Table of Contents

Zinc plating is a kind of popular surface finishing treatment for corrosion protection. By applying a layer zinc onto the surface of a metal part, zinc plating can effectively prevent metal parts from rusting and extend their service life for the physical barrier effect of the zinc layer itself and its priority over metal parts to be corroded.

This article will provide a detailed guide of zinc plating.

Key Takeaways:

- The fundamental value of zinc plating lies in its provision of sacrificial anode protection for steel/iron substrates. The zinc layer corrodes preferentially to the base metal, effectively extending the part’s service life, especially in harsh environments.

- Zinc Plating are classifed into Hot-Dip Galvanizing, Electro Zinc Plating,Mechanical Zinc Plating and Electroless Zinc Plating.

- Zinc plating have many advantages like improving corrosion resistance, enhancing durability, and improving appearance.

1. What is Zinc Plating?

Zinc plating is a kind of surface finishing method for metal part protection. It can be traced back to the 9th century B.C. and has developed as one of the most popular technologies for excellent rust-resistance and durability of metal components.

Using zinc ions suspended in electrolyte by an electrochemical technology, zinc plating can coat a thin zinc layer onto a metal part. The zinc layer provides a barrier to prevent the surfaces of metal parts from being directly exposed to moisture and oxygen, from which we know how zinc plating works.

Zinc plating mainly works on providing electrochemical and physical barrier protection for metal parts from corrosion.

- Sacrificial Anode Protection: This is a kind of electrochemical protection. As we know, metal rust is essentially a kind of electrochemical oxidation reaction where iron reacts with water and oxygen to form iron oxide, commonly known as rust.

Since zinc’s standard electrode potential (–0.76 V) is significantly lower than that of iron (–0.44 V), when the zinc coating is electrically connected to the steel substrate (e.g., after local damage to the coating), zinc would act as the sacrificial anode and be preferentially oxidized and corroded, while the steel would be protected as the cathode until the zinc layer is fully consumed.

Such a characteristic is one of the most crucial distinctions of zinc plating from other coatings such as paint. Even if the zinc coating is locally damaged, it continues to protect the underlying steel, whereas damage to a paint coating would lead to direct corrosion of the substrate.

- Physical Barrier Protection: A continuous zinc coating forms a dense barrier on the steel surface, effectively isolating the substrate from external corrosive agents such as water, oxygen, carbon dioxide, and other aggressive substances like acid rain and salts, which prevents the oxidation reaction of steel at the source.

Furthermore, zinc would gradually develop a protective film composed of zinc oxide (ZnO), zinc hydroxide (Zn(OH)₂), and zinc carbonate (ZnCO₃) when exposed to the atmosphere.

With excellent stability and density, such a film can effectively promote the barrier effect and slow down the consumption rate of the zinc layer itself.

2. Zinc Plating By Process

This part will comprehensively introduce the main methods and processes of zinc plating, including Hot-Dip Galvanizing, Electro Zinc Plating, Mechanical Zinc Plating, and Electroless Zinc Plating.

2.1. Hot-Dip Galvanizing

Hot-dip galvanizing involves immersing steel parts into molten zinc(melt approximately at 419°C), where an interfacial reaction forms a composite coating on the surface consisting of a zinc-iron alloy layer and a pure zinc layer.

2.1.1. Process Steps

Step 1: Pre-process (Key Step)

To remove oil, rust, and scale from the part’s surface for full contact between the molten zinc and the steel, which can prevent coating detachment.

* Degreasing: Clean oil stains with alkaline solutions such as sodium hydroxide solutions.

* Pickling: Remove rust and scale by hydrochloric or sulfuric acid solutions.

* Fluxing: Immerse the part in a flux, typically zinc chloride or ammonium chloride solution, to form a protective film, which can prevent re-oxidation before immersion in the zinc bath and promote zinc wetting.

Step 2: Hot-Dip Galvanizing

Immerse the pre-processed part in the molten zinc at 440-460°C for several minutes (adjusted based on the part’s thickness). Then a diffusion reaction would occur between the iron on the steel surface and the zinc, forming a Zn-Fe alloy layer topped with a pure zinc layer.

Step 3: Post-process

Get the part out the zinc bath, and then cool it by water or air cooling. Passivate the part if required, to enhance corrosion resistance and finally trim it to remove excess zinc dross.

2.1.2. Key Characteristics

* Coating Thickness: Relatively thick(typically 50-150 μm), with an extremely strong bond between the alloy layer and the part (peel strength >10 MPa), making it resistant to detachment.

* Corrosion Resistance: Excellent, with a service life of 20-50 years in outdoor atmospheric environments such as highway guardrails and transmission towers, and even longer in freshwater or mildly corrosive environments.

* Cost: Lower cost per unit area compared to electro zinc plating, suitable for large-scale and large-sized components.

* Limitations: Lower surface smoothness, appearing as a silver-gray matte finish; inability to achieve refined coatings for complex precise parts; potential deformation issues due to high-temperature treatment (temperature control is critical for thin parts).

2.2. Electro Zinc Plating

Electro zinc plating utilizes the principle of electrolysis, where steel parts act as the cathode and zinc plates serve as the anode in an electrolyte solution containing zinc ions like zinc chloride or zinc sulfate solutions.

When an electric current is applied, zinc ions are reduced to metallic zinc at the cathode (the part’s surface), forming a uniform pure zinc plating. As the entire process occurs at room temperature, it is also known as cold zinc plating.

2.2.1. Process Steps

Step 1: Pre-treatment

More meticulous than hot-dip galvanizing, it requires completely removing oil and scale from the part, and activating it with a weak acid, to ensure the surface clean and prevent pinholes or pits in the plating.

Step 2: Electrodeposition

Suspend the part in an electrolytic tank, and control the current density(typically 1-5 A/dm²), temperature(15-35°C), and time, to make zinc ions uniformly deposit on the surface and then form a pure zinc layer.

Step 3: Post-process

The key step that directly impacts corrosion resistance and appearance.

* Passivation: Immerse the part in chromate or chromium-free passivation solutions (commonly for environmental compliance) to form a colored, blue, or black passivation film on the zinc layer, which would improve corrosion resistance by 3-5 times.

* Sealing (optional): Applies a transparent sealer like organic coating to further enhance corrosion resistance and gloss.

* Drying: Remove surface moisture to prevent rusting again.

2.2.2. Key Characteristics

* Coating Thickness: Relatively thin(typically 5-20 μm), with precise control such as localized thickening or thinning and high surface smoothness. The surface can appear bright silver or colored with excellent aesthetics.

* Corrosion Resistance: The base pure zinc layer has relatively weak corrosion resistance with outdoor service life of about 1-3 years, but it would be significantly improved after passivation.

* Applicability: Suitable for precision parts(such as bolts, nuts, and electronic connectors), and complex structural components, enabling uniform plating without deformation due to room-temperature processing.

* Limitations: The coating adhesion to the substrate is weaker than that of hot-dip galvanizing (peel strength approximately 3-5 MPa), and the cost per unit area is higher(not suitable for oversized parts).

2.3. Mechanical Zinc Plating

Mechanical zinc plating, also known as cold galvanizing(noting to distinguish it from electro zinc plating), is a physical deposition process used to press and cover zinc powder onto the part surface to form zinc plating through physical mechanical actions like impact and friction, without the need for electrolysis or high temperatures.

2.3.1. Process Steps

Step 1: Pre-process

Similar to hot-dip galvanizing, it requires degreasing and pickling to remove surface impurities and activating the part surface.

Step 2: Mechanical Deposition

* Sequentially add the following materials to the barrel in strictly controlled proportions(taking 100 kg of steel parts as an example):

Part: 100 kg (must ensure no sharp edges to avoid scratching the coating during impact).

Impact Media: Glass beads (diameter 1-3 mm, hardness 6-7 HRC), used at 1.5-2 times the mass of the parts, functioning to transmit impact force and prevent direct collision deformation.

Zinc Power: Atomized zinc powder (purity ≥98.5%, particle size 5-20 μm, high specific surface area for easy deposition). The amount is calculated based on the target coating thickness (e.g., for a 20 μm coating, approximately 1.2 kg of zinc powder is required; zinc density is 7.14 g/cm³).

Additives: Binder, such as polyvinyl alcohol or carboxymethyl cellulose, to temporarily adsorb zinc powder onto the part surface; activator, such as ammonium chloride or ammonium sulfate, to adjust the system pH to 5-7 and promote zinc powder dispersion; water, with solid-liquid ratio of 1:(0.2-0.3) typically, to control system humidity and avoid over-drying (caking) or over-wetting (adhesion).

* After starting the barrel, add zinc powder in 2-3 batches to avoid uneven coating from one-time addition. The entire process lasts 30-60 minutes and can be divided into three phases:

Initial Deposition Phase (5-10 min): The barrel rotates at low speed (10-15 rpm) and the glass beads gently impact the parts. Then the zinc powder preliminarily adsorbs onto the surface with the help of the binder, forming a 5-10 μm base layer.

Rapid Deposition Phase (20-30 min): Increase the barrel speed to 20-25 rpm to enhance impact force. Zinc powder is mechanically embedded into the base layer, rapidly increasing the coating thickness to 80% of the target value. And note to stir continuously to prevent localized accumulation especially in threaded holes or grooves.

Densification Phase (5-10 min): Reduce the speed to 10-15 rpm, and add a small amount of densifier such as ultra-fine zinc or aluminum powder. Then tightly bind coating particles with gentle impact to reduce porosity(final porosity ≤5%).

* Separation and Cleaning

After galvanizing, the barrel is stopped. Then separate the parts and glass beads by screening method(The glass beads are reusable but require regular cleaning to remove residual zinc powder). Rins the parts with clean water to remove residual additives and undeposited zinc powder and prevent white spots during subsequent drying.

Step 3: Post-process

Passivate the zinc plating anddry the parts to enhance the corrosion resistance.

2.3.2. Key Characteristics

* Low-Temperature Processing with No Deformation: The entire process occurs at room temperature, eliminating the risk of high-temperature oxidation or deformation.

* Dense Zinc Layer with No Hydrogen Embrittlement: Avoid the hydrogen embrittlement issue associated with electro zinc plating(where hydrogen atoms infiltrate the steel substrate during electrolysis, causing brittleness).

Environmental Friendliness: No electroplating waste liquid generated, only a small amount of cleaning wastewater, resulting in lower treatment costs compared to electro zinc plating.

* Limitations: The adhesion of the zinc layer is slightly weaker than that of hot-dip galvanizing and electro zinc plating, with moderate corrosion resistance(outdoor service life of 5-10 years). And it is challenging to achieve uniform coating on complex-shaped parts.

2.4. Electroless Zinc Plating

Electroless zinc plating is a type of chemical conversion process which utilizes autocatalytic reduction to deposit a zinc layer on the part surface without an external power source.

2.4.1. Process Steps

Step 1: Pre-process

During the pre-process all oil, rust and other surface pollutant should be removed and the part should be activated to create deposition condition.

* Degrease to remove oil from the surface.

* Pickle to dissolve surface oxide layers. And the pickling solutions vary by substrate.

For Steel substrates: Use 10%-20% hydrochloric acid (HCl) or 8%-15% sulfuric acid (H₂SO₄) solutions at 20-50°C for 5-15 minutes and corrosion inhibitors like urotropine must be added to prevent over-etching.

Aluminum alloys: Employ dilute nitric acid (HNO₃) or phosphoric acid (H₃PO₄) solutions to avoid strong acid-induced substrate corrosion.

Copper alloys: Utilize a mixture of dilute sulfuric acid and hydrogen peroxide for gentle oxide removal.

* Activate the surface to provide catalytic center for autocatalytic reaction. And activation methods differ by substrate.

For Steel substrates: For direct zinc deposition, use weak acid activation like 0.5%-1% dilute HCl for 1-2 minutes, or pre-plate a thin nickel layer (electroless nickel) before zinc plating to improve adhesion.

For Non-conductive substrates: Firstly, sensitize the part by immersing it in stannous chloride solution to adsorb Sn²⁺ ions. And then activate the part by transferring it to palladium chloride solution, where Sn²⁺ reduces Pd²⁺ to metallic Pd(palladium), forming catalytic nuclei to initiate zinc deposition.

Step 2: Electroless Zinc Deposition

Formulate electroless zinc plating bath and immerse the pre-processed part in the bath to deposit zinc plating.

Below is the bath formulation table.

Note for bath preparation:

- Use deionized water for preparation to prevent Ca²⁺and Mg²⁺ in water from reacting with complexing agents, which could compromise bath stability.

- First dissolve the complexing agents, then add the main saltto prevent Zn²⁺ hydrolysis, and finally incorporate reducing agents and additives.

- After preparation, adjust the pH to the target range by pH regulators, and heat to the reaction temperature(typically 60-90°C). Step

Step 3: Post-process

Passivate that part.

2.4.2. Key Characteristics

* Excellent Uniformity: The zinc plating can achieve uniform coverage even on complex geometries without “edge effects.”

* No Hydrogen Embrittlement or Deformation: The process requires no electrical current, eliminating hydrogen atom infiltration. The low-temperature operation can prevent deformation, making it suitable for precision and high-strength components.

* Limitations: High cost for plating bath and the bath’s lifespan is short; the zinc layer is thin and offers inferior corrosion resistance compared to hot-dip galvanizing; maintaining stability in batch production is difficult due to stringent operational requirements.

| Zinc Plating Methods Comparison | ||||

| Comparison Dimension | Hot-Dip Galvanizing | Electro Zinc Plating | Mechanical Zinc Plating | Electroless Zinc Plating |

| Thickness | 50–150 μm | 5–30 μm | 10–50 μm | 5–20 μm |

| Process Temperature | 445–465°C | Room Temperature – 60°C | Room Temperature | 80–95°C |

| Zinc Plating Adhesion | Extremely Strong | Strong | Moderate | Strong |

| Corrosion Resistance | 20–50 Years | 3–5 Years | 5–10 Years | 3–8 Years |

| Appearance Quality | Average (Zinc Nodules Possible) | Excellent (Smooth and Uniform) | Good (Slightly Rough) | Excellent (Uniform and Fine) |

| Environmental Friendliness | Moderate | Poor | Good | Moderate |

| Unit Cost | Low (Bulk Production) | High (Precision Parts) | Medium | High (Expensive Plating Bath) |

Hot-dip galvanizing offers the best long-term corrosion resistance but with a rougher appearance, making it ideal for outdoor structures.

Electro zinc plating provides a smooth and uniform finish, preferred for CNC machined and precision parts, though with lower corrosion resistance.

These two zinc plating methods are most used.

3. Color Zinc Plating Treatment

For the CNC-machined zinc-plated parts, some customer requires blue-white zinc plating, others with yellow zinc plating, and some with black zinc plating.

It’s essential to recognize that yellow, black, and blue zinc are not distinct zinc plating processes themselves.

Instead, the variations come from the post-plating passivation or finishing treatments applied to the surface. This method is commonly known as color zinc treatment.

In the following sections, we will explain the process, types, and applications of color zinc treatment in detail, helping you choose the right finish for your CNC parts.

3.1. Yellow Zinc Plating

Yellow zinc plating is produced by immersing the galvanized parts in the chromate solution to form a chromate conversion coating. There are two kinds of processes.

Yellow zinc plating is produced by immersing the galvanized parts in the chromate solution to form a chromate conversion coating. There are two kinds of processes.

One is the traditional hexavalent chromium process, in which parts are immersed in a hexavalent chromium compound solution to form a bright yellow or golden chromate conversion film. However, due to the toxicity and environmental concerns associated with hexavalent chromium, this method is being phased out.

The other is trivalent chromium process, in which a trivalent chromium conversion coating is deposited on the zinc surface, forming an iridescent film with a yellowish hue. It is more environmentally friendly than hexavalent chromium process.

With excellent corrosion resistance, good durability, and specific aesthetics, yellow zinc plating is commonly applied to automotive, construction, and industrial applications.

3.2. Blue/Clear Zinc Plating

Blue/Clear zinc plating is commonly a light-colored transparent or bluish trivalent chromium coating formed through weak passivation reaction by immersing galvanized parts in the low-concentration and weakly oxidizing passivation solution(trivalent chromium).

Blue/Clear zinc plating is commonly a light-colored transparent or bluish trivalent chromium coating formed through weak passivation reaction by immersing galvanized parts in the low-concentration and weakly oxidizing passivation solution(trivalent chromium).

Besides fundamental properties of common zinc plating, blue/clear zinc plating also has properties of high transparency, minimal decorative interference, and environmental friendliness.

It is commonly used for parts with requirements on ultra-minimalist appearance or natural metallic finish.

3.3. Black Zinc Plating

Black zinc plating is formed through specialized black passivation or dyeing treatment over the base zinc layer. It stands out on high corrosion resistance, strong concealment, and low reflectivity.

Black zinc plating is formed through specialized black passivation or dyeing treatment over the base zinc layer. It stands out on high corrosion resistance, strong concealment, and low reflectivity.

4. What Are the Applications of Different Zinc Plating Methods?

This part will introduce the applications of zinc plating induced by different processes.

4.1. For Hot-Dip Galvanizing

•Large Steel Structures: Bridges, transmission towers, street light poles, highway guardrails, industrial plant steel frames.

•Basic Components: Bolts, nuts, scaffold couplers, oil and gas pipelines.

•Outdoor Durability Components: Agricultural machinery parts, shipping containers, wastewater treatment equipment.

4.2. For Electro Zinc Plating

•Precision Mechanical Parts: Gears, bearings, fasteners (small-sized bolts).

•Electronic and Electrical Products: PCB brackets, connectors, household appliance housings.

•Automotive Components: Body panels, door handles, small chassis parts.

4.3. For Mechanical Zinc Plating

•High-Strength Fasteners: Wind turbine bolts, automotive high-strength bolts.

•Springs and Elastic Components: Valve springs, damping springs.

•Heat-Sensitive Parts: Thin-walled stainless steel tubes, precision castings.

4.4. For Electroless Zinc Plating

•Precision Complex Parts: Aerospace components like engine blade cooling channels, medical devices like surgical instrument grooves.

•Pre-plating Conductive Base for Non-conductive Substrates: Zinc plating on non-conductive materials such as plastics and ceramics.

•Electronic Components: Miniature connectors, zinc plating on inner walls of PCB vias.

5. What Are the Advantages of Zinc Plating?

5.1. Zinc Plating Can Improve Corrosion Resistance

Zinc plating creates a barrier to effectively protect the metal parts from corrosion. Therefore, zinc plating can increase the service life of steel, iron, and other materials.

5.2. Zinc Plating Can Enhance Durability

Zinc plating can protect the metal parts from friction, scratching, and many other environmental factors, making the base parts more durable in challenging conditions.

5.3. Zinc Plating Can Improve Appearance

Zinc plating can cover the original surface defects of parts and provide a clean and polished look. In addition, the plating can vary from bright to matte with specific color, which helps to improve appearanceof parts.

5.4. Zinc Plating Has Good Electrical Conductivity

Electro zinc plating’s excellent electrical conductivity makes it suitablefor electronic components, providing corrosion protection without compromising current transmission.

6. What are the Limitations of Zinc Plating?

Limited Protection in Extreme Environments: The protectional effect of zinc plating might not be good as that of thicker coatings or specialized materials in extreme harsh environments like high salinity and extreme industrial exposure.

Hydrogen Embrittlement: It is easy to cease hydrogen embrittlement during zinc plating for high-strength steel, which would make the metal brittle and less load-bearing.

Reduced Effectiveness in Marine Environments: It is difficult for zinc plating to hold up effectively in the high moisture and salt content environment of marine.

7. Suitable Materials For Zinc Plating

Zinc plating essentially uses electrochemical or hot-dip reactions to coat a zinc layer onto a substrate, forming a corrosion-resistant protective layer. Its primary purpose is rust prevention, mainly based on the cathodic protection principle, where the zinc layer acts as a sacrificial anode. As a result, zinc plating is mainly applied to steel materials. The zinc layer corrodes first, protecting the underlying iron substrate.

7.1. Materials Suitable for Zinc Plating

7.1.1. Low and Medium Carbon Steel

These are the most commonly used and typical zinc-platable materials, such as Q235, 1018, 1020, and various grades of cold-rolled or hot-rolled steel. They are widely applied in structural parts, fasteners, and enclosures.

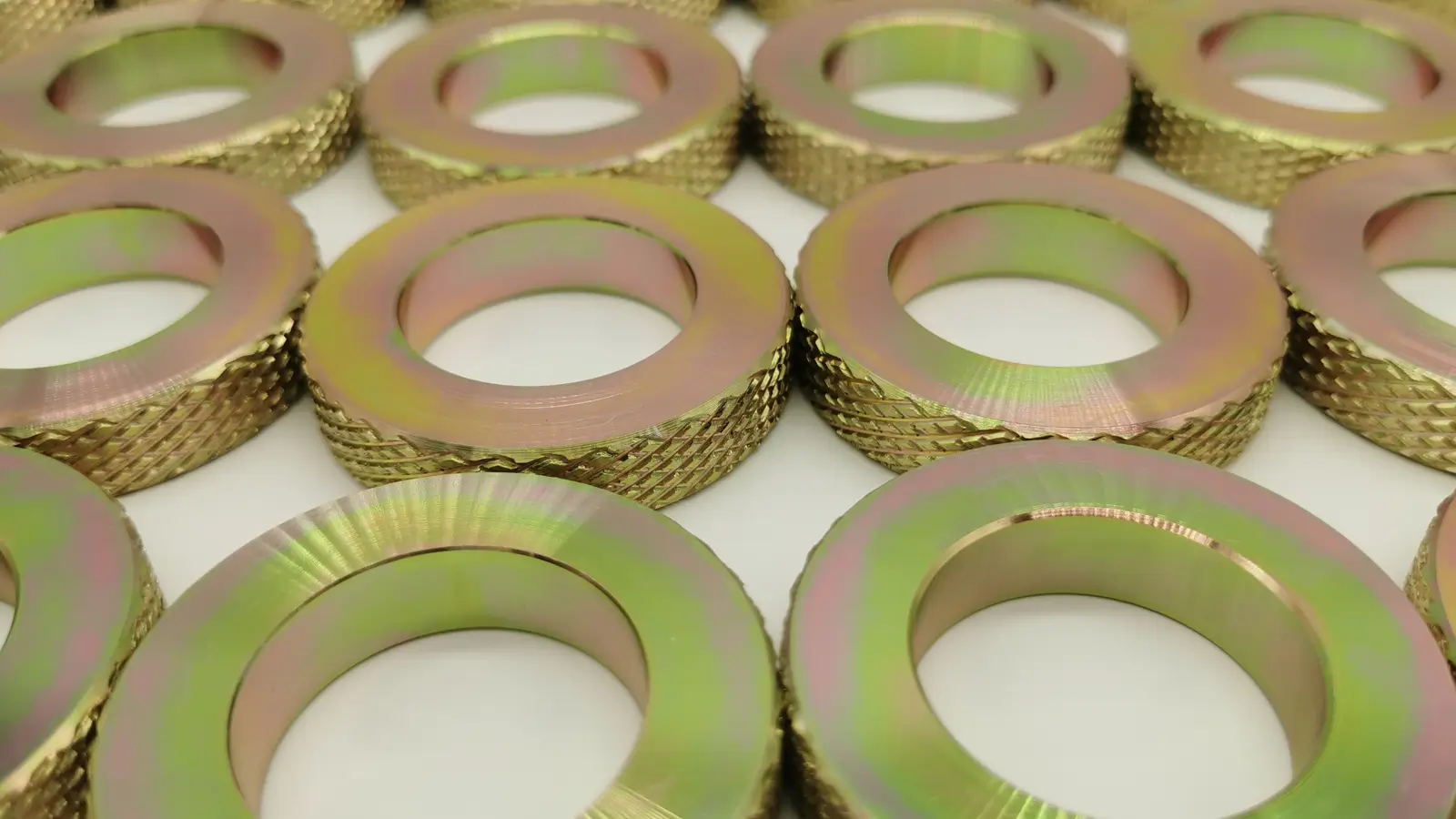

Below is Q235 low-carbon steel with yellow Zinc plating photo.

7.1.2. Cast Iron

Ductile iron and gray cast iron can also be zinc-plated. However, their surfaces are often porous and may contain impurities, requiring more thorough cleaning and pickling in pre-treatment. The plated layer may not be as smooth or shiny as on steel.

7.1.3. Alloy Steel

Many alloy steels can be zinc-plated. Special attention is needed for high-strength steel (typically tensile strength > 1000 MPa or hardness > HRC 32), which is highly susceptible to hydrogen embrittlement during pickling and electroplating. These parts must undergo post-plating hydrogen relief baking (e.g., around 200°C for several hours), or they may experience sudden brittle fracture under stress, which is extremely dangerous.

7.2. Materials Unsuitable for Zinc Plating

7.2.1. Stainless Steel

Stainless steel naturally resists corrosion through its passive film, which is far superior to a zinc layer. Zinc plating is unnecessary, and adhesion is very poor. To alter appearance or enhance performance, stainless steel usually undergoes passivation, other metal plating (chrome, nickel), or PVD coatings.

7.2.2. Aluminum and Aluminum Alloys

Aluminum surfaces form a dense oxide layer that prevents proper adhesion of zinc. Protective treatments usually include anodizing, chemical oxidation, zinc-nickel plating, or coating. While there is a “hot-dip zinc” process for aluminum, it serves as a special pre-treatment before plating other metals, not traditional corrosion-protective zinc plating.

7.2.3. Copper and Copper Alloys

Copper is naturally corrosion-resistant (develops a patina) and has a more positive potential than zinc, so it cannot achieve sacrificial anode protection. Decorative or protective finishes usually involve nickel, chrome, silver, or gold plating.

7.2.4. Non-Metallic Materials

Materials such as plastics or wood are generally unsuitable. Some plastics like ABS can undergo special activation for electroplating (commonly copper, nickel, or chrome), but this is not considered zinc plating.

8. Key Considerations for CNC Machined Parts Before Zinc Plating

Before zinc plating CNC machined parts, it is essential to ensure proper surface preparation and dimensional control. CNC parts must be thoroughly cleaned from oils, cutting fluids, and burrs, as surface defects like scratches will remain visible after plating.

Below is a low carbon steel parts without good polish before zinc plating. The tool marks are visiable after zinc plating.

Zinc coating adds thickness (typically 5–25 μm), so engineers should leave plating allowance in precision dimensions, especially for threads.

For high-strength steels, post-plating hydrogen relief treatment is necessary to avoid brittle failure. In addition, complex geometries may require vent holes to achieve uniform coating.

By addressing these factors during CNC machining, manufacturers can achieve high-quality, durable zinc-plated components.

9. Conclusion

All in all, since zinc plating has excellent corrosion resistance and good durability, it is a considerable method for corrosion protection.

Shall you have any CNC parts with zinc-plated surface treatment, please contact us.

10. FAQ

10.1. How long does zinc plating last?

30 years under optimal conditions but would vary due to environmental conditions. The service life would be shorter in outdoor and humid settings and longer in converse conditions.

10.2. How much zinc plating thickness should be?

It is usually 5 to 25 microns for different level of corrosion protection requirements.

10.3. Is zinc plating conductive?

Yes, zinc plating is conductive. And the conductivity depends on the purity, thickness, integrity, and surface condition of the zinc plating.

10.4. What are the main certifications for zinc plating?

ASTM B633 and ISO 2081 are two of the most popularly executive standards.

10.5. What is the differerance between galvanizing and zinc plating?

Zinc coating, or “zinc plating,” is a broad category of surface treatments that protect metal parts from corrosion.

Within this category, Galvanizing typically refers to Hot-Dip Galvanizing, where parts are immersed in molten zinc to form a robust protective layer.

Traditionally, this process involves immersing steel parts in molten zinc to form a relatively thick zinc layer (50–150 μm). It provides excellent corrosion resistance, making it ideal for outdoor and heavy-duty anti-corrosion applications.

Zinc Plating usually means Electro Zinc Plating, where zinc is deposited onto the surface via an electrochemical process with a thinner zinc layer (5–30 μm). It offers a smooth, bright finish and is suitable for precision parts, such as CNC-machined components.

Both methods belong to the zinc coating family, but they differ in process, coating thickness, and corrosion resistance.

Other techniques, such as Mechanical Zinc Plating and Electroless Zinc Plating, also fall under the broader zinc coating category.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

What is Nickel Plating?

Nickel plating is a finishing process that coats a thin layer of nickel onto a part using electroplating or chemical methods, improving a part’s corrosion resistance, wear resistance, and appearance.

Zinc Plating VS Nickel Plating

Both zinc plating and nickel plating are popular finishing method for metals. They can significantly improve corrosion resistance, abrasion performance, appearance, and certain functions of substrates.

What is Black Oxide Coating?

Black oxide, also known as Black Oxide or Blackening, is a surface finishing process that forms a dense black oxide coating on the surface of metals through a chemical reaction.

Phosphating Coating Guide

Phosphate conversion coating, also known as phosphating, is a surface treatment process that forms an insoluble phosphate protective film on the metal surface through a chemical conversion reaction.