Table of Contents

CNC machining stands out as the premier manufacturing method for small-batch prototyping when high precision, material fidelity, and reliable performance are non-negotiable.

Unlike 3D printing, CNC uses subtractive technology to carve parts from production-grade materials, delivering prototypes with superior surface finish, tight dimensional tolerances (often <0.01mm), and the full mechanical strength required for rigorous functional testing.

For late-stage validation, aerospace, medical devices, and any low-volume application demanding repeatability, CNC is the essential bridge between concept and final production.

Learn more:

CNC Machining for Small Batch Prototyping: Why It’s the Best Choice for Precision and Performance?

CNC machining excels for small-batch prototyping needing high precision and material strength.

Learn more:What Is A CNC Machining Center? Types, Features, And Application

It delivers parts with tight tolerances, accurate dimensions, and production-grade materials, outperforming 3D printing in accuracy and finish.

Ideal for low-volume, reliable, cost-effective production.

- Precision and Repeatability: Achieves extremely tight tolerances (often <0.01mm) and ensures consistent results across every part in a small batch, which is vital for functional validation of form, fit, and function.

- Material Fidelity: Prototypes are made from native, solid materials (including production-grade metals and high-strength plastics), retaining the full mechanical properties and strength required for rigorous testing.

- Superior Surface Finish: Delivers a smooth, realistic surface finish that often eliminates the need for extensive post-processing, providing a close resemblance to final production parts.

- Speed from CAD-to-Part: Once the setup is programmed, CNC allows for fast iteration and quick turnaround for subsequent parts with minimal rework, making it efficient for low-volume manufacturing (tens to low hundreds).

- CNC vs. 3D Printing: While 3D printing excels at geometric complexity, CNC is generally superior for parts requiring high dimensional accuracy, strength, and a fine surface finish in standard engineering materials.

What Makes CNC Machining Ideal for Small Batch Prototypes?

CNC machining is highly effective for small-batch and low-volume prototyping due to its core benefits in quality, repeatability, and speed of iteration:

- High Precision & Repeatability: The computer-controlled, subtractive process ensures exceptional dimensional accuracy and tight tolerances across all parts, which is essential for validating form, fit, and function (e.g., in aerospace and medical devices).[Read more:What is G and M Code in CNC Machining ? ]

- Production-Grade Materials: It works with a wide range of final materials (metals, plastics, composites), producing prototypes that have the true mechanical properties and surface finish of a production part.

- Cost-Effective Iteration: CNC requires no expensive molds or fixed tooling, reducing startup costs. Design changes are implemented rapidly by simply modifying the CAD file and machine code, making it fast and economical for multiple design versions.

- Ideal for Functional Parts: Unlike some 3D printing methods, CNC parts are fully dense and exhibit minimal anisotropy, making them the preferred choice when structural integrity and reliable performance are non-negotiable.

Key Advantages of CNC Prototyping

CNC prototyping offers high precision, tight tolerances, and repeatable results for small-batch production.

It supports metals and engineering plastics, delivers superior surface finish, and enables rapid, reliable prototyping for functional testing and early production validation.

- Ultimate Precision and Repeatability: Achieves tight tolerances (often <0.01mm) with superior consistency. This is essential for functional validation of fit, form, and assembly in critical fields like aerospace and medical devices.

- Fast Iteration: Requires no fixed tooling. Once programmed, toolpaths are reused for subsequent parts, allowing rapid, low-cost adaptation to design changes and quick turnaround for multiple iterations.

- Production Material Fidelity: Supports a wide range of engineering materials (metals and high-performance plastics), ensuring prototypes have the true mechanical properties needed for reliable stress and functional testing.

- Superior Finish: Delivers excellent surface finish compared to many 3D printing methods, with extensive options for post-processing (anodizing, polishing) to meet final aesthetic and functional specifications.

Comparing CNC Machining vs 3D Printing for Prototyping

CNC machining is the ideal choice for small-batch functional prototypes where quality, precision, and material integrity are non-negotiable.

3D printing is better suited for early-stage design exploration and complex geometries.

| Feature | CNC Machining (Subtractive) | 3D Printing (Additive) |

| Precision | Highest:Achieves tight tolerances (sub-0.01mm) and superior repeatability. | Good/Variable:Tolerances can be looser; best for non-structural parts. |

| Material | Production-Grade: Works with a wide range of metals and robust engineering plastics; properties match final parts. | Polymers: Wide material range, but mechanical properties may be anisotropic (layer-dependent). |

| Cost | Economical for Batches: Higher setup cost, but lower per-part cost as volume (dozens to hundreds) increases. | Economical for Singles: Lower upfront cost for one-off parts or very small runs. |

| Finish | Excellent: Delivers smooth, near-production surface finishes with comprehensive post-processing options. | Layered: Requires post-processing to achieve smooth, functional-grade finishes. |

| Ideal Use | Functional testing, late-stage validation, and industries requiring stringent specifications (Aerospace, Medical). | Rapid ideation, concept models, and highly complex or organic geometries. |

Cost Considerations for Small Batch CNC Machining

The unit cost of CNC prototypes decreases as batch size grows, primarily by spreading fixed upfront costs over more parts.

Optimizing these factors is key to cost-effective low-volume production.

| Cost Component | Description | Cost Impact in Small Batches |

| Setup and Tooling | Fixed costs for initial process planning, programming, fixtures, and cutting tools. | High Per-Part Cost: Upfront costs are amortized over very few units. |

| Machine Time | Hourly rate multiplied by the time spent cutting, which includes cycle time and complexity. | Increases Cost: Complex geometries, tight tolerances, and intricate finishes require longer machine hours. |

| Material & Waste | Price of raw material block plus the scrap generated during the subtractive process. | Affected by Design: Complex parts with poor material utilization increase raw material consumption and waste cost. |

| Post-Processing | Costs for finishing, coating, or assembly that do not benefit from economies of scale. | Adds to Unit Cost: Separate setups for finishing steps increase charges for small lots. |

How to Choose Between CNC and Additive Prototyping?

The choice between CNC machining and 3D printing depends on your prototype’s stage, complexity, and performance needs.

| Factor | Favor CNC Machining | Favor 3D Printing |

| Goal/Stage | Functional testing, late-stage validation, and near-production performance. | Rapid iteration, concept verification, and early form/fit checks. |

| Precision | Tight Tolerances (sub-0.01mm), superior repeatability, and isotropic (uniform) strength. | Moderate Tolerances, high geometric flexibility, but potentially anisotropic strength. |

| Material | Production-Grade Metals/Plastics (e.g., aluminum, PEEK); material properties are critical. | Polymers for quick iterations; material properties are secondary to geometry. |

| Geometry | Features easily produced by subtraction (simple curves, precise holes). | Complex features, internal channels, or organic/lattice structures. |

| Volume | Small Batches (dozens to hundreds) where cost-per-part decreases due to setup amortization. | Single Parts or very low-volume early testing. |

What are the limitations of CNC machining?

CNC machining limitations include geometric constraints due to its subtractive nature, making complex internal features and sharp internal corners difficult to achieve.

It also involves high initial setup costs and significant material waste.

Furthermore, achieving very tight tolerances or smooth surface finishes often requires additional, costly post-processing steps.

1.Geometric and Design Constraints

- Subtractive Nature: Requires external access for material removal, making internal cavities, deep pockets, and complex internal channels difficult or costly. Features like undercuts often require workarounds or multi-axis strategies.

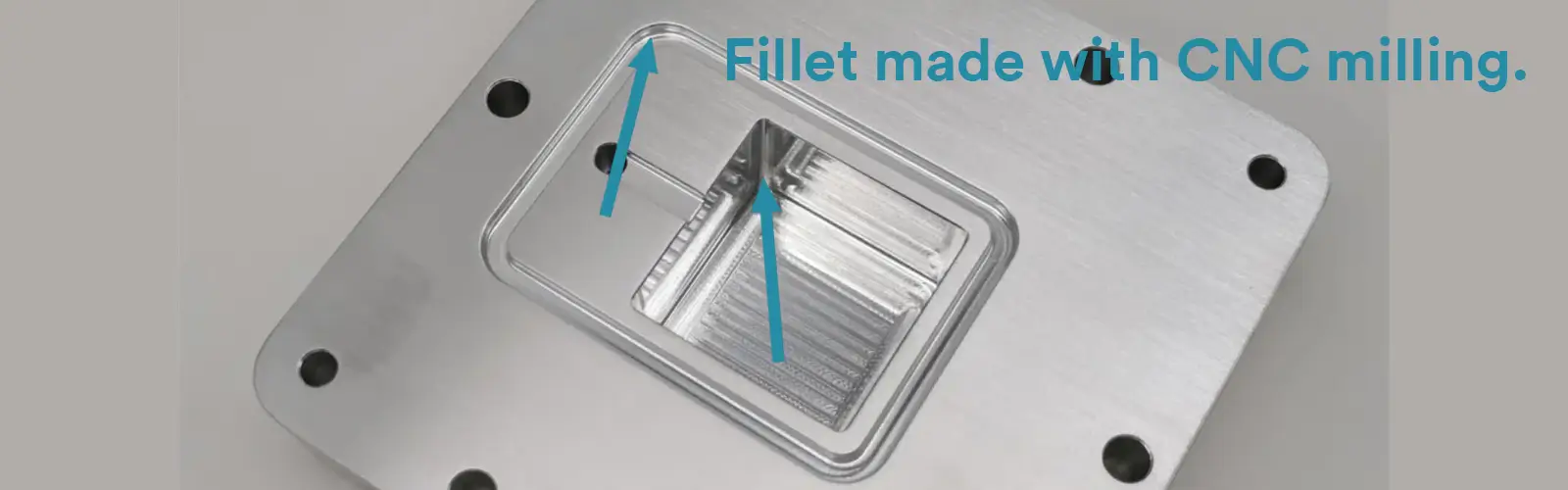

- Radiused Internal Corners: Due to tool geometry, CNC produces radiused (rounded) internal corners, making sharp interior corners impossible and constraining tolerances for mating parts.

- Limits on Depth and Slender Features: Practical constraints on cavity depth and the required thickness of long, slender features.

2.Cost and Efficiency Overhead

- Material Waste: Subtractive process inherently generates more material waste, especially for complex shapes.

- High Setup Overhead: Significant upfront time and cost for programming, fixture design, and calibration. This fixed cost makes very small runs expensive per part.

- Longer Lead Times for Complex Parts: Complex geometries or tight tolerances extend cycle times and setup changes, slowing down rapid prototyping and iteration.

3.Manufacturing and Tolerance Trade-offs

- Surface Finish and Tolerance: Achieving very smooth finishes or tight tolerances requires additional finishing steps (polishing, micro-machining), adding cost and time.

- Size Constraints: Finite machine work envelopes limit part size and may require multiple setups or segmented assemblies for large components.

Practical Takeaway: To optimize prototyping, assess which features must be CNC for performance and fit (high stress, tight tolerance), and which could be validated using additive manufacturing (complex geometry, form/fit check).

A hybrid approach often provides the best balance of speed, cost, and fidelity.

CNC Machining:The Bridge Between Concept and Production

CNC Prototyping is essential for late-stage design validation because it delivers high-precision, repeatable parts that closely mimic the final product’s material properties and surface finish.

It is best used for:

- Functional Testing: Verifying performance under realistic load and stress.

- Critical Features: Validating tight tolerances and complex assembly interfaces.

- Risk Reduction: Providing reliable, near-production parts before committing to expensive mass production tooling.

Practical Strategy: Use 3D printing for early, fast-turnaround concepts, then switch to CNC for functional, high-precision verification.

pgsql Source: Verified data from the U.S. Department of Commerce Manufacturing Extension Partnership (MEP) , ISO Technical Committee 39 (Machine tools) standards database , and official ASTM International additive and subtractive manufacturing standards.

Information aligns with certified ISO 9001 / CE-compliant CNC machining suppliers and recognized AS9100 aerospace manufacturing protocols.

Rapid Prototyping Knowledge Hub

1.Understanding CNC Rapid Prototyping

- What is CNC Rapid Prototyping? Complete Guide for 2025

- What are the Benefits of CNC for Rapid Prototyping?

- CNC Machining for Rapid Prototyping: How to Choose the Right Solution

- 3 Types of Prototyping Services for Fast and Cost-Effective Prototypes

2.CNC vs Other Prototyping Methods

- CNC Rapid Prototyping vs 3D Printing: Which to Choose in 2025?

- 3D Printing vs CNC Machining: Which Is Right for You?

- CNC Milling vs CNC Turning: Which Is Better for Prototyping?

3.Engineering & DFM Considerations

- CNC Prototype Tolerances Explained

- How to Optimize CAD Files for CNC Prototyping

- How Material Selection Affects CNC Prototype Performance

- ABS vs Aluminum: Which is Better for CNC Prototypes?

- Why Production Time Matters in Prototype CNC Parts Manufacturing?

4.From Prototype to Production

- CNC Machining for Small Batch Prototyping

- From Prototype to Production: How CNC Companies Support Scalability

5.CNC Prototyping Services in China

- CNC Prototyping Services China (Complete Buying Guide)

- Key Factors to Consider When Sourcing CNC Prototypes from China

- Top 5 Prototype Manufacturers in China

- 5 Key Benefits of Using Chinese Prototyping Services

Get Rapid Prototyping Services

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.