Table of Contents

Apart from Parallelism GD&T and Perpendicularity GD&T, Angularity GD&T also belongs to the orientation symbols in GD&T. It is a general standard used to control the specific inclination of a feature with respect to the datum. Here we will provide a comprehensive guide on angularity GD&T.

Key Takeaways:

- GD&T Angularity is an orientation tolerance that controls the specific angle between a feature and a datum, ensuring precise inclined surface or axis alignment in mechanical assemblies.

- Uses parallel planes for surface angularity and cylindrical zones for axis angularity, controlling deviation indirectly through linear distance rather than direct angular measurement.

- Ranges from basic sine bar with dial gauges for on-site checks to advanced CMMs and optical projectors for high-precision, automated measurement of complex components.

1. What is Angularity?

When an inclined feature of a component needs to be controlled, the angularity GD&T comes into play. In this part, we will further explain its definition, tolerance zone and callout.

1.1 Angularity GD&T Definition

As one of the orientation tolerances in GD&T Symbols, angularity GD&T is used to control a particular angle between the specified feature and the datum feature, which will hugely influencing assembly accuracy.

Angularity GD&T can be used to control the angular relationship between a specified line to a reference line, but it is more commonly applied to maintain a surface at a specific angle to a datum plane.

When used in a feature of size, it controls the central axis of the feature. What’s more, it can also be used to control the derived median plan of a non-circular feature like a tab or a slot.

1.2 Angularity GD&T Tolerance Zone

According to the controlled element of angularity GD&T, it is easy to misunderstand that the tolerance zone of angularity GD&T would directly refine the angle like 60°+/-5’, which means that the tolerance zone would be a sector zone, and the controlled feature should be at 60° with the datum, allowed to deviate from 3’ on either side.

However, the specified angle is indirectly controlled by the tolerance zone of angularity GD&T.

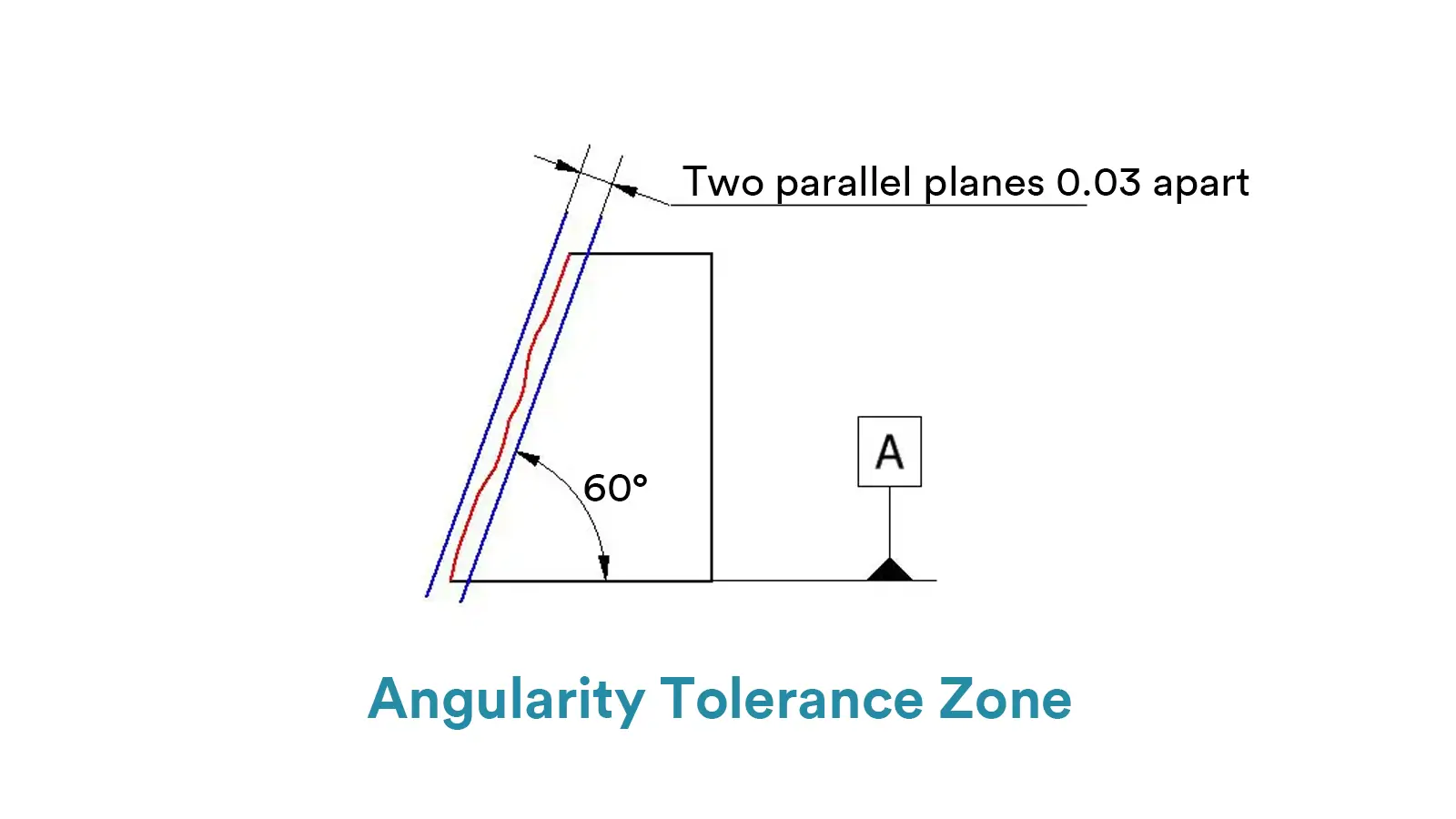

For surface angularity, the tolerance zone consists of two parallel planes that are both at a specific angle with the datum surface. All points on the measured surface are demanded to lie within these two planes.

And the tolerance value, the permissible deviation, is the perpendicular distance between the two parallel planes.

That is to say, the allowed deviation of surface angularity is indirectly controlled by the distance of the tolerance zone instead directly by angular changing, which is same as surface parallelism and surface perpendicularity.

In short, surface angularity does not directly control the angular variation of the measured surface, but controls the envelope where the entire surface must lie within.

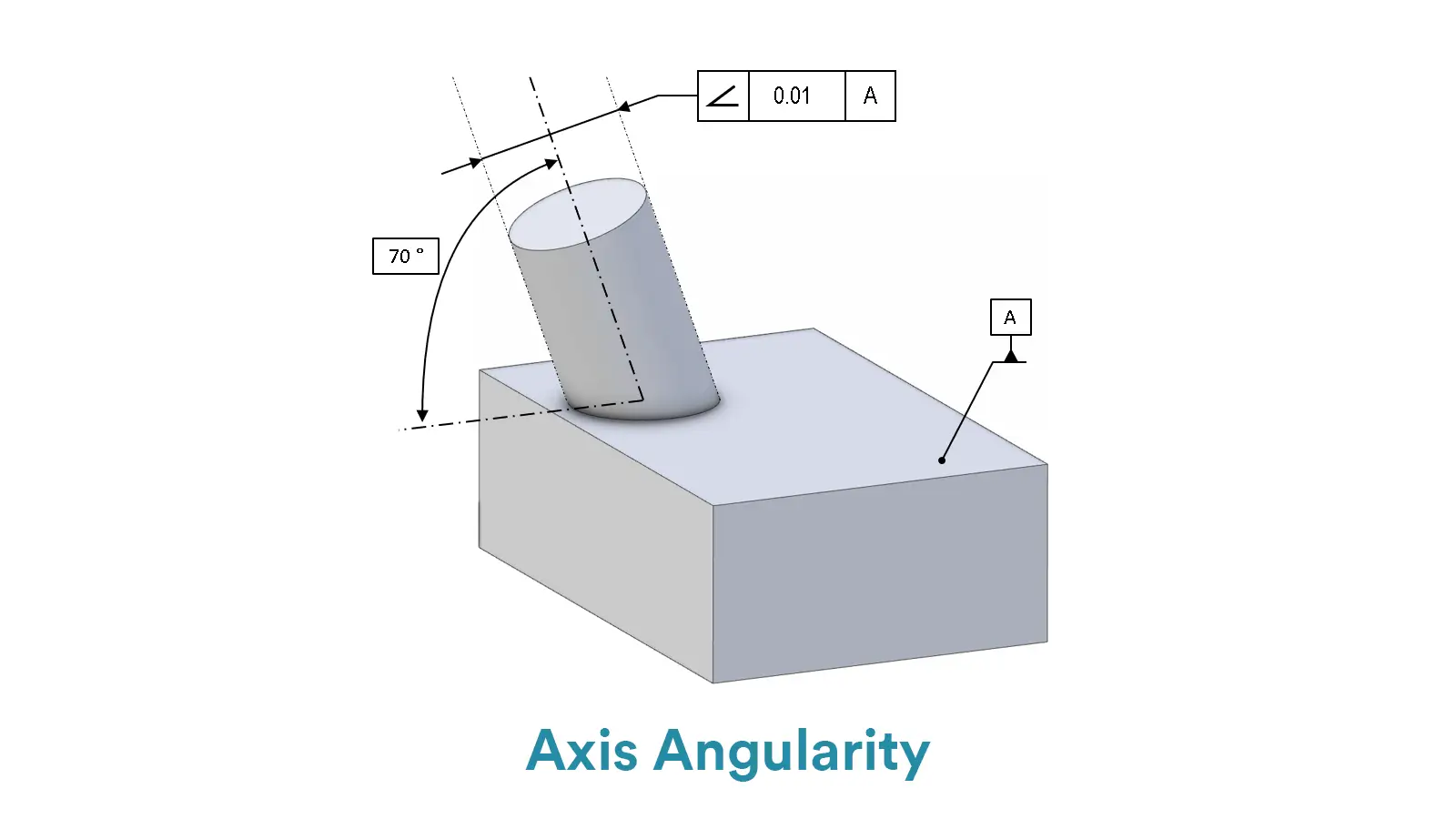

For axis angularity, the tolerance zone is a cylindrical zone whose center axis is at exact specified angle with the datum. All points on the measured axis should lie within this cylinder and the accepted angular deviation is controlled by shortening or lengthening the diameter of this cylinder.

And note that though the tolerance value is the diameter of the cylindrical tolerance zone, the max deviation of the measured axis would be only half of the diameter.

2. How to Show Angularity GD&T in Engineering Drawings?

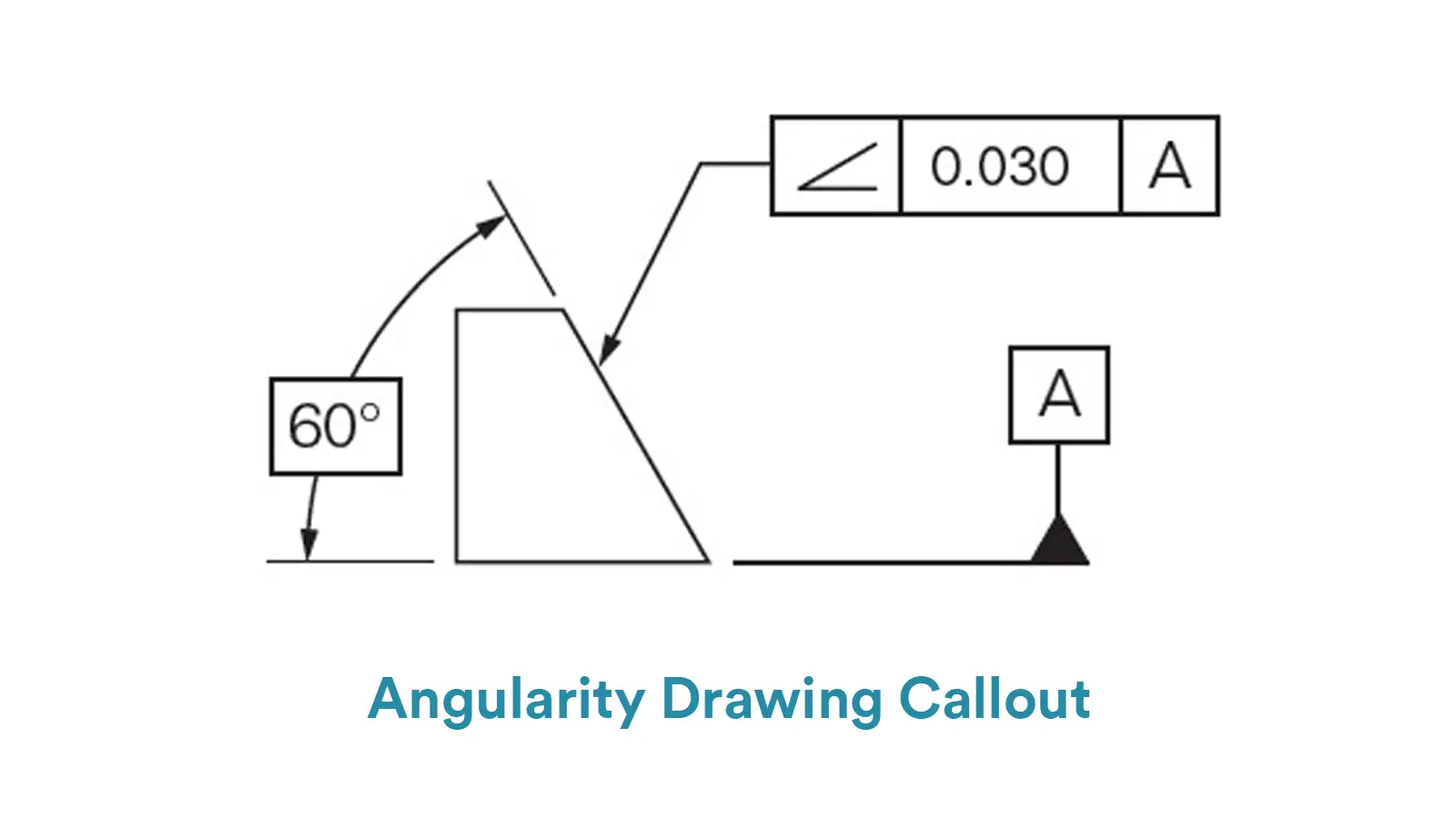

For surface angularity, the feature control frame is composed with three elements.

The first element is the GD&T symbol of angularity, which is an acute angle opening to the right.

The second element is the tolerance value of GD&T angularity, which is the distance of the two parallel planes that form the tolerance zone of surface angularity.

And the third element is the datum that the measured surface is supposed to refer to.

Then the feature control frame is directly leaded to the measured surface with a pointing arrow, or is connected with an extension line of the measure surface to indirectly show the controlling relation.

For axis angularity, the feature control frame is also comprised of three elements, with main difference in the second subsection from surface angularity.

Similar to surface angularity, the GD&T symbol of angularity is also the first element of axis angularity’s feature control frame. While the composition of second part is much different.

As the tolerance zone of axis angularity is a cylinder and the tolerance value is its diameter, the second part mainly includes the symbol of diameter and the tolerance value itself. Symbols of material modifiers may appear in the second part, but it is not common.

The third element is the datum axis or surface. The callout of axis angularity is usually shown by connecting the measured axis with the feature control frame leaded through a pointing arrow.

Note that the specified angle is not indicated in the feature control frame but is commonly shown as a basic angle on engineering drawings.

Just as that shown in mathematics, the basic angle in engineering drawings is also shown by a curve line with value of degree between a measured surface and the datum surface.

3. How to Measure Angularity GD&T

For measurement of angularity, you should know that it is measured actually through flatness measurement, since angularity actually maintains the flatness of a surface at a specified angle and the tolerance zone is made of parallel planes.

Here we will produce some common methods for angularity measurement with their pros and cons.

3.1 Using Sine Bar with Dial Gauge to Measure Angularity

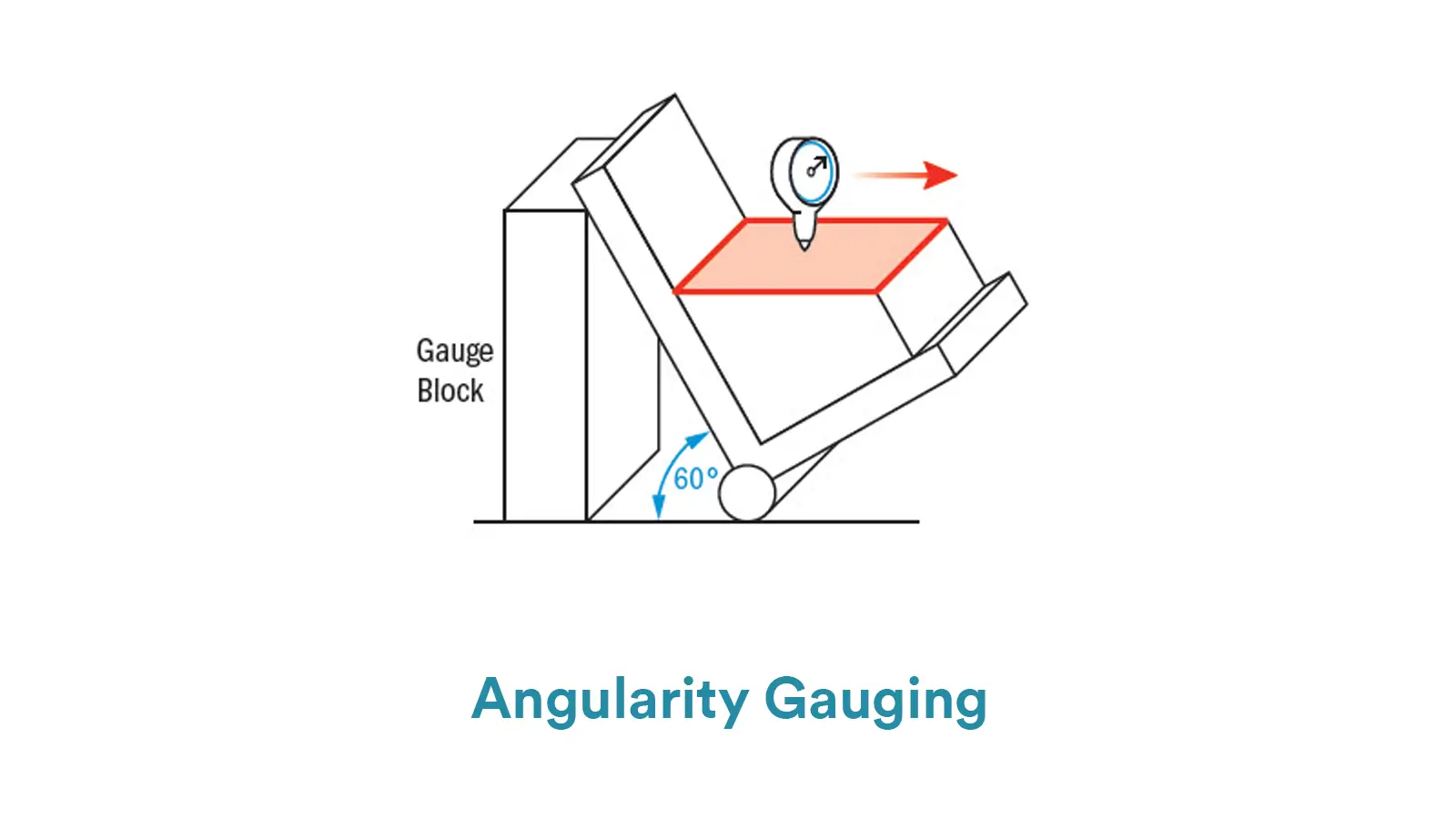

Using a sine bar with dial gauge is the traditionally simplest method for surface angularity measurement. For simple tools and low cost, this method is suitable for on-site measurement.

While the accuracy is certainly low due to manual operation and at the same time it takes much time to adjust angle. The step-by-step operation to measure angularity by this method is as follows:

Firstly, fix the datum surface of the measured component on the sine bar and adjust to the theoretically specified angle by gauge blocks, causing the measured surface parallel to the granite slab.

Secondly, slide the dial gauge along the measured surface and record the reading data.

Thirdly, compare the difference between the max and min readings. If the difference does not fall outside the tolerance zone, the measured feature passes.

3.2 Using Coordinate Measuring Machine to Measure Angularity

Coordinate measuring machines(CMMs) are high-end automate equipment that can measure various geometric features including surface angularity and axis angularity.

However, CMMs are disadvantage in high cost for both purchase and maintenance. And the equipment is sensitive to measuring environment. The step-by-step operation to measure angularity by this method is as follows:

Firstly, measure the datum feature with the CMM probe to establish the coordinate system(simulating a XY plane and setting a datum orientation).

Secondly, enter the design angle in the software and collect data of multiple points along the surface or axis.

Thirdly, fit the data and calculate the max deviation from the theoretical angle. And then calculate the linear deviation through particular formula by software. If the linear deviation is small than the tolerance value, the measured feature passes.

3.3 Using Optical Projector to Measure Angularity

With high accuracy up to micrometer dimension, optical projectors are suitable to measure complex features or small components. And the non-contact measurement can prevent geometric deformation.

However, the equipment is disadvantage in high cost and sensation to environmental factors. The step-by-step operation to measure angularity by this method is as follows:

Firstly, fix the measured component on the platform and align the datum feature with the equipment’s coordinate system.

Secondly, set the theoretically specified angle based on the datum plane or axis. And then use the optical probe or laser to scan the measured surface and collect data of multiple points.

Thirdly, calculate the max deviation from the specified angle by software. If the value lie within the tolerance zone, the measured feature passes.

4. Angularity VS Flatness VS Angular Dimension Tolerance

For angularity, it is easy to confuse its tolerance zone with that of flatness and angular dimension tolerance. It is important to clearly know their similarities and differences.

4.1 Angularity VS Flatness

If you deeply distinguish the respective tolerance zones of angularity and flatness, you would find that the angularity GD&T also impliedly controls the flatness of feature.

The tolerance zone of them are both comprised with two parallel planes. The difference is that when flatness is used, the two planes of tolerance zone should just parallel to each other; the parallel orientation of the planes are not controlled, that is to say, it is independent from datum.

While for angularity, the two parallel planes should be at specified angle with datum feature at the same time, which implies that not only the angle is controlled, but the flatness is certainly controlled by angularity GD&T.

4.2 Angularity VS Angular Dimension Tolerance

Although both of angularity GD&T and angular dimension tolerance are used to control the specific angle between the measured feature and the datum feature, the former is much more commonly applied in engineering and manufacturing.

With the tolerance zone as a sector, angular dimension tolerance controls the theoretically specified angle by indicating the value of angle degree as well as the allowed upper and lower deviation, which means that it does not control the form and orientation deviation of the actual surface.

While angularity GD&T not only controls the orientation deviation of the measured feature, but also impliedly controls the form deviation to some extent, since the tolerance zone of angularity is composed with two parallel planes that are at the same tilt a specified angle from the datum feature.

Obviously, compared with angular dimension tolerance, angularity GD&T can effectively avoid the overlay of multiple deviation.

5. Conclusion

As one of the orientation tolerances in GD&T Symbols, angularity GD&T really makes huge effect on assembly in engineering and manufacturing. It is critical to get comprehensive knowledge of GD&T angularity and then to use it correctly and effectively on your industry.

And if you want to get some information of other GD&T Symbols, we have produced Datum GD&T, Straightness GD&T, Flatness GD&T, Circularity GD&T, Cylindricity GD&T, Parallelism GD&T, and Perpendicularity GD&T in previous articles. You can contact us directly.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

GD&T Cylindricity

Cylindricity is to control the overall deviation of a cylindrical surface from a perfect geometric cylinder.

GD&T Parallelism

Parallelism GD&T is to ensure that the reference surface or axis is parallel to the datum surface or axis.

Perpendicularity

Perpendicularity GD&T is used to control the measured surface or axis, keeping 90° with the datum surface or axis.

GD&T Angularity

GD&T angularity GD&T is used to control a particular angle between the specified feature and the datum feature