How much does CNC machining cost?

Updated: December 06, 2023

Introduction

If you have CNC machining projects, your first need to consideration is the machining process and cost.

In this post, you will know the factors impacting CNC manufacturing process cost. Also, you will learn ways to cut expenses on CNC machining.

1. What Determines CNC Machining Cost?

There are five major aspects that define the final price for CNC machining company.

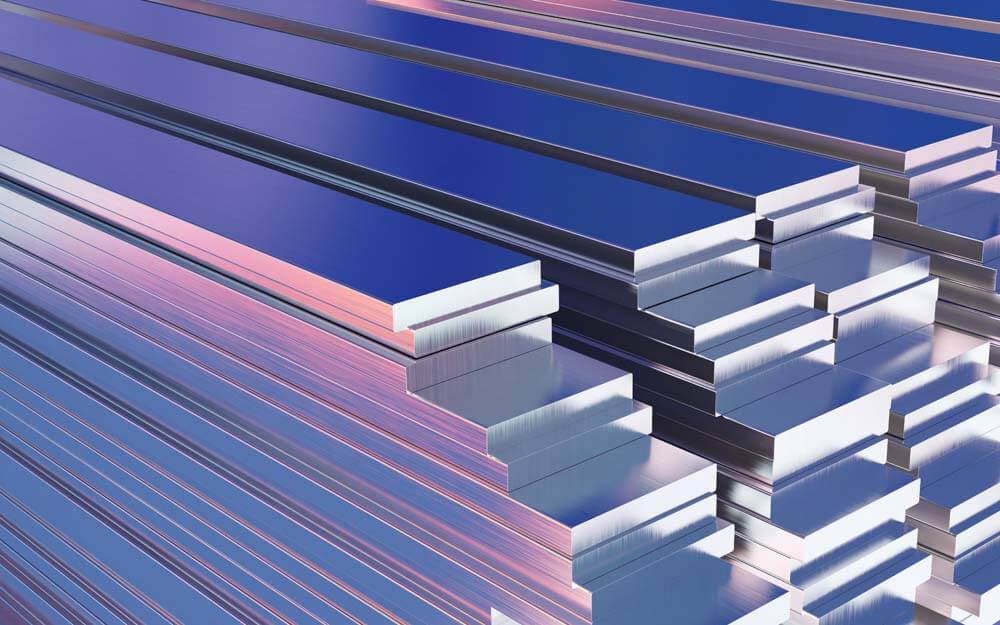

1.1. Raw Material

In case you include material cost in the calculations, it would be one of your substantial expenditures. This nuance is linked to the choice of machining units and their tooling. But let’s start by reviewing the two most popular materials for CNC machining.

Metal

This includes a vast range of metallic materials. They tend to be dense and vary in their properties, making it especially difficult to choose appropriate tooling to work with them. Here is the list of metals for CNC machining listed in descending order according to their popularity:

- Aluminum. Common grades are 6061, 6082, 7050, and 7075. Cost is about $2,000-$3,000/t.

- Stainless steel. Common grades are 303, 304, and 304L. Cost is about $4,000-6,000/t.

- Copper. Red/bronze metals are prevalent. Cost is about $9,000-10,000/t.

- Brass. CZ 121 and CZ 131 are common. Cost is about $8,500-11,000/t.

- Titanium. Prevalent grade is Ti6AI4V – grade 5. Cost is about $15,000-20,000/t.

Plastic

It is a more lightweight material that still offers enough durability to suit multiple applications in nearly any industry. Here are the types of CNC machining plastics listed in descending order according to their popularity:

- ABS.

- Polytetrafluoroethylene (PTFE).

- Polyetheretherketone (PEEK).

- Nylon 66.

- Polycarbonate (PC).

- Polypropylene (PP).

- High-density polyethylene plastics (HDPE).

- Polymethyl methacrylate (PMMA).

Generally, the price for the listed plastic does not fluctuate much. All they fall in the range of $2,000-5,000/t.

1.2. Design Cost

It is a tricky aspect that impacts finish costs significantly. Depending on the machining unit chosen, some designs are more or less complex to perform. And the extent to which your design is intricate will impact other labor and machine operating costs.

Just a few design and geometry considerations are the following:

- A number of different design elements require separate sets of tooling.

- Presence of design elements in hard-to-reach places of workpieces.

- Component geometry that will complicate its mounting/fixating.

In case your desired design includes any of the above-described, it will likely impact the finish price per fabricated component.

1.3. Machine Operating Costs

You may have heard that 1 hour of a CNC unit operating may be priced somewhere between $20 and $200. And this cost does not even include other expenses. But it is formed by the following expenditures, just for reference:

- Costs of covering the investment in the machine itself and its tooling. Such as multi-Axis machines and custom fixture.

- Depreciation cost (unless it is not included in the supplier’s margin).

- Technical support and maintenance cost and downtime

1.4. Labor-Related Costs

Such an aspect includes all the labor-consuming activities the cost of which is formed by the number of employees and their wages.

Programming

Probably, it is the most expensive part of arranging a new CNC machining line. It comprises the following activities:

- Design. It is creating a 3D CAD model in specialized software. The model of a future component must be especially accurate to benefit the following digitalization. It is basically a complicated stage that may undergo many revisions and adjustments. Both designers and engineers may be required to complete the project.

- Digitalization. Another tricky stage focuses on transforming the prepared 3D CAD model into a G-coded CAM file. CNC machining units operate as per sets of instructions written in the specific programming language. Each corresponding to the design’s specific actions of a CNC unit should be written in a file. This stage also includes testing of the finished CAM file and ensuring that a CNC unit can perform the machining correctly.

- Tool Path. This is another item which will affect the machining cost. There has plenty of toolpaths for option, you need to optimize the machining stragety for the project. In this post, you will learn more details.

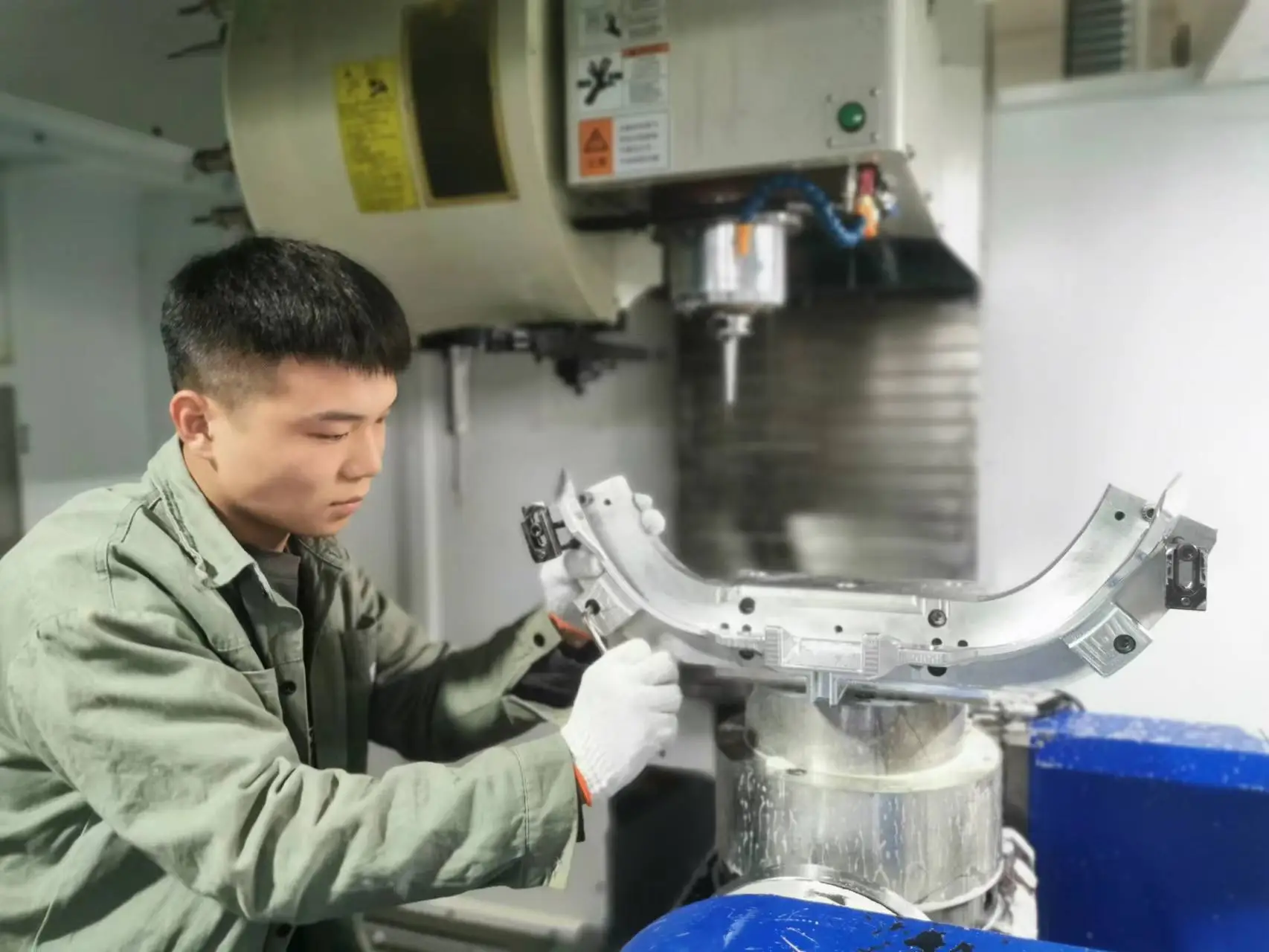

Set-Up Procedures

These are done by a CNC machine operator. It involves technical preparation of the unit, setting its tooling up, loading workpieces and unloading finished components, etc.

Although it does not seem to be a complicated stage, it does require the constant presence of 2-3 employees.

Post-Processing

These procedures include manual or transportation units-assisted assembly and delivery to the desired location. For example, it may be a warehouse from which you will be receiving batches of products prepared.

Depending on the sizes of your orders, it may require many workers, ranging from two of them to dozens.

1.5. Other Expenditures

Tooling

Although costs for tooling are included in the machine operating costs by definition, sometimes there is a need for extra sets of cutting tools. For example, if your component’s design is so intricate that no standard tooling can perform it.

This way, you will need to purchase custom tooling yourself or pay for an outsourcing agency to buy one. You also should pay attention to the hardness of your workpiece and the appropriate tooling selection. It is so because cutting tools may deteriorate quickly if their use is not sufficient.

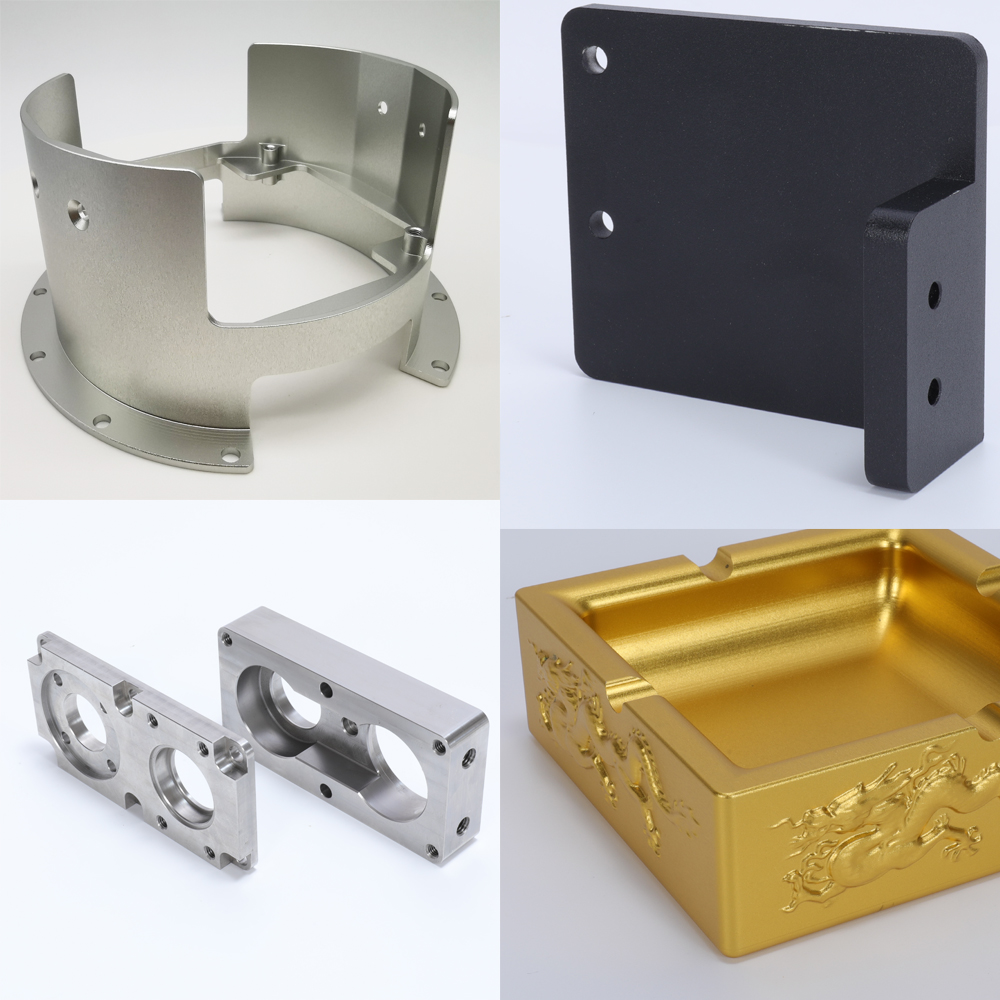

Surface Finish

Machining of a component obligatory involves cutting operations. This way, you receive the ready-to-use part. But most manufacturers also include surface finish operations in their manufacturing cycles. They enhance both the appearance and some properties of components.

However, extra operations always result in a higher cost per fabricated component overall. An increase in price depends on the exact finish method chosen. Here are some examples:

- Grinding.

- Honing.

- Buffing,

- Anodizing.

- Bead blasting.

- Electroplating.

- Polishing.

- Painting/application of ink or spray dye.

2. How to Reduce CNC Machining Cost?

In case you are looking for ways to minimize expenses, here are some of the generally applicable tips and advice.

2.1. Reconsider Material

Since the material is a huge price determinant in CNC machining, you should start by reconsidering your workpieces. For example, you may look for more affordable materials that have the essential properties that you require but are deprived of minor advantages. For example, you may go with aluminum if the titanium’s superior strength, durability, and density are of no use to you.

Also, it is essential that you compare grades of metal or types of plastic. You may find that you typically have 2-3 perfectly suitable options. Depending on your region, one or another material may be more or less affordable.

Also, consider the properties of the material as well. For example, its density and machinability. While the first affects the wear of tooling, the second is about how time-consuming the process will be. And as you already know, tooling wear and hours of machine operating time are what define the final cost per part as well.

2.2. Optimize Design

Since you already know how expensive intricate designs may be, you should consider optimizing this aspect alike.

Here are some design specificities to pay attention to.

- Use rounded internal corners. In case you consider 90-degree conventional corners, machine units will have to stop and rotate, which will result in time losses.

- Avoid deep pockets. Unless you really have to achieve that depth, consider not including deep pockets in your designs. Their creation requires removing much material. Also, you will likely have to use some special types of tooling, and perhaps, even custom ones.

- Limit tight tolerance. Of course, you want your components to be as precise as possible. But be sure not to make toleranceS more strict than really necessary. It will be required to use lower speeds, more precise tools and equipment units, etc., to meet your requirements. All these will necessarily result in higher costs that you are willing to avoid.

- Expand thin walls. Unless it is microcomponents you intend to produce, be sure that your parts’ walls are as thick as possible. This will make them less fragile, and, as a result, will not require multiple depth adjustments in the process of machining. It will also reduce rejection rates.

- Limit the length of threads. Similar to pockets, way too deep threads do not strengthen the connection but conceive additional challenges. As a rule of thumb, the length of the thread, which is 1.5 times its diameter, is enough.

- Use standard sizes. This advice concern absolutely any CNC machining unit and cutting tools type. Try to stick to the standard size of threads, drill bits, etc. This will eliminate the need to purchase custom tooling and will minimize operating time.

- Avoid multiple finishes. For example. there is no need to bead blast a finished stainless steel component just to paint it with a dry dye further. Choose that very finish that meets all your needs alone.

- Split complex designs. Sometimes, it is more time and cost-effective to design and fabricate two or three components and assemble them together. It is instead of struggling with an extra complicated one.

- Avoid multiple machine setups. Make sure that your design does not require operators to change the tooling of a machine and adjust its settings. In case something intricate is absolutely necessary – split the design.

- Order large quantities. Try not to stick with small batches of products ordered frequently. It is easier for a supplier, and more cost-effective for you, to plan large batches on a regular basis. This way you may even have a discount.

2.3. Outsource Your Needs

In case you are a manufacturer that assembles products from the purchased parts, you naturally need CNC machining services. Of course, you still may build your own manufacturing line. But as per the above-mentioned reasons, it is not a cost-effective decision. So, it is worth considering requesting services from a specialized provider.

An outsourcing agency will address your needs in the most efficient way. Such companies have all the standard equipment units, tooling, contacts of material, and tooling providers. They also have all the processes established and will not interfere with your regular workflow.

In contrast, the employees of outsourcing agencies are professionals that are capable of meeting your requirements better than in-house employees.

3. Summary

Setting up your CNC-empowered production line is hardly a cost-effective decision; unless you plan to fabricate large batches of the same components 24/7 of course.

If you need diverse CNC machining services or require them only occasionally, you should hand over all the fabrication to an outsourcing supplier.

Consider ECOREPRAP your trusted partner in completing this sort of project. We have been around for years delivering top-quality CNC machining components worldwide. We can significantly reduce your production expenses and streamline your company’s workflow. Contact us via the online form, and we will get back to you shortly!

4. FAQs

4.1. How to choose the type of CNC machine?

You should guide your decision based on your component’s design. The most cost-effective solutions are milling or turning machines that would support the end-to-end manufacture of your desired components.

4.2. How to choose the tooling for CNC Machining?

You should guide your decision based on your component’s material and design. You need distinct sets of conventional tooling for every CNC unit. Also, consider purchasing ones that suit a particular material rather than all-in-one solutions.

4.3. Why CNC Milling is more expensive?

Compared to other CNC units, CNC milling require higher investments into the machine and its tooling. It is also more difficult to set up, maintain, and operate, but it is capable of performing the most complex manufacturing processes.