Table of Contents

Since GD&T Symbols make huge effect on various industry fields such as engineering and manufacturing, we are all supposed to learn their definitions and functions well.

In the previous articles, we have produced GD&T Datum, GD&T Form Symbols and GD&T Orientation Symbols in detail.

And now it is GD&T Profile Symbols that would be produced, including GD&T Profile of a Line and GD&T Profile of a Surface. We will explain GD&T Profile of a Line first.

Key Takeaways:

GD&T Profile of a Line is a 2D geometric tolerance that controls the form, orientation, and location of any linear element (e.g., a cross-section) against its ideal theoretical profile.

GD&T Profile of a Line zone consists of two uniform, parallel lines (or curves) that run bilaterally along the true profile, with the total tolerance value defining the width between them.

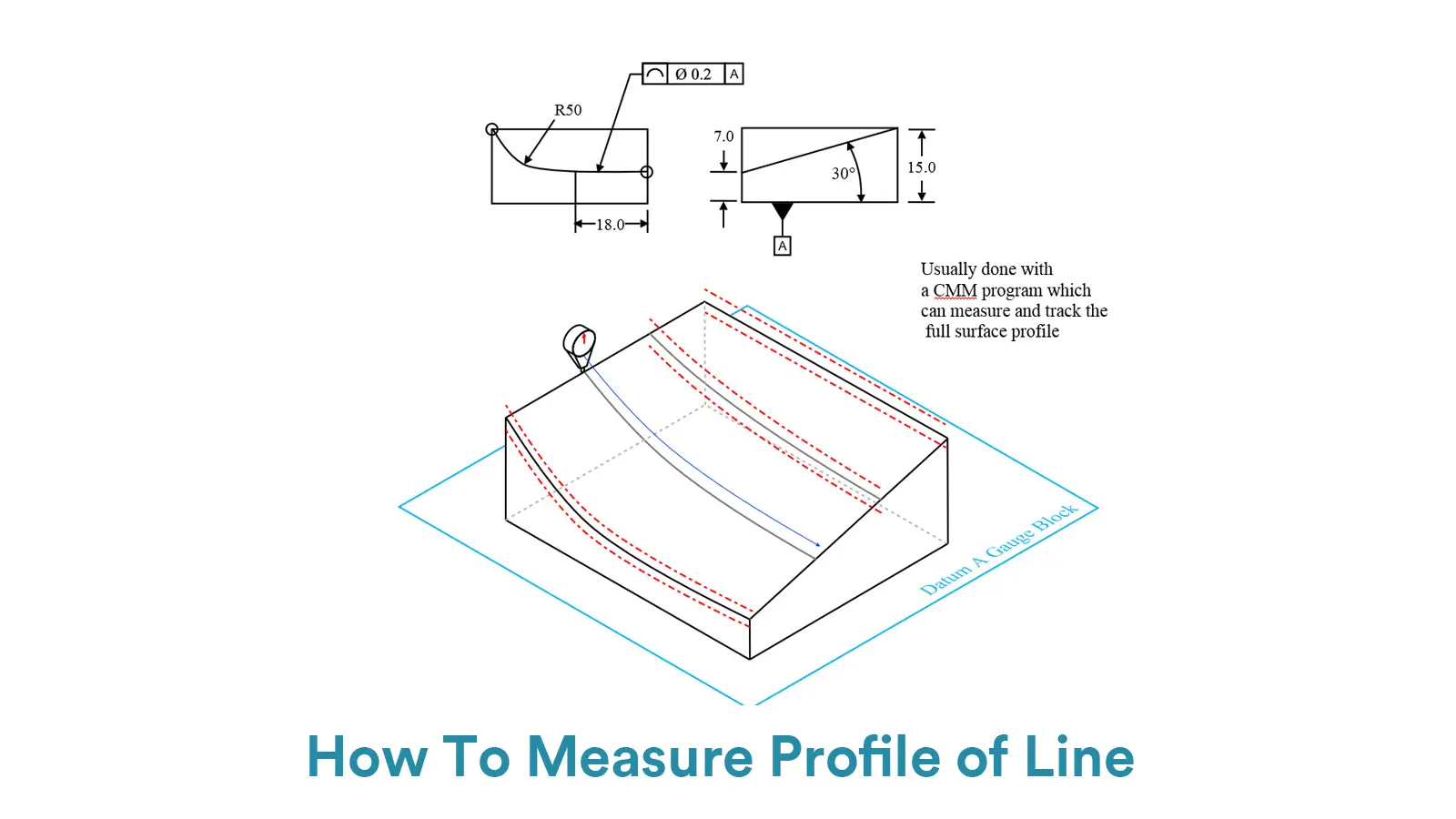

GD&T Profile of a Line can be measured using a Coordinate Measuring Machine (CMM) for high accuracy, a Profile Projector for simple 2D checks, or a Laser Scanner for flexible/large parts.

Unlike the related Profile of a Surface (which controls an entire 3D surface), it controls only individual line elements, and it can control complex curves where Straightness or Circularity cannot.

1. What is Profile of a Line in GD&T?

The foremost step to learn about GD&T profile of a line is to know what is it, including its definition and its tolerance zone. In this part, we will particularly provide comprehensive knowledge of the definition and tolerance zone of profile of a line in GD&T.

1.1 GD&T Profile of a Line Definition

GD&T profile of a line is a kind of Profile Symbols that is used to control the deviation of any actual linear element on surfaces, like straight lines, curved lines or lines on cross-section planes from their exactly ideal profile.

It is a 2D tolerance that can be applied to any linear tolerance. In short, profile of a line in GD&T functions in confining the curvature of a controlled part as remanded.

What’s more, GD&T profile of a line is a kind of synthetical tolerance that actually controls the form, orientation, location and feature of size, all of which together draw the linear profile.

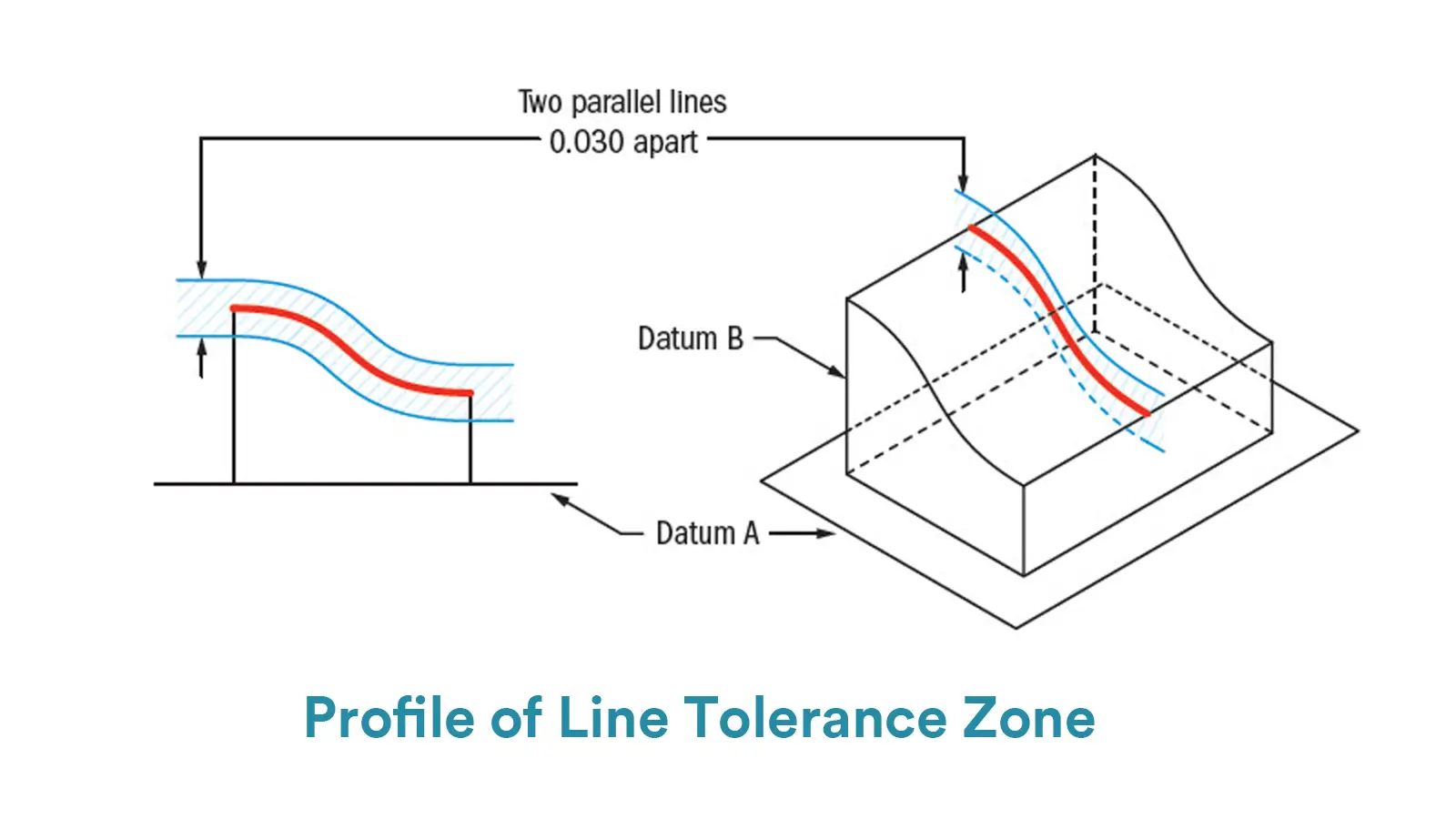

1.2 GD&T Profile of a Line Tolerance Zone

As GD&T profile of a line confines the variation of the measured linear profile from its ideally theoretical profile, its tolerance zone comprised of two parallel lines(straight or curved) that locate isometrically up or below the ideally designed linear profile ensured through the true position.

That is to say, the two lines of the tolerance zone are not only parallel to each other, but also both parallel to the true profile, and the respective distance of each point on the two lines to the true profile is the same distance.

Therefore, if the measured profile of a line on the feature want to pass, all points of the measured profile of the line should lie within these two parallel linear profiles and the tolerance value is the distance of these two lines. But note that the permissible deviation is half the tolerance value.

2. How to Show GD&T Profile of a Line?

After learning about what is profile of a line in GD&T, we then move towards to learn how to show GD&T profile of a line in engineering drawings.

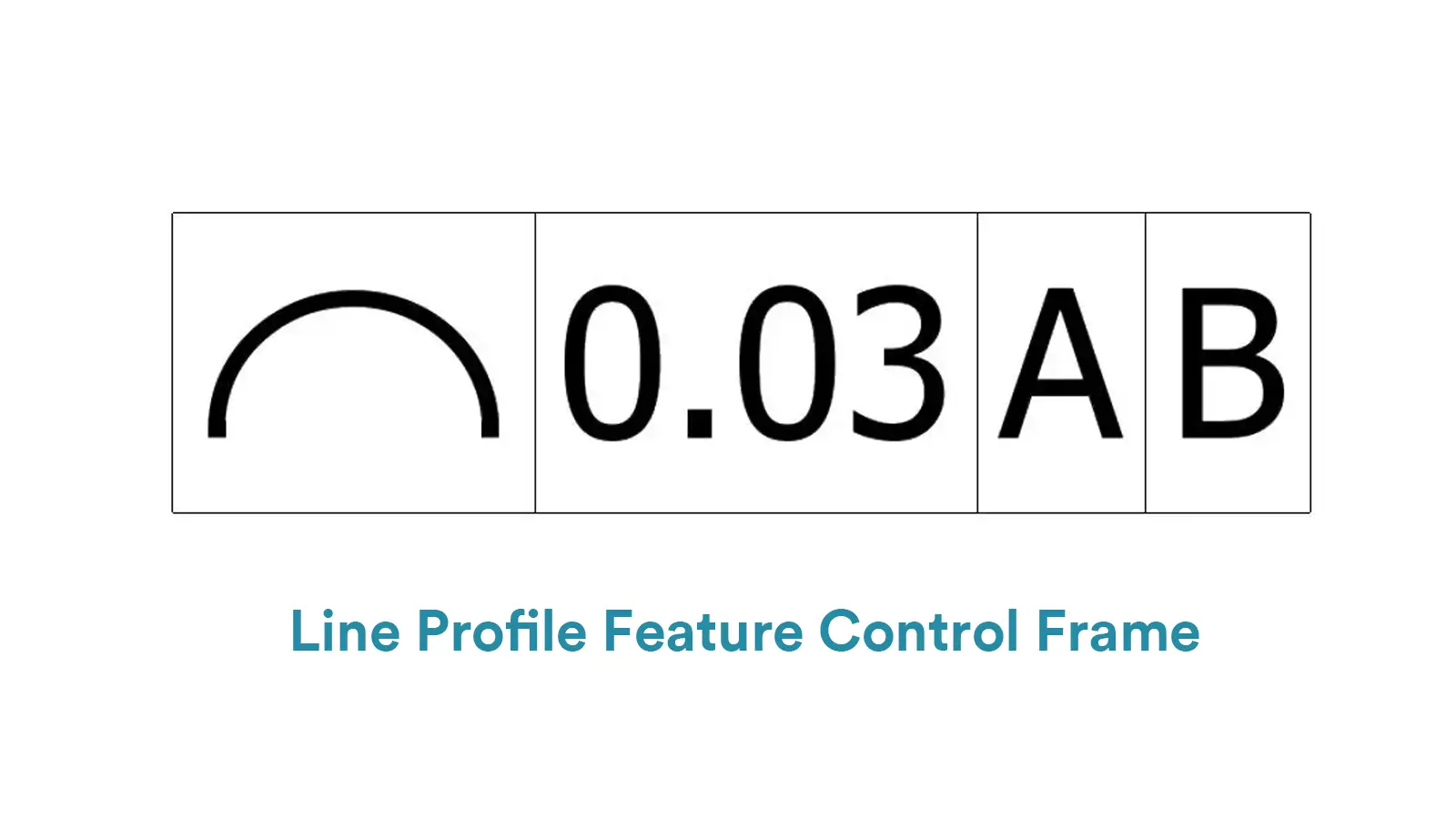

The feature control frame of profile of a line is simply composed two or three parts. The first one is the symbol of GD&T profile of a line, which is an inverted semicircle. And the second part is the tolerance value, which is the width of the tolerance zone.

The tolerance zone is a 2D zone composed with two parallel lines distributing bilaterally in relation to the true profile. The third block is the datum symbol(A, B or C) if required.

But pay attention to that GD&T profile of a line can use datums as reference or not use datums. If no datum is referred, GD&T profile of a line is simply used to paly as a form control like GD&T Straightness and GD&T Circularity.

However, if it is used with datums, GD&T profile of a line controls not only the form, but also the orientation and location by fixing the exact position of the tolerance zone with respect to the datum line profile.

And note that GD&T profile of a line is not compatible with material modifiers.

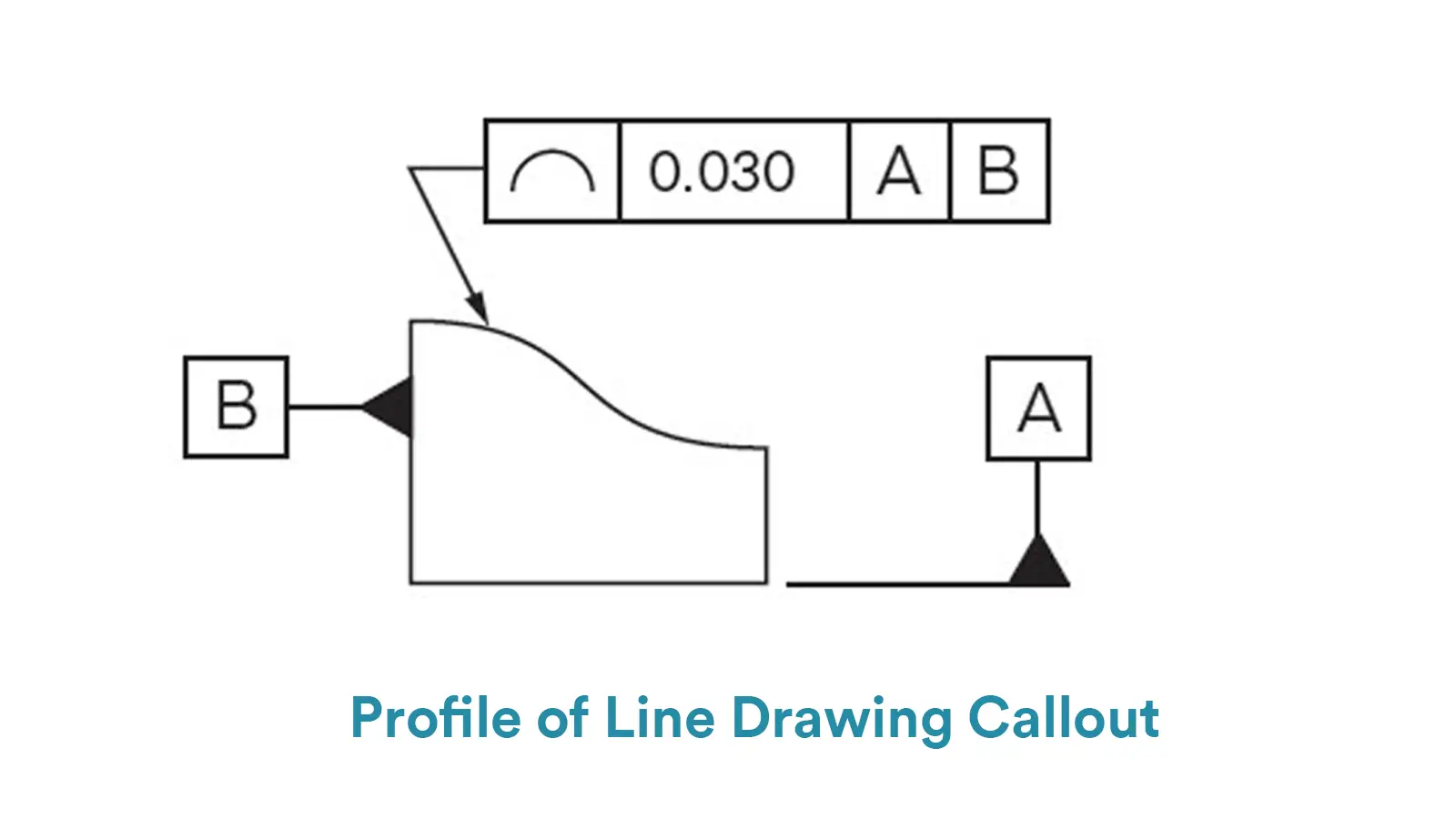

In engineering drawings, the feature control frame of GD&T profile of a line is usually connected with a leader arrow directly pointing to the edge line of the measured profile.

And if the measured profile is controlled by theoretically exact dimension, the feature control frame of GD&T profile of a line is usually connected with a leader arrow pointing to the dimension line.

More importantly, it is required that the GD&T profile of a line must be indicated in the view where the measured profile is clearly shown.

3. How to Measure GD&T Profile of a Line?

In this part, we will provide comprehensive guides of measurement procedure for GD&T profile of a line. What’s more, we will also list their respective advantages and disadvantage for your convenience to select the most proper means in measurement.

3.1 Using Coordinated Measuring Machine

We have mentioned coordinated measuring machines(CMMs) many times before. CMMs are automate machines suitable for many GD&T tolerance measurements.

For GD&T profile of a line measurement, CMMs are advantage in high accuracy and ability to generate visual deviation reports. However, they are disadvantage in high equipment cost and sensation to environment. Below is the detailed guide for GD&T profile of a line measurement by this means:

Firstly, fix the measured feature on the CMM table and establish the coordinate system.

Secondly, use the probe to densely sample points along the contour. The point spacing depends on accuracy requirements.

Thirdly, use the CMM software to compare the sampled points with the theoretical CAD contour and then calculate the profile deviation.

3.2 Using Profile Projector

Profile projector is one of the most common tools for GD&T profile of a line measurement. Their measuring procedures are simple and fast, and the measuring result is intuitive. Profile projectors are suitable for simple 2D profiles measurement with low cost and easy operation.

However, they rely on manual interpretation, which means that the measuring results would be affected easily by subjective elements. And they are only suitable for thin-walled or 2D profiles with limited accuracy. Below is the detailed guide for GD&T profile of a line measurement by this means:

Firstly, place the measured feature on the projector stage, ensuring the measured profile perpendicular to the light axis of projector, and adjust magnification to ensure proper accuracy. And then adjust the brightness and contrast of light source to ensure clear imaging of the measured contour.

Secondly, move the stage or rotate the measured feature to keep the profile clearly projected on the green, and then overlay the projected contour with the standard template for comparison.

Thirdly, calculate the deviation via software or simply analyze the deviation visually.

3.3 Using Laser Scanner

Laser scanner is suitable for flexible or fragile parts due to its non-contact measurement. Expect that, laser scanner is also suitable for large-size profiles profiting from its fast-scanning speed.

However, since laser scanner is susceptible to surface reflectivity or color, contrast spray may be required during measurement. And the equipment is expensive. Below is the detailed guide for GD&T profile of a line measurement by this means:

Firstly, align the laser scanner and fix the measured feature steadily on the plate.

Secondly, operate the laser scanner to scan along the contour to obtain the cloud data of points.

Thirdly, fit the cloud data of points to the CAD model to calculate the profile deviation.

4. Profile of a Line VS Profile of a Surface VS Straightness and Circularity

In GD&T Symbols, there may be some tolerances easily to make confusion. As for GD&T profile of a line, it is important to distinguish it from GD&T profile of a surface and GD&T straightness, as well as GD&T circularity.

Profile of a Line VS Profile of a Surface

In GD&T Symbols, the GD&T profile of a line is closely related to the GD&T profile of a surface mostly.

Same as the relationship between GD&T circularity and GD&T cylindricity, GD&T profile of a surface can also be seen as the 3D equivalent of GD&T profile of a line.

The key difference is that the GD&T profile of a line only controls a single specific cross-section or other linear features, while the GD&T profile of a surface is used to control the entire surface(usually curved) by taking the variance of adjacent cross-sections into consideration.

Therefore, the tolerance zone of the GD&T profile of a line is composed with two parallel profile lines, whereas that of the GD&T profile of a surface consists of two parallel profile planes.

In addition, pay attention to that when the GD&T profile of a line is used in conjunction with the GD&T profile of a surface, the former tolerance will commonly tighter than the later tolerance.

Since GD&T profile of a line controls smaller and more detailed feature, tighter tolerance for it makes more convenience to ensure both line and surface control.

Profile of a Line VS Straightness and Circularity

Same as the relationship between parallelism/perpendicularity and angularity, straightness and circularity can also be seen as the specific examples of profile of a line.

Since features with requirements on straightness and circularity are very commonly used in engineering and manufacturing, GD&T straightness and GD&T circularity are listed out for more accurately control.

Compared with them, GD&T profile of a line is used to control more complex curved line.

Additionally, note that the GD&T straightness and circularity are only form tolerance, which means that they do not refer to datums, whereas the GD&T profile of a line can used with datums.

5. Conclusion

Nowadays, many high-end features have accuracy requirements on their complex curved lines to ensure their key functions perform well. GD&T profile of a line plays a hugely critical role in this way.

If you still have confusion about GD&T profile of a line, please contact with us directly. And below we list other GD&T Symbols that we have produced before.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

Profile of a Line

GD&T profile of a line is to control the deviation of any actual linear element on surfaces, like straight lines, curved lines or lines on cross-section planes from their exactly ideal profile.

GD&T Symmetry

Symmetry controls that the Median Plane of a non-rotating feature must be aligned with the Datum Center Plane. It has been removed from the standard GD&T toolbox.

GD&T Concentricity

Concentricity is a position tolerance that measures the degree to which the center points of circular features (cylinders, cones, spheres) coincide relative to a shared datum axis or point.

GD&T True Position

True position GD&T is one of the position symbols in GD&T that is used to control the positional accuracy of a feature of size, such as a hole, shaft or slot, with respect to the datum coordinate system.