Table of Contents

When you’re ready to dive into the world of woodworking or crafting, one question pops up: CNC router or laser cutter? Both CNC routers and laser cutters fall under the CNC machine umbrella, but they work differently. CNC routers use a spindle and various bits, like a handheld router. They can handle a range of tasks from pocketing to 3D routing. Laser cutters, on the other hand, cut using a beam of light that vaporizes the material.

What is a CNC Router/Cutter?

When it comes to precision cutting tools for a wide range of materials, CNC routers and laser cutters are two of the most popular choices. Both tools offer unique advantages and are suitable for different applications.

A CNC (computer numerical control) router is a versatile machine used to cut, engrave, and shape a variety of materials, including wood, plastic, and metal. Unlike laser cutters, which use a focused laser beam to cut through materials, CNC routers use a rotating cutting tool to physically remove material to create a design.

This approach enables CNC routers to handle a wider range of cutting tasks, from simple engraving to complex 3D engraving. However, this versatility also brings its own set of challenges, including noise, dust, and the need for more complex setup and software.

Pros:

- Variety of Cuts: You can choose different bits for pocketing, engraving, and even 3D carving.

- Depth of Cut: CNCs can carve deeper than laser cutters, limited only by the Z-axis and bit length.

- 3D Carving Capability: Try creating complex pieces like a wooden ashtray or even a detailed 3D carving that a laser simply can’t match.

- Attachments: Options like engraving tools and even a 3D printer head expand its functionality.

Cons:

- Clamping Material: Clamping can be tricky and requires techniques like using composite nailers or vacuum tables.

- Dust and Noise: CNC routers are loud and messy; good dust collection is essential.

- Complex Software: The learning curve with CNC software can be steep for beginners.

- Limited for Thin Materials: Not the best choice for thin items like veneers.

What are Laser Cutters

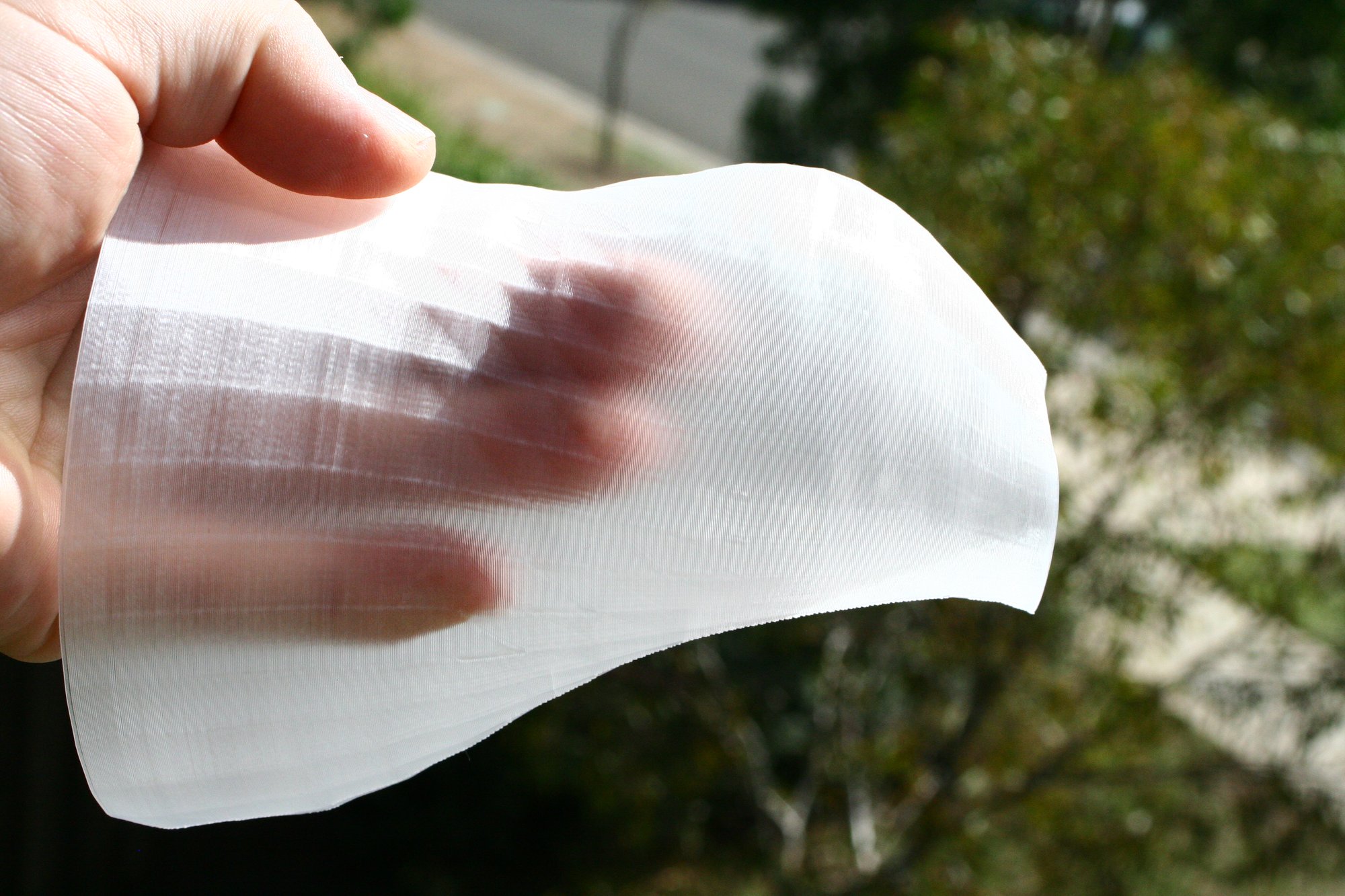

Laser cutters are precision tools that use a focused laser beam to cut, engrave, or etch various materials. Unlike CNC routers, which physically remove material using cutting bits, laser cutters vaporize the material along the cutting path, making them highly efficient and precise, particularly for thin materials.

This process, known as laser cutting, is renowned for its ability to produce clean, detailed cuts with minimal material waste, making it a preferred method in industries like manufacturing, crafting, and prototyping. Laser cutters are favored for their user-friendliness, especially when compared to more complex tools like CNC routers. But they also have limitations, particularly regarding material compatibility and thickness, which are important factors to consider when choosing the right tool for a specific application.

Read more: Difference between feed rate and cutting speed in CNC machining.

Pros:

- Simple Setup: No large clamping setups are needed; just place your material and start cutting.

- Minimal Waste: The kerf or cut width is very thin, leading to less waste.

- Quick for Thin Materials: Ideal for cutting through wood veneers, paper, and thin acrylic quickly.

- User-Friendly Software: Cloud-based systems make it easy for beginners to get started.

Cons:

- Burnt Edges: Laser cutting leaves edges that need sanding.

- Depth Limitations: Not suitable for cutting thick materials beyond 1/8 inch.

- Material Restrictions: Some materials can be toxic to cut and damage the machine.

- Tube Replacement: CO2 lasers have a lifespan, and replacing the tube can be costly and cumbersome.

The Difference Between CNC Routers & Laser Cutters

Deciding between a CNC router and a laser cutter depends on your specific needs. Consider the types of materials you want to work with and their thickness. Each has unique benefits and limitations, and many creators find that having both machines can cover a wider range of projects.

Cost

When comparing the cost of CNC routers and laser cutters, there are significant differences depending on the scale and type of machine. Entry-level CNC routers typically range from $200 to $6,000, making them accessible for hobbyists and small businesses.

Industrial-grade CNC routers, however, can be much more expensive, with prices ranging from $10,000 to $300,000. On the other hand, laser cutters generally start at a slightly lower price point, with desktop models ranging from $500 to $5,000. Industrial laser cutters can be more costly, ranging from $10,000 to $500,000, depending on the power and features of the machine. Overall, both tools can be a significant investment, but laser cutters tend to offer more affordable entry-level options.

Cutting Tool

The cutting tools used in CNC routers and laser cutters are fundamentally different, leading to distinct cutting processes and results. CNC routers use a router bit, a rotating tool that physically removes material to create cuts and carvings. This method requires direct contact with the material. In contrast, laser cutters utilize a focused laser beam to vaporize the material along the cutting path, a non-contact process that reduces wear and tear on the machine and allows for finer details in the cut.

Process Type

The process type is another key distinction between these two tools. CNC routers operate through a contact process, where the router bit directly interacts with the material to remove it. This contact can lead to increased wear on the cutting tool and the need for regular maintenance. Laser cutters, however, perform their tasks through a non-contact process. The laser beam does not physically touch the material; instead, it cuts by applying concentrated heat to vaporize the material. This non-contact nature often results in cleaner cuts and less physical stress on the machine.

Precision

In terms of precision, laser cutters have a clear advantage. They are known for their high precision, capable of creating extremely detailed and intricate cuts with minimal material waste. This makes them ideal for applications requiring fine detail, such as jewelry making, model creation, and intricate pattern cutting. CNC routers, while versatile, generally offer lower precision compared to laser cutters. The physical interaction between the router bit and the material can result in less accurate cuts, especially for very fine details.

Depth of Cut

When it comes to the depth of cut, CNC routers outperform laser cutters. CNC routers can make deep cuts, limited only by the Z-axis travel and the length of the cutting bit. This capability makes them suitable for projects requiring deep recesses or thick material processing. Conversely, laser cutters are limited in their depth of cut, typically handling materials up to about 1/8 inch (3mm) thick. This limitation restricts their use in projects that require significant material removal or deep cuts.

Cutting Speed

Cutting speed is another area where laser cutters have the upper hand. Laser cutters operate at very high speeds, especially when working with thin materials like paper, fabric, or acrylic. This makes them ideal for production environments where speed is critical. CNC routers, while powerful, generally have lower cutting speeds. The need to physically remove material with each pass of the router bit slows down the process, especially for complex or deep cuts.

3D Carving Support

One of the standout features of CNC routers is their support for 3D carving. CNC routers can create complex, multi-dimensional shapes and designs, making them ideal for detailed woodworking, sculpting, and other artistic applications. In contrast, laser cutters do not support 3D carving. They are limited to cutting and engraving in two dimensions, which restricts their use in projects that require depth and multi-dimensionality.

Noise

Noise levels differ significantly between CNC routers and laser cutters. CNC routers are known for being noisy, primarily due to the rotating router bit and the physical contact with the material. This noise can be disruptive and requires hearing protection or noise reduction measures in the workplace. Laser cutters, on the other hand, operate with low noise. The non-contact nature of the laser cutting process generates very little sound, making laser cutters a quieter and more comfortable option for indoor environments.

Support for Multiple Tools

CNC routers offer the flexibility to support multiple tools. They can be equipped with different bits for various types of cuts, engraving tools, and even 3D printer heads, significantly expanding their functionality. This versatility allows users to tackle a wide range of projects with a single machine. Laser cutters, however, do not support multiple tools. They are limited to using the laser beam for all tasks, which, while precise, restricts their versatility compared to CNC routers.

Software

Both CNC routers and laser cutters use specialized software to control their operations, but there are differences in the complexity and types of software available. CNC routers typically use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to design and generate toolpaths for cutting. Laser cutters also use CAD and CAM software, but they often come with additional software options like Lightburn or XCS, which are designed specifically for laser cutting and engraving tasks. These programs tend to be more user-friendly and accessible to beginners, making laser cutters easier to learn and use.

Final Thoughts

In the end, the choice between a CNC router and a laser cutter hinges on your goals and resources. If you’re focused on rapid prototyping with thin materials, a laser cutter might be more your speed. For detailed, complex projects requiring depth, a CNC router could be more suitable.

Remember, each machine requires an investment, not just in money, but in learning. Choose based on your creative priorities, and you’ll set yourself up for success.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.