Table of Contents

Are you uncertain about 3D printing materials? Between PLA and TPU, which one comes out on top? You are not alone if you are undecided when choosing 3D printing materials. Many people are not sure whether to use PLA or TPU.

Today, 3D printing has become more available. More and more people are using 3D printers. Nevertheless, the materials used have become very refined. However, the two common materials used are PLA and TPU.

This article looks at the two common 3D printing materials, PLA and TPU. Discuss their pros and cons, when is the best time to print with PLA or TPU, and also help you decide which one to use for 3D printing and why.

ECOREPRAP’s main business has shifted from 3D printing filaments manufacturing to 3d printing services and CNC machining services since 2023. We will continue to share related blogs about filaments and CNC machining.

What is PLA?

PLA or Polylactic Acid is a common material for 3D printing. It is the most common and the most used 3D material. It is cheaper and easier to print than other materials. Additionally, thermoplastic is prepared from organic materials like sugarcane and corn.

PLA is popular and frequently used because it is environmentally friendly. It is the ideal material for printing things like protective phone cases. Moreover, it is stress-free to work with and available in many blends and colors.

Unlike other 3D printing materials, PLA does not need a heated print bed. Besides, it is very forgiving where anyone can use it. Thus, it is good material for starters.

Nevertheless, the material can become fragile. In addition, your 3D printer has to meet specific requirements for you to print with PLA material.

For example, you need a glue stick, glass plate, PEI, build surface, and a bed with a temperature of 45 °C to 60 °C.

Pros

- It is the easiest material for 3D printing

- PLA is environmentally friendly since it is entirely organic.

- It is a perfect choice for starters.

- Available in different colors and blends

Cons

- PLA cannot make flexible designs

- It is prone to oozing when heated

- Cannot be used to make flexible designs

- It does not stretch

- Has print gaps making it easier for bacteria to prosper.

What is TPU?

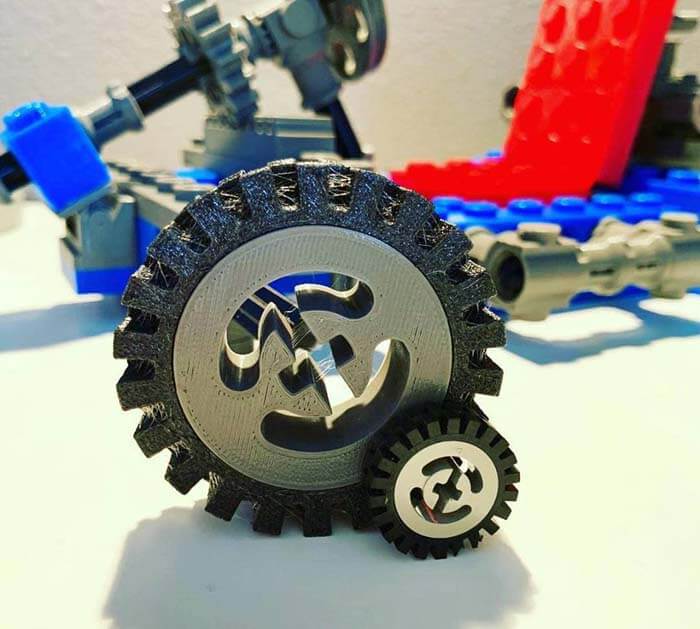

TPU or Thermoplastic Polyurethane is another popular material for 3D printing. It is commonly used to print elastic and stand up against oil and abrasion.

Even though TPU is more expensive than PLA, it can stretch and bend. In addition, designs made with TPU can easily be cleaned using soap and water.

One major shortcoming of TPU is that it is difficult to use. Beginners using the material will have a hard time using it. This is because it is elastic and very flexible.

Nevertheless, it provides unique possibilities that cannot be achieved when using other printing materials such as PLA. For instance, it can combine the properties of plastic and rubber.

Some industries that use TPU for 3D printing are automotive, aerospace, footwear, and sporting goods.

Pros

- It is a material that can stretch TPU can be used for food printing

- The material can withstand tensile forces and is highly compressive

- It is chemical resistant

- It is low warpage and contraction.

Cons

- TPU is prone to stringing

- Hard to use

- Must be printed at a low temperature

What’s the difference?

PLA and TPU are the two common materials for 3D printing. However, the two materials behave differently, have different properties, and have several advantages and disadvantages.

Here are the differences between PLA and TPU:

Ease of printing

PLA is one of the easiest 3D printing materials you can use. It is an ideal choice for beginners and is available in various colors and blends. Oppositely, TPU is a bit hard to use. It is challenging to post-process and likely to clog.

Clogging and jamming

PLA is more environmentally friendly and compostable than TPU. Thus, it is easier to print and a good choice for beginners. On the other hand, TPU is more prone to clogging and stringing than PLA.

Smell and health issues while printing

PLA is made from sugarcane and cornstarch. Thus, it gives out a sweet aroma when printing. In addition, it is the least harmful 3D printing material to human health. On the other hand, TPU emits an odor when printing. Even though the odor is not hostile, it is not as sweet as the PLA aroma. Also, the fumes are not so strong for someone to leave the printing room. The use of TPU can cause a harmful allergy. The toxic substances released when printing can cause health problems such as eye irritation, difficulty breathing, or even organ damage.

Hygroscope and post-processing

One shortcoming of PLA is that it is highly hygroscopic. It means it can easily absorb moisture from the environment. Based on the humidity, the material can be rendered unusable. Nevertheless, it is easier to post-process a PLA material. Also, TPU is hygroscopic. It is a material that can easily absorb moisture when exposed. You are therefore advised to keep the material in a dry box. Moreover, it is a challenge to post-process a TPU material. Performing any task on printed art is not easy.

Flexibility

When you compare PLA and TPU, PLA cannot make flexible designs. So, if you are looking for a material to design flexible designs, the best one to consider is TPU. However, since TPU is so flexible, it isn’t easy to print. It is elastic and flexible, making it unpopular to beginners.

Durability and strength

LA is user-friendly and among the easiest materials for 3D printing. However, it has poor durability and strength compared to TPU. On the other hand, TPU is a bridge between plastic and rubber. The material is flexible, rubber-like, and smooth. In addition, it is solid and durable.

Temperature requirements

PLA is a versatile material that prints best at 210 °C. However, it can work well from 180 °C to 230 °C. PLA does not need a heated bed. Nevertheless, if the printer has one, you can set it at 20 °C to 60 °C. With TPU, it works best from 220 °C to 250 °C. Also, the material does not require a bed. But if your printer has a bed, the temperature should not be higher than 60 °C.

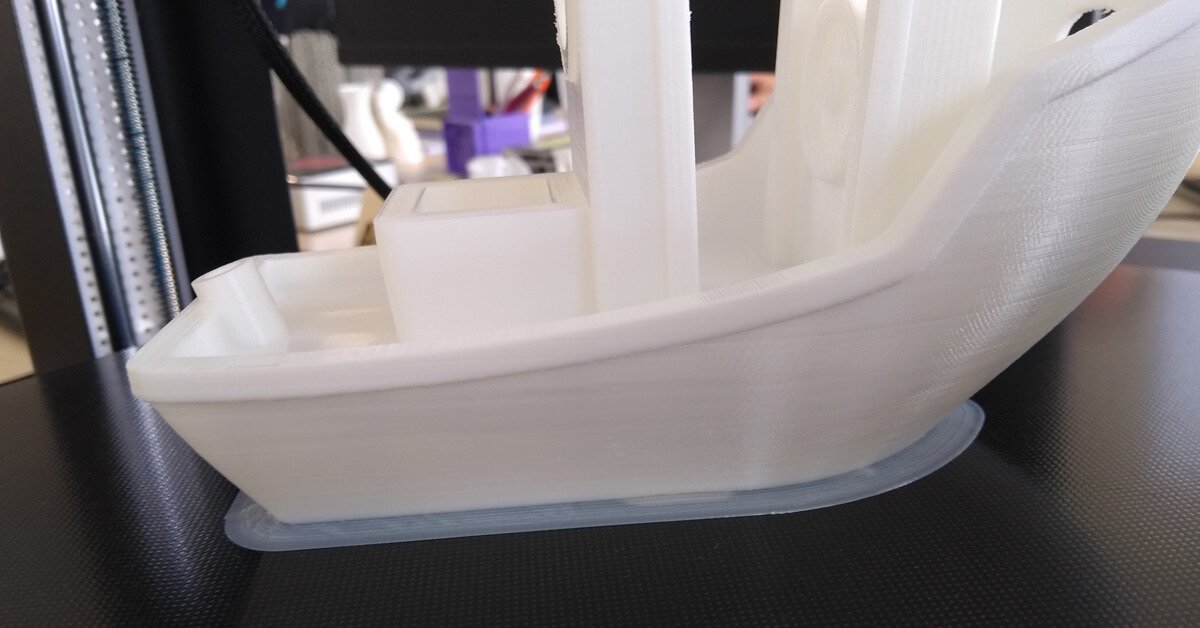

Cracking, warping, heated bed, and adhesion

When using PLA, you may have issues with cracking. This is because the material can absorb moisture causing it to reduce flexibility. Also, warping can happen due to PLA shrinkage while printing. PLA is a printing material that does not require a heated bed. But for the layers to be successfully printed, the first layer has to stick to the printer surface, also known as bed adhesion. TPU does not have a significant cracking issue like PLA. Also, there are no warping issues experienced when using PLA and other 3D printing materials. For quality 3D printing, heat beds are needed. However, TPU does not require a heated bed to print. Also, TPU is resistant to low temperatures. Moreover, it has interlayer adhesion.

When to print with PLA?

PLA is the most common material used in 3D printing. Most users prefer it due to its ease to use, low cost, and accuracy. The best time to use PLA is when learning 3D printing. This is because It is easy to print, inexpensive, and the most economically friendly 3D printing material you can get. It is obtained from crops such as sugarcane and corn.

Tips with PLA 3D Printing

Before you start printing with PLA, it is essential to learn how to get the material’s best. Below are 3D print tips with PLA.

- Try to keep the PLA filament dry – the PLA material should be kept in a cool and dark place. This will preserve PLA quality and ensure you receive the best printing results.

- Lower viscosity level – some filaments may have a lower viscosity level than other PLA materials. To avoid leaking at lower temperatures, you need to change the retraction distance by some millimeters.

- Layers may fail to adhere if the temperature is too cold – when the temperature is too cold, the filament may fail to stick to the previous layer. If this happens, you need to increase the printhead temperature.

- Regulate the temperature – when using PLA material, it is essential to ensure the temperature is right. You can increase and reduce the temperature by 5-degree to make sure you get the right quality.

- Check out for stinging – strings may appear when the temperature is too high. If it happens, you need to decrease the temperature. Decreasing the temperature will ensure the extruder does not leak too much material.

3D print tips with TPU

TPU is a great 3D printing material that offers unique properties and many possible applications. However, printing with 3D is very tricky. Hence, it is vital to understand some tips for successful printing with TPU.

- Make sure you have the correct printer settings – to achieve better results, you need to use the correct settings on your 3D printer.

- Optimize the feed rate – it is essential to use a regular feed rate that is a bit slow when 3D printing with flexible filaments like TPU. This is because the material is elastic and uncontrollable if there are sudden changes in the printing speed.

- Optimize the retraction sets – since TPU material is elastic and flexible, it is very sensitive to fast actions such as retractions. Therefore, you need to optimize retraction settings to limit the movements and to have a successful 3D print.

FAQ

When to print with TPU?

TPU 3D printing provides unique possibilities that cannot be achieved using other printing materials like PLA, nylon, or ABS. The best time to print with TPU is to produce consumer goods such as footwear and phone cases, flexible electronics, and automotive. Happily, the material is soft and elastic, chemical resistant, and available in a wide range of colors.

Is PLA better than TPU?

PLA and TPU are the two common 3D printing materials. However, both of them have pros and cons. If you are looking for an inexpensive filament and one that is easy to print, the best one to consider is PLA. Moreover, PLA is compostable and more environmentally friendly than TPU. But if you would like to add flexibility to the prints, then the material to use is TPU. Generally, PLA is easier to print, inexpensive, more environmentally friendly, and the best 3D material for beginners. However, it is impossible to make flexible designs with PLA. Also, it is prone to oozing when heated. On the other hand, TPU is flexible, chemical resistant, and withstands higher compressive strength. But it is prone to clogging, must be printed at a low temperature, and is difficult to post-process.

Is flexible PLA the same as TPU?

Flexible PLA and TPU have many similarities. However, they have differences as well. For instance, it is easier to work with TPU than with flexible PLA. On the other hand, flexible PLA is food-safe. The material can be used to print food containers and utensils. But TPU is not food-safe. But Flexible PLA is more flexible than TPU. So, when planning to print something to wear, the best material to consider is flexible PLA. But TPU is more rigid than flexible PLA. Thus, it is resistant to abrasion.

Can you mix PLA and TPU?

One fantastic thing about 3D printing material is that you can experience it with two filaments. It is possible to mix PLA and TPU. You can improve models using the two materials. But the two materials are different. PLA is one of the easiest to print 3D materials. On the other hand, TPU is a flexible material. By mixing the two materials, you open new possibilities. But keep in mind that PLA and TPU are two materials that cannot bond well with each other. However, many people had succeeded in combining the two materials. It is also an excellent strategy to add a unique feel to your 3D prints.

Is TPU flexible?

Yes, Thermoplastic Polyurethane (TPU) is notably flexible. It is a 3D printing filament valued for its elastic properties, capable of stretching up to 500% without breaking. With its rubber-like characteristics, TPU is ideal for creating parts that need to bend or flex, such as tubes, seals, and vibration dampeners. Its ability to absorb impact makes it suitable for various practical applications.

Is TPU filament toxic?

Thermoplastic Polyurethane (TPU) filament is generally considered safe as it is non-toxic and odorless. However, like many plastics, it can emit harmful fumes if burned or exposed to high temperatures during processing. Proper ventilation and air filtration are crucial in your workspace to mitigate exposure to any potentially toxic fumes during 3D printing.

What does PLA stand for in 3D printing?

PLA stands for Polylactic Acid. It is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. This eco-friendly material is one of the most popular filaments used in 3D printing, known for its ease of use, good surface quality, and low shrinkage rate.

Is TPU food safe?

TPU can be food safe, but not all TPU filaments are automatically suitable for contact with food. Food-safe TPU must meet specific FDA regulations that certify it does not contain harmful chemicals and will not leach substances into food. Always check if the TPU filament is certified for food contact before using it for culinary applications, such as creating containers, utensils, or other items that come into direct contact with food.

Conclusion

So, PLA vs. TPU, which one should I choose? If you are getting started with a 3D printer, the best material to consider is PLA. Moreover, it is environmentally friendly, inexpensive, and biodegradable. But if you want to print flexible designs, the recommended one is TPU. It is flexible and the only material that can bend. Moreover, TPU can withstand temperatures of 80 °C and above, which is very durable. Now you know the best 3D material to consider if you plan to create various designs. Keep in mind that it is possible to mix both PLA and TPU.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He also spent three years in CNC engineering, quoting, design, and project management. Lucas holds an associate degree in mold design and has self-taught knowledge in materials science. He’s a lifelong learner who loves sharing his expertise.