Table of Contents

It’s often said that you need to get your first layer perfect in 3d printing so that the rest of the project prints smoothly. Unfortunately, getting that ideal first layer is easier said than done.

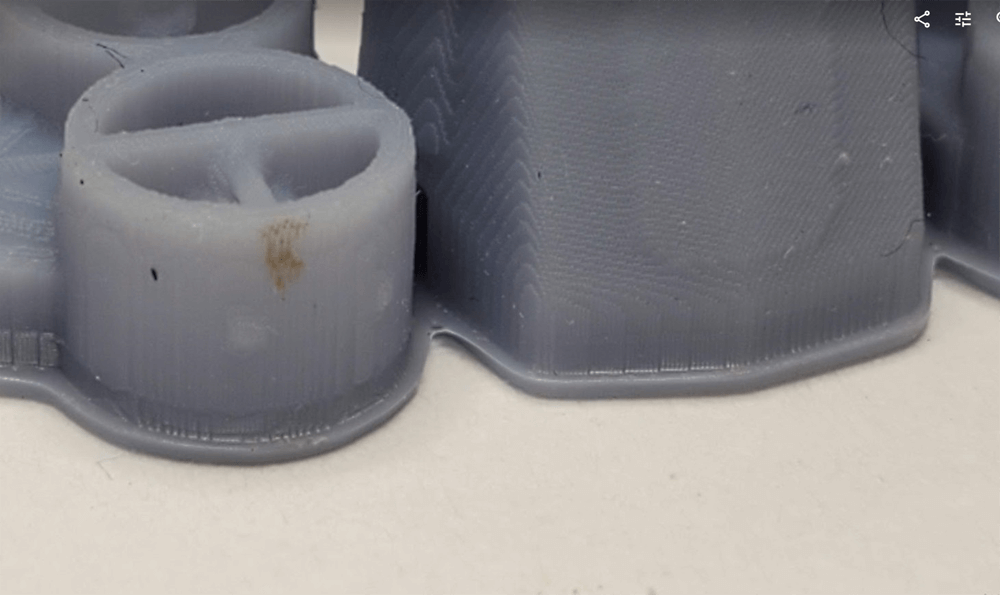

Elephant Foot is one of the more common issues when printing in the first layer. This error is easy to spot but also relatively easy to address.

What Is Elephant Foot?

“Elephant Foot” is a 3D printing defect where the first layer flares out slightly. This subtle issue can make printed objects look less appealing.

It becomes a bigger problem when printing models that need precise dimensions, like functional parts or pieces meant to fit together. Although it happens in the first layer, the weight of the upper layers can cause this defect, making it noticeable only after wasting some filament.

While Elephant Foot is considered a minor issue compared to other 3D printing problems, it can still affect the model’s appearance. It can be fixed during post-processing, but it’s best to address it to maintain quality and detail in your prints.

What Causes 3D Printing Elephant Foot?

As opposed to most first-layer problems, Elephant Foot has nothing to do with warping. It can happen even with traditionally “easy” material such as PLA or PETG filament.

In most cases, the elephant foot is caused by improper 3D printer settings.

Related more: 3D Printing Speed: How to Get the Best Setting for PLA?

Excess Filament at the First Layer

In some cases, the first layer bulging is simply a case of the layer having too much material.

When the nozzle extruders more filament than is needed for the first layer, some of this excess filament will push out of the extruder’s side. This is enough to create the characteristic appearance of the elephant foot.

Excess Compression from Top Layers

The Elephant Foot defect’s delayed onset can come about as more and more layers are printed. This puts more pressure on the base layer, making it more prone to deforming by flaring outside.

Even under normal circumstances, it is inevitable for the base layer to bear the whole model’s weight. However, the elephant foot becomes prominent when the base layer is not strong enough to support this weight. Naturally, the effects of weight compression are more pronounced in bigger or taller prints.

In some cases, the effect becomes unavoidable – you have to compensate for it in your design.

Excess Compression from Nozzle

Sometimes, the excess compression does not come from the top layers.

If the base layer is flaring out at the early stages, there is a good chance that the nozzle will press down the material due to improper Z-offset setting or a bed that has poorly leveled.

Insufficient Cooling

Another way for the base layer to lack strength is to overheat. It is possible either with excess heat from the print bed or with insufficient cooling.

If the base layer fails to develop rigidity, it will almost certainly deform once it needs to support the upper-layer weight. The uncooled first layer will progressively get wider and create a prominent Elephant’s Foot.

How to Fix Elephant Foot 3D Printing?

There are two strategies to avoid elephant foot: to make the base layer as strong as possible or anticipate an unavoidable Elephant’s Foot effect.

The choice of which option is more viable depends on several factors. The types of 3d filament you are using, the model you are printing, and the ability to edit 3D models are all considerations.

Bed Leveling

The most straightforward action to 3d printing elephant foot is to level your bed. Something that you should be doing anyway as part of regular 3D printing practice.

The goal of bed leveling is to ensure that the nozzle and print bed distance are uniform at all points. This makes it a lot easier to dial in the proper Z-offset settings for the nozzle. Not only does this solution help prevent elephant foot, but it also results in more consistent bed adhesion and layer cooling.

Some 3D printers come with an automatic bed leveling feature. If this is the case for you, then there should be no reason not to run it every time you start a new 3D printing project. This feature is available on many new 3D printers, whether it’s a professional 3D printer or a 3D printer for kids.

If your 3D printer has no such feature, then you can do the bed leveling manually. You will involve setting the bed height by adjusting each of the four adjustment screws on the bottom.

A piece of paper or cardboard can serve as a makeshift “feeler gauge” that you can stick between the print bed and nozzle. This feeler gauge is inserted between the nozzle and print bed at various points, adjusting screws as necessary. It is an easy process and should not take more than five minutes.

Reduce Heated Bed Temperature

Although heated bed massively helps with bed adhesion, it can also cause adverse effects if set improperly. It is a clear sign that the heated bed is set at too high a temperature for the elephant foot.

If the bed is too hot for the filament, it prevents the material from becoming more rigid and developing strength. This makes it more prone to deforming into an elephant foot as soon as it needs to bear the model’s upper layer weight. You may even see the elephant foot getting worse as the 3D printing proceeds.

The first thing to do is check the recommended bed temperature for the filament. Make sure that you are working within this range. If there’s some wiggle room, then lower the bed temperature by 5 °C increments. Even small reductions in temperature should significantly improve if this is the root cause of the problem.

You can even try and go below the recommended temperature range for your filament, as long as you don’t run into any bed adhesion or warping issues. If this still does not solve your elephant foot problem, you might need to look into other solutions.

Add Raft to The Model

A more robust option to avoid elephant foot is to print with a raft. You can make it easily through slicer software.

Raft is another layer of filament printed right below the base layer of your model. It acts as a sacrificial layer, significantly reducing the chances of errors becoming visible in the actual first layer.

Among most 3d printing problems, printing with a raft is considered a last resort. Because raft can consume a significant amount of filament that goes to disposal after, it’s not very practical if you’re planning to 3D print many models.

Typically, the raft is always used to facilitate bed adhesion and avoid warping. In this case, the raft becomes a buffer to absorb a potential Elephant’s Foot error. After printing, you can remove the raft from the rest of the print. This preserves the appearance of the model’s base layer.

Printing with a raft does not precisely address the root cause of elephant foot defects. It is still a good option if you don’t have the time to tweak your printer’s settings. However, solutions that do not require printing with a raft are a lot more sustainable.

Use Chamfers for Your Print

Instead of printing the base layer of the model, you can consider adding a chamfer to it. It is one of the more unconventional solutions.

The chamfer is simply a 45-degree slope that you can add to the model’s first few layers. This effectively means that the base layer of the model becomes narrower. This strategy is that the base layer’s swelling will cause it to become the ideal size.

A 45-degree angle is particularly ideal for this technique as it prevents the print from collapsing even with narrower base layers. This is one of the most reliable methods used in printing overhanging features.

The advantage is that it does not consume any extra filament. Since you’re printing with smaller layers, you might even end up using less filament – although the savings are minimal.

However, it’s going to take a bit of trial and error to anticipate precisely how much the base layer will swell. The best practice is to limit the chamfer to a 1-millimeter height or about two to three layers.

Adjust Z-offset

Sometimes, elephant foot is simply the result of the filament material being compressed too tightly on the base layer. This could cause the filament to flare out and form the classic elephant foot appearance.

If reducing the bed temperature does not solve the problem, you may need to increase your nozzle Z-offset. The Z-offset determines the nozzle’s height relative to the print bed and plays a massive role in deciding bed adhesion and extrusion quality.

Although a low Z-offset aids bed adhesion by pressing down on the filament, too much of this pressure can cause the filament to deform excessively. Try to increase the Z-offset setting by about 0.1-millimeter increments until improvement can be observed.

Take note that increasing the Z-offset can cause other problems to pop up, the most likely poor bed adhesion. This can cause the base layer to lift off or become warped.

If this happens, then you may need to solve the bed adhesion problem differently. Printing at higher temperatures, using a different adhesive, or printing with a skirt can be good options. Sometimes this happens in 3d printing – solving one problem leads to worsening another.

“Elephant Foot Compensation” Settings

Some 3D printers or slicers come with an automatic ‘elephant foot compensation’ setting. It is a convenient solution if the option is available.

When activated, this option reduces the size of the first layer of the model. Think of it like an automatic horizontal size compensation that only applies to the first layer. In this regard, this strategy is similar to the chamfer method but does not rely as much on guesswork.

As the following layers print, they press down on the first layer and compress the filament outwards. Ideally, this will result in perfect alignment of the first layer with the rest of the print. The size of the model determines precisely how large the compressive force on the first layer will be.

Even if your finished print comes out with a prominent elephant foot, all is not lost. If you’re not up to starting over with your project, then you can sand or deburr the imperfections in your finished print. This will take a lot of time but not as much as starting from scratch.

Summary

Compared to other 3D printing flaws, the elephant foot isn’t too bad. It doesn’t lead to catastrophic failure, and may even become unnoticeable with some sanding.

However, an elephant’s foot can affect the shape of the substrate. Knowing exactly how to solve the problem is important to get the desired substrate. I hope this article has been helpful. If you need 3D printing services, please contact us for a quote.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.