Table of Contents

E-bikes have become an ideal choice for urban commuting and recreation due to their efficient, lightweight, and environmentally friendly features. To ensure its excellent performance and high safety, CNC machining technology provides an important guarantee.

With the advantages of high precision and high efficiency, CNC machining is widely used in various components of e-bikes, such as frame, motor, battery, transmission system and braking system.

In this paper, we will discuss the specific application of CNC machining technology in e-bike components and analyze its role in improving productivity and product quality.

Electric Bike Parts List

E-bikes are composed of several key components, each of which plays an important role in the performance and safety of the whole vehicle. The following are the main components of an e-bike and their detailed descriptions:

1. Frame

The frame is the skeleton of the e-bike, which plays the role of supporting the weight of the whole bike and connecting other parts. Historically, bicycle frames were mainly made of steel, but today common frame materials include aluminum alloy and carbon fiber, with steel and titanium still being alternatives.

Aluminum and carbon fiber are lightweight, strong, and corrosion-resistant. Aluminum alloy frames are relatively inexpensive and suitable for mass-market e-bikes, while carbon fiber frames are lighter, stronger, and suitable for high-end models. CNC machining technology in the manufacturing process of the frame can ensure precise dimensions and structure, and improve the stability and durability of the frame. Read about: Aluminum CNC Machining.

2. Electric Motor

The electric motor is one of the core components of the e-bike, responsible for converting electric energy into kinetic energy to drive the wheel rotation. Commonly used motor types include brushless DC motors (BLDC) and brushed DC motors.

BLDC motors have become the mainstream choice in the market due to their high efficiency, low noise, and long life. CNC machining technology in the manufacturing of motor casing and internal parts can ensure high precision and quality, and enhance the performance and reliability of the motor.

3. Battery

Batteries are the source of energy for e-bikes, storing and providing the electrical energy needed to drive the motor. Commonly used battery types are lithium-ion batteries, which are widely used because of their high energy density, lightweight, and long life.

Battery housings need to have good heat dissipation and protection to ensure the safety and stability of the battery in operation. CNC machining technology can accurately machine the battery case, optimize its heat dissipation design, and extend the service life of the battery.

4. DriveTrain

The drivetrain, which includes chains, gears and transmissions, is responsible for transferring power from the electric motor to the wheels, ensuring a smooth ride for the bike. A high-quality drivetrain can improve the efficiency and driving experience of an e-bike.

CNC machining technology enables high precision and durability in manufacturing drive train parts, reducing friction loss and improving transmission efficiency.

5. Braking System (Brakes)

For riders, brake performance should be one of the most important checks when purchasing a new e-bike, responsible for quickly slowing down or stopping when needed. Common types of braking systems include.

- Mechanical Disc Brakes: Mechanical disc brakes use a cable-actuated mechanism to engage the caliper when the lever is pulled.

- Rim Brakes: The classic brakes commonly found on non-electric bikes are rim brakes, including caliper brakes and V-brakes.

- Regenerative Brakes: Some e-bike systems feature regenerative braking, which utilizes the motor to help slow the bike down. However, they are often used in conjunction with conventional brakes as a backup braking system rather than as the primary braking mechanism.

- Hydraulic Disc Brakes: Hydraulic disc brakes offer higher braking forces, precise control and good heat dissipation.

Hydraulic disc brakes are the preferred choice for e-bikes due to their excellent performance and reliability.

High-precision machining enables the brake discs and calipers to provide stable braking force under various working conditions, enhancing the safety of the e-bike. The efficient working of the brake system can ensure the rider’s quick reaction and safe stopping in emergencies.

What is CNC Machining

CNC Machining (numerical control machining) is a manufacturing technology that involves controlling a machine tool to perform machining through a computerized numerical control system. It utilizes pre-programmed software and code to control the movement of the machine to accurately cut, drill, and shape a variety of materials. CNC machining enables highly accurate, efficient, and highly automated production processes for the manufacture of complex and demanding parts.

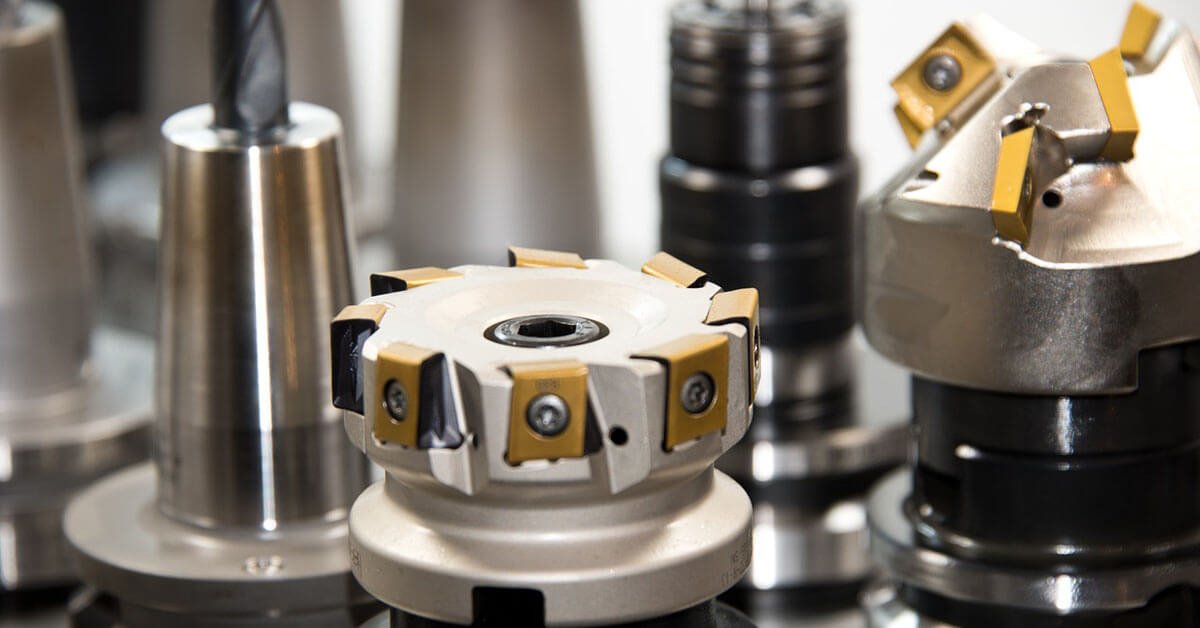

Types of CNC Machines

There are several types of CNC machines, each suitable for different machining tasks. Common CNC machines include:

CNC Milling Machine: Suitable for machining flat, curved surfaces and parts with complex geometries. CNC Milling Machines can perform a variety of operations such as milling, drilling, and tapping, and are widely used in the manufacturing industry. For example, a bicycle manufacturer mentioned that they CNC mill the inside and outside of frames to tolerances as high as 0.01 millimeters, while keeping the frames lightweight and strong.

CNC Lathe: It is mainly used for machining rotary parts such as shafts, disks and bushings. CNC Lathe achieves high precision turning by workpiece rotation and tool movement.

Related read: Mill vs Lathe Machine

CNC Grinding Machine: Suitable for high-precision grinding of workpieces to achieve smooth surfaces and precise dimensional control.

CNC EDM: Precision machining of hard materials and complex shapes using electric discharge machining technology.

Advantages of CNC Machining in Ebike

In the e-bike industry, CNC machining technology is the preferred method of manufacturing high-quality components due to its unique advantages. The following are the main advantages of CNC machining in the e-bike industry:

High Precision, High Efficiency

CNC machining allows for extremely high machining accuracy, often down to the micron level. The high degree of automation reduces errors from multiple clamping and positioning. For e-bike manufacturers, this means faster production speeds and shorter lead times, allowing them to better respond to market demands.

Enhanced Structural Strength

Through CNC machining, the size and shape of frames and other critical components can be precisely controlled to ensure their strength and rigidity. Complex joints and reinforcements can be molded directly into the frame through CNC milling and bonding processes, reducing errors during welding and assembly.

Flexibility

CNC machining is suitable for multi-species and small batch production, which can flexibly adjust the machining parameters according to different design requirements and quickly respond to the market demand. For the e-bike industry, different models and configurations of e-bikes require customized parts, CNC machining technology can easily meet this demand, providing flexible production solutions.

Repeatability

Each machining step of CNC machining is precisely controlled by a computer, ensuring consistency and high quality from batch to batch. For e-bike manufacturers, this means that every bike meets the same high standards, reducing quality issues caused by component variations.

High Degree of Automation

CNC machine tools are equipped with advanced automation devices that enable automatic tool changing, automatic measurement, automatic compensation and other functions, which reduces manual intervention, human error and labor intensity. This not only improves productivity but also increases the safety and reliability of the production process.

Material Saving

CNC machining reduces material waste, improves material utilization and lowers production costs by optimizing the machining path and cutting parameters. In the manufacture of electric bicycles, the material cost occupies a large proportion, this advantage of CNC machining can significantly reduce the manufacturing cost and improve the competitiveness of enterprises.

Processing Ability of Complex Parts

CNC machining technology can easily cope with complex geometry and difficult machining tasks. For example, the motor casing, complex transmission system components and highly efficient heat dissipation of the battery shell, all require high precision and complex shape processing, which can be realized by CNC machining.

CNC machining technology also allows for the integration of multiple components into a monolithic structure, reducing the number of welding and assembly steps and improving overall strength and durability. This integrated design not only improves productivity but also enhances the aesthetics and aerodynamics of the entire vehicle.

Conclusion

CNC machining technology is important in e-bike manufacturing, driving the industry’s rapid growth by increasing productivity, reducing costs, improving product quality and enabling customized production.

Ecoreprap offers specialized CNC machining services for everything from rapid prototyping to small production runs of custom parts. We have robust machining capabilities in CNC, sheet metal fabrication, and 3D printing, with over 20 finishes and 100 metal and plastic options.

Quality is guaranteed with every order and is trusted by over 100 customers worldwide to ensure high quality solutions for the e-bike industry. Feel free to inquire to get an instant quote!

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.