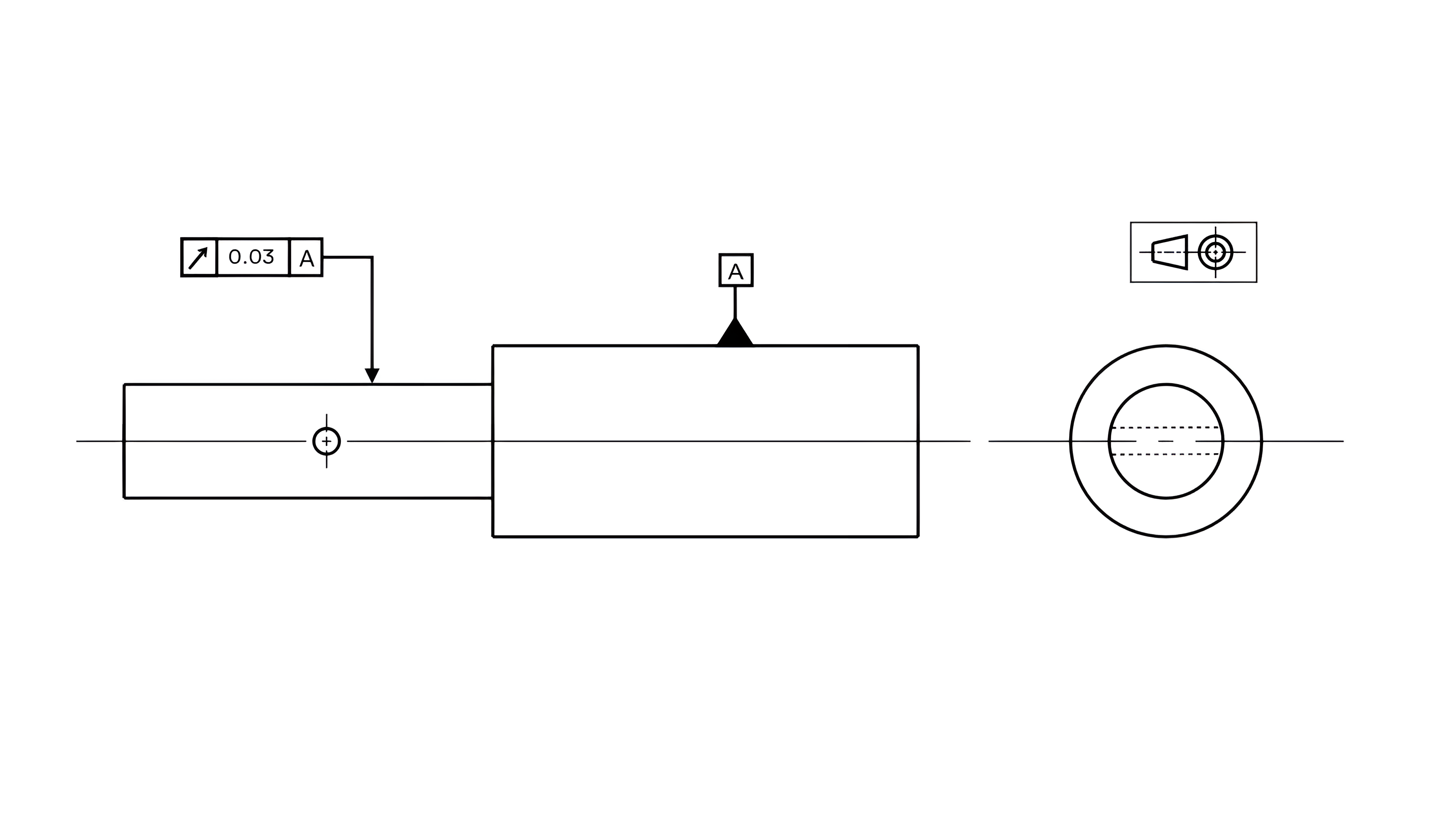

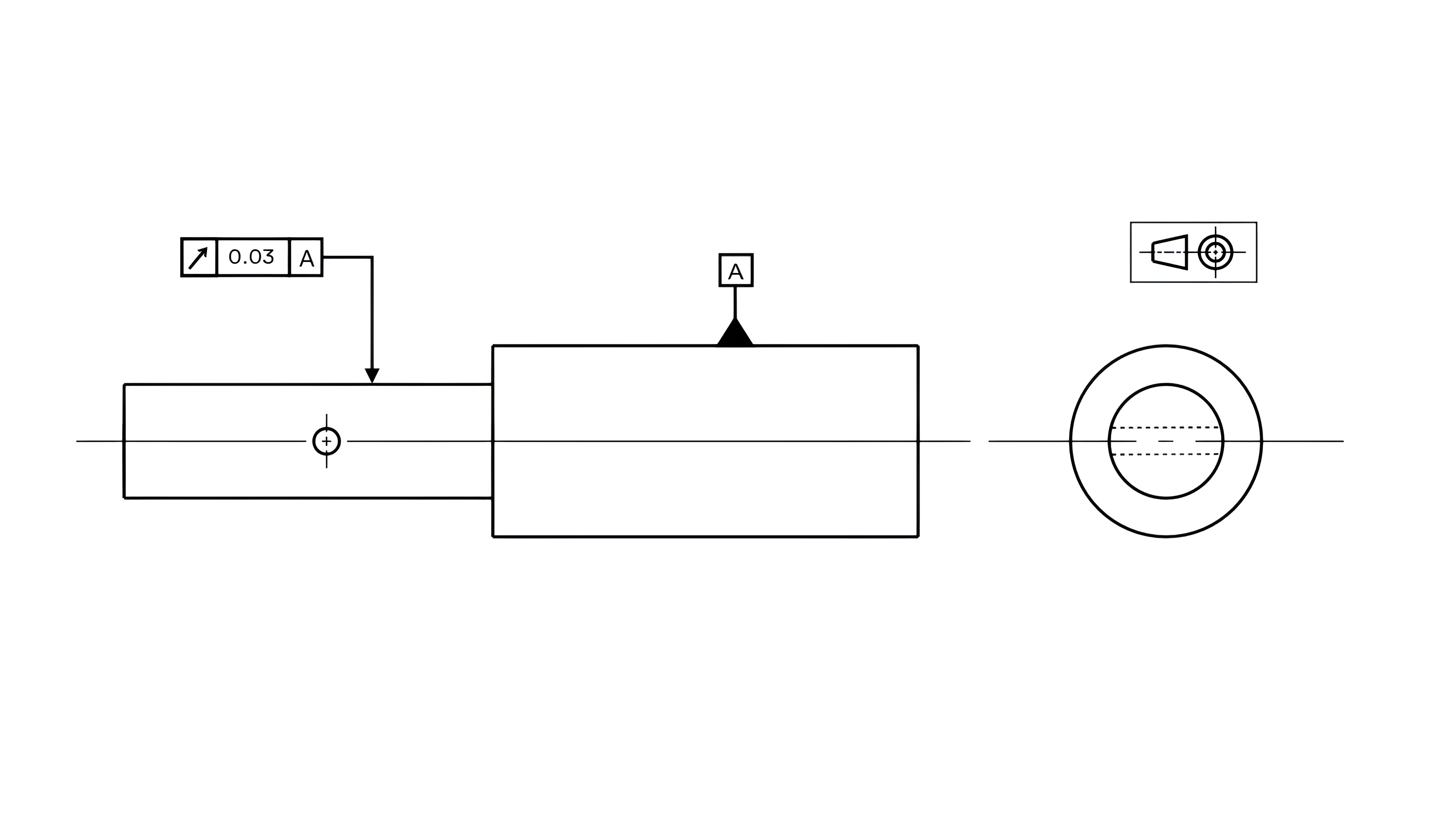

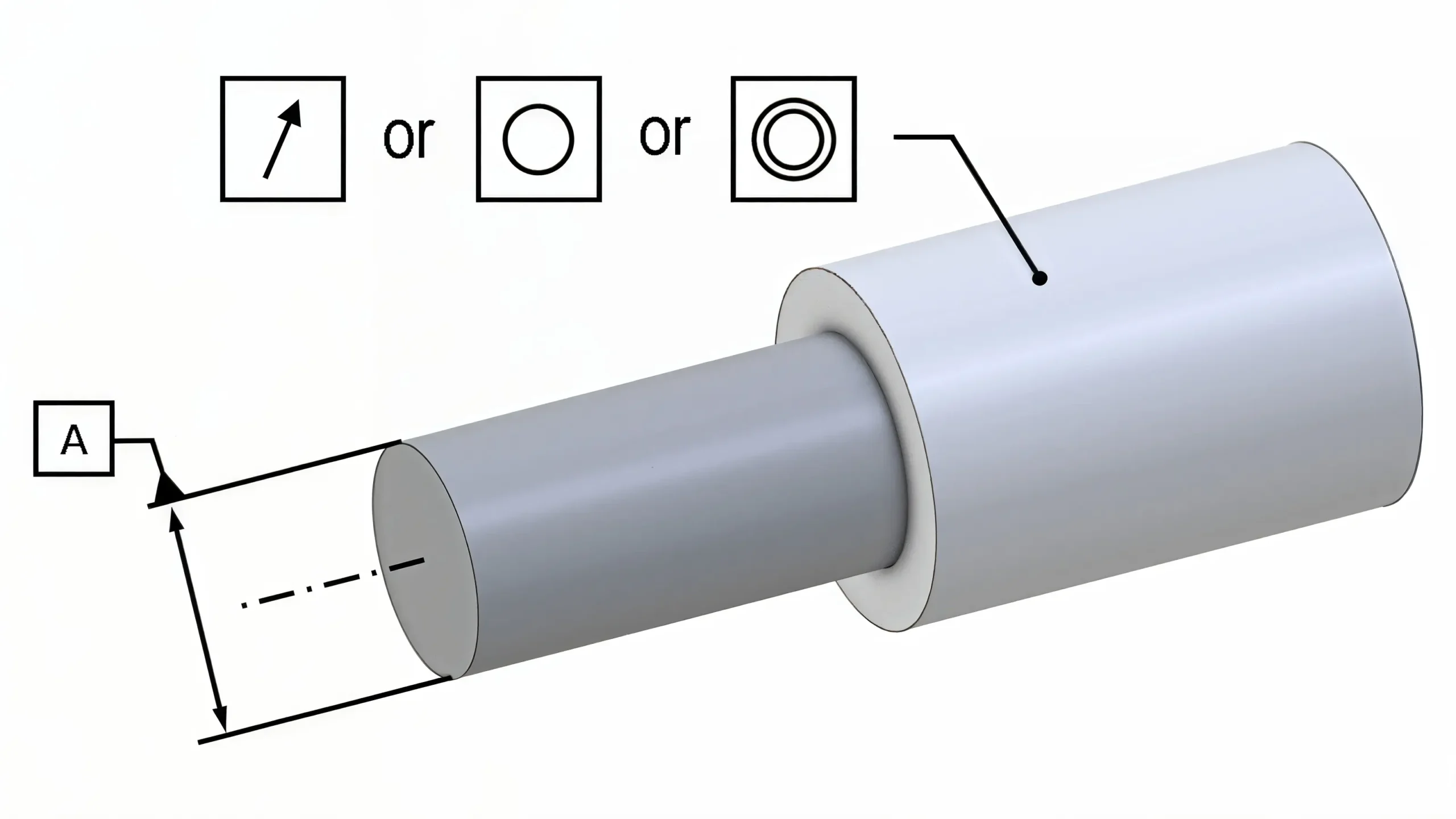

The feature control frame of circular runout GD&T is simply composed of three single factors.

The first factor is the GD&T symbol of circular runout. It is an arrow that points to the northeast.

The second factor is the tolerance value. It is the measured feature’s biggest permissible runout deviation along the radial or axial direction when rotating around the datum axis. And note that the symbol of diameter is not included in this block.

The third block contains the symbol of datum. As circular runout GD&T usually refers to simply one datum, only symbol “A” would appear in this block. And we mostly choose the central axis as the reference datum.

In engineering drawings, we usually indicate the circular runout control by connecting the feature control frame of circular runout GD&T with an arrow that points to the measured feature.

4. How to Measure Circular Runout GD&T?

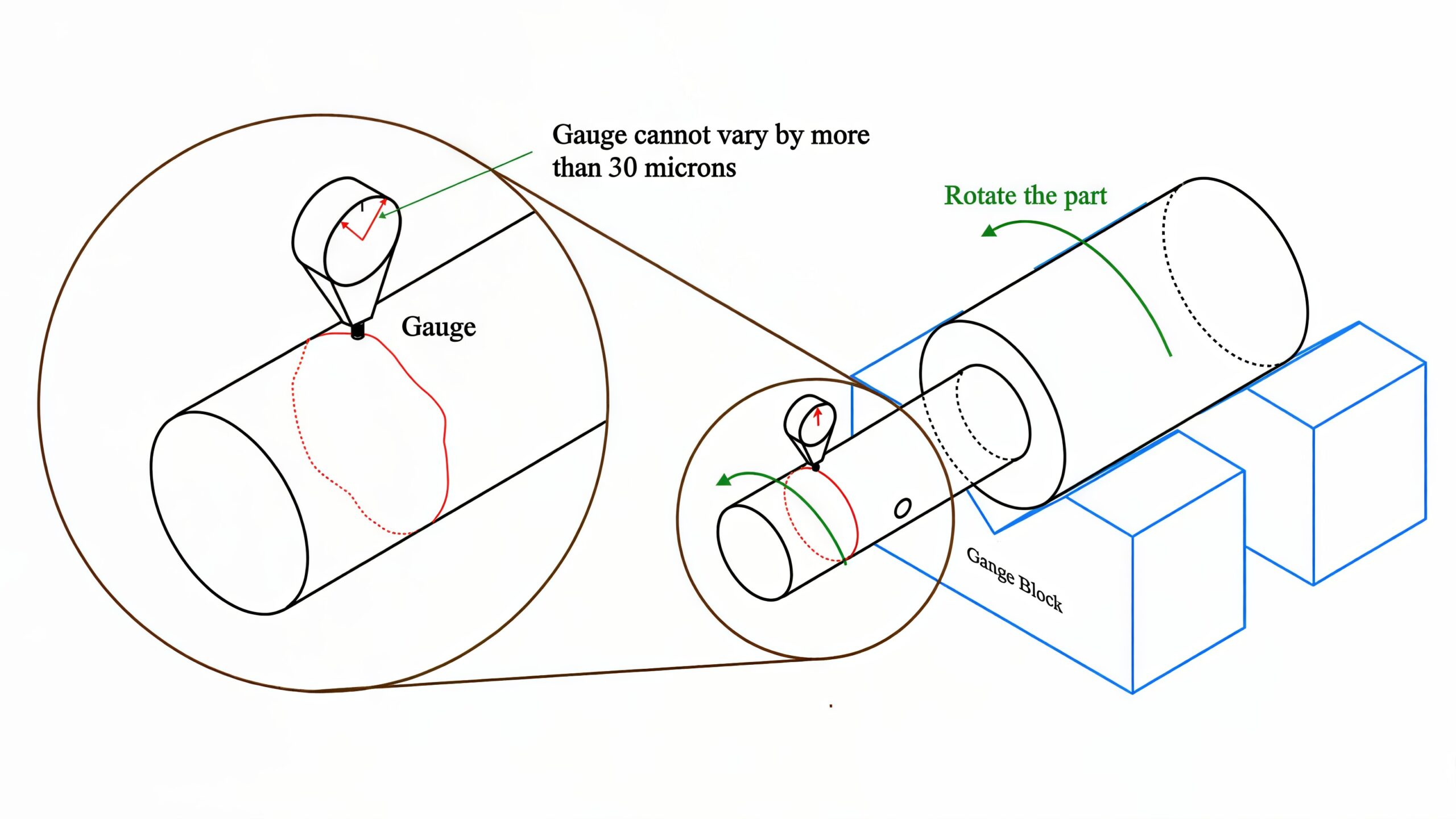

4.1. Using Dial Indicator to Measure Circular Runout

Dial indicator is one of the most commonly used tools for circular runout measurement. This measuring method cost low and is suitable for on-site inspection. More importantly, the runout deviation is directly displayed.

However, the measuring accuracy of dial indicators is limited. And the measuring efficiency is certainly low, thus not suitable for high-volume rapid inspection.

The concrete steps to measure circular runout by this method are shown below:

Step 1: Fix the measured part on the precision rotating equipment(like a lathe, indexing head, or V-block), ensuring co-axiality with the rotational axis.

Step 2: Fix the dial indicator on a magnetic stand, with the probe perpendicular to the measured surface.

Step 3: Lightly press the probe to pre-compress the indicator by 1-2 turns, then rotate the dial to zero.

Steps 4: Slowly rotate the measured feature around the axis one full revolution, and record the difference between the maximum and minimum readings. Note to move the probe axially as needed to measure multiple cross-sections.

4.2. Using Coordinate Measuring Machine to Measure Circular Runout

CMM is a kind of versatile machine that can be used to measure various GD&T tolerance, including circular runout GD&T.

The concrete steps to measure circular runout by this method are shown below:

Step 1: Establish a measurement coordinate system based on the datum axis of the part.

Step 2: Automatically collect data of multiple points along the measured circumference.

Step 3: Use the CMM software to fit the actual contour and calculate the maximum radial/axial deviation relative to the datum axis.

Step 4: Output runout values and visual graphs.

4.3. Using Roundness Tester to Measure Circular Runout

Roundness tester can also be used to measure circular runout. With high accuracy, it is designed specifically for runout and roundness. Thus, it is only suitable for rotary parts.

The concrete steps to measure circular runout by this method are shown below:

Step 1: Fix the measured part on precision spindle centers or V-blocks, adjusting the axis to be co-axial with the spindle.

Step 2: Set the radius and sampling density, and then use an inductive probe to contact the measured feature.

Step 3: Rotate the spindle and collect the data by the sensor, with the software analyzing the runout in real time.

Step 4: Output the maximum and minimum values of radial/axial runout.

5. Circular Runout VS Circularity VS Concentricity

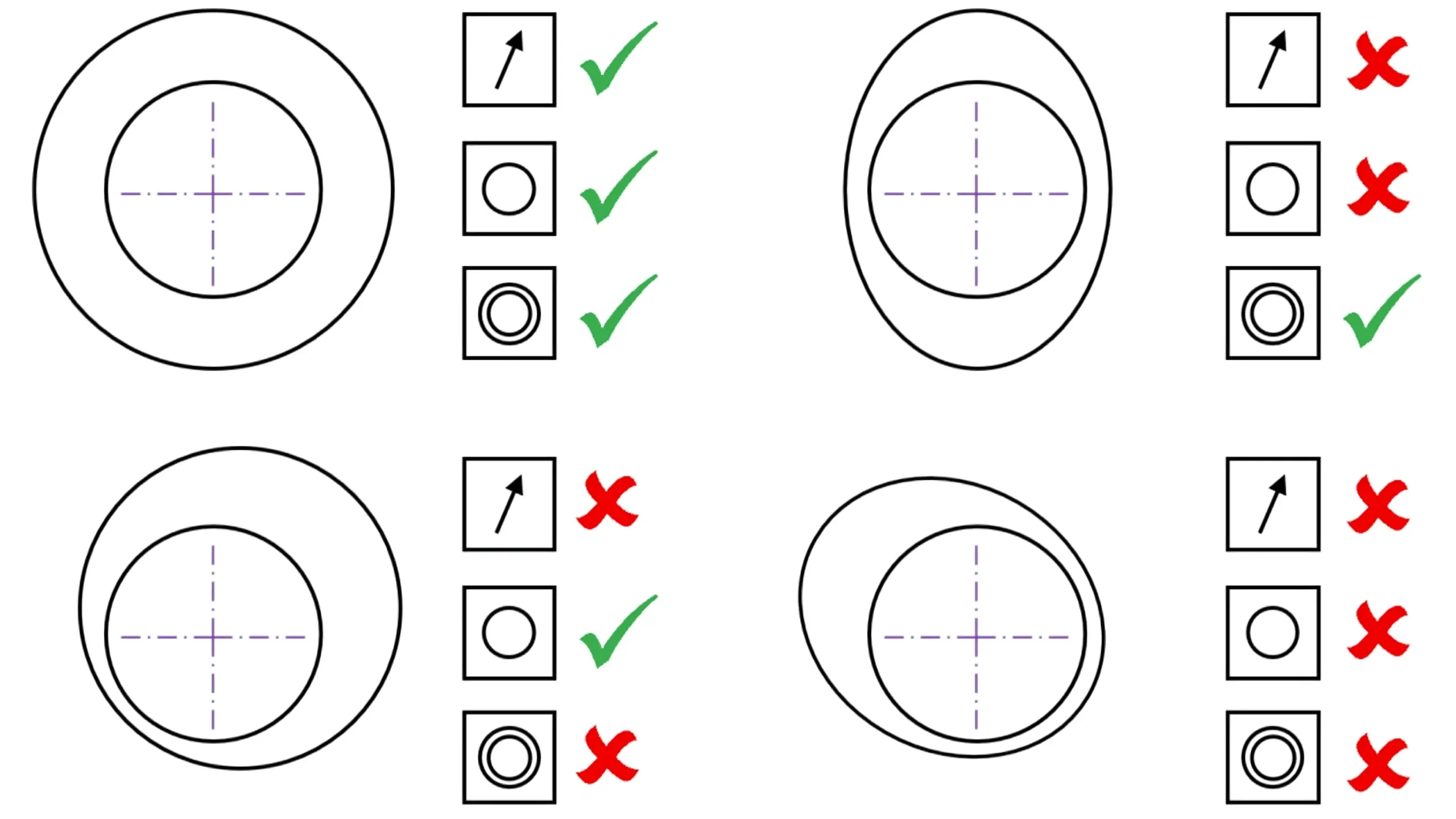

Circular runout GD&T controls circularity and concentricity at the same time.

As it is used to control the runout deviation of the measured feature when rotating around the datum axis, all factors that would influence the runout deviation should be controlled, including the circularity and concentricity, which would mainly make effect on the radial runout.

In short, circular runout is a kind of synthetical tolerance that controls the circularity, concentricity and perpendicularity at the same time, thus to confine the runout deviation during rotation, and then to ensure the whole rotational function.

Compared with circular runout GD&T, circularity and concentricity are both static tolerances.

Circularity GD&T only controls how much the measured circle deviates from the theoretical circle. It is simply a kind of form tolerance used to confine the measured feature as circular as possible.

And as a form tolerance, circularity GD&T should not use any datum as a reference. But the tolerance zones of circular runout and circularity are both composed of two concentrical circles.

As a kind of location tolerance, concentricity controls the maximum permissible deviation of the measured axis from the datum axis, trying to make the two axes overlay.

The tolerance zone of concentricity is a cylinder whose central axis is the datum axis and the diameter is the tolerance value. Both of circular runout and concentricity need refer to the datum axis.

6. Conclusion

As a runout tolerance, circular runout GD&T makes huge effect on ensuring the working stability of rotating parts. This article has provided as comprehensive information of circular runout GD&T as possible. But if you still have any confusion about it, please contact us directly.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

MMC

MMC is a feature of size symbol which refers to the dimensional condition where the particular feature contains the maximum amount of material within its indicated tolerance.

LMC

LMC is a feature of size symbol which refers to the dimensional condition where the particular feature contains the least amount of material within its indicated tolerance.

Circular Runout

Circular runout GD&T is a geometric tolerance used to control the variation of a part’s circular profile as it rotates 360° around the datum axis.

Total Runout

Total runout is one of the runout symbols that mainly controls the runout deviation of the measured feature’s entire surface during rotation around the datum axis.