Table of Contents

Deburring is the process of smoothing out the rough edges, or “burrs,” left behind after drilling or cutting metal. Burrs might seem like small imperfections, but they can mess up your project in several ways. For example, they can prevent metal surfaces from sitting flush together and, in some cases, even reduce joint strength.

Whether you’re working with drilled holes or the edges of metal panels, deburring is key for ensuring your parts fit correctly and, of course, that you don’t cut yourself handling sharp edges!

What is Deburring Metal?

Metal deburring is a finishing process used to remove rough edges or ridges from metal objects. These burrs are usually tiny pieces of metal formed during machining, cutting, or grinding operations. Leaving these burrs on metal parts can lead to assembly problems, create potential operational hazards, and adversely affect the aesthetics and performance of the final product.

The goal of deburring is to create smoother edges, enhance safety, and improve the overall quality of the metal part. Deburring techniques include manual methods using hand tools, mechanical processes using machines such as deburring wheels or rollers, and even advanced methods such as laser or electrochemical deburring. The choice of technique usually depends on the type of metal, the configuration of the part, and the required accuracy of the finished product.

What Causes a Burr?

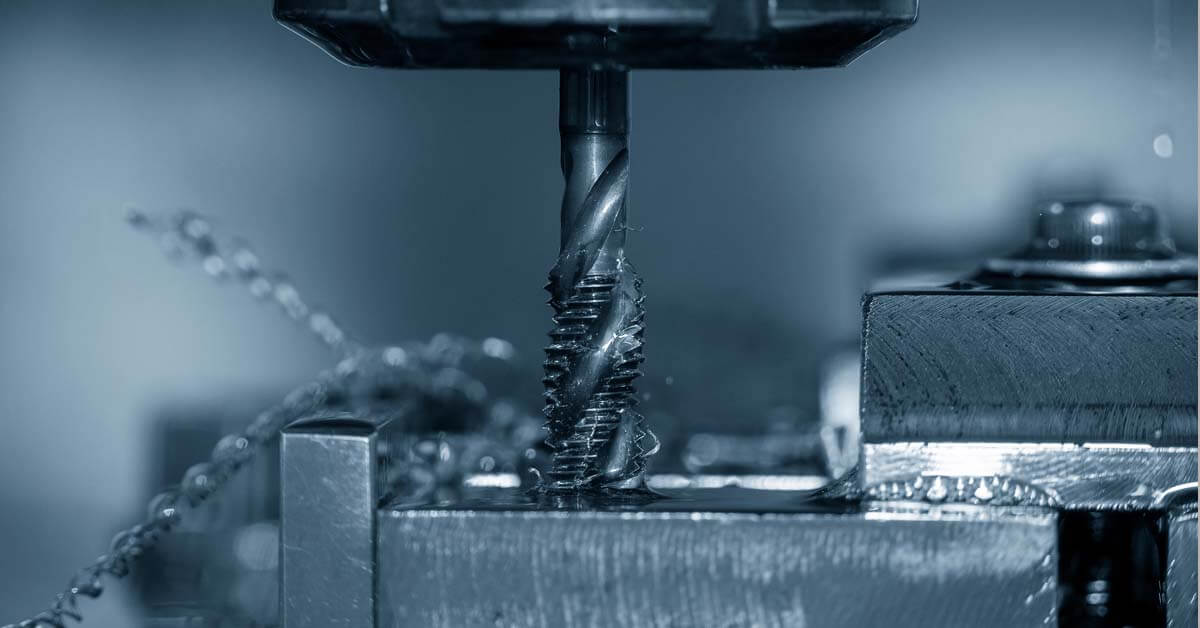

In metalworking, burrs are tiny, often sharp pieces of metal that appear along the edges of a part after machining operations such as cutting, drilling, or milling. These defects are not just by-products; they are a direct result of the mechanical forces applied to the metal during the machining process.

Why Is Deburring Necessary?

If you’re new to the world of metalworking, you might consider skipping the deburring process. However, doing so can lead to several issues that affect the functionality and safety of the final product:

Safety issues: burrs are sharp and can easily cut the skin. Simply sliding your hand along the freshly cut edge can result in painful cut marks that are dangerous to handle without proper finishing.

Fit and Finish: When assembling parts, burrs can prevent surfaces from being perfectly aligned. This misalignment can lead to bulges and uneven seams, which not only look unprofessional but can also lead to structural issues, especially with how the parts fit together.

Rivet Integrity: In structures where rivets are used, burrs can seriously affect the fit of these fasteners. Burrs may prevent the rivet from sitting flush with the material, resulting in a weaker connection. This not only compromises the structural integrity of the component but also leads to failure under stress.

In short, deburring is not just about improving the appearance of metal parts – it’s a critical step in ensuring job safety, functionality, and durability. Skipping this step can lead to a host of problems that can compromise the overall quality and safety of a project, making deburring an essential practice in any metalworking operation.

What is A Deburring Tool?

A deburring tool is a piece of equipment designed to remove burrs – small, sharp protrusions or rough edges that appear on metal, plastic, or wood after machining processes such as cutting, drilling, or milling. Deburring tools are essential in manufacturing and metalworking to ensure that parts have a clean and smooth surface and that they are handled safely and installed correctly during assembly.

Deburring tools come in a variety of shapes and sizes, each designed for a specific material or application:

Manual Deburring Tools: These hand tools typically have handles with interchangeable blades or bits for different materials and burr locations. They are often used for quick or precise deburring tasks on smaller parts.

Rotary Deburring Tools: These tools use a rotary action to deburr and are usually powered by electricity or air. They can be fitted with different tips, such as carbide burrs or wire brushes, making them suitable for a wide range of materials and complex part geometries.

Abrasive deburring tools: These include belts, brushes or wheels for bench grinders or handheld power tools. They are particularly effective on soft metals and can handle larger burrs or oxidized skin on welded joints.

Deburring Machines: For industrial applications, deburring machines automate the process, handling large quantities of parts with consistent results. These tools range from vibratory rollers that smooth rough edges through agitation to more sophisticated CNC deburring tools that can accurately deburr complex shapes.

How Do You Remove Burrs From Metal?

1. Manual Deburring

This traditional method involves skilled operators using hand tools like scrapers, files, and brushes to manually remove burrs. It offers high precision but is labor-intensive and time-consuming, making it less suitable for large-scale production. Manual deburring is best for custom jobs or when fine detailed work is necessary.

2. Machine Deburring

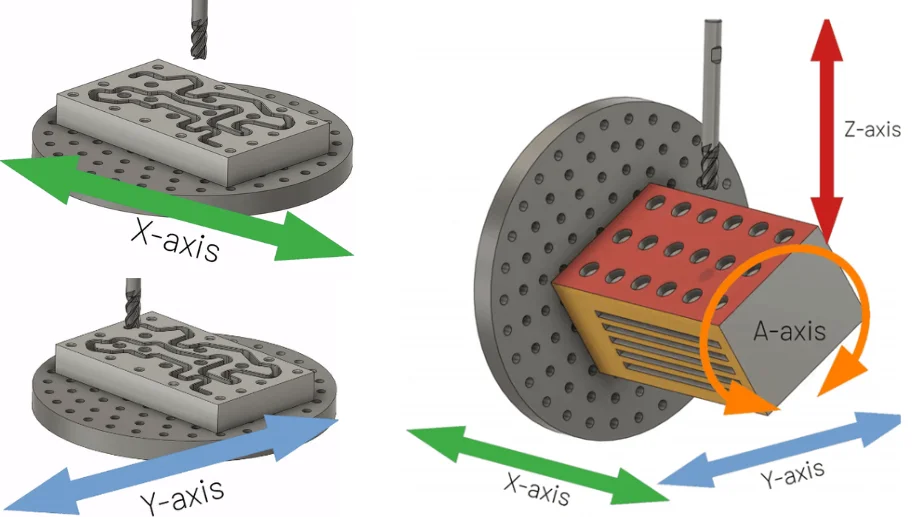

Automated deburring machines provide a consistent and efficient way to remove burrs, essential in modern manufacturing settings. These machines excel in handling large volumes but may require sophisticated programming and setup when dealing with complex part geometries or varying burr sizes.

3. Chemical and Electrochemical Deburring

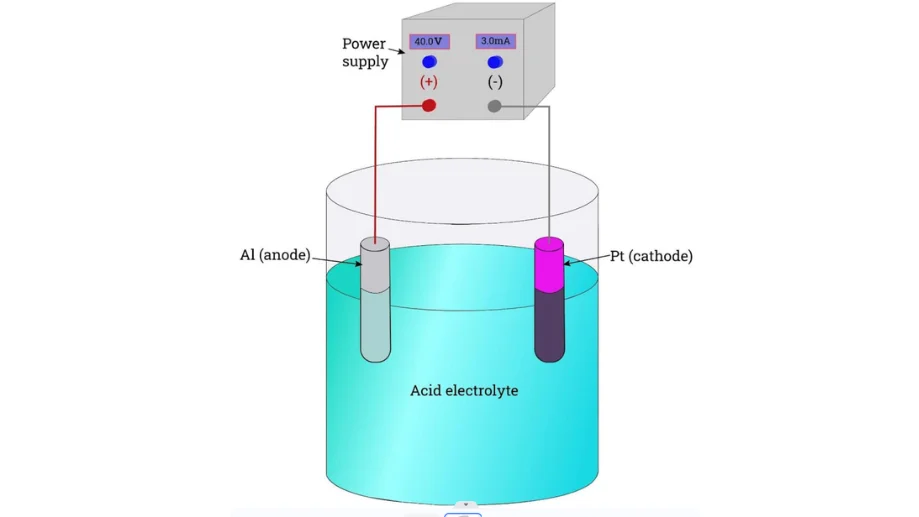

Chemical deburring uses specific chemicals to dissolve burrs, which is effective for reaching inaccessible areas. It requires careful chemical handling and disposal, adhering strictly to safety and environmental standards. Electrochemical deburring (ECM), on the other hand, is precise but comes with higher setup and maintenance costs. It’s ideal for high-precision industries like aerospace and automotive where exact edge finishing is critical.

4. Specialty Deburring Techniques

- Abrasive Deburring: Utilizes abrasive materials to mechanically remove burrs, which can cause heat and friction, potentially damaging surfaces or wearing out tools over time.

- Thermal Deburring: Effective for removing all burrs simultaneously through intense heat exposure, but it may alter the metal’s properties or shape, requiring careful quality control.

- Cryogenic Deburring: Uses extremely cold temperatures to make burrs brittle and easy to remove. While innovative, it demands specialized equipment and knowledge in handling cryogenic materials.

- Ultrasonic Deburring: Good for detailed and intricate areas but may be less effective on harder materials or thicker burrs.

- Brush Deburring: Adaptable to various shapes and sizes but might require frequent brush changes, affecting workflow and efficiency.

- Waterjet Deburring: Offers precise, non-destructive burr removal suitable for a variety of materials, though adjustments may be necessary for complex shapes.

- Each deburring method has its unique advantages and challenges. The choice of technique largely depends on the material, part geometry, and production requirements. Understanding these options helps manufacturers optimize their deburring processes, enhancing both the functionality and the quality of the finished products.

At Ecoreprap, our CNC machining services utilize state-of-the-art CNC equipment, and we ensure that each component is precision machined to avoid the formation of rough edges and corners that are common in traditional machining, cutting, or sanding operations. Our advanced machining process not only improves the aesthetics and performance of the final product, it also increases safety and reduces the need for additional finishing operations such as deburring.

Our commitment to quality means that we produce parts that are ready to be assembled without the operational risks associated with burrs. This precise manufacturing process provides our customers with a smoother production process and higher quality results.

Conclusion

Whether you’re drilling holes or cutting sheet metal edges, taking a little extra time to remove burrs means a better fitting, stronger assembly in the end. When it comes to critical constructions like airplanes, this step cannot be overlooked.

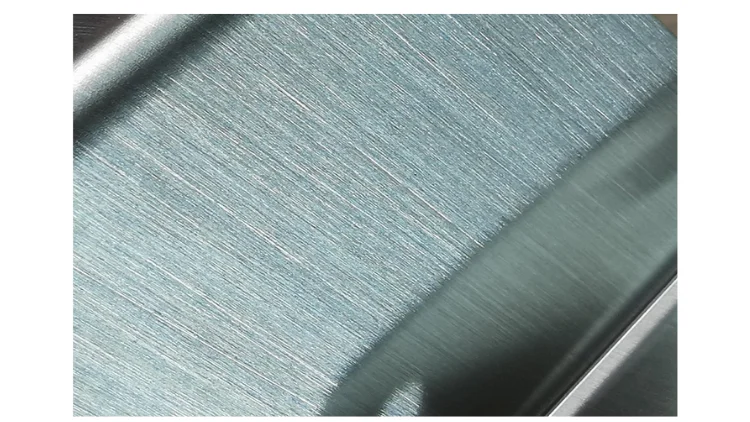

After removing burrs from all edges and holes, be sure to physically inspect them. Run your finger along all edges and surfaces. If there are any rough spots, tap them again with your favorite tool.

The goal? You should be able to slide your hand along the material without any obstacles. Perfectly deburred edges also ensure that all joining surfaces are flush, resulting in a stronger, smoother assembly.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.