Table of Contents

With the increase of multitasking and other production processes, there is a need for higher precision and faster production times. Traditional CNC machining cannot meet the dimension and accuracy request, 5 axis, 6 axis, and 7 axis CNC machines are developed for machining more complex parts.

Due to the affordable cost and quality, 5-axis and 7-axis CNC are the most commonly used machines in the market. In this post, we will explain the information about 7-axis CNC machines.

What is a 7 axis CNC machining?

A 7 axis CNC machine is also known as a high-precision industrial mill. It is explicitly designed for accuracy, consistency, and customization of part shape to be ideal.

7 axis controller is a system that provides the computer with data on seven axes or three dimensions, this increases the function or capability of the machine by enabling it to perform more complex operations.

A 7 axis CNC machine can be used in nearly any standard geometry (round, square, rectangular) and maintain the safety factor for most chips/part shapes, it provides more important features or unique geometry.

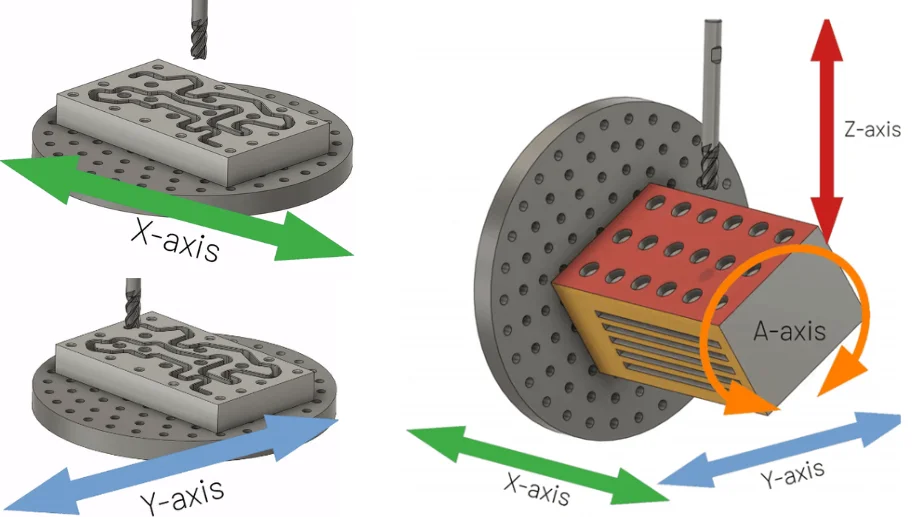

7 axis CNC machining means that the machine can handle 7 operations to machine parts in one process, including the X, Y, and Z operations in standard CNC machining. It also includes rotational axes such as Yaw, Pitch, and Rotation.

For instance, you could rotate a sphere with a radius of 100mm around its axis, which would widen or narrow the surface area of the cut shape.

Main structure of a 7-axis CNC machine

The main structure of 7 axis CNC machining is the gantry. The cups and collets provide the threaded and indexable interface to support various pallets and tool head mounts. The term 7 axis CNC machining refers to a system that can rotate in three axes, forming a 3D volume to accomplish the cut.

The benefits of this type of automation include better accuracy, reduced processing time, and improved quality. This is achieved due to a steady crane to feed the components automatically or by a conveyor system that continuously supplies them for cutting to the highest precision.

The machines are equipped with four fixed spindles with threading. The spindle head feeds the cutting tool on each of the tools individually. These four spindles also move in conjunction to provide different types of capabilities. Using them together, they can grind, turn, bore, cut tricky angles (5 axes), and drill thru (3 axes).

The size of the space of the sensor indicates the type of circle that oscillates. Significant oil leakage on the ground is caused by wear and tear of the belt.

It will initiate wear on some points on the surface of the camshaft when the gear becomes too tight or too loose. This is one reason why there are bearing pads for this complex mechanism, increasing stability and operation speed.

Here is the video link for you to learn more.

Work principle of a 7-axis CNC machine

A conventional milling machine uses a single rotating spindle and rotating cross-slide table to move the cutting tool laterally and vertically. This movement requires large machinery, substantially increasing production costs.

In comparison, CNC machining only needs a linear movable table and one stationary axis mounted on the stand. There’s no need for a complex structure or additional axes to control the cutter.

When it comes to the working principle of a 7 axis CNC machining system, one tool is mounted vertically on the origin, while the other six axes are arranged around it. This type of arrangement features six fixed directions to ensure symmetrical working precision over 360 degrees. CNC machining uses computer-controlled techniques to cut or sculpt material on a machine tool.

CAM software can also automate some or all of the processes. This type of machining has replaced hand methods in most production environments.

In a 7 axes CNC machining process, six axes are used to position the workpiece, and one is for cutting. CNC operators will have a very intuitive knowledge of machine setup, parametric plotting, pattern generation, toolpath programming, and simulation tools.

Available material for 7-axis CNC machining

7-axis CNC machining centers can process all types of materials. Their high rigidity and vibration resistance allow them to handle even rigid materials. Steel Aluminum Brass Copper Plastic, etc. But manufacturing with seven-axis CNC machines can be expensive.

Therefore, it is generally not preferable to process relatively soft materials as cheaper alternatives exist.

The available material of a 7 axis in CNC machining include carbon steel, stainless steel, aluminum, brass, zinc, bronze, lead, and nickel. You can use a 7 axis to machine just about any wire or object that has a turning, moving component – it’s designed for multi-axis manufacturing. It can have one or more axes on both the X and Y plane.

7-axis CNC machining dimension precision

The quality of the CNC machine’s performance is determined by precision. You can measure the clearance between the tool and the machined surface in microns, 1/1,000th of a millimeter. The dimension will vary depending on the material and cutting speed.

The machine’s axis design will determine the precision of the dimensions you can achieve. If your machine is designed with an X-axis that is significantly shorter than the Y-axis, then your precision will be “longer” in one direction and “shorter” in another.

One of the essential factors in precision is how well the X, Y, Z axes are calibrated. The machine should be able to make up to .0004 inches without trouble. Another critical factor is how accurately the spindle is controlled.

The spindle should also have an accuracy of .0004 inches or better. The higher-level clearance axis often depends on what type of workpiece is being machined and what material it’s being made from.

The accuracy of the machine’s axis is crucial for a successful production. The better the accuracy, the less waste, and the faster production will be., it is essential to measure axes accurately before machining To guarantee precision.

7-axis CNC machining application

You can utilize 7 axis CNC machine in various applications. This machine can shape, mold, or cut workpieces via various operations coordinated under computer control, It converts the workpiece to the desired product by using machine tools.

A 7 axis CNC machine can use for many different applications, this includes 3D milling, metal forming, surface finishing, waterjet cutting, EDM wire cutting, and wood milling. You can even produce investment castings meaning that machining is an essential tool for custom parts.

The increased interest in home-built automobiles means a growing demand for precision machined parts. As most tasks are best served with large industrial machinery, smaller CNC machines have been developed to fill the need for small machining jobs that require tooling that you can’t use on a more giant machine. They are the most beneficial for manually programmed work.

But many machines can be expensive and time-consuming to set up for various tasks; automating the process makes it possible to spend more time solving other issues.

Conclusion

A 7 axis CNC machining is no longer an expensive technology that is only available to high-end stores. It has become substantially affordable through advances in technology, new techniques, and the extension of CNC milling techniques to other machines. 7 axis refers to the concept that tools are not restricted to a single x, y, or z coordinate.

As CNC machining has progressed, there will have higher requests for products. When it comes to high-quality precision metal machining, 7-axis CNC machines will much more popular in the future. Our company offers OEM 7 axis CNC machining service now, if you have parts that need to use 7 axis CNC machining, feel free to contact us.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.