Table of Contents

Though determining the optimal choice between localized and global CNC machining can be challenging for each CNC machining projects.

The best country for CNC machining ultimately depends on project requirements — while China is advantageous in cost and scalability, Japan or Germany may be better for ultra-high precision, and the USA excels in aerospace-grade customization.

This article explores key factors in CNC machining across different countries.

Key Takeaways:

- CNC machining is a subtractive manufacturing process that uses computer-controlled tools to create custom parts by removing material from a workpiece.

- The cost of CNC machining is determined by a combination of factors cost, quality, lead time, and communication, all of which are influenced by material, design complexity, machine capabilities, operator skill, tolerances, production scale, finishing processes, and geographic and logistical factors.

- Japan, Germany, the USA, and China each offer distinct CNC machining advantages and drawbacks.

- China is often regarded as a leading destination for CNC machining because it offers cost-effective, fast, and scalable machining with vast industrial support.

1. What is CNC Machining?

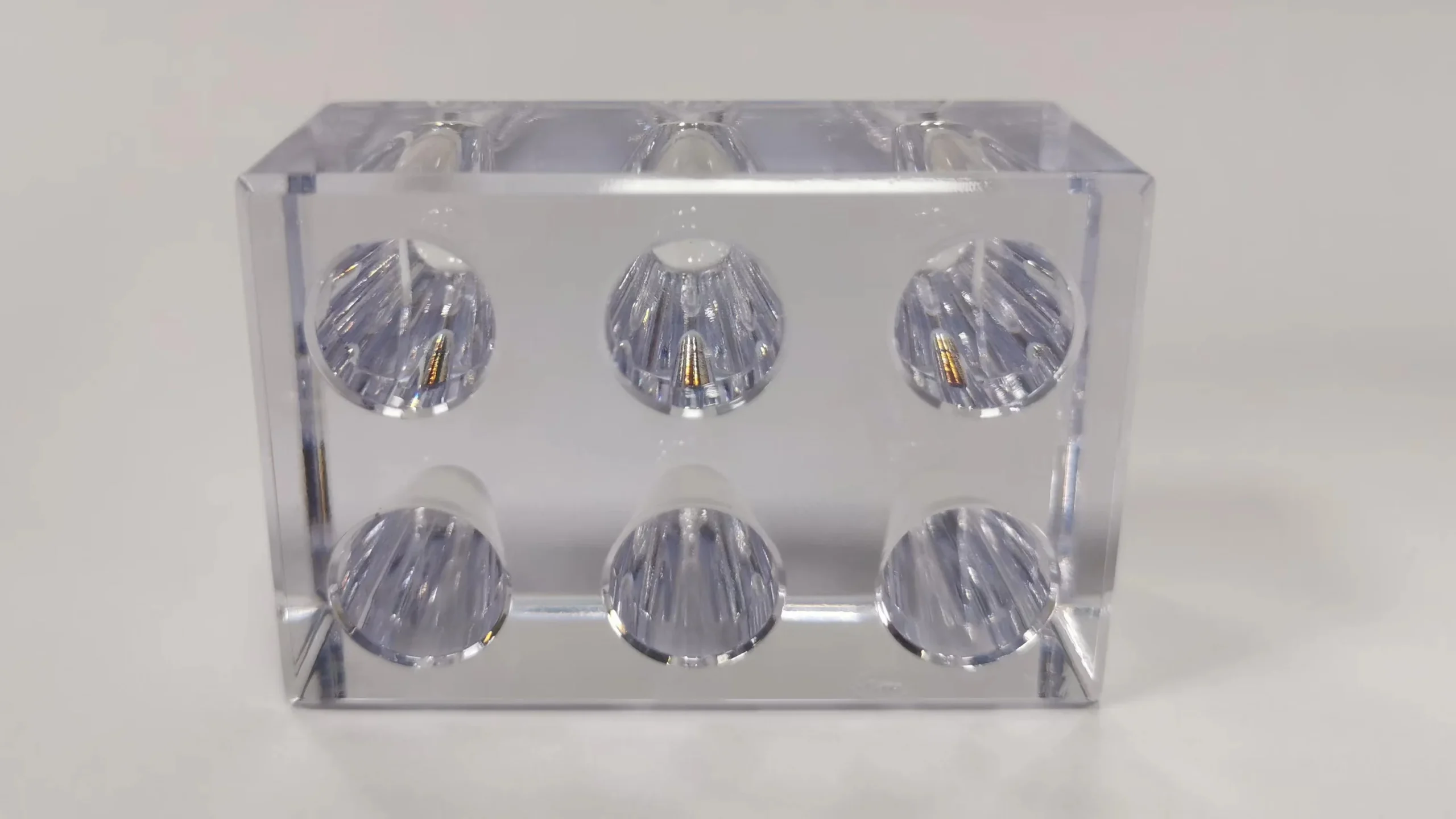

CNC machining, short for computer numerical control, is a subtractive production process using computerized controls and machine tools to selectively remove material from a stock piece, commonly known as the blank or workpiece, to produce custom-designed parts.

CNC machining is applicable to a diverse range of materials, including metals, plastics, wood, glass, foam, and composites.

It is widely used in various industries, including automotive, telecommunication, medical, and others.

From prototypes to low-volume production, and large-scale production, CNC machining is always used when precise tolerance is required.

In CNC machining process, pre-programmed software and code dictate the movements of production equipment. CNC machining exercises control over an array of intricate machinery, including grinders, lathes, and turning mills, all of which are instrumental in cutting, shaping, and fabricating various parts and prototypes.

CNC machinists blend elements of mechanical design, technical drawings, mathematics, and computer programming skills to transform raw materials, such as a sheet of metal, into critical components for applications like aerospace or automotive manufacturing.

2. CNC Machining History

In 1751, turning machines appeared. The machine used to replace handcrafted techniques and increase precision. But the CNC concept was brought up hundred of years later.

In 1949, the first numerical control concept was developed. John t. Parsons, an early computing pioneer, developed it as part of an air force research project carried out at the massachusetts institute of technology (mit).

They made an experimental milling machine to produce helicopter blades and stiffer skins for aircraft by using motorized axes.

In 1952, the idea was further developed. Richard kegg (in collaboration with mit) introduced the cincinnati hydro-tel, a 28-inch vertical-spindle contour milling machine. He was patented for a “motor controlled apparatus with positioning machine tool.”

The initial prototype, although it was operated using eight-column paper tape, a tape reader, and a vacuum-tube electronic control system, became a focus for future developments.

In the 1940s and 1950s,early CNC machines used punched tape, which was then commonly used in telecommunications and data storage, which was replaced by analog computing technologies later.

From the 1960s into the 1970s, digital technologies emerged, making the production process automated and more efficient.

In 1968, parsons was awarded for his early work and received the first joseph marie jacquard memorial award from the numerical control society.

In 1975the society of manufacturing engineers awarded him an honorary plaque, which named parsons “the father of the second industrial revolution.”

John t. Parsons, is called as the “Father of numerical control”.

3. CNC Machining Considerations-Cost

When considering CNC machining services, the following factors shall be taken into consideration.

Below are the important factors influencing CNC machining costs.

3.1. Material costs

The type of material used significantly impacts costs. Different metals, plastics, or composite materials have varying prices.

Generally speaking, plastic material is cheaper than metals. But some pleastic material like PEEK can be quite expensive. Metals like aluminum 6061T6 and stainless steel 304 are often used in CNC machining for its low cost.

3.2 Machining Time

CNC machining costs often correlate with the time a machine is operational. Longer machining times result in higher costs. Machining time can be reduced by optimizing tool paths through programming.

There is a range of hourly processing costs in different countries. Therefore, the longer the processing time, the higher the CNC processing cost.

3.3 Labor Costs

Skilled labor is essential for programming and operating CNC machines. Labor costs contribute to the overall expenses.

In the CNC processing, the main personnel involved are programmers, operators and inspectors. Among them, the programmer’s design of the tool path and the programming level are closely related to the processing time. The operator is responsible for the processing quality.

3.4 Tooling Costs

Specialized tools are often required for different CNC machining processes. Tooling costs include the purchase, maintenance, and replacement of these tools.

Machining aluminum and plastic parts causes relatively little wear on the tool, but machining steel parts, especially heat-treated steel parts, causes a lot of wear on the tool. The higher the hardness, the greater the wear on the tool.

3.5 Complexity of Design

Complex designs or intricate geometries may require more time and precision, affecting overall costs.

The more complex the design of the part, the more details need to be considered when programming and operating the CNC machine, the greater the possibility of errors, and therefore the longer the processing time.

3.6 Tolerance and Quality Requirements

Tighter tolerances and higher quality standards may necessitate additional time and meticulous attention, influencing costs.

ISO 2768MK is the standard CNC machining tolerances. If finer tolerances are required, roughing and then finishing may be required.

3.7 Quantity of Parts

Economies of scale often apply in CNC machining. Producing larger quantities of parts can result in lower per-unit costs.

For example, making one CNC part and making 100 parts both require the same programming and machine adjustment, and the cost of these two segments are the same. Assuming one part is scrapped, the cost of making one part increases by 50%, but if 100 parts are made, it only increases by 1%.

Therefore, when quoting CNC projects, the difference between the price of making one part and the average price of making 100 parts is huge.

3.8 Material Wastage

The efficiency of material usage affects costs. Minimizing material wastage is crucial for cost-effective CNC machining.

3.9 Setup and Programming

Initial setup and programming costs are incurred at the beginning of a CNC machining project. For small runs, these costs may contribute significantly to the overall expenses.

3.10 Machine Capabilities

Different CNC machines have varying capabilities. Advanced machines with multiple axes or high-speed capabilities may come with higher operational costs.

Taking the current situation of CNC machining in China as an example, the cost of 3+2 five-axis is twice that of three-axis, and continuous five-axis is twice that of 3+2. Therefore, parts processed by three axes are cheaper than those processed by five axes.

3.11 Finishing Processes

Additional finishing processes, such as coating or polishing, can add to the overall CNC machining costs.

For plastic parts, they are usually kept as machined and no surface treatment is required.

For aluminum parts, sandblasting and anodizing are usually required, while steel parts need blackening and heat treatment. These subsequent surface treatments require a certain amount of money.

3.12 Location of the CNC Machining Service

Costs can vary based on the geographical location of the CNC machining service provider due to differences in labor rates and overhead expenses.

4. CNC Machining Considerations-Quality

CNC machining quality is a critical aspect that directly influences the performance and reliability of manufactured parts. Achieving high-quality CNC machining involves several key factors:

4.1 Material Selection

4.2 Programming Accuracy

Accurate and error-free CNC programs are necessary for achieving the intended design specifications. Programming errors can lead to defects and compromise quality.

4.3 Operator Skill and Training

Skilled CNC machine operators play a crucial role in maintaining quality. Proper training ensures that operators understand the intricacies of the machining process and can address issues promptly.

Proper material handling and secure work holding are essential to prevent vibrations, deflection, or inaccuracies during the machining process. Well-trained operators know how to handle the materials properly.

4.4 Machine Calibration and Tool Quality and Maintenance

Properly calibrated machines ensure consistent and precise machining. High-quality cutting tools regularly maintained and replaced as needed, are crucial for achieving precise and clean cuts.

4.5 Surface Finish

The surface finish of machined parts is a visual indicator of quality. Proper tool selection, machining parameters, and finishing processes contribute to achieving the desired surface finish.

4.6 Inspection and Quality Control

Rigorous inspection processes and quality control measures are essential at various stages of CNC machining. This includes both in-process and final inspections to identify and rectify any deviations from specifications.

Setting high standards and specifications can ensure the final products meet recognized quality benchmarks, which must be closely adhered to, to achieve higher quality parts.

4.7 Feedback Loops

Implementing feedback loops and continuous improvement processes based on inspection results contributes to ongoing quality enhancement.

4.8 Documentation and Traceability

Comprehensive documentation of the machining process, including materials used and machining parameters, aids in traceability and quality assurance.

5. CNC Machining Considerations-Lead Time

When we talk about CNC machining lead time, we shall consider the following two.

5.1 Production Time

From material purchase time, programming time, to quality check time, every segment shall be considered. For each CNC machining project, a project schedule shall be arranged once the order is placed to make sure the parts are machined with promised lead time. Coordination among different stages also contribute to minimize the lead time.

5.2 Shipping Time

For local CNC machining shops, the shipping time is only about 1 to 2 days at a relatively cost. But outsource CNC machining shops overseas, the shipping time is about 3 to 10 days by air and by sea, it may takes about 15 to 45 days.

6. CNC Machining Considerations-Communication

Speaking a common language makes communication easier in CNC machining. Notably, English has become an international language. In both Chinese and Japanese CNC machining facilities, reputable factories often have customer managers proficient in both spoken and written English, rendering language barriers less of a concern.

Global collaborations in CNC machining often involve teams located in different time zones. Managing time zone differences is crucial for maintaining efficient communication and project coordination.

7. Countries are Known for CNC Machining

China, Germany, Japan, and the United States are CNC machining well-known countries with different strengths. See a brief introduction in the table below.

| Country | Advantages | Considerations |

|---|---|---|

| China |

|

|

| Japan |

|

|

| Germany |

|

|

| United States |

|

|

Japan CNC Machining Cons and Pros

Cons:

Japanese CNC machining is known for high precision and high-quality output with cutting-edge CNC machinery and forefront CNC technology.

Germany CNC Machining Cons and Pros

Cons:

Like Japan, German CNC machining is renowned for precision engineering and adherence to strict quality standards. Also, the German market always uses high-quality materials.

United States CNC Machining Cons and Pros

Cons:

In the USA, English is the primary language of communication. The USA also has advanced CNC machining technology.

USA is a pioneer in industrial software and automation control. For example, CAD/CAM software such as Mastercam, Fusion 360, and SolidWorks are all American products.

The technology in five-axis machining, high-speed cutting, and hard material processing is mature, and it is particularly good at aerospace and military-grade precision parts.

In the USA, there are many CNC workshops (job shops) with strong customization capabilities and can quickly respond to customers’ personalized needs. They are suitable for prototype proofing and small batches of high-end parts with multiple varieties.

In addition, English is the mother tongue, so the service orientation is good and communication is efficient.

Pros:

However, the machining cost is also very high.

China CNC Machining Cons and Pros

Cons:

Due to lower labor costs and rent, the CNC machining cost is low compared with the above 3 countries.

Considering the CNC machining cost, production capabilities, lead time, and shipping, China is widely recognized as one of the top choices, especially for rapid prototypes, fast turnaround CNC machining, low-volume production, and large-scale production projects with no tightest tolerance requirements.

When choosing China CNC machining services, the most important thing is to select a machining factory that has strong processing capabilities, focuses on quality and keeps its word.

For example, at ECOREPRAP, we implemented a dual-shift schedule to better serve European and US customers. This practice illustrates how Chinese suppliers adapt to time zone challenges.

8. Frequently Asked Questions About Which Country is Best for CNC Machining?

8.1 Where are the CNC machining manufacturers located in China?

There are many cities in China that have many CNC machining factories, for example, Shenzhen, Dongguan, Guangzhou, Suzhou, Shanghai, Ningbo, Xiamen. Among them, Shenzhen is known as China’s Silicon Valley, a hub for technology and manufacturing, including CNC machining.

Related blog: Top 10 5-Axis CNC Machining Services in China 2025 – Get Your Right Machining Supplier Quickly

8.2 What are the benefits of choosing Shenzhen CNC machining services?

Shenzhen’s reputation for rapid prototyping ensures swift development cycles, while the cost-effectiveness of manufacturing services remains competitive.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.