Table of Contents

If you are curious about shaping complex components from rough workpieces, you should discover more about CNC machining machines.

CNC turning centers are advanced and widespread tools. However, easily accessible information about their particularities and distinctive features is usually incomplete and mixed up with similar machinery called CNC milling centers. It results in difficulty in choosing an appropriate one for a particular manufacturer’s needs, CNC turning machine.

Below is the complete guide for CNC turning machines, in this post, you will get answers to all common topic-related questions.

What Is a CNC Turning Machine?

CNC is short for computer numerical control. Simultaneously, CNC turning is a subtractive machining process when a cutting tool is placed against a spinning piece to remove material.

Thus, a CNC turning machine or a milling center can be defined as a computer-controlled piece of machinery used to remove material parts from a spinning workpiece with high precision.

Such machines are used for commercial and industrial production of components from prepared materials, listed below.

Readers are often confused when a lathe is called a turning machine and vice versa. There is no formal distinction, but a CNC lathe is usually referred to as a more primitive turning machine. Such tools can perform turning operations with only X and Z axes. Simultaneously, a CNC turning machine or center can have milling, drilling, and sub-spindle capabilities integrated and include a Y-axis.

CNC turning machines can be used to produce machine parts that are symmetrical from an axial perspective. Depending on a particular component’s unique curvatures, a combination of drilling, tapping, slots, recesses, and other elements may be required.

CNC turning machines are prevalent for the high-volume production of symmetrical and relatively simple components from various materials.

Available Materials CNC Turning Machines Work

- Metals. Including aluminum 6061, aluminum 7075, brass, magnesium AZ31, stainless steel 404, stainless steel 304, stainless steel 316, carbon steel 1045, titanium, alloy steel, and others). Check all the metal materials ECOREPRAP turning services provide.

- Plastic. Including ABS, Acetal, Noryl, Nylon 6, PAI, PBT, PEEK, Polycarbonate, Polyethylene, PPS, Ultem, PVDF, and others). Check all the plastic machining we offer here.

- Wood. Including softwood, hardwood, and plywood.

- Foam. Including polyethylene, polyurethane, cross-linked polyethylene, and specialty foams.

- Composites. Ceramic matrix composite, metal matrix composite, reinforced concrete, glass fiber reinforced concrete, and others.

The choice of materials for a particular CNC turning machine or vice versa significantly depends on a specific manufacturer’s needs. The crucial point is that materials can withstand the machining process (i.e., have sufficient hardness, tensile strength, and chemical and temperature resistance).

How Does a CNC Turning Machine Work?

The operation process of the CNC turning center can be divided into 4 parts. They are designing the CAD model, converting the CAD file to a CNC program or pre-programming, preparing a CNC machine, and executing the machining operation, i.e., material cutting itself.

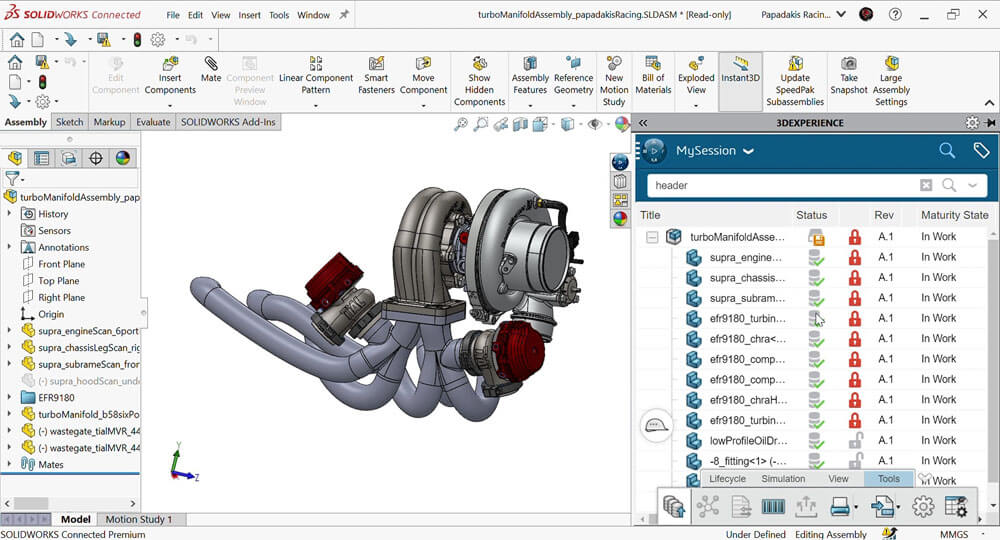

Designing the CAD Model

The acronym CAD implies Computer-Aided Design. It is intended to create a 2D vector or 3D solid part design of an object enabling a CNC machine to produce a model with the necessary technical specifications.

CAD software automatically performs complex geometrical calculations while creating a realistic model, as shown in the image below.

CAD modeling assists in creating a virtual reality object that has the same properties as a physical object. Some of the properties that can be considered include material, weight, size, optical and psychical ones, and others.

After a CAD design is complete, it should be exported to a CNC-compatible file format, for example, STEP and IGES.

Then, it is necessary to convert a CAD file into an actual CNC program; a CNC turning machine works by which.

Pre-Programming

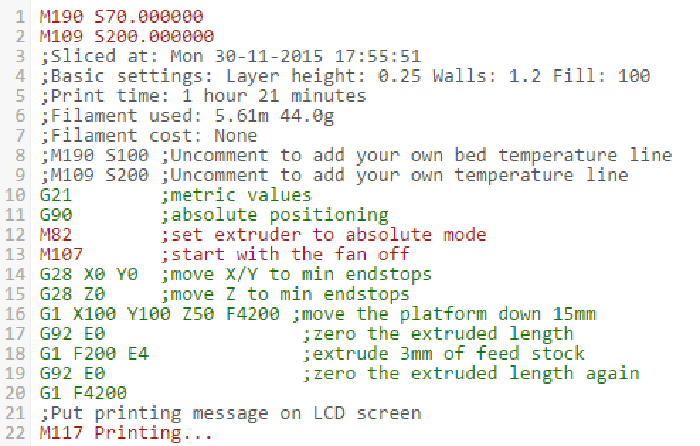

In CNC turning, pre-programmed CAD software installed on a computer connected to a CNC turning center dictates the movement of the machine’s axis. To be executed, instructions to the turning machine must be coded using means of G-code and M-code programming.

Numerous software solutions enable the transfer of a CAD file into a CNC file, including CAD programs with this option. The basics is that all of them use a programming language known as G and M code programming. It enables activating a CNC machine’s programmable logic controller and executes the intended function.

An example of a CNC program that has an integrated CAD file is shown in the image below.

G-code

This software programming language is used to control a CNC machine directly. Its function is to command a CNC turning machine to change the geometric coordination of its tools’ axes.

G-code is a set of instructions and looks like a letter “G” followed by a number. For instance, “G00” means a rapid, non-cutting move. Another part of the G-code is commanding a center to change the geometric coordinates. It looks like the name of an axis, for instance, “X” followed by a number meaning a distance, for instance, “-80”. Such instruction to a CNC turning machine implies moving -80 mm on the X-axis.

M-code

M-code is a complementary part of G-code and is responsible for non-geometry machine functions. Examples are spindle rotation start and stop, pallet change, flood coolant on and off, and others.

All the existing commands to a CNC turning machine can be coded using the described programming language, as shown in the image below.

A CNC turning center must have a well-coded program to construct a component that is exactly the same as the previously designed 3D CAD object.

Preparation of a CNC Turning Machine

In CNC milling, the preparation of a piece of machinery that executes the function can be roughly divided into two stages. These parts are adjustment of settings and choosing and attaching the required tooling.

Adjustment of Settings

The properties of a material selected are used to determine the setting of the mode they are to be machined at. It is explained with the possibility for a material to be cracked, chipped, partially melted, or deteriorated in any other way if settings are not appropriate.

The following CNC turning machine settings should be adjusted for every distinct material.

- Cutting speed. This parameter refers to how a CNC turning center’s tooling removes material from a workpiece. It is measured in surface feet per minute (SFPM or SFM).

- Cutting feed rate. In other words, it is how fast the workpiece is fed toward the machine tool. It is measured in inches per minute (IPM).

- Depth of cut. It implies how deep a CNC turning center’s tooling cuts into the workpiece. It is also measured in inches per minute (IPM).

Along with adjusting settings, adjustment of cutting tools should also be implemented.

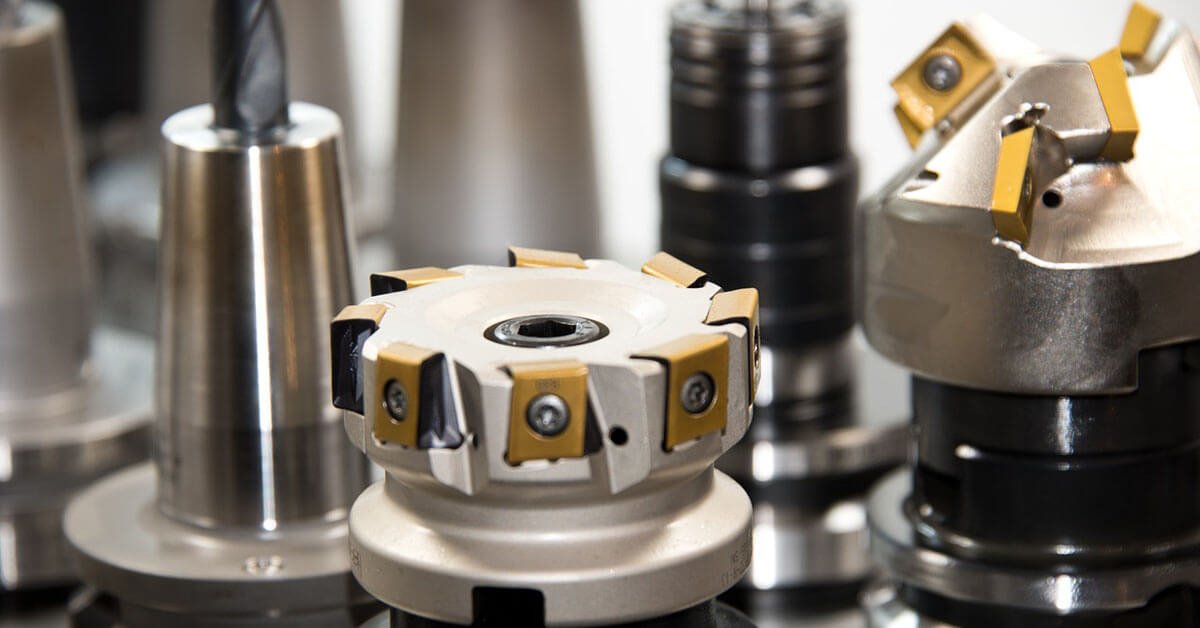

Adjustment of Tooling

Ensuring that the set of cutting tools installed is sufficient for a particular component manufactured is vital. Without this stage, a program cannot be executed correctly, and it should be done before changing material and design.

As exemplified previously, CNC turning machines are more advanced than a lathe and can perform functions genuinely attributed to milling machines. The examples of tooling used for specific purposes in CNC turning centers are the following.

- CNC drilling equipment. It includes rotating drill bits to produce cylindrical holes. Types of drill bits are spotting drills (shallow or pilot holes) and peck drills (reduction of the number of chips). The other existing forms of drills are screw machine drills (holes without a pilot hole) and chucking reamers (enlarging previously produced holes).

- CNC Turning equipment. It includes rotating multipoint cutting tools for shaping. Types of such cutting equipment are a chamfering tool (creating a bevel or furrow) and a knurling tool (creating or pressing a pattern onto a round section). The other existing turning tools are facing tools (cutting flat surfaces perpendicularly) and grooving tools (slot cutting).

Besides choosing the appropriate types of equipment, tooling parameters such as size, diameter, and material it is made of, should also be paid attention to.

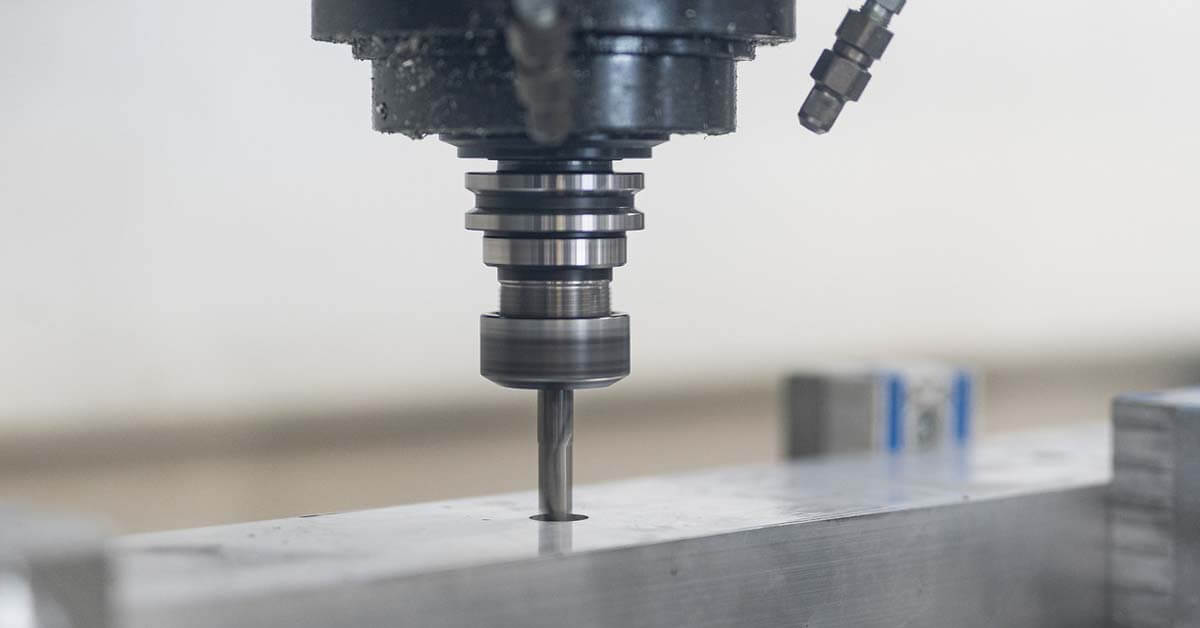

Machining Operation

Removing material from a workpiece is the primary function of a CNC turning machine, intended to produce components with high precision.

The general principle of turning can be described as holding a workpiece in a chick and rotating while a tool is being fed to the workpiece. Thus, it creates the desired shape and is called subtracting machining.

The moving section of a CNC turning center, which is called the spindle, includes the cutter and moves along the axis of the machined part while it is being rotated. The workpiece is fixed and positioned in a linear direction to the spindle.

Machining operations a CNC turning machine can perform include the following:

- Contour turning. Forming a contoured form in the turned part.

- Taper turning. Creating a tapered cylinder or conical shape.

- Chamfering. Cutting an angle of the cylinder to form a “chamfer.”

- Facing. Creating a flat surface on the face of the workpiece.

- Form turning. Plunging a tool radially into the workpiece.

- Boring. Feeding a single-point tool linearly on the inside diameter of an existing hole in a workpiece.

- Drilling and Reaming. Feeding a drill/reamer into the rotating workpiece along its axis.

- Grooving/Cut-off. Feeding a toll radially to a rotating workpiece to groove or to cut off the end of a part (parting).

- Threading. Feeding a pointed tool linearly across the outside surface of a rotating workpiece parallel to the axis.

- Knurling. Producing a regular cross-hatched pattern in the workpiece’s surface.

A CNC turning center is a highly versatile piece of machinery capable of implementing multiple operations to shape the material into a designed object.

What are the Main Components of a CNC Turning Machine?

The CNC turning machine is a complex center consisting of parts, outlined in the image below and listed further in the text.

1. Machine bed. It is also known as the main base for a CNC turning center on which the other components are mounted.

2. Headstock. Located on the machine’s left side, this wall-holding device includes the master spindle connected to servo motors utilized as spindle drivers.

3. Sub-spindle. It is separated from the main one and intended to fulfill complementary cutting functions.

4. Tailstock. It supports the workpiece axially and can be adjusted along the length axis.

5. Chuck. This three-jaw hydraulic part is the workpiece holding device.

6. Tool turret. This part enables the change of the cutting tools required for machining.

7. Guideway. This device enables the tool to move horizontally or vertically.

What are the Types of CNC Turning Centers?

Although CNC turning centers can be modified, it is possible to list several standard types of CNC Turning Centers that are always offered to purchase.

- Standard 2-axis CNC lathe. The basic turning machine that implements standard functions.

- 3-axis CNC lathe. Similar to the standard one, but adds opportunities for milling and the extra axis.

- Multi-spindle/dual turret. Such machines have two spindles (either equal ones or one main and one sub) and two turrets to reduce machining time.

- Chucking lathe. This CNC turning machine does not have a tailstock and is utilized for the second operation turning. It is considered a smaller version of the standard one.

- Flatbed CNC lathe. It is equipped with a removable gap for larger turning diameters.

It is vital to carefully choose the type of CNC turning center based on the type and size of components intended to be produced.

CNC Milling vs. CNC Turning

CNC milling and CNC turning are two different machining processes, mainly distinguished by how the workpiece and tool move. In CNC turning, the workpiece rotates while the cutting tool stays mostly stationary, moving linearly to remove material. This process is ideal for making cylindrical or conical shapes, like shafts and bolts.

On the other hand, CNC milling involves a stationary workpiece, with the cutting tool rotating and moving in different directions to shape it. This allows for creating more complex shapes, flat surfaces, and detailed features. CNC milling is widely used for parts that require intricate designs and precision.

In CNC turning, material is removed from the outer or inner diameter of the rotating workpiece, making it best for symmetrical round parts. CNC milling, however, removes material from the surface of a fixed workpiece, making it more versatile for a wide range of shapes and designs.

Both methods offer high precision, but CNC turning generally produces smoother surfaces on cylindrical parts due to continuous cutting. CNC milling can also achieve fine finishes but may need additional polishing for smoother results. The choice between the two depends on the specific requirements of the part being produced.

Is a CNC Lathe Worth It?

This question can be replaced with “can a CNC lathe do important machining that other tools do not?” It is unarguable that CNC lathes are focused precisely on producing symmetrical components, parts, and objects. It significantly restricts the scope of their application compared to CNC milling centers.

Alternatives using a CNC lathe are mechanical, chemical, electrochemical, and thermal machining processes. However, they may be considered complementary rather than basic ones.

It is worth considering that any other existing piece of machinery cannot implement the function the CNC lathe does with the same precision and efficiency. Therefore, if the manufacturer is focused on producing symmetric parts, there is no better solution than an appropriately chosen CNC lathe. Thus, a CNC lathe is worth purchasing.

How much does a CNC Turning Machine cost?

From the points listed above, it is evident that CNC turning machines are highly versatile. Prices for a new CNC turning machine can vary from $30k for an entry-level 2-axis lathe to $500k for a multi-axis, multi-spindle, multi-turret machine with a robot. Here is a list of the key factors that affect the cost of the CNC turning machine.

- Size of the machine.

- Weight of the machine.

- Supported speed, including RPM, max rapid mode travels, and tool change time.

- Size and power of the servo motors and spindle torque.

- Country of manufacture.

- Additional options (pallet pool, bar feeder, coolant pressure, tool changer, and others).

- A number of axes.

Focusing on a particular manufacturer’s necessities is recommended while choosing the optimal CNC turning machine.

Summary

CNC turning centers are the second-most widespread machinery (after CNC milling centers) used to shape workpieces into a finished component. They are versatile, and their functions can be improved by several modifications, making such machines a single solution for some manufacturers. The average cost of a CNC turning center is $70k and is highly dependent on the scope of features required.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.