Table of Contents

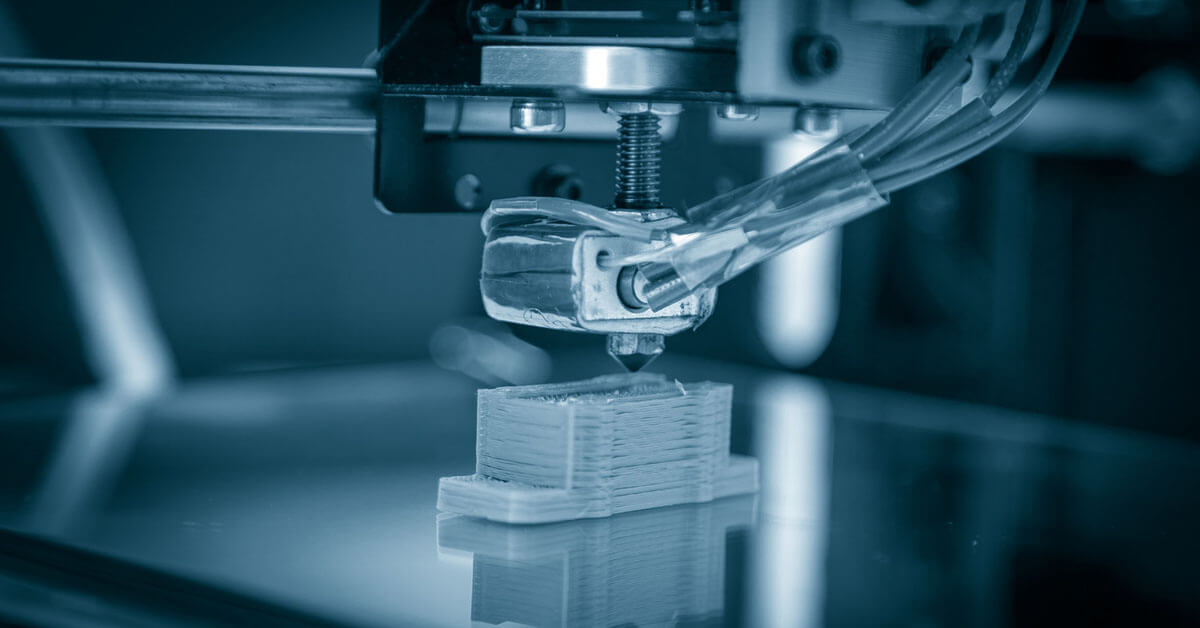

When people first see 3D printing in action, one of the most common questions is, “How long did that take to print?” The quick answer: It depends. Print time can vary based on a few key factors, and yes, you have some control over it.

- SLA 3D Printing: 5 hours

- LCD 3D Printing: 4 hours

- FDM 3D Printing: 6 hours

In this post, we’ll explore the main settings that affect 3D print time. I’ll also explain how to tweak those settings to either speed up or slow down your print without compromising too much on quality.

Scale of the Model

One of the simplest things you can change that directly influences print time is the scale of your model. Bigger prints take longer; that’s obvious. But the relationship isn’t always straightforward.

How Scale Impacts Print Time

If you double the size of your model, you might expect the print time to double. But it doesn’t stop there. When you scale your model up, you’re not just increasing its height, but also its width and depth. That means it’s scaling in three dimensions: height, width, and depth. This makes your model eight times larger, in total volume, giving you an increase in print time that’s more than double.

For example:

- At 100% scale, a small model might take 51 minutes to print.

- At 150%, the same model could take 1 hour 24 minutes.

- At 200%, you’re looking at more than double that: 2 hours and 2 minutes.

Most prints are somewhat hollow, so the increase in print time isn’t perfectly 8x, but it’s something you should keep in mind when scaling up.

Print Speed

Everyone’s first thought when they want to go faster is to turn up the print speed. While that sounds nice in theory, the reality is that higher speeds often result in messy prints. There’s a balance between speed and quality, and it’s important to know where that tradeoff makes sense for your project.

Here’s an example:

- 30mm/s (Slow): Takes 1 hour 47 minutes

- 60mm/s (Normal): Takes around 1 hour 24 minutes

- 120mm/s (Fast): Prints faster at 1 hour 18 minutes, but at the cost of lower quality.

The Role of Acceleration

It’s also worth noting that your printer’s acceleration plays a part in print time. Faster speeds don’t always result in faster prints if your model is complex. For models like figurines, which have lots of curves and details, the printer may never reach its maximum speed before it has to change direction again.

So while speed matters, don’t crank it up without expecting quality to take a hit, especially on detailed prints.

Number of Perimeters (Shells)

Perimeters, or “shells,” are the outer walls of your model. You can control how many layers the printer makes on the outside before filling in the interior. This setting can affect print time, but surprisingly, not as much as people expect.

- 1 perimeter: 1 hour 25 minutes

- 10 perimeters: 1 hour 54 minutes (only about a 30-minute difference despite increasing shells 10x)

Adding more shells doesn’t linearly increase print time because each new shell is smaller than the one before it. So, while it does affect time, it’s not a huge change unless you’re doing something extreme.

Infill Percentage

Infill is the internal structure of your print. You can set it anywhere from 0% (totally hollow) to 100% (solid). Logically, less infill should mean faster prints. But, much like perimeters, infill plays a smaller role in print time than you’d expect.

For comparison:

- 0% infill: 1 hour 23 minutes

- 15% infill: 1 hour 24 minutes

- 50% infill: 1 hour 29 minutes

The print time difference between no infill and 50% infill is only 6 minutes! That’s because the infill structure is mostly straight lines, and the printer can move faster along those straight paths.

Want to save serious time? Reducing infill isn’t the answer. You’ll likely still need some infill to support layers on the top of your print, and going from 15% to 0% infill only saved one minute in most cases.

Layer Height

Of all the settings, layer height has the most dramatic impact on print time. It’s also tied directly to print quality. The thinner each layer is, the better your print looks, but the longer it takes to print, for one simple reason: more layers.

Here’s how layer height changes the game:

- 0.3mm layer height: 45 minutes to print, but it looks rough.

- 0.15mm (default): 1 hour 24 minutes, with good quality for most projects.

- 0.1mm layer height: 2 hours 2 minutes, with smooth, high-quality prints.

While thinner layers give you finer detail and better overhangs, they dramatically increase print time. Once you drop under the 0.15mm range, time quickly ramps up without offering much extra benefit for most prints.

The key is finding a balance. Printing at 0.1mm will give beautiful results, but for casual prints or functional parts, 0.15mm is often the sweet spot between time and quality.

Related read: 3D printing tips: How to fix layer separation and avoid it?

Finding the Right Balance

You now know that scale, speed, perimeters, infill, and layer height can all affect your print time. But they don’t affect it equally. If you’re trying to save time, reducing layer height and speeding up prints may sound appealing, but you’ll need to accept some compromises in quality.

Most hobbyists settle on a good middle ground, balancing speed and quality. For example, 150% scaled, 0.15mm layers, and 15% infill is a great “default” for many projects.

3D Printing Time Calculator

A 3D Printing Time Calculator is a tool that helps estimate how long a 3D print will take. By inputting key parameters like the object’s dimensions, layer height, print speed, infill percentage, and the type of printer, the calculator provides an estimated print time. This is especially useful for planning and optimizing print jobs, allowing you to make adjustments for speed or quality based on the projected duration. Whether you’re a beginner or an experienced user, a 3D printing time calculator can save you time and help manage your printing schedule more effectively.

How Long Does 3D Printing Usually Take?

On average, printing a small and simple object might take around an hour, while more complex designs can take several hours or even days to complete. The printing time largely depends on factors like the object’s size, complexity, and the technology and capabilities of the 3D printer being used.

How Long Does It Take to 3D Print 1 Cubic Inch?

Printing one cubic inch can take anywhere from 20 minutes to over an hour. This variation is influenced by the printer’s speed, the complexity of the design, and the chosen print settings, such as layer height and infill density.

Conclusion

On average, it takes anywhere between 30 minutes and 12 hours to 3D print an object. Sometimes it can even take days, depending on the size and detail of your 3D model.

With the right knowledge, you can adjust your print settings to speed up the process or slow it down for better quality. Each of the factors discussed (scale, speed, shell, infill, and layer height) plays a key role in determining the final print time.

So the next time you start a print, think about what you’re going to use it for. Is it a quick prototype, where speed is more important than detail? Or a final piece, where quality is everything? Adjust your settings to find the ideal balance and save yourself some waiting time—without sacrificing results.

Interested in how 3D printing stacks up against other manufacturing methods? 3D printing vs. CNC machining offers an intriguing comparison, highlighting the strengths and limitations of each technique.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.