Table of Contents

Passivation and anodizing are two types of surfact treatments that are primarily used to enhance the corrosion resistance of CNC metal parts.

Passivation and anodizing are two types of surfact treatments that are primarily used to enhance the corrosion resistance of CNC metal parts.

But they are different in various aspects. It is important to know their distinctions well and choose the best one for your metal parts.

Key Takeaways:

- Passivation is a chemical treatment that removes contaminants and forms a thin, self-healing oxide layer, ideal for stainless steel.

- Anodizing is an electrochemical process that builds a thick, hard, decorative oxide coating, primarily for aluminum and titanium.

Passivation keeps the original dimensions and conductivity, while anodizing enhances hardness, wear resistance, and color options.

Choose passivation for precision corrosion protection and anodizing for durable, aesthetic, and wear-resistant finishes.

1. What is Passivation?

Passivation is a kind of chemical finishing technique that would form an extremely thin and dense oxide film on the part’s surface. Such a coating can turn the active surface to be passive, which would significantly reduce the surface’s reactivity to corrosive items.

What’s more, as a protective film, the oxidized passivation layer can effectively resist the oxygen, water, and other corrosive components to directly contact the base metal and corrode the part.

Passivation of stainless steel is the most common and typical instant. Stainless steel can inherently form a passivation film on the surface itself as long as the part is exposed to oxidized conditions.

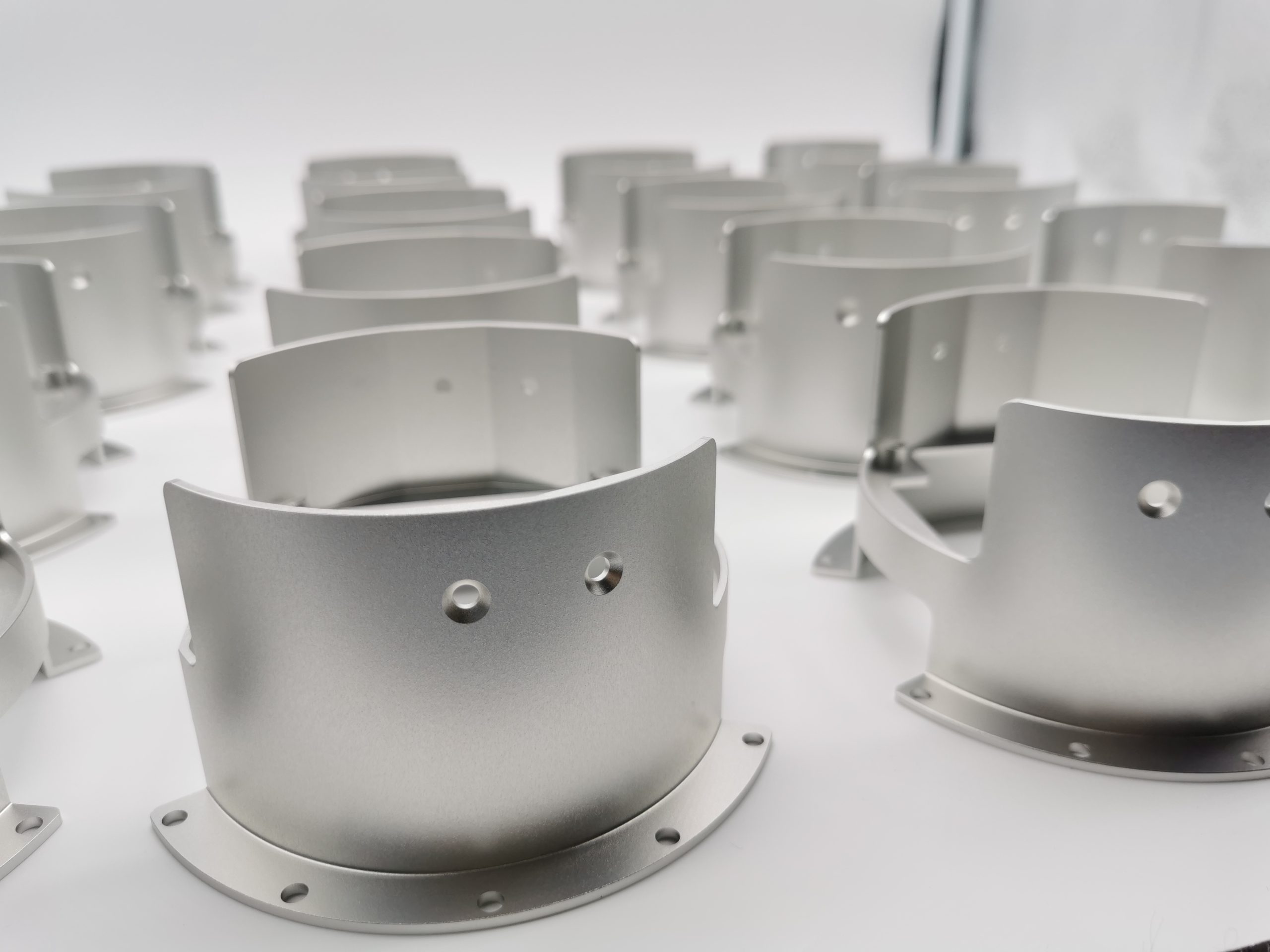

Below is a photo of stainless steel CNC part with passivation.

However, during the machining process, the surface might be damaged by the mechanical tools and be contaminated by free irons and other contaminants from the tools, which would severely cut the film’s corrosion resistance down.

Therefore, when all the machining processes have been done, it is required to passivate the part. The passivation would remove contaminants, especially free irons from the surface, making it clean and resistant to corrosion.

In addition, the passivation would centralize chromium and form a complete Cr₂O₃ film on the surface. Though the film is extremely thin, it has exceptional stability and corrosion resistance.

More importantly, this passivation layer possesses self-healing capability. When the surface is slightly damaged, the film can reform as long as sufficient oxygen is present in the environment.

In a word, passivation can effectively protect the stainless steel from corrosion while not affect the part’s dimension. Other metals for passivation include nickel, titanium, and iron.

Visit our blog for a complete guide about passivation: A Practical Guide to Passivation for CNC Machined Parts 2025

2. What is Anodizing?

Anodizing is a kind of electrochemical finishing technique that would form a hard, dense, and corrosion-resistant oxidation film on the metal surface. It is a process that would artificially rust the metal surface.

In natural conditions, aluminum would inherently form an extremely thin oxidation film on the surface to resist corrosion. But the coating is too thin and not resistant to abrasion and brushing.

Anodizing is exactly to accelerate and control such an oxidation process, by electrolyte and current, to form a much thicker oxidation film with better performance.

Anodizing of aluminum is the most typical instant. In the initial stage of anodizing, aluminum atoms lose electrons under the influence of electric current and become aluminum ions (Al³⁺) into the electrolyte.

Meanwhile, oxygen ions (O²⁻) from the electrolyte combine with aluminum ions on the anode surface to form aluminum oxide film(Al₂O₃). As the reaction proceeds, the oxide film continues to grow.

However, an unavoidable side reaction, metal dissolution, would also occur. During the anodizing process, the newly formed oxide film is not that dense.

Although it provides some electrical resistance, the acidic components in the electrolyte can still attack the metal, causing aluminum ions to continue dissolving into the solution.

Over time, as the rate of aluminum oxide formation and the rate of metal dissolution reach equilibrium, the oxide film would attain its maximum thickness under the given electrolysis conditions.

With highly stability and outstanding properties, this oxide film acts like a meticulously crafted armor on the metal surface.

For more information about anodizing types and standars, please visit our blog: Aluminum Alloy Anodizing-MIL-PRF-8625F Specifications and Standards Explained

3. What is the Process of Passivation?

3.1. Pre-process

3.1. Pre-process

Remove contaminants such as oil, welding slag, and metal debris throughalkaline cleaning or solvent degreasing.

If necessary, perform pickling by a mixed solution of hydrofluoric acid and nitric acid to remove oxide scale generated during heat treatment or welding.

3.2. Passivation

Immerse the cleaned workpiece in a passivation solution (commonly 20–50% nitric acid or a more environmentally friendly citric acid solution).

The temperature is typically between room temperature and 60°C, with treatment times ranging from 20 minutes to 2 hours.

During the process of passivation, active elements such as iron (Fe) would dissolve preferentially, while chromium would become enriched on the surfaceand form a protective oxide film.

3.3. Post-process

Thoroughly rinse the part with deionized water to prevent residual acid from causing pitting corrosion.

Dry the surface by hot air to avoid water spots.

3.4. Inspection

Copper Sulfate Test:

If free iron is present on the surface or the passivation film is incomplete,a displacement reaction will occur between the copper sulfate solution and the iron, resulting in the deposition of red-colored copper.

Note: Copper Sulfate is mainly applicable to austenitic stainless steels such as 304 and 316 but not suitable for martensitic or ferritic stainless steels, as their high iron content can lead to false indications.

Potassium Ferricyanide Test:

If there are free iron on the surface, iron ions would react with the reagent to form a blue Prussian blue precipitate.With high sensitivity, it is commonly used in applications requiring high cleanliness, such as in the pharmaceutical and semiconductor industries.

Water Break Test:

Rinse the surface with deionized water and observe whether the water film remains continuous and unbroken. A clean and well-passivated surface allowswater to spread evenly across it. If there are oil or other contaminations on the surface, the water will retract and form droplets.

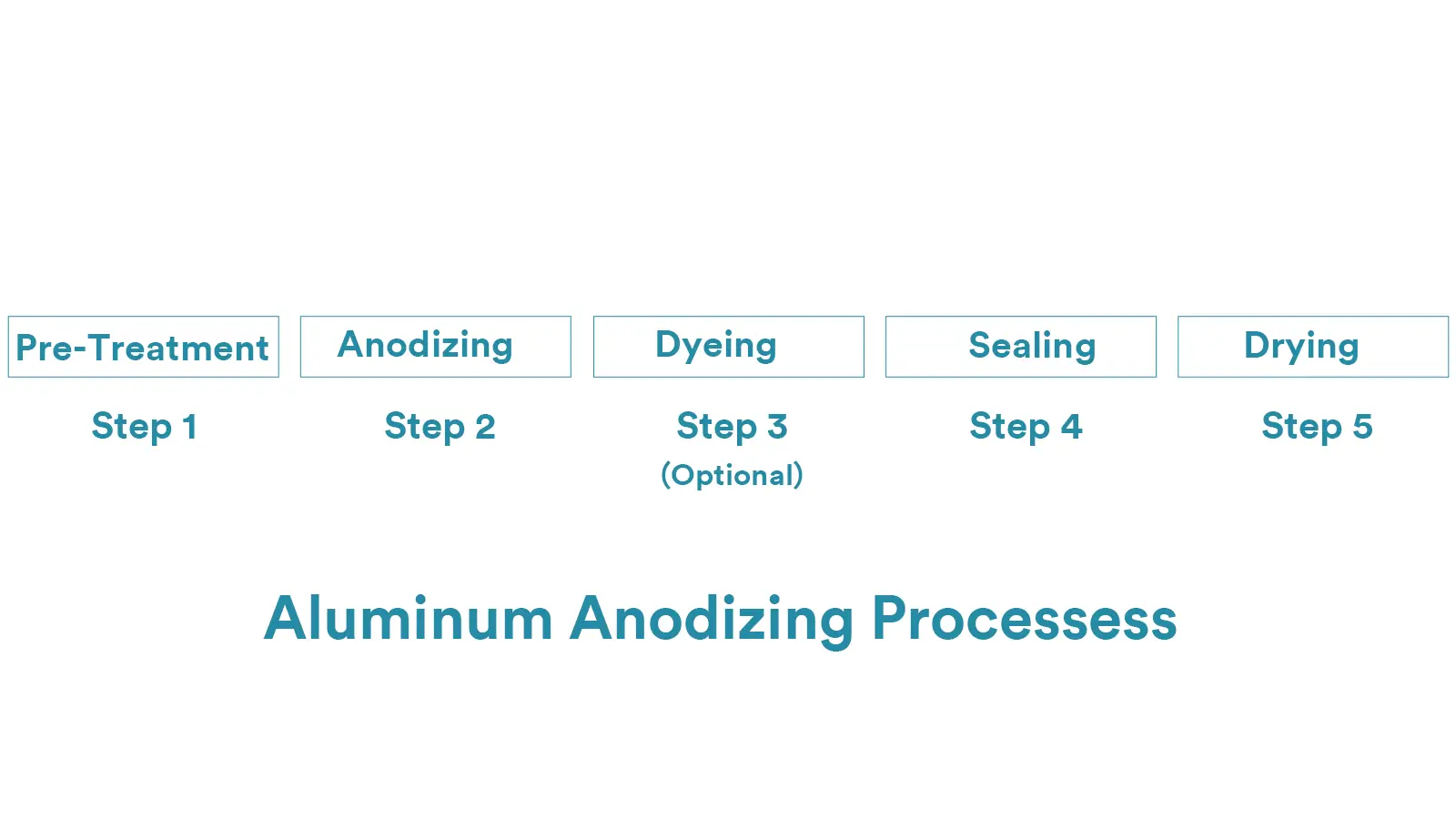

4. What is the Process of Anodizing?

4.1. Pre-process

4.1. Pre-process

- Degreasing: Remove oils and grease by an alkaline or neutral cleaner.

- Alkaline Etching: Remove the natural oxide layer and minor scratches by a NaOH solutionto achieve a matte finish.

4.2. Anodizing

- Immerse the part in a specific acid electrolyte.

- Connect the part, as the anode, and an inert materialsuch as stainless steel or lead, as the cathode, with the current power.

- Apply direct current to initiatethe anodizing process. At the anode, aluminum atoms will react with oxygen ions generated in the electrolyte to form an aluminum oxide (Al₂O₃) coating. While at the cathode, a reduction reaction would occur, typically resulting in the evolution of hydrogen gas.

- Control thevoltage 12-24V for standard anodizing and 30-100V for hard coat anodizing. Meanwhile, keep the temperature 18-22℃ for standard anodizing and less than 10℃ for hard anodizing to prevent excessive film dissolution. And the processing time is usually 20-60 minutes depending on the desired thickness.

During the anodizing process, there will form two distinct aluminum oxide layers.

- Barrier Layer: This compact and dense layer adheres tightly to the aluminum substrate. It is thin but provides strong protection.

- Porous Layer: It would form on top of the barrier layer, thick and porous, enabling subsequent coloring and sealing processes.

4.3. Coloring(Optional)

- Electrolytic Coloring: Immerse the part in a solution containing metal salts such as Sn²⁺ or Ni²⁺. By the applicationof alternating current, metal particles would be deposited at the bottom of the pores, producing colors such as bronze, black, or gold. This method offers excellent lightfastness and durability.

- Dyeing: Immerse the part in organic or inorganic dye solutions. Dye molecules would be adsorbed onto the pore walls and make the coating colorful. This process provides a wide range of vibrant colors but generally offers lower UV and light resistance.

4.4. Sealing

To close the microscopic pores of the porous oxide layer. Proper sealing can prevent the penetration of corrosive agents and improve both corrosion resistance and dye fastness.

- Hot Water Sealing: Immerse the part in deionized water at 95–100°C. The Al₂O₃ layer would hydrate to form AlO(OH), which will expand in volume and effectively blocks the pores.

- Nickel/Cobalt Slat Sealing: To enhance sealing speed and corrosion resistance, commonly used for architectural aluminum profiles.

- Cold Sealing: Seal the pores by nickel fluoride solution at room temperature. It saves energy but has a higher material cost.

- Organic Sealing: Used for specialized applications where properties such as electrical conductivity must be maintained.

4.5. Cleaning and Drying

Completely clean all the residual solutions off from the part by deionized water. Thoroughly dry the part by hot air to prevent water spots.

4.6. Inspection

Inspect the thickness, color, corrosion resistance, and abrasion resistance.

5. What are the Pros and Cons of Passivation?

Passivation is a surface treatment process that would form a dense and stable oxide film on the metal surface to reduce the chemical reactivity of metals and enhance their corrosion resistance.

Passivation is commonly applied to materials such as stainless steel, aluminum, and titanium.

The following are the main advantages and disadvantages of passivation.

5.1. Advantages of Passivation

- Enhancing Corrosion Resistance: The passive film can effectively isolate the metal substrate from external corrosive agents such as oxygen, moisture, and acids or alkalis, which significantly improves the material’s corrosion resistance, especially for easily passivated metals like stainless steel.

- Extending Service Life: By minimizing corrosion and oxidation, passivation helps extend the lifespan of components, equipment, and structural parts.

- Keeping Surface Clean: The passivation process would remove free iron, machining residues and other contaminants from the surface. This makes the surface cleaner and brighter.

- No Impact on Dimensions or Mechanical Properties: The passive film is extremely thin (typically on the nanometer scale), so it does not affect dimensional accuracy or mechanical strength, making it suitable for precision parts.

- Low Cost and Mature Technology: Passivation is a simple, well-established process with minimal equipment requirements, making it cost-effective and ideal for large-scale production. And it is significantly cheaper than electroplating or coating methods.

5.2. Disadvantages of Passivation

- Thin Film with Limited Protection: The passive film is extremely thin and offers minimal resistance to wear or abrasion. Once the film is damaged, localized corrosion like pitting wouldoccur rapidly.

- Sensitve to Certain Environments: In environments containing chloride ions such asseawater and salt spray, or strong acids and alkalis, the passive film may degrade, leading to accelerated localized corrosion.

- Not Suitable for All Metals: Only metals with inherent capability to passivate themselves, such as stainless steel, aluminum, and titanium, are suitable for passivation. Materials like carbon steel cannot achieve effective protection through conventional passivation.

- Cannot Repair Existing Corrosion: Passivation is only a preventive process. It cannot restore surfaces already affected by rust or corrosion. Any existing corrosion must be completely removed before passivation treatment.

6. What are the Pros and Cons of Anodizing?

Anodizing is an electrochemical surface treatment process primarily used for aluminum and its alloys, though it can also be applied to metals such as magnesium and titanium.

During the process, the metal would act as the anode in an electrolytic solution, and an electric current would be applied to induce the formation of a dense, porous oxide layer on the surface.

This oxide layer can then undergo sealing or coloring to enhance its performance and appearance.

The following are the main advantages and disadvantages of anodizing.

6.1. Advantages of Anodizing

- Enhancing Corrosion Resistance: With good chemical stability, the aluminum oxide film(Al₂O₃) can effectively isolate the metal substrate from corrosive media, providing excellent corrosion resistance.

- Improving Hardness and Wear Resistance: The anodic oxide layer is much harder than the aluminum substrate, typically 200–600 HV, and over 1000 HV for hard anodizing, which can greatly enhance surficial resistance to wear and scratching.

- Excellent Decorative Appearance: The porous structure of the anodic film allows for dye absorption, enabling a wide range of rich and durable colors. This makes it ideal for consumer electronics, architectural finishes, and decorative components.

- Electrical Insulation: Aluminum oxide is an excellent electrical insulator. After anodizing, the part’s electrical resistance is significantly increased, making it suitable for use in electronic housings and insulating applications.

- Strong Bond with the Part: The anodic film grows in situ from the metal surface itself, forming an integral part of the substrate. This ensures excellent adhesion and eliminates the risk of peeling.

- Ideal Base for Subsequent Coating: The porous nature of the anodic layer enhances the adhesion of paints, adhesives, and other coatings, making it an effective base for further finishing processes.

6.2. Disadvantages of Anodizing

- Limited to Specific Metals: Anodizing is mainly applicable to valve metals such as aluminum, magnesium, and titaniumthat are capable of forming stable oxides. It is not suitable for materials like steel or iron.

- High Brittleness: Although the oxide film is hard, it is also brittle. Anodized parts are easy to crack under impact or bending, unsuitable for applications involving high deformation or heavy mechanical stress.

- Slight Impact on Dimensions: The oxide layer grows both inward and outward (approximately one-third inward, two-thirds outward), resulting in a slight increase in part dimensions, typically from a few to several tens of micrometers. Dimensional allowances must be considered for precision fits.

- Loss of Electrical Conductivity: Since the oxide film is an electrical insulator, anodized surfaces would lose conductivity and are unsuitable for components requiring electrical contact.

- Uniformity of Color: The final color depends on alloy composition, film thickness, and anodizing parameters. As a result, batch-to-batch color variation may occur, requiring strict control for products with high aesthetic standards.

- Difficult to Repair Defects: Once anodized, any scratches or surface defects are difficult to repair locally, typically requiring complete reprocessing of the entire part.

7. Top 9 Differences between Passivation and Anodizing

7.1. On Process

Passivation is a type of chemical finishing process that can remove free iron and other contaminants from the surface and form a protective oxide film on it by chemical reactions within solutions. The process of passivation needs only specific solutions but does not need current.

However, anodizing is a type of electrochemical finishing process that can form a thicker and harder film than natural oxidation layer. The process of anodizing would apply direct current and immerse the metal part in electrolyte as the anode.

7.2. On Material

Passivation is primarily applied to stainless steels to remove free iron and improve the formation of chromium oxidation. It can also be used to metals such as nickel, titanium, and copper that can inherently form passive layers themselves.

However, anodizing can only be used to light metals such as aluminum, magnesium, titanium and their alloys. And anodizing is primarily used to protect aluminum and its alloys.

7.3. On Thickness

Passivated layers are extremely thin, typically at the nanometer scale and almost invisible to the naked eye.It would not change the original dimension or surface finish of the part.

Compared with passivation, anodizing would provide a certainly thicker protective film, ranging from a few to several tens of micrometers and visible to the naked eye.

In addition, hard anodizing film is usually thickest one among those anodizing types. Therefore, the dimension of the part would be changed slightly by the film.

7.4. On Hardness and Wear Resistance

Since the passivation film is extremely thin and not that hard itself, the hardness and wear resistance of passivated part would not be significantly improved.

While the hardness and abrasion resistance of anodic coating are much higher. Because the film is thicker, and the structure of aluminum oxidation provides good hardness itself.

In addition, the hard anodizing film can provide the best hardness and abrasion resistance.

7.5. On Appearance

The passivationfilm is usually transparent or colorless. It cannot be colored. Compared with the appearance of passive film, that of anodizing layer is much more various. The film of an anodizing part can be transparent or colorful. And the color can be various by dyeing.

7.6. On Function

The main function of passivation is to enhance corrosion resistance, particularly by removing contaminants from the surface of stainless steel to allow chromium to form its protective film properly.While that of anodizing is to improve corrosion resistance, wear resistance, decorative appearance, electrical insulation, and adhesion for subsequent coatings.

7.7. On Repairment

The passivation film of stainless steel possesses self-healing capability. When the surface is scratched, chromium in the alloy can oxidize over and over again in the presence of enough oxygen to form a new passive film.

However, anodic oxide film of aluminum has no self-healing ability. Once the oxide layer is damaged, the exposed aluminum substrate is prone to localized corrosion, and the oxide film cannot regenerate on its own.

7.8. On Corrosion Resistance

The corrosion resistanceof passivation is moderate, primarily for pitting or crevice corrosion. It is suitable for general atmospheric, water, and mild acid/alkali environments.

While the corrosion resistance of anodizing film is commonly better, especially when the poles are sealed properly well. It can resistant to salt spray, industrial atmospheres, and certain chemicals.

However, the corrosion resistance of passivation film might be more stable in under dynamic load or abrasion since it can repair by itself.

7.9. On Conductivity

The electrical conductivity of the base metal would not be changed by the passivationfilm while that of the anodic part would be eliminated since aluminum oxidation is not conductive.

Quick Comparison Table Of Passivation VS Anodizing

| Feature | Passivation | Anodizing |

|---|---|---|

| Process Nature | Chemical process; forms a dense oxide film on the surface | Electrochemical process; grows a thick oxide layer on the surface |

| Dimensional Change | Virtually no change in part dimensions | Significantly increases dimensions; the coating has thickness |

| Applicable Materials | Primarily stainless steel, but also copper, aluminum, etc. | Primarily aluminum and aluminum alloys, but also titanium, magnesium, etc. |

| Appearance | Maintains metal’s original color, or may darken slightly (e.g., blue passivation) | Can present various colors (black, gold, red, blue, etc.) |

| Primary Performance | Mainly: Improves corrosion resistance (rust prevention) | Mainly: Improves wear resistance, corrosion resistance, and electrical insulation |

| Coating Thickness | Very thin, typically less than 0.1 micrometers | Relatively thick, ranging from a few micrometers to several tens of micrometers |

| Electrical Conductivity | Maintains conductivity | The oxide layer is an insulator (hard anodizing offers excellent insulation) |

| Cost | Relatively low | Relatively high |

8. When to Choose Passivation for CNC Parts

In following situations, passivation shall be prioritized.

- The core requirement is rust prevention, and the operating environment is not extremely harsh.

The components require excellent rust prevention without the risk of coating contamination affecting the product or functionality.

- The original dimensions and tolerances of the part must be maintained.

The passivation layer is extremely thin and does not affect precision dimensions like thread fits or press fits. This is crucial for high-precision mechanical parts and aerospace components.

- Electrical conductivity of the metal needs to be maintained.

The metal itself remains conductive after passivation, whereas the anodized layer is insulating.

- The material being processed is primarily austenitic stainless steel (e.g., 304, 316).

Passivation is the most common and cost-effective anti-rust method for stainless steel.

- Cost-sensitive with simple functional requirements.

When your budget is limited, and the only requirement is to prevent rust during storage and use, passivation is the best choice.

9. When to Choose Anodizing for CNC Parts

Anodizing shall be choosed in the following situations.

- The core requirement is surface hardness and wear resistance.

Components that frequently slide or make contact, such as robotic arms, optical device housings, firearm components, and automotive pistons. The surface hardness of hard anodizing can reach over HV 500, close to that of quenched steel.

- Decorative appearance and durable color are needed.

Aluminum alloy casings for consumer electronics (e.g., phones, laptops), architectural aluminum profiles, outdoor equipment, water bottles. Anodizing can provide a wide range of durable color options.

- A thicker, more durable protective layer is required.

When components will be exposed to harsher environments, such as long-term outdoor exposure, marine environments, or frequent contact with sweat, the thicker anodized layer offers better protection than passivation.

- Surface electrical insulation is needed.

Mounting bases that need to prevent electrical short circuits, heat sinks (note: anodizing can affect the thermal conductivity of heat sinks, requiring comprehensive evaluation).

- The material being processed is primarily aluminum and aluminum alloys.

Anodizing is the most mainstream and effective surface treatment for aluminum materials.

10. Decision Flowchart to Choose Passivation and Anodizing

You can follow this line of thinking to make your decision:

Step 1: Identify the base material.

Stainless Steel? -> Prefer Passivation (Anodizing is less common and less effective).

Aluminum/Aluminum Alloy? -> Proceed to Step 2.

Step 2: What is your core requirement?

Requirement A: Only need rust prevention, must not change dimensions, and cost needs to be low. -> Choose Passivation (Aluminum can also be passivated, but the anti-rust effect is inferior to anodizing).

Requirement B: Need wear resistance, coloring, or a thicker protective layer, and can accept slight dimensional increase and higher cost. -> Choose Anodizing.

A Special Case: Electrical Conductivity

If your component must remain conductive while preventing rust, then regardless of whether the base material is aluminum or stainless steel, you must choose Passivation.

11. Conclusion

In summary, although both passivation and anodizing are used to protect the base metal, there are various differences between them.

The primary one is that passivation is mostly applied to stainless steel while anodizing is for aluminum. It is important to know them clearly and choose the proper one for CNC parts.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

A Practical Guide to Passivation for CNC Machined Parts

Passivation chemically creates an ultra-thin, dense, and stable oxide film, transforming the metal from an “active” to a “passive” state. This process significantly enhances corrosion resistance without altering the part’s dimensions.

Aluminum Alloy Anodizing-MIL-PRF-8625F

Aluminum anodizing is systematically classified under MIL-PRF-8625F into six distinct Types (I, IB, IC, II, IIB, III) and two Classes (1: non-dyed, 2: dyed), each with specific applications, from environmental protection (Type IC) to extreme wear resistance (Type III Hardcoat).

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.